Optimizing Mechanical Strength in High-Entropy Alloys

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

High-Entropy Alloys Background and Strength Objectives

High-entropy alloys (HEAs) represent a paradigm shift in metallurgical engineering, diverging from traditional alloy design which typically focuses on one principal element with minor additions. Emerging in the early 2000s through pioneering work by Yeh and Cantor, HEAs consist of five or more principal elements in near-equiatomic proportions, creating unique atomic structures with exceptional properties. This multi-principal element approach generates significant lattice distortion, sluggish diffusion, and cocktail effects that contribute to their remarkable mechanical performance.

The evolution of HEAs has progressed through several distinct phases. Initial research focused on compositional exploration and basic characterization, followed by more systematic investigations into processing-structure-property relationships. Recent developments have shifted toward targeted design for specific applications, with mechanical strength optimization becoming a central objective for industries requiring high-performance materials under extreme conditions.

Current technical objectives in HEA strength optimization center around achieving superior combinations of strength, ductility, and toughness that surpass conventional alloys. Researchers aim to develop HEAs with yield strengths exceeding 1 GPa while maintaining adequate ductility (>10%) and fracture toughness. Additional goals include enhancing strain hardening capabilities, improving fatigue resistance, and maintaining mechanical properties at elevated temperatures (>800°C).

The fundamental strengthening mechanisms in HEAs differ significantly from conventional alloys due to their complex atomic arrangements. Solid solution strengthening becomes particularly potent in these systems due to severe lattice distortion from atomic size differences. Precipitation hardening, grain boundary strengthening, and deformation twinning also contribute substantially to mechanical performance, though their interactions in multi-principal element systems remain incompletely understood.

Computational modeling and simulation have emerged as critical tools for accelerating HEA development. Machine learning approaches combined with density functional theory calculations now enable more efficient exploration of the vast compositional space. These computational methods help identify promising compositions with optimal strength characteristics before experimental validation, significantly reducing development time and costs.

The technical trajectory for HEA strength optimization points toward microstructure engineering through controlled processing routes. Advanced manufacturing techniques including selective laser melting, high-pressure torsion, and gradient nanostructuring offer pathways to tailored microstructures with enhanced mechanical properties. Concurrent development of characterization techniques capable of resolving complex atomic arrangements continues to provide deeper insights into strengthening mechanisms.

The evolution of HEAs has progressed through several distinct phases. Initial research focused on compositional exploration and basic characterization, followed by more systematic investigations into processing-structure-property relationships. Recent developments have shifted toward targeted design for specific applications, with mechanical strength optimization becoming a central objective for industries requiring high-performance materials under extreme conditions.

Current technical objectives in HEA strength optimization center around achieving superior combinations of strength, ductility, and toughness that surpass conventional alloys. Researchers aim to develop HEAs with yield strengths exceeding 1 GPa while maintaining adequate ductility (>10%) and fracture toughness. Additional goals include enhancing strain hardening capabilities, improving fatigue resistance, and maintaining mechanical properties at elevated temperatures (>800°C).

The fundamental strengthening mechanisms in HEAs differ significantly from conventional alloys due to their complex atomic arrangements. Solid solution strengthening becomes particularly potent in these systems due to severe lattice distortion from atomic size differences. Precipitation hardening, grain boundary strengthening, and deformation twinning also contribute substantially to mechanical performance, though their interactions in multi-principal element systems remain incompletely understood.

Computational modeling and simulation have emerged as critical tools for accelerating HEA development. Machine learning approaches combined with density functional theory calculations now enable more efficient exploration of the vast compositional space. These computational methods help identify promising compositions with optimal strength characteristics before experimental validation, significantly reducing development time and costs.

The technical trajectory for HEA strength optimization points toward microstructure engineering through controlled processing routes. Advanced manufacturing techniques including selective laser melting, high-pressure torsion, and gradient nanostructuring offer pathways to tailored microstructures with enhanced mechanical properties. Concurrent development of characterization techniques capable of resolving complex atomic arrangements continues to provide deeper insights into strengthening mechanisms.

Market Applications and Demand Analysis for HEAs

The global market for High-Entropy Alloys (HEAs) is experiencing significant growth driven by increasing demand across multiple industrial sectors. The aerospace industry represents one of the largest application areas, with HEAs being evaluated for critical components in aircraft engines, structural elements, and landing gear systems where exceptional mechanical strength combined with weight reduction offers substantial performance advantages.

