Role of Spinodal Decomposition in High-Entropy Alloys

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

High-Entropy Alloys Evolution and Research Objectives

High-entropy alloys (HEAs) represent a paradigm shift in metallurgical engineering, moving beyond conventional alloy design principles that typically focus on one principal element with minor additions. First conceptualized in the early 2000s, HEAs contain multiple principal elements in near-equiatomic proportions, creating unique microstructures and properties that have captivated researchers worldwide. The evolution of HEAs has progressed from initial exploratory studies to sophisticated design methodologies incorporating computational modeling and advanced characterization techniques.

The field has witnessed exponential growth in research publications, with significant milestones including the discovery of exceptional mechanical properties at cryogenic temperatures, superior radiation resistance, and remarkable corrosion resistance. Recent developments have focused on tailoring HEAs for specific applications through controlled processing and composition optimization, moving beyond the initial emphasis on single-phase solid solutions to explore multi-phase systems with enhanced performance characteristics.

Spinodal decomposition, a mechanism of phase separation occurring without nucleation barriers, has emerged as a critical phenomenon in HEAs. This process creates compositionally modulated nanostructures that significantly influence mechanical and functional properties. Understanding and controlling spinodal decomposition represents a frontier in HEA research, potentially enabling unprecedented property combinations through nanoscale engineering of composition fluctuations.

The technical objectives in this field encompass several dimensions. First, developing predictive models for spinodal decomposition in complex, multi-component systems remains challenging but essential for rational alloy design. Second, establishing processing-structure-property relationships specific to spinodally decomposed HEAs will enable targeted engineering of materials for extreme environments. Third, exploring the stability of these nanostructured states under service conditions is crucial for practical applications.

Research aims to elucidate the fundamental thermodynamics and kinetics governing spinodal decomposition in HEAs, which differ significantly from conventional binary or ternary systems due to complex diffusion pathways and configurational entropy effects. Additionally, there is growing interest in leveraging this phenomenon for hierarchical microstructure design, where spinodal nanostructures exist within larger microstructural features to create multi-scale strengthening mechanisms.

The convergence of advanced characterization techniques, computational methods, and novel processing approaches is expected to accelerate progress in this domain, potentially revolutionizing materials design for aerospace, energy, and transportation sectors where performance under extreme conditions is paramount.

The field has witnessed exponential growth in research publications, with significant milestones including the discovery of exceptional mechanical properties at cryogenic temperatures, superior radiation resistance, and remarkable corrosion resistance. Recent developments have focused on tailoring HEAs for specific applications through controlled processing and composition optimization, moving beyond the initial emphasis on single-phase solid solutions to explore multi-phase systems with enhanced performance characteristics.

Spinodal decomposition, a mechanism of phase separation occurring without nucleation barriers, has emerged as a critical phenomenon in HEAs. This process creates compositionally modulated nanostructures that significantly influence mechanical and functional properties. Understanding and controlling spinodal decomposition represents a frontier in HEA research, potentially enabling unprecedented property combinations through nanoscale engineering of composition fluctuations.

The technical objectives in this field encompass several dimensions. First, developing predictive models for spinodal decomposition in complex, multi-component systems remains challenging but essential for rational alloy design. Second, establishing processing-structure-property relationships specific to spinodally decomposed HEAs will enable targeted engineering of materials for extreme environments. Third, exploring the stability of these nanostructured states under service conditions is crucial for practical applications.

Research aims to elucidate the fundamental thermodynamics and kinetics governing spinodal decomposition in HEAs, which differ significantly from conventional binary or ternary systems due to complex diffusion pathways and configurational entropy effects. Additionally, there is growing interest in leveraging this phenomenon for hierarchical microstructure design, where spinodal nanostructures exist within larger microstructural features to create multi-scale strengthening mechanisms.

The convergence of advanced characterization techniques, computational methods, and novel processing approaches is expected to accelerate progress in this domain, potentially revolutionizing materials design for aerospace, energy, and transportation sectors where performance under extreme conditions is paramount.

Market Applications and Demand Analysis for HEAs

High-Entropy Alloys (HEAs) have emerged as revolutionary materials in the advanced manufacturing sector, with global market projections reaching $12 billion by 2030, growing at a CAGR of 15.2% from 2023. This significant growth is driven by increasing demand across multiple high-value industries seeking materials with superior performance characteristics.

The aerospace and defense sectors represent the largest market segment for HEAs, accounting for approximately 35% of current applications. These industries require materials that can withstand extreme conditions, including high temperatures, corrosive environments, and mechanical stress. The unique microstructural stability provided by spinodal decomposition in HEAs directly addresses these requirements, offering enhanced creep resistance and thermal stability at temperatures exceeding 1000°C.

Energy sector applications constitute the fastest-growing market segment with 22% annual growth, particularly in next-generation nuclear reactors, hydrogen storage systems, and advanced turbine components. The phase separation mechanisms in spinodally decomposed HEAs create coherent nanostructures that significantly improve hydrogen embrittlement resistance and radiation damage tolerance, critical properties for these applications.

Automotive manufacturers are increasingly exploring HEAs for lightweight structural components and high-temperature engine parts, representing 18% of the current market. The industry's push toward electrification has created demand for materials with improved electrical and thermal management properties, where spinodal decomposition-enhanced HEAs offer competitive advantages over traditional alloys.

