How High-Entropy Alloys Improve Biofouling Resistance

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HEA Biofouling Resistance Background and Objectives

High-entropy alloys (HEAs) represent a revolutionary class of metallic materials that have emerged over the past two decades, fundamentally transforming materials science paradigms. Unlike conventional alloys that contain one principal element with minor additions, HEAs incorporate multiple principal elements in near-equiatomic proportions, typically five or more elements each with concentrations between 5-35 atomic percent. This unique compositional strategy creates exceptional structural and functional properties through increased entropy stabilization.

The evolution of HEAs began in 2004 when Yeh and Cantor independently published groundbreaking papers introducing the concept. Since then, research interest has grown exponentially, with publications increasing from fewer than 10 in 2004 to over 1,000 annually by 2020. This rapid growth reflects the transformative potential of these materials across multiple industries.

Biofouling—the unwanted accumulation of microorganisms, plants, algae, and animals on wetted surfaces—represents a critical challenge across marine, medical, and industrial sectors. Traditional anti-fouling approaches often rely on toxic compounds or coatings with limited durability and environmental concerns. The global cost of biofouling exceeds $200 billion annually across affected industries, highlighting the urgent need for innovative solutions.

The convergence of HEA technology with biofouling challenges presents a promising frontier. HEAs offer unique advantages including superior mechanical properties, exceptional corrosion resistance, and the ability to create multifunctional surfaces through compositional tuning. These characteristics make them potentially ideal candidates for next-generation anti-fouling materials.

The technical objectives of this research focus on understanding and developing HEA-based solutions for biofouling resistance through several key approaches: investigating the fundamental mechanisms by which specific HEA compositions resist biological adhesion; developing scalable manufacturing processes for HEA coatings with optimized anti-fouling properties; establishing structure-property-performance relationships between HEA composition, microstructure, and biofouling resistance; and evaluating long-term performance under realistic environmental conditions.

Current technological trends indicate growing interest in environmentally friendly anti-fouling solutions, with particular emphasis on non-toxic mechanisms that physically deter organism attachment rather than relying on biocide release. HEAs align perfectly with this trend, offering the potential for passive anti-fouling through surface energy manipulation, topographical modifications, and electrochemical stability.

The ultimate goal is to develop HEA-based materials and coatings that provide superior biofouling resistance while maintaining mechanical integrity and corrosion protection in harsh environments. Success would represent a significant advancement in sustainable materials technology with wide-ranging applications from marine vessels and offshore structures to medical implants and industrial heat exchangers.

The evolution of HEAs began in 2004 when Yeh and Cantor independently published groundbreaking papers introducing the concept. Since then, research interest has grown exponentially, with publications increasing from fewer than 10 in 2004 to over 1,000 annually by 2020. This rapid growth reflects the transformative potential of these materials across multiple industries.

Biofouling—the unwanted accumulation of microorganisms, plants, algae, and animals on wetted surfaces—represents a critical challenge across marine, medical, and industrial sectors. Traditional anti-fouling approaches often rely on toxic compounds or coatings with limited durability and environmental concerns. The global cost of biofouling exceeds $200 billion annually across affected industries, highlighting the urgent need for innovative solutions.

The convergence of HEA technology with biofouling challenges presents a promising frontier. HEAs offer unique advantages including superior mechanical properties, exceptional corrosion resistance, and the ability to create multifunctional surfaces through compositional tuning. These characteristics make them potentially ideal candidates for next-generation anti-fouling materials.

The technical objectives of this research focus on understanding and developing HEA-based solutions for biofouling resistance through several key approaches: investigating the fundamental mechanisms by which specific HEA compositions resist biological adhesion; developing scalable manufacturing processes for HEA coatings with optimized anti-fouling properties; establishing structure-property-performance relationships between HEA composition, microstructure, and biofouling resistance; and evaluating long-term performance under realistic environmental conditions.

Current technological trends indicate growing interest in environmentally friendly anti-fouling solutions, with particular emphasis on non-toxic mechanisms that physically deter organism attachment rather than relying on biocide release. HEAs align perfectly with this trend, offering the potential for passive anti-fouling through surface energy manipulation, topographical modifications, and electrochemical stability.

The ultimate goal is to develop HEA-based materials and coatings that provide superior biofouling resistance while maintaining mechanical integrity and corrosion protection in harsh environments. Success would represent a significant advancement in sustainable materials technology with wide-ranging applications from marine vessels and offshore structures to medical implants and industrial heat exchangers.

