High-Entropy Alloys in Smart Material Technologies

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HEA Development History and Objectives

High-entropy alloys (HEAs) represent a paradigm shift in metallurgical engineering, emerging in the early 2000s when traditional alloy design principles were challenged. The concept was formally introduced in 2004 by Yeh et al. and independently by Cantor et al., proposing that multi-principal element alloys with near-equiatomic compositions could form single-phase solid solutions due to their high configurational entropy. This revolutionary approach departed from conventional alloy design, which typically relied on one principal element with minor additions.

The evolution of HEAs has progressed through distinct phases. The initial discovery phase (2004-2010) focused on validating the core concept and exploring basic compositions, primarily centered around transition metals. During this period, researchers established fundamental understanding of the four core effects in HEAs: high entropy, sluggish diffusion, severe lattice distortion, and cocktail effects.

The second development phase (2010-2015) witnessed expanded exploration of composition spaces and processing techniques. Researchers began investigating non-equiatomic compositions and incorporating elements beyond transition metals, leading to the broader concept of complex concentrated alloys (CCAs). This period also saw the first applications of HEAs in specialized fields requiring extreme performance characteristics.

Since 2016, HEA research has entered a maturation phase characterized by targeted design for specific applications and integration with smart material technologies. The focus has shifted from fundamental discovery to engineering HEAs with tailored functional properties such as shape memory effects, magnetocaloric properties, and stimuli-responsive behaviors essential for smart material applications.

The primary objective of current HEA research in smart materials is to develop compositions that can respond predictably to external stimuli while maintaining structural integrity under extreme conditions. Researchers aim to create materials that combine sensing and actuating capabilities with the inherent advantages of HEAs, such as exceptional mechanical properties, thermal stability, and corrosion resistance.

Additional objectives include establishing reliable manufacturing processes for HEA-based smart materials, reducing production costs to enable commercial viability, and developing computational models that can accurately predict the behavior of these complex systems. The ultimate goal is to position HEAs as a versatile platform for next-generation smart materials that can operate in environments where conventional materials fail, particularly in aerospace, energy, and biomedical applications.

The evolution of HEAs has progressed through distinct phases. The initial discovery phase (2004-2010) focused on validating the core concept and exploring basic compositions, primarily centered around transition metals. During this period, researchers established fundamental understanding of the four core effects in HEAs: high entropy, sluggish diffusion, severe lattice distortion, and cocktail effects.

The second development phase (2010-2015) witnessed expanded exploration of composition spaces and processing techniques. Researchers began investigating non-equiatomic compositions and incorporating elements beyond transition metals, leading to the broader concept of complex concentrated alloys (CCAs). This period also saw the first applications of HEAs in specialized fields requiring extreme performance characteristics.

Since 2016, HEA research has entered a maturation phase characterized by targeted design for specific applications and integration with smart material technologies. The focus has shifted from fundamental discovery to engineering HEAs with tailored functional properties such as shape memory effects, magnetocaloric properties, and stimuli-responsive behaviors essential for smart material applications.

The primary objective of current HEA research in smart materials is to develop compositions that can respond predictably to external stimuli while maintaining structural integrity under extreme conditions. Researchers aim to create materials that combine sensing and actuating capabilities with the inherent advantages of HEAs, such as exceptional mechanical properties, thermal stability, and corrosion resistance.

Additional objectives include establishing reliable manufacturing processes for HEA-based smart materials, reducing production costs to enable commercial viability, and developing computational models that can accurately predict the behavior of these complex systems. The ultimate goal is to position HEAs as a versatile platform for next-generation smart materials that can operate in environments where conventional materials fail, particularly in aerospace, energy, and biomedical applications.

Smart Materials Market Analysis

The global smart materials market is experiencing robust growth, with a current valuation exceeding $60 billion and projected to reach $125 billion by 2025, representing a compound annual growth rate of approximately 13.5%. This expansion is primarily driven by increasing demand across automotive, aerospace, construction, and healthcare sectors, where materials with adaptive properties offer significant performance advantages.

High-Entropy Alloys (HEAs) are emerging as a revolutionary component within the smart materials ecosystem, particularly as they demonstrate exceptional mechanical properties, corrosion resistance, and thermal stability. The integration of HEAs into smart material technologies is creating new market segments with an estimated potential value of $3.2 billion by 2027.

Regionally, North America currently leads the smart materials market with approximately 35% market share, followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is demonstrating the fastest growth rate at 15.2% annually, driven by rapid industrialization in China, Japan, and South Korea, where significant investments are being made in HEA research and development.

Consumer electronics represents the largest application segment for smart materials incorporating HEAs, accounting for 31% of market revenue. This is followed by aerospace and defense (24%), automotive (18%), and medical devices (14%). The remaining 13% is distributed across various industrial applications. The electronics sector's dominance is attributed to the increasing demand for miniaturized components with enhanced durability and functionality.