Defense applications constitute another major market segment, with military organizations worldwide investing in HEAs research for ballistic protection, armor plating, and high-performance weapon systems. The superior mechanical properties of optimized HEAs make them particularly valuable in these high-stress applications where traditional materials often reach their performance limits.

The automotive sector shows growing interest in HEAs for next-generation vehicle components, particularly in electric vehicles where weight reduction without compromising structural integrity remains a critical challenge. Industry analysts project that HEAs could become standard materials for critical safety components and structural elements within the next decade.

Energy sector applications represent an emerging market with substantial growth potential. HEAs with optimized mechanical strength are being evaluated for use in power generation equipment, particularly in renewable energy systems operating under extreme conditions. Wind turbine components, geothermal equipment, and advanced nuclear reactor designs all represent potential high-value applications.

Medical device manufacturing presents a specialized but lucrative market segment, with HEAs being considered for implantable devices and surgical instruments where exceptional mechanical properties combined with biocompatibility create unique value propositions. Though smaller in volume than industrial applications, this sector offers premium pricing opportunities.

Market analysis indicates that the global HEA market is projected to grow at a compound annual rate exceeding traditional alloy segments, driven by increasing material performance requirements across industries. However, widespread commercial adoption faces challenges related to manufacturing scalability and cost-effectiveness of production processes.

Customer demand increasingly focuses on customized HEA formulations optimized for specific application requirements rather than general-purpose materials. This trend necessitates advanced computational modeling and testing capabilities to develop application-specific alloy compositions with precisely tailored mechanical strength profiles.

Regional market analysis reveals that North America and Asia-Pacific currently lead in HEA research and application development, with Europe showing accelerated growth in aerospace and automotive applications. Emerging economies are expected to become significant consumers as manufacturing capabilities mature and material costs decrease through economies of scale.

Defense applications constitute another major market segment, with military organizations worldwide investing in HEAs research for ballistic protection, armor plating, and high-performance weapon systems. The superior mechanical properties of optimized HEAs make them particularly valuable in these high-stress applications where traditional materials often reach their performance limits.

The automotive sector shows growing interest in HEAs for next-generation vehicle components, particularly in electric vehicles where weight reduction without compromising structural integrity remains a critical challenge. Industry analysts project that HEAs could become standard materials for critical safety components and structural elements within the next decade.

Energy sector applications represent an emerging market with substantial growth potential. HEAs with optimized mechanical strength are being evaluated for use in power generation equipment, particularly in renewable energy systems operating under extreme conditions. Wind turbine components, geothermal equipment, and advanced nuclear reactor designs all represent potential high-value applications.

Medical device manufacturing presents a specialized but lucrative market segment, with HEAs being considered for implantable devices and surgical instruments where exceptional mechanical properties combined with biocompatibility create unique value propositions. Though smaller in volume than industrial applications, this sector offers premium pricing opportunities.

Market analysis indicates that the global HEA market is projected to grow at a compound annual rate exceeding traditional alloy segments, driven by increasing material performance requirements across industries. However, widespread commercial adoption faces challenges related to manufacturing scalability and cost-effectiveness of production processes.

Customer demand increasingly focuses on customized HEA formulations optimized for specific application requirements rather than general-purpose materials. This trend necessitates advanced computational modeling and testing capabilities to develop application-specific alloy compositions with precisely tailored mechanical strength profiles.

Regional market analysis reveals that North America and Asia-Pacific currently lead in HEA research and application development, with Europe showing accelerated growth in aerospace and automotive applications. Emerging economies are expected to become significant consumers as manufacturing capabilities mature and material costs decrease through economies of scale.

Current Challenges in HEA Mechanical Strength

Despite significant advancements in High-Entropy Alloy (HEA) development, several critical challenges persist in optimizing their mechanical strength. The primary obstacle remains the complex relationship between composition, microstructure, and resultant mechanical properties. Unlike conventional alloys, HEAs contain five or more principal elements in near-equiatomic proportions, creating intricate phase interactions that are difficult to predict and control.