Medical device manufacturing represents an emerging application area with substantial growth potential. The biocompatibility combined with exceptional wear resistance and antimicrobial properties of certain spinodally decomposed HEAs makes them ideal candidates for implantable devices and surgical instruments, with market adoption expected to grow at 28% annually through 2028.

Regional market analysis indicates North America and Europe currently lead HEA adoption with 40% and 35% market share respectively, while Asia-Pacific represents the fastest-growing region at 19% annual growth rate, driven by rapid industrialization in China, Japan, and South Korea. These countries are making substantial investments in advanced materials research and manufacturing capabilities.

Industry surveys indicate that 78% of materials engineers and procurement specialists cite improved performance-to-cost ratio as the primary driver for HEA adoption, while 65% identify manufacturing scalability as the main barrier to wider implementation. The role of spinodal decomposition in enhancing material properties while potentially simplifying processing routes addresses both these market factors simultaneously.

The aerospace and defense sectors represent the largest market segment for HEAs, accounting for approximately 35% of current applications. These industries require materials that can withstand extreme conditions, including high temperatures, corrosive environments, and mechanical stress. The unique microstructural stability provided by spinodal decomposition in HEAs directly addresses these requirements, offering enhanced creep resistance and thermal stability at temperatures exceeding 1000°C.

Energy sector applications constitute the fastest-growing market segment with 22% annual growth, particularly in next-generation nuclear reactors, hydrogen storage systems, and advanced turbine components. The phase separation mechanisms in spinodally decomposed HEAs create coherent nanostructures that significantly improve hydrogen embrittlement resistance and radiation damage tolerance, critical properties for these applications.

Automotive manufacturers are increasingly exploring HEAs for lightweight structural components and high-temperature engine parts, representing 18% of the current market. The industry's push toward electrification has created demand for materials with improved electrical and thermal management properties, where spinodal decomposition-enhanced HEAs offer competitive advantages over traditional alloys.

Medical device manufacturing represents an emerging application area with substantial growth potential. The biocompatibility combined with exceptional wear resistance and antimicrobial properties of certain spinodally decomposed HEAs makes them ideal candidates for implantable devices and surgical instruments, with market adoption expected to grow at 28% annually through 2028.

Regional market analysis indicates North America and Europe currently lead HEA adoption with 40% and 35% market share respectively, while Asia-Pacific represents the fastest-growing region at 19% annual growth rate, driven by rapid industrialization in China, Japan, and South Korea. These countries are making substantial investments in advanced materials research and manufacturing capabilities.

Industry surveys indicate that 78% of materials engineers and procurement specialists cite improved performance-to-cost ratio as the primary driver for HEA adoption, while 65% identify manufacturing scalability as the main barrier to wider implementation. The role of spinodal decomposition in enhancing material properties while potentially simplifying processing routes addresses both these market factors simultaneously.