Market Analysis for Anti-Biofouling Solutions

The global anti-biofouling solutions market is experiencing significant growth, driven by increasing awareness of biofouling's economic and environmental impacts across multiple industries. Currently valued at approximately $4.7 billion, the market is projected to reach $7.2 billion by 2028, representing a compound annual growth rate of 8.9%. This growth trajectory is particularly evident in marine applications, where biofouling on ship hulls alone costs the global shipping industry an estimated $30 billion annually through increased fuel consumption and maintenance requirements.

Maritime transportation represents the largest market segment, accounting for nearly 40% of the total anti-biofouling market. This dominance stems from regulatory pressures to reduce invasive species transfer and greenhouse gas emissions associated with increased drag from fouled surfaces. The aquaculture sector follows as the second-largest market segment, growing at 10.2% annually due to expansion of global fish farming operations and the critical need to maintain clean enclosures for optimal fish health and production efficiency.

Regional analysis reveals that Asia-Pacific dominates the market with a 38% share, driven by extensive maritime activities in China, Japan, South Korea, and Singapore. North America and Europe follow with 27% and 24% market shares respectively, with Europe showing accelerated growth due to stringent environmental regulations limiting traditional biocide-based solutions.

Traditional copper and tributyltin-based coatings are rapidly losing market share due to environmental concerns and regulatory restrictions. This has created substantial market opportunities for innovative, environmentally friendly solutions. High-entropy alloy (HEA) technologies represent an emerging segment with promising growth potential, currently capturing only 3% of the market but expanding at 15.7% annually—significantly outpacing the overall market growth rate.

Customer segmentation analysis indicates that large commercial vessel operators demonstrate the highest willingness to invest in premium anti-biofouling solutions, prioritizing long-term performance over initial cost. This segment shows particular interest in advanced materials like HEAs that offer extended service life and reduced maintenance requirements. Conversely, recreational boating and smaller commercial operations remain more price-sensitive, creating a bifurcated market with distinct value propositions required for different segments.

Market forecasts suggest that environmentally sustainable solutions will capture over 60% of the market by 2030, with regulatory drivers accelerating this transition. High-entropy alloy technologies are positioned to benefit from this shift, particularly as production scales and costs decrease, potentially disrupting the current market dominance of polymer and silicone-based solutions.

Maritime transportation represents the largest market segment, accounting for nearly 40% of the total anti-biofouling market. This dominance stems from regulatory pressures to reduce invasive species transfer and greenhouse gas emissions associated with increased drag from fouled surfaces. The aquaculture sector follows as the second-largest market segment, growing at 10.2% annually due to expansion of global fish farming operations and the critical need to maintain clean enclosures for optimal fish health and production efficiency.

Regional analysis reveals that Asia-Pacific dominates the market with a 38% share, driven by extensive maritime activities in China, Japan, South Korea, and Singapore. North America and Europe follow with 27% and 24% market shares respectively, with Europe showing accelerated growth due to stringent environmental regulations limiting traditional biocide-based solutions.

Traditional copper and tributyltin-based coatings are rapidly losing market share due to environmental concerns and regulatory restrictions. This has created substantial market opportunities for innovative, environmentally friendly solutions. High-entropy alloy (HEA) technologies represent an emerging segment with promising growth potential, currently capturing only 3% of the market but expanding at 15.7% annually—significantly outpacing the overall market growth rate.

Customer segmentation analysis indicates that large commercial vessel operators demonstrate the highest willingness to invest in premium anti-biofouling solutions, prioritizing long-term performance over initial cost. This segment shows particular interest in advanced materials like HEAs that offer extended service life and reduced maintenance requirements. Conversely, recreational boating and smaller commercial operations remain more price-sensitive, creating a bifurcated market with distinct value propositions required for different segments.

Market forecasts suggest that environmentally sustainable solutions will capture over 60% of the market by 2030, with regulatory drivers accelerating this transition. High-entropy alloy technologies are positioned to benefit from this shift, particularly as production scales and costs decrease, potentially disrupting the current market dominance of polymer and silicone-based solutions.