Market penetration of HEA-based smart materials faces several challenges, including high production costs averaging $150-200 per kilogram compared to $20-50 for conventional alloys. Additionally, manufacturing scalability remains limited, with current production capabilities restricted to specialized facilities capable of precise compositional control.

Investment in HEA research has seen a 45% increase over the past three years, with venture capital funding exceeding $780 million in 2022 alone. Major corporations including General Electric, Siemens, and Toyota have established dedicated research divisions focused on HEA applications, signaling strong commercial interest.

Customer adoption trends indicate growing acceptance of premium-priced smart materials incorporating HEAs, particularly in high-performance applications where traditional materials fail to meet increasingly stringent requirements. Market surveys reveal that 68% of industrial customers are willing to pay a 15-20% premium for materials offering demonstrable performance improvements and longer service life.

High-Entropy Alloys (HEAs) are emerging as a revolutionary component within the smart materials ecosystem, particularly as they demonstrate exceptional mechanical properties, corrosion resistance, and thermal stability. The integration of HEAs into smart material technologies is creating new market segments with an estimated potential value of $3.2 billion by 2027.

Regionally, North America currently leads the smart materials market with approximately 35% market share, followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is demonstrating the fastest growth rate at 15.2% annually, driven by rapid industrialization in China, Japan, and South Korea, where significant investments are being made in HEA research and development.

Consumer electronics represents the largest application segment for smart materials incorporating HEAs, accounting for 31% of market revenue. This is followed by aerospace and defense (24%), automotive (18%), and medical devices (14%). The remaining 13% is distributed across various industrial applications. The electronics sector's dominance is attributed to the increasing demand for miniaturized components with enhanced durability and functionality.

Market penetration of HEA-based smart materials faces several challenges, including high production costs averaging $150-200 per kilogram compared to $20-50 for conventional alloys. Additionally, manufacturing scalability remains limited, with current production capabilities restricted to specialized facilities capable of precise compositional control.

Investment in HEA research has seen a 45% increase over the past three years, with venture capital funding exceeding $780 million in 2022 alone. Major corporations including General Electric, Siemens, and Toyota have established dedicated research divisions focused on HEA applications, signaling strong commercial interest.

Customer adoption trends indicate growing acceptance of premium-priced smart materials incorporating HEAs, particularly in high-performance applications where traditional materials fail to meet increasingly stringent requirements. Market surveys reveal that 68% of industrial customers are willing to pay a 15-20% premium for materials offering demonstrable performance improvements and longer service life.

Global HEA Research Status and Challenges

High-Entropy Alloys (HEAs) have emerged as a revolutionary class of materials in the global materials science landscape. Currently, research centers across North America, Europe, and Asia are actively pursuing HEA development, with China, the United States, and Germany leading in publication output and patent filings. The global research community has made significant strides in understanding the fundamental principles governing HEAs, particularly their unique properties such as exceptional mechanical strength, superior corrosion resistance, and remarkable thermal stability.

Despite these advances, several critical challenges persist in the global HEA research arena. The lack of standardized manufacturing processes presents a significant hurdle, as reproducibility issues hamper consistent production at industrial scales. Computational modeling limitations also restrict the ability to accurately predict HEA properties and behaviors, necessitating extensive experimental validation that slows development cycles.

Cost factors remain prohibitive for widespread commercial adoption, with rare element incorporation and complex processing requirements driving up production expenses. Additionally, the integration of HEAs with existing smart material systems presents compatibility challenges that researchers worldwide are struggling to overcome.

The geographical distribution of HEA research shows interesting patterns, with Asian institutions focusing predominantly on structural applications, European research centers emphasizing functional properties, and North American groups leading in computational design approaches. This regional specialization has created knowledge silos that impede holistic advancement of the field.

Recent international collaborations have begun addressing these challenges through initiatives like the International HEA Consortium and the Smart Materials Global Alliance. These partnerships facilitate knowledge exchange and resource sharing across borders, accelerating progress in overcoming technical barriers.

The environmental impact of HEA production represents another significant challenge, with sustainability concerns regarding energy-intensive manufacturing processes and the use of critical raw materials. Research groups in Scandinavia and Japan are pioneering eco-friendly synthesis routes and recycling methodologies to address these issues.

Looking forward, the global research community must overcome these challenges to fully realize the potential of HEAs in smart material technologies. Interdisciplinary approaches combining materials science, computational modeling, and systems engineering are increasingly recognized as essential for advancing the field. The development of application-specific HEAs tailored for smart material integration represents the frontier of current research efforts worldwide.

Despite these advances, several critical challenges persist in the global HEA research arena. The lack of standardized manufacturing processes presents a significant hurdle, as reproducibility issues hamper consistent production at industrial scales. Computational modeling limitations also restrict the ability to accurately predict HEA properties and behaviors, necessitating extensive experimental validation that slows development cycles.

Cost factors remain prohibitive for widespread commercial adoption, with rare element incorporation and complex processing requirements driving up production expenses. Additionally, the integration of HEAs with existing smart material systems presents compatibility challenges that researchers worldwide are struggling to overcome.