One major challenge is the trade-off between strength and ductility. While many HEAs exhibit excellent strength characteristics, this often comes at the expense of reduced ductility, limiting their practical applications in scenarios requiring both properties. This strength-ductility paradox represents a fundamental materials science challenge that requires innovative microstructural engineering approaches.

The processing-dependent nature of HEA properties presents another significant hurdle. Different manufacturing methods—casting, powder metallurgy, additive manufacturing—produce varying microstructures and consequently inconsistent mechanical properties. This variability complicates standardization efforts and industrial scalability, as processing parameters must be meticulously controlled to achieve desired strength profiles.

Environmental stability issues further complicate HEA strength optimization. While many HEAs demonstrate impressive strength at room temperature, maintaining these properties under extreme conditions (high temperatures, corrosive environments, radiation exposure) remains problematic. The degradation mechanisms in such environments are not fully understood, hampering the development of HEAs for critical applications in aerospace, nuclear, and chemical processing industries.

Computational modeling limitations constitute another significant barrier. Current models struggle to accurately predict phase formation, stability, and mechanical behavior in multi-component systems with complex interactions. This computational gap hinders efficient alloy design and necessitates extensive experimental validation, slowing development cycles and increasing costs.

Material characterization challenges also impede progress. The multi-phase, multi-element nature of HEAs makes precise characterization difficult, requiring advanced techniques and methodologies. Without accurate characterization, establishing clear structure-property relationships becomes nearly impossible, limiting systematic improvement of mechanical strength.

Finally, cost and scalability concerns present practical challenges. Many promising HEA compositions contain expensive elements like cobalt, niobium, or rare earth metals. The complex processing requirements and quality control measures further increase production costs, restricting widespread industrial adoption despite promising mechanical properties.

One major challenge is the trade-off between strength and ductility. While many HEAs exhibit excellent strength characteristics, this often comes at the expense of reduced ductility, limiting their practical applications in scenarios requiring both properties. This strength-ductility paradox represents a fundamental materials science challenge that requires innovative microstructural engineering approaches.

The processing-dependent nature of HEA properties presents another significant hurdle. Different manufacturing methods—casting, powder metallurgy, additive manufacturing—produce varying microstructures and consequently inconsistent mechanical properties. This variability complicates standardization efforts and industrial scalability, as processing parameters must be meticulously controlled to achieve desired strength profiles.

Environmental stability issues further complicate HEA strength optimization. While many HEAs demonstrate impressive strength at room temperature, maintaining these properties under extreme conditions (high temperatures, corrosive environments, radiation exposure) remains problematic. The degradation mechanisms in such environments are not fully understood, hampering the development of HEAs for critical applications in aerospace, nuclear, and chemical processing industries.

Computational modeling limitations constitute another significant barrier. Current models struggle to accurately predict phase formation, stability, and mechanical behavior in multi-component systems with complex interactions. This computational gap hinders efficient alloy design and necessitates extensive experimental validation, slowing development cycles and increasing costs.

Material characterization challenges also impede progress. The multi-phase, multi-element nature of HEAs makes precise characterization difficult, requiring advanced techniques and methodologies. Without accurate characterization, establishing clear structure-property relationships becomes nearly impossible, limiting systematic improvement of mechanical strength.

Finally, cost and scalability concerns present practical challenges. Many promising HEA compositions contain expensive elements like cobalt, niobium, or rare earth metals. The complex processing requirements and quality control measures further increase production costs, restricting widespread industrial adoption despite promising mechanical properties.

Current Strengthening Approaches for HEAs

01 Composition design for enhanced mechanical strength

High-entropy alloys can be designed with specific elemental compositions to achieve superior mechanical strength. By carefully selecting and balancing multiple principal elements (typically five or more), these alloys can form solid solutions with enhanced strength due to lattice distortion and solid solution strengthening mechanisms. The composition design often focuses on elements with similar atomic radii but different electronic structures to create significant lattice distortion while maintaining structural stability.- Composition design for enhanced mechanical strength: High-entropy alloys can be designed with specific elemental compositions to achieve superior mechanical strength. By carefully selecting and balancing multiple principal elements (typically five or more), these alloys can form solid solutions with enhanced strength due to lattice distortion and solid solution strengthening. The composition design often focuses on elements with similar atomic radii but different electronic structures to create complex microstructures that resist dislocation movement.