Current Status and Challenges in HEA Biofouling Technology

The global research on High-Entropy Alloys (HEAs) for biofouling resistance has accelerated significantly in the past decade, with notable advancements in both fundamental understanding and practical applications. Currently, several research institutions across North America, Europe, and Asia are actively exploring HEAs as novel materials for marine and biomedical applications. The United States, China, and Germany lead in patent filings related to HEA biofouling technologies, indicating concentrated innovation hubs.

Despite promising developments, the field faces substantial technical challenges. The complex composition-property relationships in HEAs make predictive design difficult, requiring extensive experimental validation. Researchers struggle with optimizing the balance between corrosion resistance, mechanical properties, and biofouling prevention capabilities. The multi-principal element nature of HEAs creates manufacturing complexities, particularly in achieving consistent microstructures and surface properties at scale.

Another significant challenge lies in the long-term stability of HEA surfaces in biological environments. Current research indicates that while initial biofouling resistance may be excellent, performance degradation over time remains problematic. The mechanisms behind this degradation are not fully understood, creating barriers to developing truly durable solutions.

Cost factors present additional obstacles to widespread adoption. Current manufacturing processes for HEAs with specific biofouling properties require precise control and often expensive alloying elements, making them prohibitively expensive for large-scale applications like ship hulls or water treatment facilities.

The environmental impact of HEAs also presents challenges. While they potentially offer alternatives to toxic antifouling compounds, comprehensive lifecycle assessments are lacking. Questions remain about their long-term environmental fate and potential for metal leaching in aquatic environments.

Testing standardization represents another constraint. The field lacks universally accepted protocols for evaluating biofouling resistance of HEAs, making cross-study comparisons difficult and slowing knowledge accumulation. Laboratory tests often fail to replicate the complex biological and chemical conditions of real-world environments.

Geographically, research capabilities are unevenly distributed. Advanced characterization techniques necessary for understanding HEA surface interactions with biological materials are concentrated in developed nations, creating knowledge gaps in regions where biofouling problems may be most severe due to tropical conditions.

Recent breakthroughs in computational modeling offer promising pathways forward. Machine learning approaches are beginning to predict HEA compositions with optimal biofouling resistance, potentially accelerating discovery timelines. However, these models require extensive validation and refinement before becoming reliable design tools for next-generation biofouling-resistant materials.

Despite promising developments, the field faces substantial technical challenges. The complex composition-property relationships in HEAs make predictive design difficult, requiring extensive experimental validation. Researchers struggle with optimizing the balance between corrosion resistance, mechanical properties, and biofouling prevention capabilities. The multi-principal element nature of HEAs creates manufacturing complexities, particularly in achieving consistent microstructures and surface properties at scale.

Another significant challenge lies in the long-term stability of HEA surfaces in biological environments. Current research indicates that while initial biofouling resistance may be excellent, performance degradation over time remains problematic. The mechanisms behind this degradation are not fully understood, creating barriers to developing truly durable solutions.

Cost factors present additional obstacles to widespread adoption. Current manufacturing processes for HEAs with specific biofouling properties require precise control and often expensive alloying elements, making them prohibitively expensive for large-scale applications like ship hulls or water treatment facilities.

The environmental impact of HEAs also presents challenges. While they potentially offer alternatives to toxic antifouling compounds, comprehensive lifecycle assessments are lacking. Questions remain about their long-term environmental fate and potential for metal leaching in aquatic environments.

Testing standardization represents another constraint. The field lacks universally accepted protocols for evaluating biofouling resistance of HEAs, making cross-study comparisons difficult and slowing knowledge accumulation. Laboratory tests often fail to replicate the complex biological and chemical conditions of real-world environments.

Geographically, research capabilities are unevenly distributed. Advanced characterization techniques necessary for understanding HEA surface interactions with biological materials are concentrated in developed nations, creating knowledge gaps in regions where biofouling problems may be most severe due to tropical conditions.

Recent breakthroughs in computational modeling offer promising pathways forward. Machine learning approaches are beginning to predict HEA compositions with optimal biofouling resistance, potentially accelerating discovery timelines. However, these models require extensive validation and refinement before becoming reliable design tools for next-generation biofouling-resistant materials.