The geographical distribution of HEA research shows interesting patterns, with Asian institutions focusing predominantly on structural applications, European research centers emphasizing functional properties, and North American groups leading in computational design approaches. This regional specialization has created knowledge silos that impede holistic advancement of the field.

Recent international collaborations have begun addressing these challenges through initiatives like the International HEA Consortium and the Smart Materials Global Alliance. These partnerships facilitate knowledge exchange and resource sharing across borders, accelerating progress in overcoming technical barriers.

The environmental impact of HEA production represents another significant challenge, with sustainability concerns regarding energy-intensive manufacturing processes and the use of critical raw materials. Research groups in Scandinavia and Japan are pioneering eco-friendly synthesis routes and recycling methodologies to address these issues.

Looking forward, the global research community must overcome these challenges to fully realize the potential of HEAs in smart material technologies. Interdisciplinary approaches combining materials science, computational modeling, and systems engineering are increasingly recognized as essential for advancing the field. The development of application-specific HEAs tailored for smart material integration represents the frontier of current research efforts worldwide.

Current HEA Implementation in Smart Materials

01 Composition and design of high-entropy alloys

High-entropy alloys (HEAs) are composed of multiple principal elements in near-equiatomic proportions, typically containing five or more elements. The design of these alloys focuses on achieving a single-phase solid solution with high configurational entropy. Various element combinations can be used to create HEAs with specific properties, including transition metals, refractory elements, and rare earth metals. The composition design often involves consideration of atomic size differences, mixing enthalpy, and valence electron concentration to predict phase stability.- Composition and structure of high-entropy alloys: High-entropy alloys (HEAs) are composed of multiple principal elements in near-equiatomic proportions, typically containing five or more elements. This multi-element composition creates unique crystalline structures with high configurational entropy, which contributes to their exceptional properties. The alloys can form single-phase solid solutions or multi-phase structures depending on the constituent elements and processing conditions. The composition design focuses on achieving a balance between elements to optimize specific properties while maintaining the high-entropy effect.

- Manufacturing methods for high-entropy alloys: Various manufacturing techniques are employed to produce high-entropy alloys, including arc melting, mechanical alloying, powder metallurgy, and additive manufacturing. Each method offers different advantages in terms of microstructure control, scalability, and final properties. Post-processing treatments such as heat treatment, hot isostatic pressing, and thermomechanical processing are often applied to optimize the microstructure and enhance specific properties. These manufacturing approaches can be tailored to achieve desired phase compositions and grain structures for specific applications.

- Mechanical properties and applications of high-entropy alloys: High-entropy alloys exhibit exceptional mechanical properties, including high strength, excellent ductility, superior wear resistance, and remarkable fracture toughness. These properties make them suitable for structural applications in extreme environments such as aerospace components, cutting tools, and high-temperature machinery parts. The unique combination of strength and ductility is attributed to their complex microstructures and deformation mechanisms, including twinning, dislocation movement, and phase transformations under stress. Some HEAs also demonstrate excellent performance at cryogenic temperatures, making them valuable for specialized applications.

- Corrosion and oxidation resistance of high-entropy alloys: Many high-entropy alloys demonstrate superior corrosion and oxidation resistance compared to conventional alloys, making them suitable for harsh environmental applications. This enhanced resistance is attributed to the formation of stable passive films and the sluggish diffusion kinetics inherent in these multi-element systems. The complex atomic arrangements in HEAs can impede the diffusion of oxygen and corrosive species, thereby improving their performance in aggressive environments. Surface modification techniques and compositional adjustments can further enhance the corrosion and oxidation resistance properties for specific applications.

- Functional properties and specialized applications of high-entropy alloys: Beyond mechanical applications, high-entropy alloys exhibit various functional properties including magnetic behavior, thermoelectric performance, and biocompatibility. These properties enable their use in specialized fields such as magnetic sensors, energy conversion devices, and biomedical implants. Some HEAs demonstrate shape memory effects, superelasticity, or superconductivity, expanding their potential applications. Research is ongoing to develop HEAs with tailored functional properties through compositional design and processing optimization, opening new avenues for advanced technological applications.

02 Manufacturing methods for high-entropy alloys

Various manufacturing techniques are employed to produce high-entropy alloys, including arc melting, mechanical alloying, powder metallurgy, and additive manufacturing. Each method offers different advantages in terms of microstructure control, homogeneity, and scalability. Arc melting is commonly used for laboratory-scale production, while powder metallurgy enables better control of grain size and porosity. Additive manufacturing techniques allow for complex geometries and compositional gradients in high-entropy alloys.Expand Specific Solutions03 Mechanical properties and structural applications

High-entropy alloys exhibit exceptional mechanical properties, including high strength, hardness, wear resistance, and excellent performance at elevated temperatures. These alloys often demonstrate a favorable combination of strength and ductility, making them suitable for structural applications in aerospace, automotive, and energy sectors. The unique microstructure of high-entropy alloys, characterized by severe lattice distortion and sluggish diffusion, contributes to their superior mechanical behavior compared to conventional alloys.Expand Specific Solutions04 Functional properties and specialized applications