Spinodal Decomposition Mechanisms and Challenges in HEAs

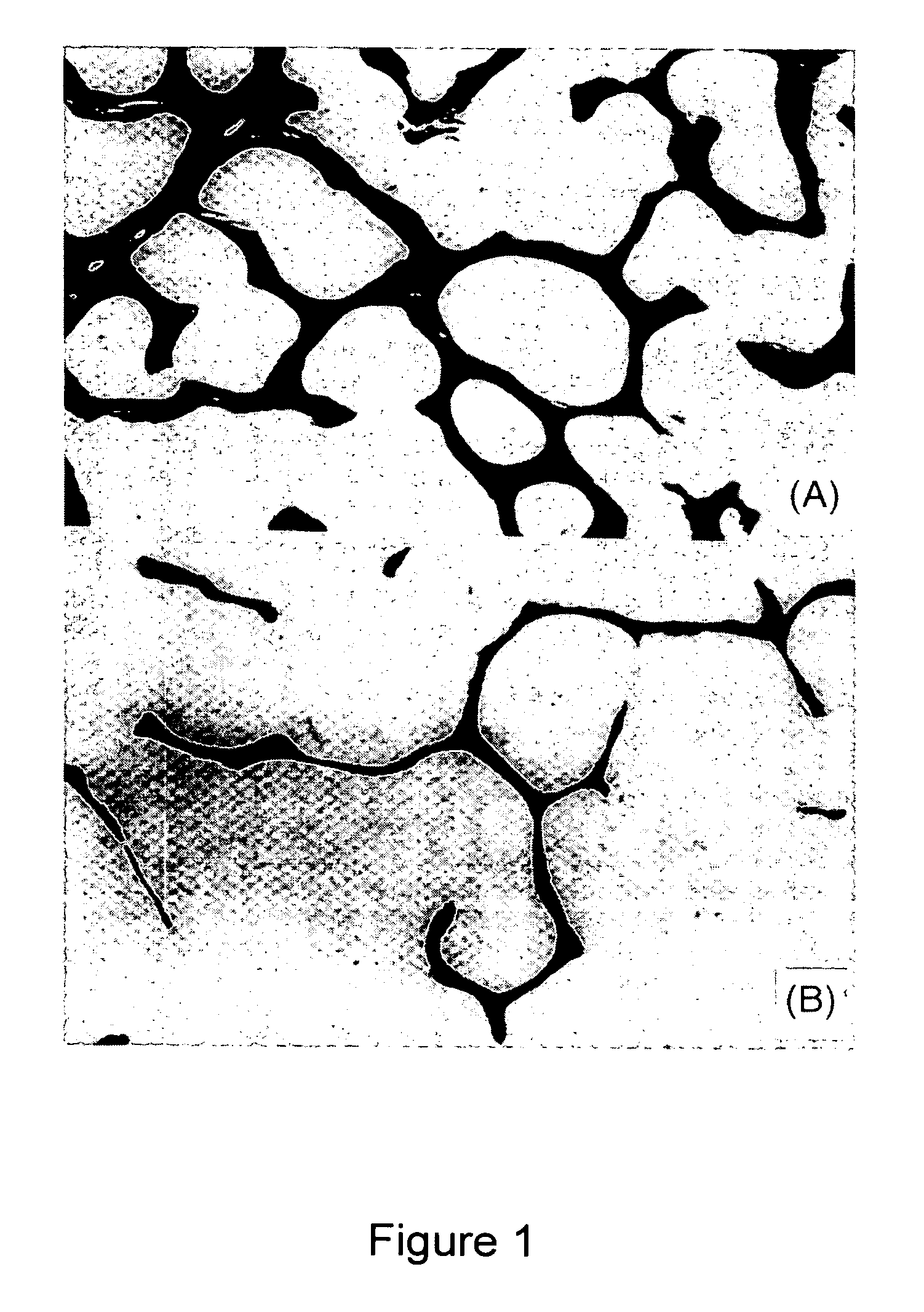

Spinodal decomposition in High-Entropy Alloys (HEAs) represents a critical phase separation mechanism that significantly influences the microstructural evolution and resultant properties of these advanced materials. Unlike conventional nucleation and growth processes, spinodal decomposition occurs through continuous compositional fluctuations without an energy barrier, leading to the formation of interconnected, periodic structures with compositional modulations.