Current HEA-Based Anti-Biofouling Solutions

01 Composition of high-entropy alloys for biofouling resistance

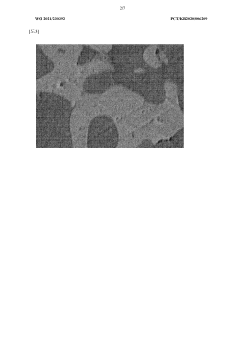

High-entropy alloys (HEAs) with specific elemental compositions can provide enhanced biofouling resistance. These alloys typically contain multiple principal elements in near-equiatomic proportions, creating complex microstructures that inhibit biological attachment. The unique surface properties of these alloys, including their electrochemical stability and surface energy, contribute to their anti-biofouling performance. Various element combinations can be tailored to optimize resistance against specific marine organisms or biofilm formation.- Composition and structure of high-entropy alloys for biofouling resistance: High-entropy alloys (HEAs) with specific compositions can provide enhanced biofouling resistance properties. These alloys typically contain multiple principal elements in near-equiatomic ratios, creating unique microstructures that resist biological attachment. The complex atomic arrangements and phase structures in these alloys contribute to their anti-biofouling properties by creating surfaces that are inhospitable to microorganisms and marine life. The specific elemental combinations can be tailored to optimize both mechanical properties and biofouling resistance.

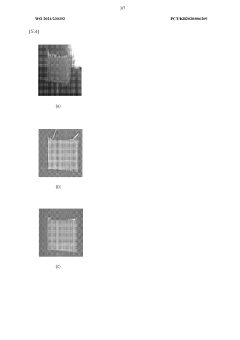

- Surface modification techniques for HEAs to enhance biofouling resistance: Various surface modification techniques can be applied to high-entropy alloys to further enhance their biofouling resistance. These include surface texturing, coating applications, and chemical treatments that alter the surface energy or create micro/nano-scale patterns. Such modifications can disrupt the attachment mechanisms of marine organisms and biofilms. Surface treatments may also incorporate antimicrobial elements or compounds that actively prevent biological colonization while maintaining the beneficial mechanical properties of the underlying high-entropy alloy.

- Corrosion resistance properties of HEAs in marine environments: High-entropy alloys demonstrate superior corrosion resistance in marine environments, which contributes to their biofouling resistance capabilities. The complex solid solution phases and unique elemental distributions in HEAs create passive films that are more stable than those in conventional alloys. This enhanced corrosion resistance prevents surface degradation that would otherwise create attachment points for marine organisms. The synergistic effect between corrosion resistance and biofouling prevention makes these alloys particularly suitable for marine applications.

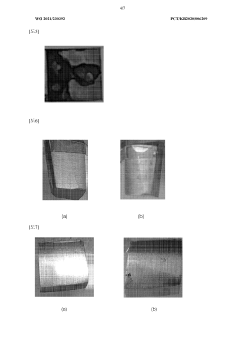

- Application of HEAs in marine structures and equipment: High-entropy alloys with biofouling resistance properties can be applied in various marine structures and equipment, including ship hulls, offshore platforms, underwater sensors, and aquaculture facilities. These applications benefit from the reduced maintenance requirements and extended service life provided by the alloys' resistance to biological attachment. The implementation of HEAs in these contexts can lead to significant operational cost savings and environmental benefits by reducing the need for toxic anti-fouling coatings and frequent cleaning operations.

- Testing and performance evaluation methods for biofouling resistance of HEAs: Specialized testing and performance evaluation methods have been developed to assess the biofouling resistance of high-entropy alloys. These include laboratory immersion tests, flow chamber experiments, and field trials in various marine environments. Advanced characterization techniques such as electron microscopy, spectroscopy, and surface analysis are employed to understand the mechanisms of biofouling resistance. Standardized protocols for evaluating the long-term performance of these alloys help in comparing different compositions and surface treatments for specific applications.

02 Surface modification techniques for HEAs

Surface modification of high-entropy alloys can significantly enhance their biofouling resistance properties. Techniques such as laser surface texturing, plasma treatment, and chemical etching create micro/nano-structured surfaces that reduce the adhesion of biological organisms. These modified surfaces can alter the wettability, surface energy, and topography of the alloys, creating physical barriers to biofouling attachment while maintaining the beneficial mechanical properties of the base alloy.Expand Specific Solutions03 Copper-containing HEAs for antimicrobial properties