Beyond mechanical properties, high-entropy alloys demonstrate various functional properties including corrosion resistance, radiation tolerance, magnetic properties, and catalytic activity. These functional characteristics enable applications in harsh environments, nuclear reactors, biomedical implants, and energy conversion systems. Some high-entropy alloys exhibit superparamagnetism, superconductivity, or enhanced hydrogen storage capacity, expanding their potential use in advanced technological applications.Expand Specific Solutions05 Surface modification and coating technologies

Surface modification techniques for high-entropy alloys include laser surface treatment, plasma spraying, physical vapor deposition, and electrochemical processing. These methods can enhance surface properties such as hardness, wear resistance, and corrosion resistance without altering the bulk properties of the material. High-entropy alloy coatings can be applied to conventional materials to impart superior surface characteristics, extending component lifetimes in demanding environments and enabling new applications in various industries.Expand Specific Solutions

Leading Companies and Research Institutions

High-Entropy Alloys (HEAs) in smart material technologies are currently in an early growth phase, transitioning from research to commercial applications. The market is expanding rapidly, projected to reach significant scale as these alloys offer superior mechanical properties and thermal stability compared to conventional materials. Technologically, HEAs are advancing through collaborative research between academic institutions and industry players. Universities like Chungnam National, Southeast University, and Huazhong University of Science & Technology lead fundamental research, while companies such as LG Electronics, Guardian Glass, and Proterial Ltd. focus on application development. The competitive landscape features strong academic-industrial partnerships, with Asian institutions particularly prominent in patent filings and publications, suggesting regional leadership in this emerging field.

University of Science & Technology Beijing

Technical Solution: The University of Science & Technology Beijing (USTB) has developed comprehensive High-Entropy Alloy (HEA) technologies for smart material applications, leveraging their extensive expertise in metallurgy and materials science. Their approach centers on designing compositionally complex alloys with controlled microstructures that exhibit responsive behaviors to environmental stimuli. USTB researchers have pioneered a novel processing technique combining electromagnetic stirring with controlled solidification to achieve homogeneous elemental distribution in large-scale HEA castings[1]. Their materials demonstrate exceptional mechanical properties, with some compositions achieving yield strengths above 1.3 GPa while maintaining ductility of 10-15%[3]. A significant innovation is their development of HEAs with temperature-adaptive properties, where the material undergoes controlled phase transformations at specific temperature thresholds, enabling applications in thermal management systems. These alloys show transformation temperatures that can be precisely tuned between -50°C and 300°C by adjusting elemental ratios[2]. USTB has also developed HEAs with remarkable corrosion resistance in harsh environments, showing corrosion rates up to 100 times lower than conventional stainless steels in acidic media[4]. Their recent work includes HEAs with thermoelectric properties, where the material can convert temperature gradients into electrical energy with figure of merit (ZT) values approaching 1.2 at elevated temperatures.

Strengths: World-class expertise in processing-structure-property relationships for complex alloys; strong capabilities in large-scale production techniques; extensive experience in microstructural engineering for specific functional properties. Weaknesses: Some compositions require precise control of trace elements that complicate quality control; intellectual property restrictions may limit technology transfer in certain markets; long-term performance under complex loading conditions requires further validation.

Korea Institute of Materials Science

Technical Solution: The Korea Institute of Materials Science (KIMS) has developed advanced High-Entropy Alloy (HEA) technologies specifically engineered for smart material applications. Their approach focuses on creating multi-principal element alloys with controlled microstructures that exhibit responsive behaviors to external stimuli. KIMS researchers have pioneered a unique processing method combining mechanical alloying and spark plasma sintering that produces nanostructured HEAs with enhanced functional properties[2]. Their materials demonstrate exceptional mechanical characteristics, with some compositions achieving yield strengths exceeding 1.5 GPa while maintaining good ductility of 8-12%[4]. A significant innovation is their development of HEAs with magnetocaloric effects, where the material undergoes reversible temperature changes in response to applied magnetic fields, with entropy changes up to 12 J/kg·K[1]. These materials show potential for solid-state refrigeration and thermal management in smart systems. KIMS has also developed HEAs with shape memory properties that can recover deformation upon heating, with transformation temperatures tunable between -20°C and 400°C by adjusting composition ratios. Their recent work includes HEAs with self-sensing capabilities, where electrical resistivity changes predictably under mechanical strain, enabling structural health monitoring applications.

Strengths: Exceptional capabilities in powder metallurgy and advanced processing techniques; strong integration of computational modeling with experimental validation; extensive experience in scaling laboratory processes to industrial production. Weaknesses: Some compositions require expensive elements like palladium or platinum that increase material costs; processing parameters often require precise control that complicates manufacturing; long-term stability under cyclic loading conditions requires further investigation.