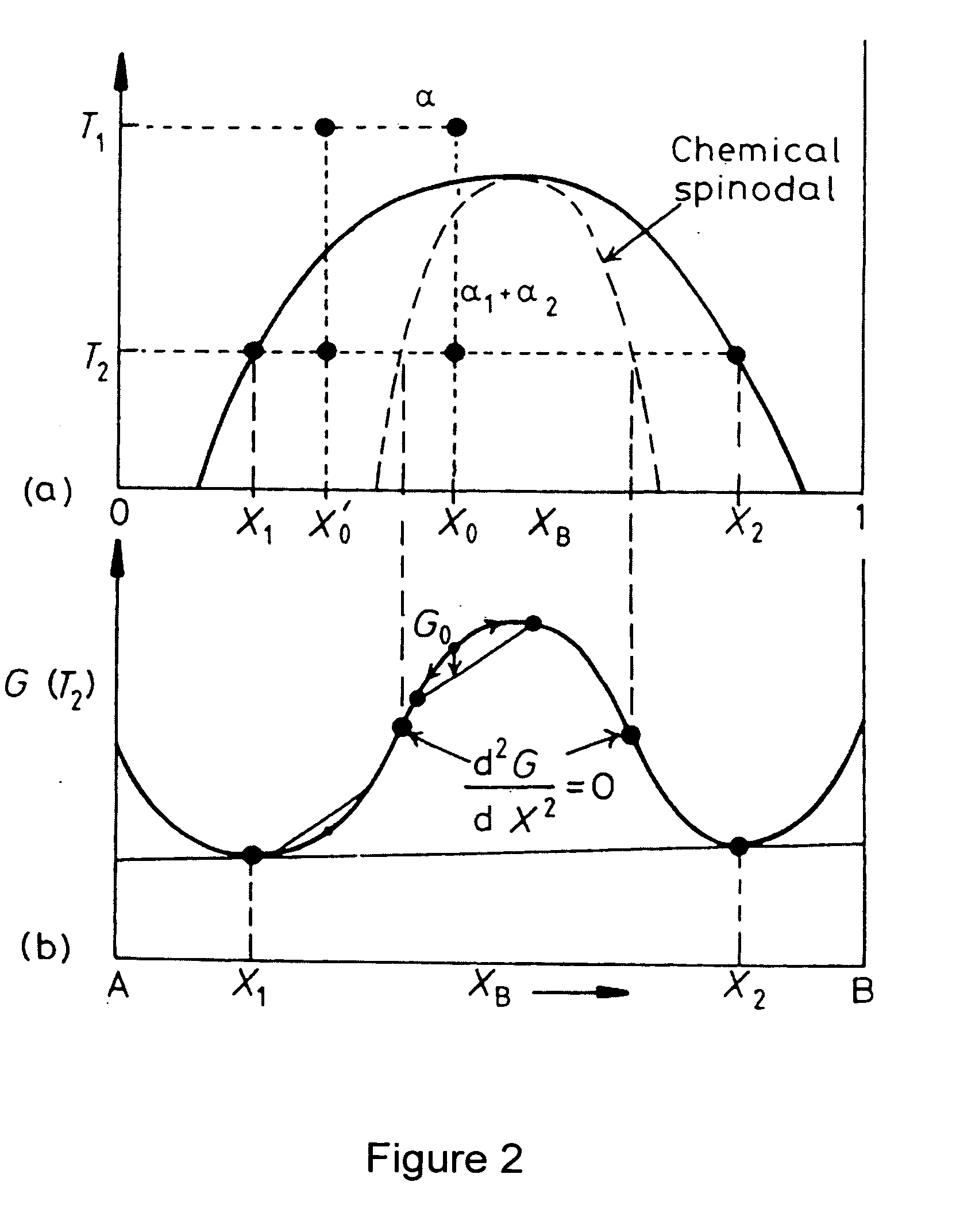

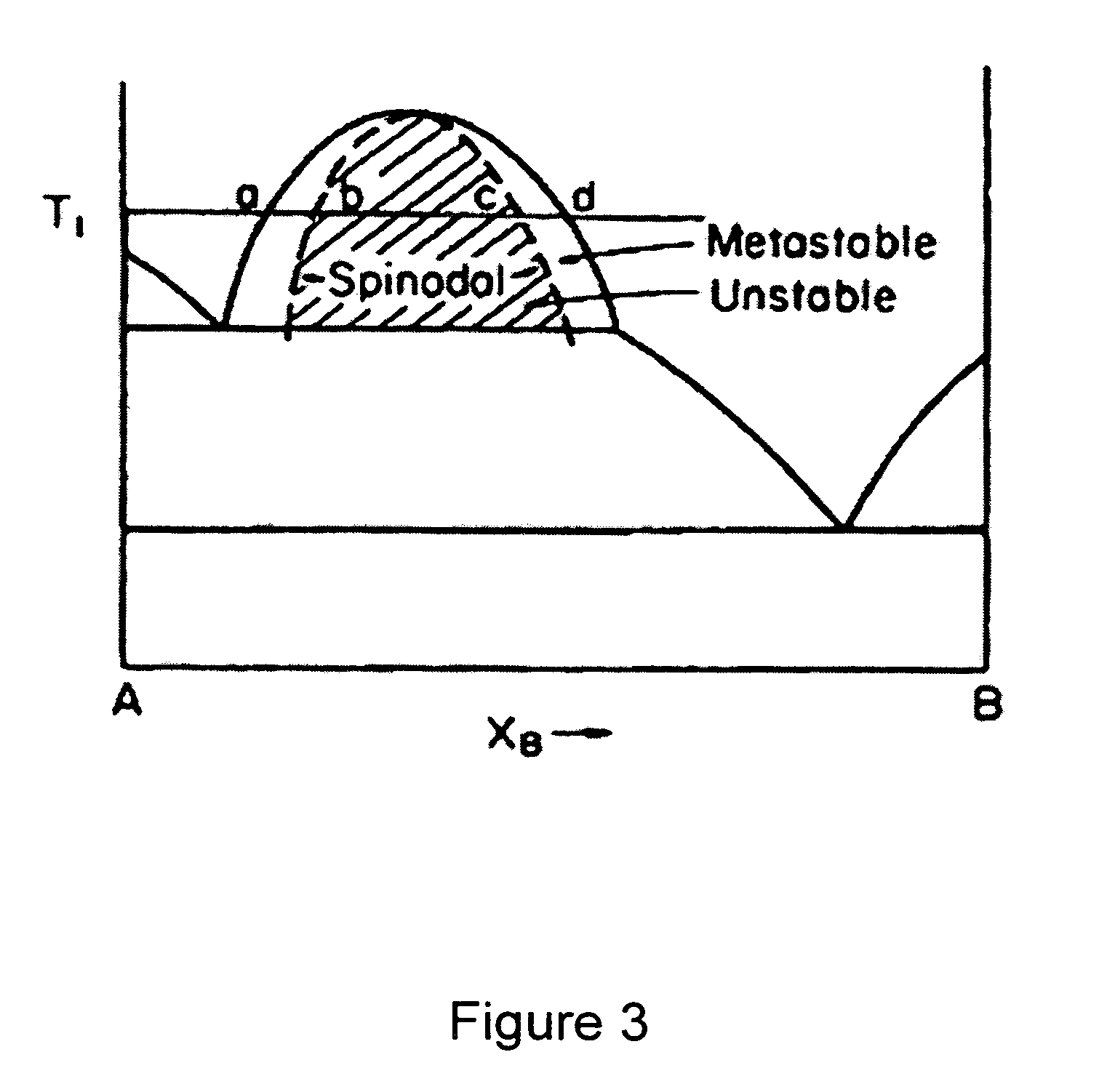

The fundamental mechanism of spinodal decomposition in HEAs involves uphill diffusion, where atoms move against the concentration gradient to create regions of higher and lower concentrations of specific elements. This process is driven by the reduction in free energy when the system enters the spinodal region of the phase diagram, characterized by a negative second derivative of the free energy with respect to composition.

In HEAs, spinodal decomposition presents unique characteristics due to the complex interactions among multiple principal elements. The sluggish diffusion kinetics, typically associated with HEAs, can significantly affect the rate and extent of decomposition. Additionally, the high configurational entropy that stabilizes the solid solution can compete with the driving force for phase separation, creating a delicate balance that determines microstructural stability.