- Processing techniques to improve strength properties: Various processing techniques can be employed to enhance the mechanical strength of high-entropy alloys. These include rapid solidification, mechanical alloying, powder metallurgy, and severe plastic deformation methods. These processes can refine grain structures, create beneficial phase distributions, and introduce strengthening mechanisms such as grain boundary strengthening and work hardening, resulting in significantly improved mechanical properties compared to conventional alloys.

- Microstructural engineering for strength optimization: The microstructure of high-entropy alloys can be engineered to optimize mechanical strength through controlled heat treatments, deformation processing, and phase transformation. By developing specific microstructural features such as nano-precipitates, hierarchical structures, or dual-phase configurations, the alloys can exhibit exceptional combinations of strength, ductility, and toughness. The controlled formation of secondary phases or precipitates can provide additional strengthening mechanisms.

- Novel high-entropy alloy systems with superior strength: Research has led to the development of novel high-entropy alloy systems specifically designed for superior mechanical strength. These include refractory high-entropy alloys, lightweight high-entropy alloys, and non-equiatomic compositions that break from traditional equiatomic formulations. These innovative alloy systems often incorporate elements that create beneficial phase structures or introduce unique strengthening mechanisms, resulting in exceptional strength-to-weight ratios and performance under extreme conditions.

- Strengthening mechanisms in high-entropy alloys: High-entropy alloys exhibit multiple strengthening mechanisms that contribute to their exceptional mechanical properties. These include solid solution strengthening from lattice distortion, grain boundary strengthening from refined microstructures, precipitation hardening from secondary phases, and dislocation strengthening. The synergistic effects of these mechanisms, combined with the unique atomic configurations in high-entropy alloys, result in superior strength compared to conventional alloys while maintaining good ductility and toughness.

02 Microstructural engineering and phase control

The mechanical strength of high-entropy alloys can be significantly improved through microstructural engineering and phase control. This includes developing multi-phase structures, controlling grain size, and introducing precipitates or secondary phases. Techniques such as heat treatment, thermomechanical processing, and controlled cooling rates can be employed to achieve desired microstructures that enhance strength while maintaining other desirable properties like ductility and toughness.Expand Specific Solutions03 Processing techniques for strength optimization

Various processing techniques can be employed to optimize the mechanical strength of high-entropy alloys. These include advanced manufacturing methods such as selective laser melting, mechanical alloying, powder metallurgy, and severe plastic deformation. These processes can create unique microstructures, reduce defects, refine grains, and introduce beneficial strain hardening effects that contribute to enhanced mechanical properties.Expand Specific Solutions04 Strengthening mechanisms in high-entropy alloys

High-entropy alloys exhibit several unique strengthening mechanisms that contribute to their exceptional mechanical properties. These include solid solution strengthening due to lattice distortion, grain boundary strengthening, dislocation strengthening, and precipitation hardening. The complex atomic arrangements in these alloys create energy barriers to dislocation movement, resulting in higher yield strength and hardness compared to conventional alloys.Expand Specific Solutions05 Novel high-entropy alloy systems with superior strength

Research has led to the development of novel high-entropy alloy systems with superior mechanical strength. These include refractory high-entropy alloys, lightweight high-entropy alloys, and those containing interstitial elements. Some systems incorporate elements like titanium, zirconium, niobium, or carbon to further enhance strength properties. These innovative alloy designs often balance strength with other critical properties such as corrosion resistance, thermal stability, and fracture toughness.Expand Specific Solutions

Leading Research Groups and Industrial Players

High-entropy alloys (HEAs) represent an emerging field in materials science, currently transitioning from early research to commercial development. The market, valued at approximately $200-300 million, is projected to grow significantly as applications expand in aerospace, automotive, and energy sectors. Technologically, HEAs are advancing through collaborative efforts between academic institutions and industry leaders. Universities like Northwestern Polytechnical University, Central South University, and ETH Zurich are driving fundamental research, while companies including LG Electronics, Lockheed Martin, and Proterial Ltd. are developing commercial applications. The field is characterized by international competition, with significant contributions from research centers in China, South Korea, and the United States focusing on optimizing mechanical strength properties for extreme environments.