Key Patents and Breakthroughs in HEA Design

High-entropy alloy, and method for producing the same

PatentActiveUS20200392613A1

Innovation

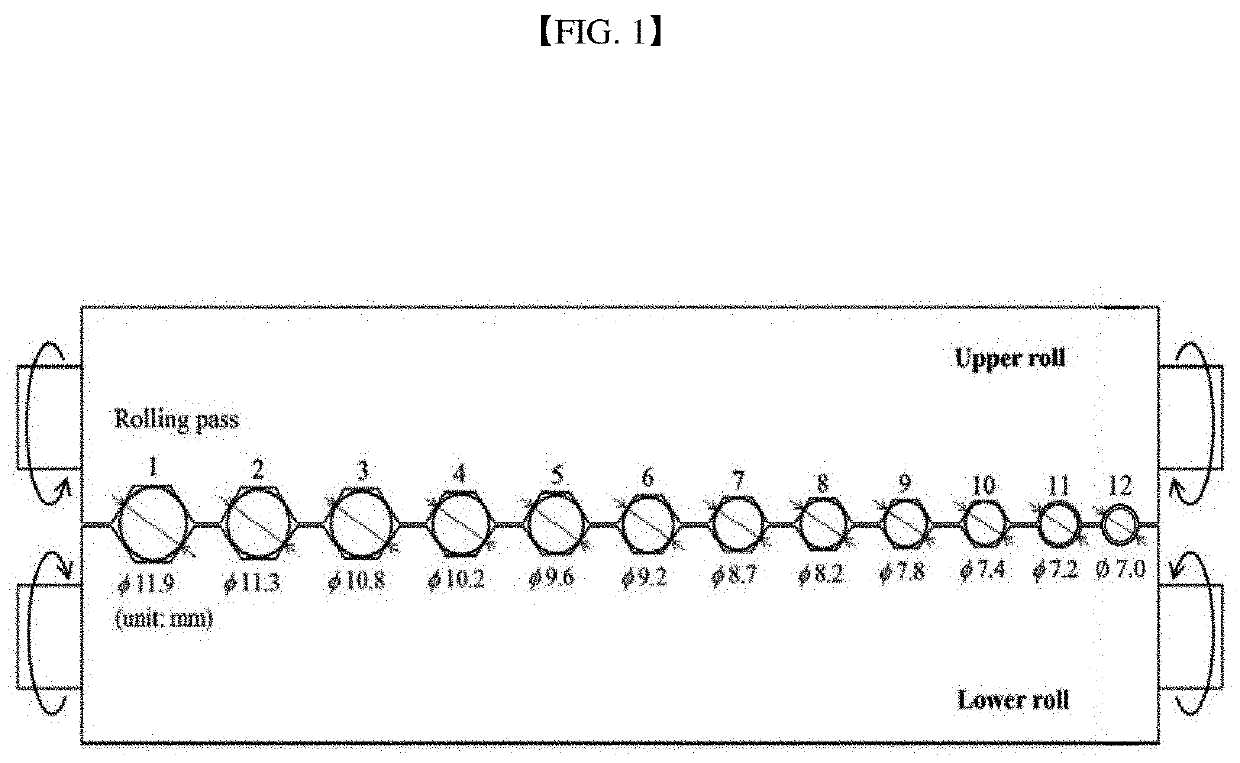

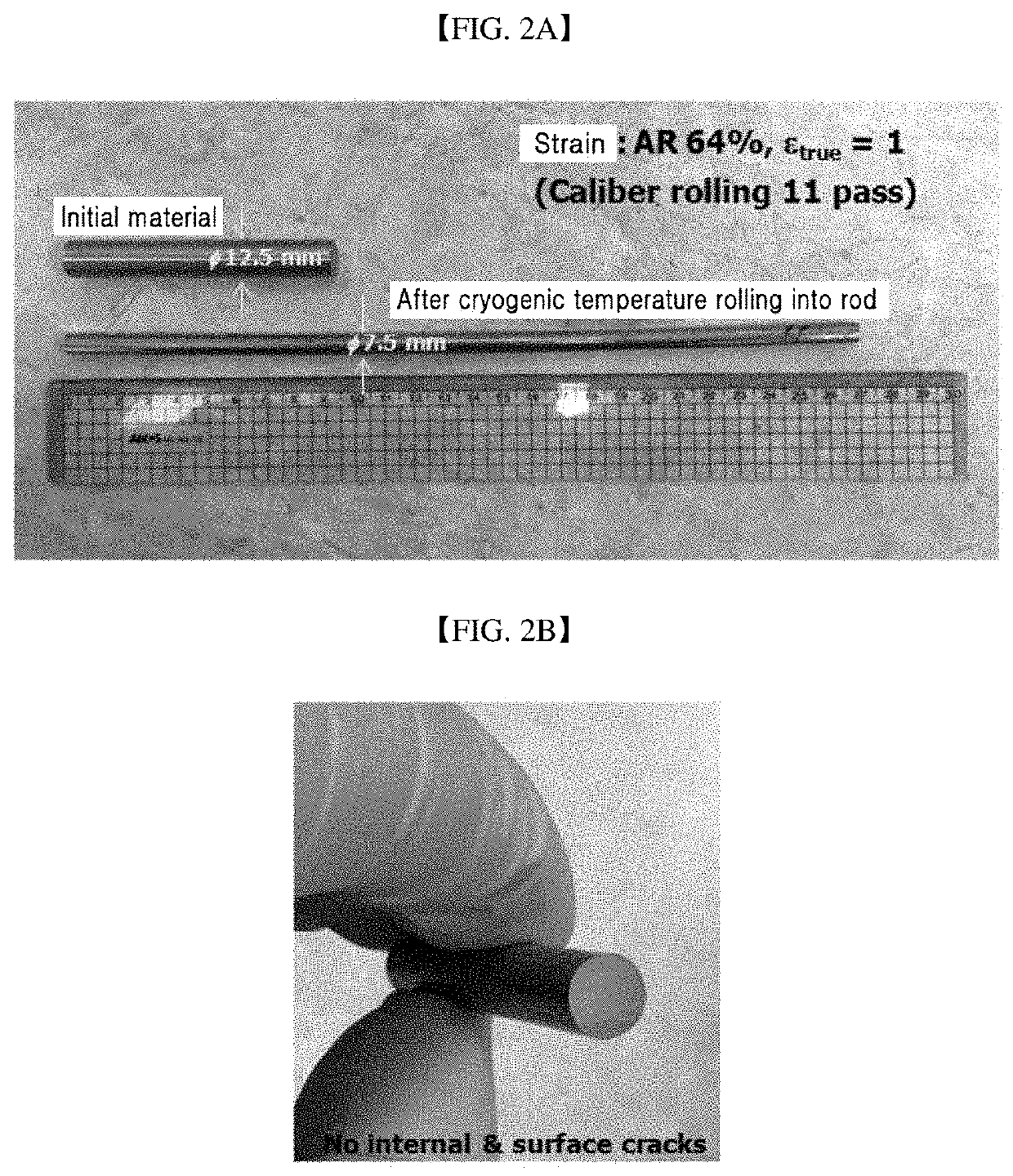

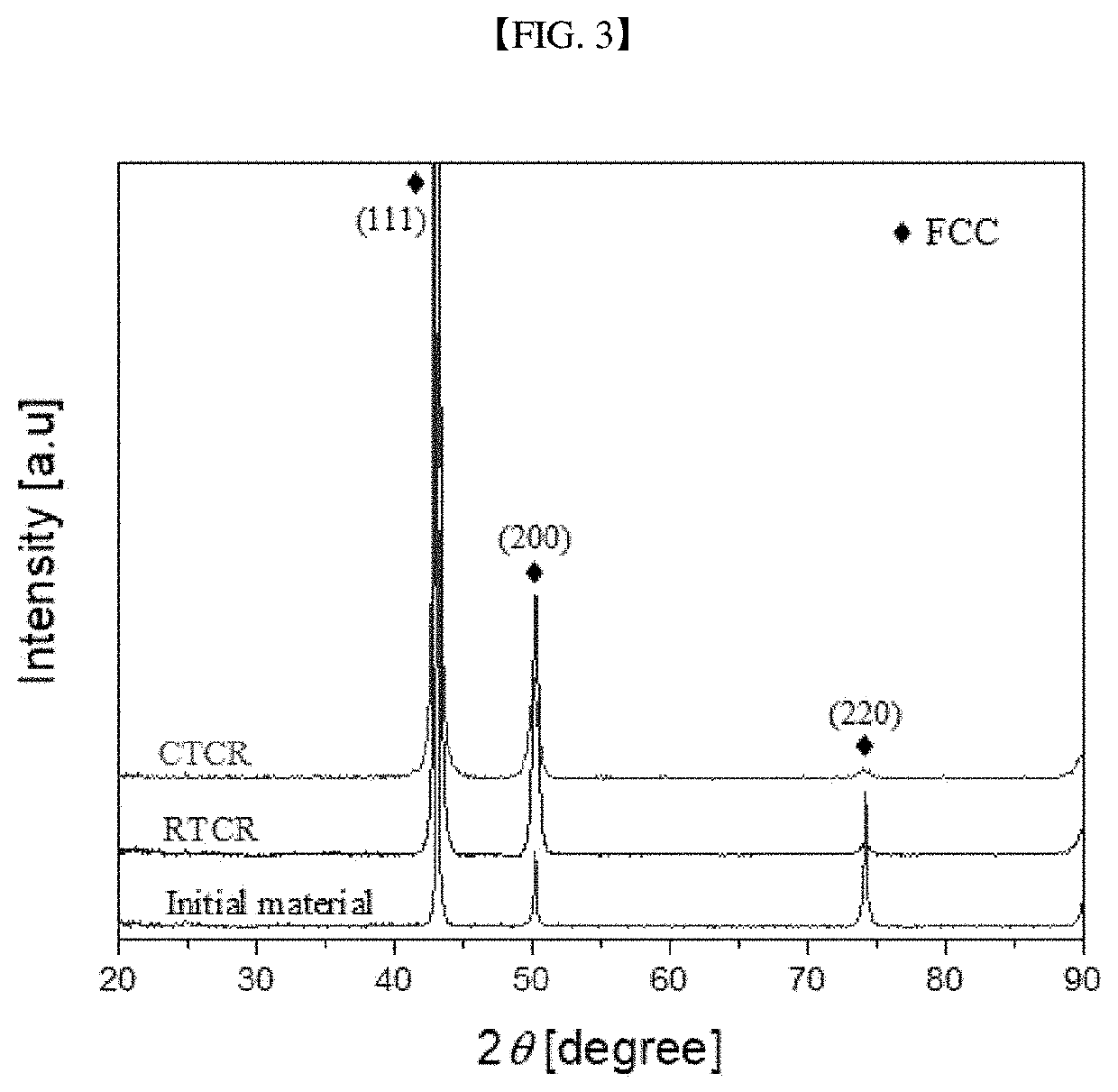

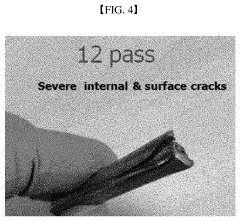

- A method involving annealing and homogenizing an initial alloy containing Co, Cr, Fe, Mn, and Ni, followed by cryogenic temperature rolling with a multi-pass caliber roller to form intersecting twins and secondary fine twins, enhancing grain refinement and hydrogen embrittlement resistance without severe plastic deformation.

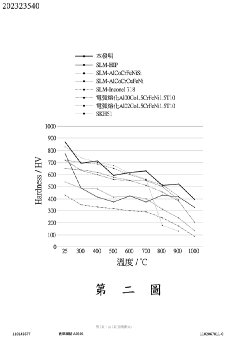

High-entropy alloys with high-temperature strengths

PatentActiveTW202323540A

Innovation

- A high-entropy alloy composed of at least seven metal elements, including aluminum, nickel, cobalt, chromium, niobium, molybdenum, and tungsten, is developed to enhance mechanical properties at high temperatures, achieved through vacuum smelting, gas atomization, and laser lamination processes.

Sustainability and Resource Considerations

The sustainability implications of High-Entropy Alloys (HEAs) in smart material technologies represent a critical dimension for their long-term viability. HEAs offer unique opportunities for resource efficiency through their compositional flexibility, enabling the incorporation of abundant elements while reducing dependence on critical raw materials. This characteristic proves particularly valuable as global supply chains face increasing pressure from geopolitical tensions and resource scarcity.