One of the primary challenges in understanding spinodal decomposition in HEAs is the multi-component nature of these alloys, which complicates both experimental characterization and theoretical modeling. Traditional binary or ternary spinodal theories often fail to capture the complexity of five or more principal elements interacting simultaneously.

Advanced characterization techniques such as atom probe tomography (APT) and high-resolution transmission electron microscopy (HRTEM) have been instrumental in revealing spinodal structures in HEAs, but interpreting the results remains challenging due to the subtle compositional variations and complex crystallographic relationships.

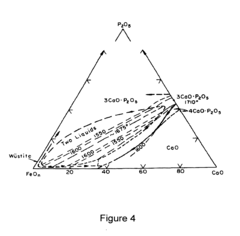

From a computational perspective, predicting spinodal decomposition in HEAs requires sophisticated models that can account for the interactions among multiple elements. Current CALPHAD (CALculation of PHAse Diagrams) approaches and first-principles calculations often struggle with the high dimensionality of the composition space in HEAs.

The temperature dependence of spinodal decomposition in HEAs presents another significant challenge. Many HEAs designed for high-temperature applications may undergo unexpected phase separations during service, potentially compromising their performance. Understanding the kinetics and thermodynamics of spinodal decomposition across different temperature regimes is therefore crucial for designing stable HEAs for specific applications.

Furthermore, the interplay between spinodal decomposition and other microstructural features, such as ordering, segregation, and precipitation, adds another layer of complexity to the analysis and prediction of HEA behavior during processing and service.

The fundamental mechanism of spinodal decomposition in HEAs involves uphill diffusion, where atoms move against the concentration gradient to create regions of higher and lower concentrations of specific elements. This process is driven by the reduction in free energy when the system enters the spinodal region of the phase diagram, characterized by a negative second derivative of the free energy with respect to composition.

In HEAs, spinodal decomposition presents unique characteristics due to the complex interactions among multiple principal elements. The sluggish diffusion kinetics, typically associated with HEAs, can significantly affect the rate and extent of decomposition. Additionally, the high configurational entropy that stabilizes the solid solution can compete with the driving force for phase separation, creating a delicate balance that determines microstructural stability.

One of the primary challenges in understanding spinodal decomposition in HEAs is the multi-component nature of these alloys, which complicates both experimental characterization and theoretical modeling. Traditional binary or ternary spinodal theories often fail to capture the complexity of five or more principal elements interacting simultaneously.

Advanced characterization techniques such as atom probe tomography (APT) and high-resolution transmission electron microscopy (HRTEM) have been instrumental in revealing spinodal structures in HEAs, but interpreting the results remains challenging due to the subtle compositional variations and complex crystallographic relationships.

From a computational perspective, predicting spinodal decomposition in HEAs requires sophisticated models that can account for the interactions among multiple elements. Current CALPHAD (CALculation of PHAse Diagrams) approaches and first-principles calculations often struggle with the high dimensionality of the composition space in HEAs.

The temperature dependence of spinodal decomposition in HEAs presents another significant challenge. Many HEAs designed for high-temperature applications may undergo unexpected phase separations during service, potentially compromising their performance. Understanding the kinetics and thermodynamics of spinodal decomposition across different temperature regimes is therefore crucial for designing stable HEAs for specific applications.

Furthermore, the interplay between spinodal decomposition and other microstructural features, such as ordering, segregation, and precipitation, adds another layer of complexity to the analysis and prediction of HEA behavior during processing and service.

Current Methodologies for Controlling Spinodal Decomposition

01 Mechanisms of spinodal decomposition in high-entropy alloys

Spinodal decomposition is a phase separation mechanism in high-entropy alloys where a homogeneous solid solution separates into two or more phases without nucleation. This process occurs due to thermodynamic instability and is characterized by continuous compositional fluctuations. In high-entropy alloys, spinodal decomposition can lead to the formation of nanoscale structures with periodic composition modulations, affecting the mechanical and physical properties of the alloy.- Mechanisms of spinodal decomposition in high-entropy alloys: Spinodal decomposition is a phase separation mechanism in high-entropy alloys where a homogeneous solid solution separates into two or more phases without nucleation. This process occurs due to thermodynamic instability and is characterized by continuous compositional fluctuations. In high-entropy alloys, spinodal decomposition can lead to the formation of nanoscale structures with periodic composition modulations, affecting the mechanical and physical properties of the alloy.

- Composition design for controlling phase separation: The composition of high-entropy alloys can be strategically designed to either promote or suppress spinodal decomposition. By adjusting the elemental ratios and selecting elements with appropriate atomic size differences, enthalpy of mixing, and electronegativity, researchers can control the thermodynamic driving forces for phase separation. This approach enables the development of alloys with tailored microstructures and enhanced properties through controlled phase separation.

- Heat treatment effects on spinodal decomposition: Heat treatment processes significantly influence spinodal decomposition in high-entropy alloys. Specific temperature regimes and cooling rates can either accelerate or inhibit the phase separation process. Aging treatments at intermediate temperatures often promote spinodal decomposition, while rapid quenching can suppress it by trapping the alloy in a metastable state. Controlled heat treatments can be used to engineer the scale and morphology of the decomposed phases.