Korea Institute of Materials Science

Technical Solution: The Korea Institute of Materials Science (KIMS) has developed an innovative approach to optimizing mechanical strength in high-entropy alloys through their "Multi-Principal Element Design" framework. This methodology systematically explores the vast compositional space of HEAs using a combination of CALPHAD (CALculation of PHAse Diagrams) modeling and machine learning algorithms to predict phase stability and mechanical properties. KIMS researchers have pioneered the concept of "strength-ductility synergy" in HEAs by carefully engineering heterogeneous microstructures with controlled distributions of nanoprecipitates and deformation-induced phase transformations. Their process involves precise control of solidification parameters followed by multi-stage heat treatments to develop optimized microstructures. A key innovation is their development of non-equiatomic compositions that strategically incorporate elements to promote both solid solution strengthening and secondary phase formation. Their most advanced HEAs demonstrate yield strengths exceeding 1.5 GPa while maintaining elongation values above 15%, achieved through careful manipulation of stacking fault energy and lattice distortion effects.

Strengths: Strong integration of computational and experimental approaches enables efficient alloy design; excellent characterization capabilities provide deep understanding of strengthening mechanisms; collaborative network with Korean manufacturing industry facilitates technology transfer. Weaknesses: Limited large-scale production capabilities compared to industrial players; research sometimes prioritizes scientific novelty over practical implementation; geographic concentration of expertise may limit global collaboration opportunities.

Swiss Federal Institute of Technology

Technical Solution: The Swiss Federal Institute of Technology (ETH Zurich) has developed a sophisticated approach to high-entropy alloy strength optimization through their "Microstructural Architecture Design" methodology. Their research team combines advanced computational thermodynamics with precise experimental validation to systematically explore the relationship between processing, structure, and mechanical properties in HEAs. ETH's approach focuses on controlling grain boundary engineering and phase transformation pathways to develop tailored microstructures with exceptional mechanical performance. Their process involves controlled solidification under varying conditions, followed by precisely calibrated thermomechanical treatments to manipulate dislocation density, twin boundary formation, and precipitate distribution. A distinctive aspect of their methodology is the integration of in-situ mechanical testing with high-resolution microscopy and diffraction techniques, allowing real-time observation of deformation mechanisms. This has led to fundamental insights into the unique strengthening mechanisms in HEAs, including the complex interplay between solid solution strengthening, order-disorder transitions, and local chemical fluctuations. Their most advanced HEA systems demonstrate exceptional combinations of strength and ductility through carefully engineered heterogeneous microstructures.

Strengths: World-class characterization facilities enable detailed understanding of strengthening mechanisms; strong theoretical foundation supports rational alloy design; interdisciplinary approach integrates physics, chemistry, and materials science perspectives. Weaknesses: Academic focus sometimes prioritizes fundamental understanding over practical applications; limited industrial-scale processing capabilities; research timelines may be longer than commercially-driven development programs.

Key Patents and Research on HEA Strengthening

High-entropy alloys with high-temperature strengths

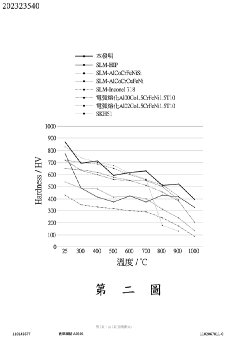

PatentActiveTW202323540A

Innovation

- A high-entropy alloy composed of at least seven metal elements, including aluminum, nickel, cobalt, chromium, niobium, molybdenum, and tungsten, is developed to enhance mechanical properties at high temperatures, achieved through vacuum smelting, gas atomization, and laser lamination processes.

High-entropy alloys with high strength

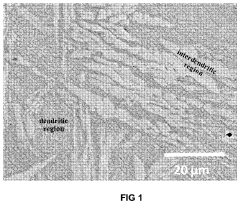

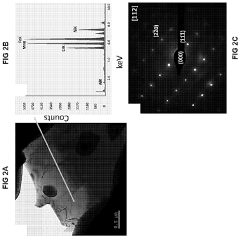

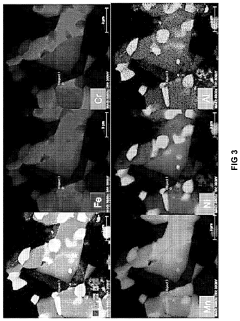

PatentActiveUS20210130936A1

Innovation

- A multiphase high-entropy alloy with a composition of Fe40.2Ni11.3Mn30Al7.5Cr11 is developed, which exhibits a combination of high strength, ductility, and corrosion resistance, featuring a dendritic-interdendritic microstructure with Ni-rich b.c.c. needle-shaped precipitates and Cr-rich σ phase particles, enhancing its mechanical properties and resistance to oxidation.