From a life-cycle perspective, HEAs demonstrate promising environmental advantages. Their exceptional mechanical properties and corrosion resistance contribute to extended service lifetimes for components, reducing the frequency of replacement and associated resource consumption. Additionally, the multi-principal element composition of HEAs allows for strategic substitution of environmentally problematic elements without compromising performance characteristics.

Energy considerations in HEA production present both challenges and opportunities. Current manufacturing processes often require high temperatures and precise control, resulting in significant energy consumption. However, emerging processing techniques such as additive manufacturing and powder metallurgy offer pathways to more energy-efficient production. These methods enable near-net-shape fabrication, minimizing material waste and subsequent processing requirements.

Recyclability represents another crucial sustainability aspect of HEAs. The complex compositions of these alloys can complicate traditional recycling processes, potentially leading to downcycling rather than true circular material flows. Research into specialized recycling technologies for HEAs is gaining momentum, with promising developments in selective extraction and separation techniques that could enable effective recovery of constituent elements.

The carbon footprint of HEA-based smart materials must be evaluated holistically. While production energy requirements may exceed those of conventional alloys, the extended service life and enhanced performance in applications like energy generation and storage systems can yield net carbon reductions over the full product lifecycle. Quantitative life cycle assessment studies are increasingly documenting these trade-offs to guide sustainable implementation.

Resource governance and ethical sourcing present additional considerations for HEA development. The flexibility to incorporate diverse elements provides opportunities to design supply chains that avoid conflict minerals and environmentally destructive extraction practices. This aligns with growing regulatory frameworks and consumer expectations regarding responsible material sourcing in advanced technologies.

From a life-cycle perspective, HEAs demonstrate promising environmental advantages. Their exceptional mechanical properties and corrosion resistance contribute to extended service lifetimes for components, reducing the frequency of replacement and associated resource consumption. Additionally, the multi-principal element composition of HEAs allows for strategic substitution of environmentally problematic elements without compromising performance characteristics.

Energy considerations in HEA production present both challenges and opportunities. Current manufacturing processes often require high temperatures and precise control, resulting in significant energy consumption. However, emerging processing techniques such as additive manufacturing and powder metallurgy offer pathways to more energy-efficient production. These methods enable near-net-shape fabrication, minimizing material waste and subsequent processing requirements.