- Mechanical properties enhancement through controlled phase separation: Controlled spinodal decomposition in high-entropy alloys can lead to significant improvements in mechanical properties. The formation of coherent nanoscale domains with compositional variations creates effective barriers to dislocation movement, enhancing strength while maintaining ductility. This microstructural refinement through phase separation can result in superior combinations of strength, hardness, and toughness compared to single-phase high-entropy alloys.

- Advanced characterization techniques for studying phase separation: Advanced characterization methods are essential for studying spinodal decomposition in high-entropy alloys. Techniques such as atom probe tomography, high-resolution transmission electron microscopy, and small-angle neutron scattering enable the visualization and quantification of nanoscale compositional fluctuations. In-situ characterization methods allow for real-time observation of phase separation dynamics, providing insights into the kinetics and mechanisms of spinodal decomposition in these complex alloy systems.

02 Composition design for controlling phase separation

The composition of high-entropy alloys can be strategically designed to control spinodal decomposition and phase separation behavior. By adjusting the elemental ratios and selecting elements with specific atomic size differences, enthalpy of mixing, and electronegativity, researchers can either promote or suppress spinodal decomposition. This approach enables the development of alloys with tailored microstructures and enhanced properties such as strength, ductility, and thermal stability.Expand Specific Solutions03 Heat treatment strategies for manipulating phase separation

Heat treatment protocols significantly influence spinodal decomposition in high-entropy alloys. Controlled heating, cooling, and aging treatments can be employed to manipulate the kinetics and thermodynamics of phase separation. Specific temperature-time profiles can either accelerate or retard spinodal decomposition, allowing for precise control over the resulting microstructure. These heat treatment strategies are essential for optimizing the mechanical and functional properties of high-entropy alloys for various applications.Expand Specific Solutions04 Microstructural evolution during spinodal decomposition

The microstructural evolution during spinodal decomposition in high-entropy alloys involves the formation of interconnected, compositionally modulated regions. This process typically begins with small compositional fluctuations that amplify over time, leading to distinct phase regions with different crystal structures or ordering. Advanced characterization techniques such as atom probe tomography and high-resolution transmission electron microscopy are used to study these microstructural changes at the nanoscale, providing insights into the mechanisms controlling phase separation.Expand Specific Solutions05 Property enhancement through controlled phase separation

Controlled spinodal decomposition can be leveraged to enhance the properties of high-entropy alloys. By engineering the phase separation process, researchers can develop alloys with improved strength, hardness, thermal stability, and corrosion resistance. The nanoscale compositional modulations resulting from spinodal decomposition create effective barriers to dislocation motion, contributing to strengthening mechanisms. Additionally, the presence of multiple phases with different compositions can enhance the alloy's resistance to environmental degradation and high-temperature deformation.Expand Specific Solutions

Leading Research Institutions and Industrial Players in HEA Field

The spinodal decomposition in high-entropy alloys (HEAs) represents an emerging research area in materials science, currently in its growth phase. The market is expanding rapidly with an estimated size of $150-200 million, driven by applications in aerospace, energy, and automotive sectors. Technologically, this field is in mid-maturity, with academic institutions like Central South University, Southeast University, and KAIST leading fundamental research, while companies including Materion Corp., Proterial Ltd., and RTX Corp. are advancing commercial applications. Research collaborations between universities and industry players such as Toshiba and LG Electronics are accelerating development of novel HEA compositions with enhanced properties through controlled spinodal decomposition, positioning this technology for significant growth in advanced materials manufacturing.

University of Science & Technology Beijing

Technical Solution: University of Science & Technology Beijing has pioneered research on spinodal decomposition in refractory high-entropy alloys (RHEAs), particularly focusing on Mo-Nb-Ta-Ti-Zr and related systems. Their technical approach combines in-situ high-temperature X-ray diffraction with phase-field modeling to track real-time evolution of spinodal structures. They've developed a novel heat treatment protocol that induces controlled spinodal decomposition, creating hierarchical microstructures with exceptional thermal stability up to 1200°C. Their research has revealed that spinodal decomposition in these systems creates alternating BCC phases with different lattice parameters but maintained coherency, resulting in significant strengthening through coherency strain fields. The university has quantified how compositional wavelength during spinodal decomposition directly correlates with mechanical properties, showing that nanoscale modulations (15-30nm) optimize strength-ductility combinations. Their work has also established processing maps for various refractory HEAs, identifying temperature-time windows where spinodal decomposition can be precisely controlled to achieve targeted microstructures.

Strengths: Their focus on refractory HEAs addresses high-temperature applications where conventional alloys fail. Their processing maps provide practical guidelines for industrial implementation of spinodal decomposition in HEAs. Weakness: The high processing temperatures required for refractory HEAs present energy efficiency challenges for commercial production. The complex multi-element diffusion models they've developed still require refinement for accurate long-term predictions.