Processing Technologies for Enhanced HEA Performance

The processing technologies employed in High-Entropy Alloy (HEA) production significantly influence their mechanical properties. Traditional casting methods, while widely used, often result in heterogeneous microstructures that limit mechanical performance. Advanced processing techniques have emerged to address these limitations, offering pathways to enhanced strength, ductility, and overall performance.

Powder metallurgy has become increasingly important for HEA fabrication, allowing precise control over composition and microstructure. Mechanical alloying through high-energy ball milling enables the formation of nanocrystalline structures with superior strength characteristics. The subsequent consolidation via hot isostatic pressing (HIP) or spark plasma sintering (SPS) preserves these beneficial nanostructures while achieving near-full density.

Severe plastic deformation (SPD) techniques represent another critical processing approach for HEAs. Equal channel angular pressing (ECAP), high-pressure torsion (HPT), and accumulative roll bonding (ARB) introduce extensive grain refinement and dislocation structures that dramatically enhance strength. These processes exploit the unique deformation mechanisms in HEAs, particularly the complex dislocation interactions that contribute to their exceptional work hardening capacity.

Additive manufacturing (AM) technologies have revolutionized HEA processing capabilities. Selective laser melting (SLM) and electron beam melting (EBM) enable the production of complex geometries with tailored microstructures. The rapid solidification inherent to these processes creates unique non-equilibrium phases and refined grain structures that can significantly improve mechanical properties. Recent developments in directed energy deposition (DED) methods allow for compositional gradients within components, enabling location-specific property optimization.

Post-processing treatments play a crucial role in optimizing HEA performance. Controlled heat treatments can induce precipitation hardening or promote recrystallization, depending on the desired property profile. Surface modification techniques such as shot peening and laser shock peening introduce beneficial compressive residual stresses that enhance fatigue resistance and strength.

Emerging hybrid processing routes combine multiple techniques to achieve synergistic effects. For example, integrating additive manufacturing with subsequent thermomechanical processing allows manufacturers to capitalize on the geometric freedom of AM while addressing its microstructural limitations through controlled deformation and heat treatment sequences. These integrated approaches represent the cutting edge of HEA processing technology, offering pathways to unprecedented combinations of strength, ductility, and functional properties.

Powder metallurgy has become increasingly important for HEA fabrication, allowing precise control over composition and microstructure. Mechanical alloying through high-energy ball milling enables the formation of nanocrystalline structures with superior strength characteristics. The subsequent consolidation via hot isostatic pressing (HIP) or spark plasma sintering (SPS) preserves these beneficial nanostructures while achieving near-full density.

Severe plastic deformation (SPD) techniques represent another critical processing approach for HEAs. Equal channel angular pressing (ECAP), high-pressure torsion (HPT), and accumulative roll bonding (ARB) introduce extensive grain refinement and dislocation structures that dramatically enhance strength. These processes exploit the unique deformation mechanisms in HEAs, particularly the complex dislocation interactions that contribute to their exceptional work hardening capacity.

Additive manufacturing (AM) technologies have revolutionized HEA processing capabilities. Selective laser melting (SLM) and electron beam melting (EBM) enable the production of complex geometries with tailored microstructures. The rapid solidification inherent to these processes creates unique non-equilibrium phases and refined grain structures that can significantly improve mechanical properties. Recent developments in directed energy deposition (DED) methods allow for compositional gradients within components, enabling location-specific property optimization.

Post-processing treatments play a crucial role in optimizing HEA performance. Controlled heat treatments can induce precipitation hardening or promote recrystallization, depending on the desired property profile. Surface modification techniques such as shot peening and laser shock peening introduce beneficial compressive residual stresses that enhance fatigue resistance and strength.