Recyclability represents another crucial sustainability aspect of HEAs. The complex compositions of these alloys can complicate traditional recycling processes, potentially leading to downcycling rather than true circular material flows. Research into specialized recycling technologies for HEAs is gaining momentum, with promising developments in selective extraction and separation techniques that could enable effective recovery of constituent elements.

The carbon footprint of HEA-based smart materials must be evaluated holistically. While production energy requirements may exceed those of conventional alloys, the extended service life and enhanced performance in applications like energy generation and storage systems can yield net carbon reductions over the full product lifecycle. Quantitative life cycle assessment studies are increasingly documenting these trade-offs to guide sustainable implementation.

Resource governance and ethical sourcing present additional considerations for HEA development. The flexibility to incorporate diverse elements provides opportunities to design supply chains that avoid conflict minerals and environmentally destructive extraction practices. This aligns with growing regulatory frameworks and consumer expectations regarding responsible material sourcing in advanced technologies.

Manufacturing Scalability Assessment

The manufacturing scalability of High-Entropy Alloys (HEAs) for smart material technologies presents both significant opportunities and challenges. Current production methods for HEAs include arc melting, induction melting, mechanical alloying, and additive manufacturing techniques. Each method offers distinct advantages but faces limitations when scaling to industrial volumes required for widespread smart material applications.

Arc and induction melting processes, while effective for laboratory-scale production, encounter difficulties in maintaining compositional homogeneity when scaled up. The multi-element nature of HEAs (typically containing five or more principal elements in near-equiatomic proportions) creates complex solidification patterns that can lead to segregation and property variations in larger castings. This inconsistency becomes particularly problematic for smart material applications where precise and reliable performance characteristics are essential.

Powder metallurgy approaches, including mechanical alloying followed by consolidation, offer better compositional control but suffer from lower production rates and higher costs. The extended milling times required to achieve homogeneous element distribution can range from 10-100 hours, creating a significant production bottleneck. Additionally, oxygen contamination during processing remains a persistent challenge that can degrade the functional properties critical for smart applications.

Additive manufacturing technologies show promising potential for HEA production in smart material contexts. Techniques such as selective laser melting (SLM) and directed energy deposition (DED) enable the fabrication of complex geometries with reasonable compositional control. However, the layer-by-layer building process results in relatively slow production rates and size limitations that currently restrict industrial-scale implementation.

Cost factors significantly impact manufacturing scalability. The raw material costs for HEAs can be 3-10 times higher than conventional alloys due to the inclusion of multiple high-purity elements. Processing costs are further elevated by the specialized equipment requirements and extended production times. These economic barriers must be addressed through process optimization and supply chain development before HEAs can achieve widespread adoption in smart material technologies.

Recent advancements in continuous casting and spray forming techniques show promise for improving HEA production efficiency. These methods could potentially reduce processing steps and improve throughput while maintaining the compositional homogeneity necessary for smart material applications. Several research institutions and industrial partners are currently developing pilot-scale facilities to validate these approaches, with preliminary results indicating up to 40% reduction in production costs compared to conventional methods.

Arc and induction melting processes, while effective for laboratory-scale production, encounter difficulties in maintaining compositional homogeneity when scaled up. The multi-element nature of HEAs (typically containing five or more principal elements in near-equiatomic proportions) creates complex solidification patterns that can lead to segregation and property variations in larger castings. This inconsistency becomes particularly problematic for smart material applications where precise and reliable performance characteristics are essential.

Powder metallurgy approaches, including mechanical alloying followed by consolidation, offer better compositional control but suffer from lower production rates and higher costs. The extended milling times required to achieve homogeneous element distribution can range from 10-100 hours, creating a significant production bottleneck. Additionally, oxygen contamination during processing remains a persistent challenge that can degrade the functional properties critical for smart applications.

Additive manufacturing technologies show promising potential for HEA production in smart material contexts. Techniques such as selective laser melting (SLM) and directed energy deposition (DED) enable the fabrication of complex geometries with reasonable compositional control. However, the layer-by-layer building process results in relatively slow production rates and size limitations that currently restrict industrial-scale implementation.

Cost factors significantly impact manufacturing scalability. The raw material costs for HEAs can be 3-10 times higher than conventional alloys due to the inclusion of multiple high-purity elements. Processing costs are further elevated by the specialized equipment requirements and extended production times. These economic barriers must be addressed through process optimization and supply chain development before HEAs can achieve widespread adoption in smart material technologies.

Recent advancements in continuous casting and spray forming techniques show promise for improving HEA production efficiency. These methods could potentially reduce processing steps and improve throughput while maintaining the compositional homogeneity necessary for smart material applications. Several research institutions and industrial partners are currently developing pilot-scale facilities to validate these approaches, with preliminary results indicating up to 40% reduction in production costs compared to conventional methods.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!