High-entropy alloys incorporating copper as one of the principal elements demonstrate enhanced antimicrobial and anti-biofouling properties. The controlled release of copper ions from these alloys creates an environment hostile to microorganisms and prevents biofilm formation. These copper-containing HEAs combine the structural advantages of high-entropy alloys with the known antimicrobial effects of copper, making them particularly effective for marine applications where biofouling is a significant concern.Expand Specific Solutions04 Corrosion-resistant HEAs with biofouling prevention

Specialized high-entropy alloys have been developed that combine excellent corrosion resistance with biofouling prevention capabilities. These alloys typically contain elements like chromium, molybdenum, and nickel that form stable passive films in marine environments. The synergistic effect between corrosion resistance and biofouling prevention makes these alloys particularly valuable for long-term deployment in aggressive marine environments, reducing maintenance requirements and extending service life of components.Expand Specific Solutions05 Coating systems based on HEA particles

Coating systems incorporating high-entropy alloy particles provide an effective approach to impart biofouling resistance to various substrates. These coatings typically consist of HEA particles dispersed in polymer matrices or applied through thermal spray techniques. The coatings combine the inherent biofouling resistance of high-entropy alloys with the flexibility of coating application methods, allowing for the protection of complex geometries and large surfaces. The controlled release of metal ions from the HEA particles creates a sustained anti-biofouling effect.Expand Specific Solutions

Key Industry Players in HEA and Marine Materials

High-entropy alloys (HEAs) for biofouling resistance represent an emerging field at the intersection of materials science and marine engineering. The market is in its early growth phase, with increasing research interest but limited commercial applications. Academic institutions like Harbin Institute of Technology, Central South University, and Dartmouth College are leading fundamental research, while companies such as Proterial Ltd., LG Electronics, and Halliburton Energy Services are beginning to explore industrial applications. The technology maturity remains at the research and development stage, with Korea Institute of Materials Science and LG Chem advancing the practical applications. Market growth is driven by maritime industries seeking sustainable anti-fouling solutions, with projected expansion as environmental regulations against traditional biocides tighten globally.

Dalian University of Technology

Technical Solution: Dalian University of Technology has pioneered an innovative approach to high-entropy alloy (HEA) development for biofouling resistance, focusing on marine applications. Their research team has created CuCrFeTiNi-based HEAs with exceptional anti-biofouling properties through a combination of compositional design and surface engineering. The university's technology utilizes a controlled solidification process that creates unique microstructural features, including nano-precipitates and metastable phases, which disrupt the attachment mechanisms of marine organisms. Their HEAs demonstrate remarkable resistance to both microfouling (bacteria, diatoms) and macrofouling (barnacles, mussels) organisms, with laboratory tests showing up to 92% reduction in bacterial adhesion compared to conventional marine-grade alloys. Dalian's researchers have further enhanced the biofouling resistance by developing a two-step surface treatment process that modifies the surface energy and topography of the HEAs, creating an unfavorable environment for organism settlement while maintaining the excellent mechanical and corrosion properties inherent to HEAs. Field tests in the Bohai Sea have demonstrated sustained anti-biofouling performance for over 18 months without significant performance degradation.

Strengths: Exceptional resistance to both micro and macro marine fouling organisms; excellent long-term performance in actual marine environments; maintains mechanical integrity and corrosion resistance while providing anti-fouling properties; environmentally sustainable solution without toxic biocides. Weaknesses: Complex manufacturing process may limit large-scale production; higher initial cost compared to traditional materials; potential challenges in joining and forming processes for shipbuilding applications; limited testing in tropical marine environments.

Harbin Institute of Technology

Technical Solution: Harbin Institute of Technology has developed innovative high-entropy alloy (HEA) coatings with enhanced biofouling resistance through a multi-element alloying approach. Their technology utilizes a combination of elements like Cu, Cr, Fe, Ni, and Mn to create surfaces with heterogeneous microstructures that disrupt biofilm formation. The institute has pioneered a specialized magnetron sputtering technique that allows precise control over the elemental composition and surface morphology of HEAs, creating nano-structured surfaces that physically deter microorganism attachment. Their research demonstrates that these HEA coatings exhibit superior resistance to marine biofouling compared to conventional materials, with up to 85% reduction in bacterial adhesion and significantly decreased settlement rates of barnacles and algae. The institute has also developed environmentally friendly HEAs that avoid toxic elements while maintaining excellent anti-biofouling properties through their unique electrochemical characteristics and surface energy profiles.