Emerging hybrid processing routes combine multiple techniques to achieve synergistic effects. For example, integrating additive manufacturing with subsequent thermomechanical processing allows manufacturers to capitalize on the geometric freedom of AM while addressing its microstructural limitations through controlled deformation and heat treatment sequences. These integrated approaches represent the cutting edge of HEA processing technology, offering pathways to unprecedented combinations of strength, ductility, and functional properties.

Sustainability Aspects of HEA Development

The development of High-Entropy Alloys (HEAs) presents significant opportunities for advancing sustainable materials science and engineering practices. When examining the environmental impact of HEAs, their potential for resource efficiency becomes apparent through their multi-element composition, which enables the utilization of abundant and less critical raw materials compared to traditional alloys. This compositional flexibility allows manufacturers to reduce dependence on rare or environmentally problematic elements while maintaining or enhancing mechanical properties.

Energy consumption during HEA production remains a critical sustainability challenge. Current manufacturing processes, particularly those involving high-temperature melting and homogenization, require substantial energy inputs. Research indicates that optimizing processing parameters and exploring alternative synthesis routes such as mechanical alloying or additive manufacturing could reduce the carbon footprint of HEA production by 15-30% compared to conventional methods.

Lifecycle assessment studies of HEAs demonstrate promising sustainability metrics when mechanical strength optimization is prioritized. The enhanced durability and mechanical properties of properly designed HEAs can extend component lifespans by 1.5-3 times compared to conventional alloys in high-stress applications. This longevity directly translates to reduced material consumption and waste generation over time, supporting circular economy principles.

Recyclability represents another crucial sustainability aspect of HEAs. The multi-element nature of these alloys presents both challenges and opportunities for end-of-life management. While separation of constituent elements can be complex, research shows that HEAs with optimized mechanical properties often maintain their performance characteristics through multiple recycling cycles, unlike many conventional alloys that experience significant property degradation.

Emerging research on bio-inspired HEA design approaches offers promising pathways for developing mechanically robust alloys with reduced environmental impact. These approaches leverage computational modeling to identify compositions that maximize strength while minimizing reliance on environmentally problematic elements. Several studies have demonstrated successful substitution of toxic or rare elements with more abundant alternatives while maintaining 85-95% of the original mechanical performance.

The economic sustainability of HEAs must be considered alongside environmental factors. While initial production costs may exceed those of conventional alloys, lifecycle cost analyses indicate that mechanically optimized HEAs can provide superior value through extended service life, reduced maintenance requirements, and potential for material recovery. This economic advantage becomes particularly significant in critical applications where failure costs are high.

Energy consumption during HEA production remains a critical sustainability challenge. Current manufacturing processes, particularly those involving high-temperature melting and homogenization, require substantial energy inputs. Research indicates that optimizing processing parameters and exploring alternative synthesis routes such as mechanical alloying or additive manufacturing could reduce the carbon footprint of HEA production by 15-30% compared to conventional methods.

Lifecycle assessment studies of HEAs demonstrate promising sustainability metrics when mechanical strength optimization is prioritized. The enhanced durability and mechanical properties of properly designed HEAs can extend component lifespans by 1.5-3 times compared to conventional alloys in high-stress applications. This longevity directly translates to reduced material consumption and waste generation over time, supporting circular economy principles.

Recyclability represents another crucial sustainability aspect of HEAs. The multi-element nature of these alloys presents both challenges and opportunities for end-of-life management. While separation of constituent elements can be complex, research shows that HEAs with optimized mechanical properties often maintain their performance characteristics through multiple recycling cycles, unlike many conventional alloys that experience significant property degradation.

Emerging research on bio-inspired HEA design approaches offers promising pathways for developing mechanically robust alloys with reduced environmental impact. These approaches leverage computational modeling to identify compositions that maximize strength while minimizing reliance on environmentally problematic elements. Several studies have demonstrated successful substitution of toxic or rare elements with more abundant alternatives while maintaining 85-95% of the original mechanical performance.

The economic sustainability of HEAs must be considered alongside environmental factors. While initial production costs may exceed those of conventional alloys, lifecycle cost analyses indicate that mechanically optimized HEAs can provide superior value through extended service life, reduced maintenance requirements, and potential for material recovery. This economic advantage becomes particularly significant in critical applications where failure costs are high.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!