Central South University

Technical Solution: Central South University has developed a comprehensive approach to studying spinodal decomposition in high-entropy alloys (HEAs), focusing on the Al-Co-Cr-Fe-Ni system. Their research utilizes advanced characterization techniques including atom probe tomography (APT) and high-resolution transmission electron microscopy (HRTEM) to observe nanoscale phase separation. They've established that spinodal decomposition in these alloys occurs through a continuous compositional modulation without nucleation barriers, leading to interconnected Fe/Cr-rich and Ni/Al-rich regions. Their work has demonstrated that controlled spinodal decomposition can significantly enhance mechanical properties, achieving strength increases of up to 30% while maintaining ductility through the formation of coherent nanostructures. The university has also developed computational models that predict decomposition kinetics as a function of temperature and composition, allowing for tailored microstructure design in HEAs for specific applications.

Strengths: Their integrated experimental-computational approach provides comprehensive understanding of decomposition mechanisms. Their work directly connects microstructural evolution to mechanical property enhancement, offering practical applications. Weakness: Their research primarily focuses on Al-Co-Cr-Fe-Ni systems, potentially limiting applicability to other HEA compositions. Scale-up challenges from laboratory to industrial production remain unaddressed.

Critical Patents and Literature on Spinodal Effects in HEAs

Processing for improved stress relaxation resistance in copper alloys exhibiting spinodal decomposition

PatentInactiveUS4073667A

Innovation

- Copper alloys with continuous, coherent precipitates in a solute-depleted matrix, such as Cu-Ti, Cu-Be, and Cu-Ni systems, are processed using critical cooling rates after solutionizing to control precipitate morphology, enhancing strength-to-ductility ratios and stress relaxation resistance.

Porous calcium phosphate networks for synthetic bone material

PatentInactiveUS20050255159A1

Innovation

- A calcium phosphate composition with a mineral matrix lattice interpenetrated by a substantially interconnected network of pores is created through controlled spinodal decomposition of a molten mixture of inorganic starting materials, using a removable inorganic porogen like iron oxide to achieve the desired porosity and resorbability, mimicking the structure of natural bone.

Computational Modeling and Simulation Approaches for HEAs

Computational modeling and simulation have become indispensable tools for understanding the complex behavior of High-Entropy Alloys (HEAs), particularly in studying spinodal decomposition phenomena. Various computational approaches have been developed to predict and analyze the microstructural evolution and phase stability in these multi-component systems.

Density Functional Theory (DFT) calculations represent the foundation of atomic-scale modeling for HEAs, providing insights into electronic structures, formation energies, and phase stability. These first-principles calculations help researchers understand the fundamental driving forces behind spinodal decomposition in HEAs by accurately computing interaction parameters between different elements.

Monte Carlo (MC) simulations offer another powerful approach for investigating spinodal decomposition in HEAs. By employing statistical mechanics principles, MC methods can simulate atomic configurations over extended time scales, revealing how compositional fluctuations evolve during decomposition processes. These simulations have successfully captured the early stages of spinodal decomposition in various HEA systems.

Molecular Dynamics (MD) simulations complement MC methods by providing detailed information about atomic movements and interactions during decomposition. MD simulations are particularly valuable for understanding the kinetic aspects of spinodal decomposition, including diffusion pathways and interface dynamics in HEAs.

Phase-field modeling represents a mesoscale approach that bridges the gap between atomic-scale simulations and macroscopic properties. These models describe the spatial and temporal evolution of composition fields during spinodal decomposition, accounting for elastic strain energy, interfacial energy, and chemical free energy contributions. Recent advances in phase-field modeling have enabled researchers to simulate realistic microstructural evolution in multi-component HEAs.

CALPHAD (CALculation of PHAse Diagrams) methods integrate thermodynamic data from experiments and first-principles calculations to predict phase equilibria in complex alloy systems. For HEAs, CALPHAD approaches have been extended to handle multi-component systems, providing valuable insights into decomposition tendencies and phase stability across wide composition and temperature ranges.

Machine learning techniques are increasingly being integrated with traditional simulation methods to accelerate materials discovery and predict decomposition behavior in HEAs. Neural networks and other AI approaches can identify patterns in simulation data, helping researchers navigate the vast compositional space of HEAs more efficiently.

Multi-scale modeling frameworks that integrate different simulation techniques across length and time scales represent the frontier of computational approaches for HEAs. These frameworks can capture both atomic-level interactions and macroscopic properties, providing a comprehensive understanding of spinodal decomposition phenomena in these complex alloy systems.

Density Functional Theory (DFT) calculations represent the foundation of atomic-scale modeling for HEAs, providing insights into electronic structures, formation energies, and phase stability. These first-principles calculations help researchers understand the fundamental driving forces behind spinodal decomposition in HEAs by accurately computing interaction parameters between different elements.

Monte Carlo (MC) simulations offer another powerful approach for investigating spinodal decomposition in HEAs. By employing statistical mechanics principles, MC methods can simulate atomic configurations over extended time scales, revealing how compositional fluctuations evolve during decomposition processes. These simulations have successfully captured the early stages of spinodal decomposition in various HEA systems.

Molecular Dynamics (MD) simulations complement MC methods by providing detailed information about atomic movements and interactions during decomposition. MD simulations are particularly valuable for understanding the kinetic aspects of spinodal decomposition, including diffusion pathways and interface dynamics in HEAs.

Phase-field modeling represents a mesoscale approach that bridges the gap between atomic-scale simulations and macroscopic properties. These models describe the spatial and temporal evolution of composition fields during spinodal decomposition, accounting for elastic strain energy, interfacial energy, and chemical free energy contributions. Recent advances in phase-field modeling have enabled researchers to simulate realistic microstructural evolution in multi-component HEAs.

CALPHAD (CALculation of PHAse Diagrams) methods integrate thermodynamic data from experiments and first-principles calculations to predict phase equilibria in complex alloy systems. For HEAs, CALPHAD approaches have been extended to handle multi-component systems, providing valuable insights into decomposition tendencies and phase stability across wide composition and temperature ranges.

Machine learning techniques are increasingly being integrated with traditional simulation methods to accelerate materials discovery and predict decomposition behavior in HEAs. Neural networks and other AI approaches can identify patterns in simulation data, helping researchers navigate the vast compositional space of HEAs more efficiently.

Multi-scale modeling frameworks that integrate different simulation techniques across length and time scales represent the frontier of computational approaches for HEAs. These frameworks can capture both atomic-level interactions and macroscopic properties, providing a comprehensive understanding of spinodal decomposition phenomena in these complex alloy systems.

Manufacturing Processes and Scale-up Considerations

The manufacturing of high-entropy alloys (HEAs) exhibiting controlled spinodal decomposition presents unique challenges that require specialized processes and careful scale-up considerations. Conventional manufacturing methods such as arc melting and induction melting have been widely employed for laboratory-scale production, but these approaches often struggle to maintain compositional homogeneity across larger volumes necessary for industrial applications. The inherent complexity of multi-principal element systems demands precise control over cooling rates to either promote or inhibit spinodal decomposition depending on the desired microstructural characteristics.

Powder metallurgy routes offer promising alternatives for HEA production with controlled spinodal decomposition. Mechanical alloying through high-energy ball milling enables solid-state alloying at room temperature, circumventing segregation issues associated with solidification processes. Subsequent consolidation via hot isostatic pressing (HIP) or spark plasma sintering (SPS) can preserve the metastable phases that later undergo spinodal decomposition during controlled heat treatments. These powder-based approaches facilitate more uniform composition distribution critical for consistent spinodal decomposition behavior.

Additive manufacturing technologies, particularly selective laser melting (SLM) and electron beam melting (EBM), represent cutting-edge fabrication methods for HEAs. These processes offer unprecedented control over local cooling rates and thermal gradients, enabling spatial manipulation of spinodal decomposition. The layer-by-layer building approach creates unique opportunities to design compositional gradients that can trigger controlled decomposition in specific regions of the component, though challenges remain in managing residual stresses and porosity.

Scale-up considerations for HEAs undergoing spinodal decomposition must address several critical factors. Thermal management becomes increasingly complex at larger scales, as heat extraction rates significantly impact decomposition kinetics. Industrial-scale production requires careful design of heat treatment protocols that can accommodate larger thermal masses while maintaining the precise temperature control necessary for optimal phase separation. Computational modeling tools, particularly phase-field simulations coupled with CALPHAD databases, have emerged as essential resources for predicting decomposition behavior across different production scales.

Quality control methodologies for scaled production present additional challenges. Non-destructive testing techniques capable of characterizing spinodal microstructures in large components remain limited. Advanced characterization approaches combining high-resolution electron microscopy with atom probe tomography provide detailed insights but are typically restricted to small sample volumes. The development of rapid, scalable inspection methods represents a significant opportunity for advancing industrial implementation of spinodally decomposed HEAs.

Powder metallurgy routes offer promising alternatives for HEA production with controlled spinodal decomposition. Mechanical alloying through high-energy ball milling enables solid-state alloying at room temperature, circumventing segregation issues associated with solidification processes. Subsequent consolidation via hot isostatic pressing (HIP) or spark plasma sintering (SPS) can preserve the metastable phases that later undergo spinodal decomposition during controlled heat treatments. These powder-based approaches facilitate more uniform composition distribution critical for consistent spinodal decomposition behavior.

Additive manufacturing technologies, particularly selective laser melting (SLM) and electron beam melting (EBM), represent cutting-edge fabrication methods for HEAs. These processes offer unprecedented control over local cooling rates and thermal gradients, enabling spatial manipulation of spinodal decomposition. The layer-by-layer building approach creates unique opportunities to design compositional gradients that can trigger controlled decomposition in specific regions of the component, though challenges remain in managing residual stresses and porosity.

Scale-up considerations for HEAs undergoing spinodal decomposition must address several critical factors. Thermal management becomes increasingly complex at larger scales, as heat extraction rates significantly impact decomposition kinetics. Industrial-scale production requires careful design of heat treatment protocols that can accommodate larger thermal masses while maintaining the precise temperature control necessary for optimal phase separation. Computational modeling tools, particularly phase-field simulations coupled with CALPHAD databases, have emerged as essential resources for predicting decomposition behavior across different production scales.

Quality control methodologies for scaled production present additional challenges. Non-destructive testing techniques capable of characterizing spinodal microstructures in large components remain limited. Advanced characterization approaches combining high-resolution electron microscopy with atom probe tomography provide detailed insights but are typically restricted to small sample volumes. The development of rapid, scalable inspection methods represents a significant opportunity for advancing industrial implementation of spinodally decomposed HEAs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!