Strengths: Advanced materials science expertise with specialized equipment for precise HEA fabrication; demonstrated significant reduction in biofouling without relying on toxic elements; excellent durability in marine environments. Weaknesses: Potentially high manufacturing costs for large-scale applications; limited field testing in varied marine environments; possible challenges in scaling up the specialized magnetron sputtering technique for industrial production.

Critical Patents and Research in HEA Biofouling Resistance

High-entropy alloy and method for manufacturing same

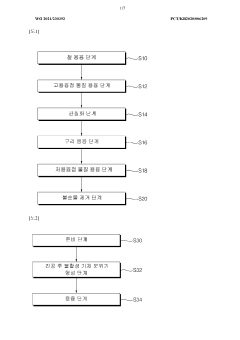

PatentWO2021230392A1

Innovation

- A high-entropy alloy with a dual-phase structure of iron-rich and copper-rich phases, including nickel for improved solid solubility and corrosion resistance, along with melting point lowering elements like carbon, silicon, and manganese, is developed, allowing for a simpler manufacturing process and reduced material costs by optimizing the composition and melting temperatures.

High entropy alloy and method for manufacturing the same

PatentActiveKR1020200060830A

Innovation

- A controlled microstructure is achieved by incorporating a BCC phase as a matrix and a B2 phase as a second phase, with a volume fraction of 30 to 50% B2 phase, and a homogenization heat treatment at 1100 to 1350 °C for 4 to 10 hours to eliminate dendrite and interdendritic regions, followed by water cooling.

Environmental Impact and Sustainability Considerations

The adoption of high-entropy alloys (HEAs) for biofouling resistance represents a significant advancement in sustainable marine technology. These innovative materials offer substantial environmental benefits compared to traditional antifouling solutions that often rely on toxic compounds. Conventional biocides and heavy metal-based coatings, while effective, leach harmful substances into aquatic ecosystems, causing long-term damage to marine biodiversity and disrupting sensitive ecological balances.

HEAs provide an environmentally responsible alternative by utilizing their inherent physical and chemical properties rather than toxic release mechanisms. Their superior corrosion resistance significantly extends service life of marine structures and vessels, reducing the frequency of maintenance operations that typically involve environmentally harmful processes such as sandblasting, recoating, and waste disposal. This longevity directly translates to reduced resource consumption and lower carbon footprints across maritime industries.

The manufacturing processes for HEAs are becoming increasingly optimized for sustainability. Advanced production techniques such as additive manufacturing allow for precise material usage, minimizing waste generation. Furthermore, the multi-element composition of HEAs offers opportunities to incorporate recycled metals, supporting circular economy principles and reducing primary resource extraction demands.

Life cycle assessments of HEA applications in marine environments demonstrate favorable environmental profiles when compared to conventional solutions. The reduced need for maintenance translates to lower lifetime energy consumption and decreased emissions associated with repair operations. Additionally, the elimination of biocide leaching prevents bioaccumulation of toxic substances in marine food chains, protecting ecosystem health and potentially safeguarding human health through seafood consumption.

Regulatory frameworks worldwide are increasingly restricting the use of environmentally harmful antifouling technologies. HEAs align well with these evolving regulations, positioning them as compliant solutions for future maritime applications. Their development supports international sustainability goals, including several UN Sustainable Development Goals related to marine conservation, responsible consumption, and climate action.

Economic sustainability also factors prominently in HEA implementation. While initial production costs may exceed traditional materials, the extended service life and reduced maintenance requirements create favorable total cost of ownership profiles. This economic viability enhances adoption potential across various maritime sectors, from commercial shipping to offshore renewable energy installations, amplifying the cumulative environmental benefits.

HEAs provide an environmentally responsible alternative by utilizing their inherent physical and chemical properties rather than toxic release mechanisms. Their superior corrosion resistance significantly extends service life of marine structures and vessels, reducing the frequency of maintenance operations that typically involve environmentally harmful processes such as sandblasting, recoating, and waste disposal. This longevity directly translates to reduced resource consumption and lower carbon footprints across maritime industries.

The manufacturing processes for HEAs are becoming increasingly optimized for sustainability. Advanced production techniques such as additive manufacturing allow for precise material usage, minimizing waste generation. Furthermore, the multi-element composition of HEAs offers opportunities to incorporate recycled metals, supporting circular economy principles and reducing primary resource extraction demands.

Life cycle assessments of HEA applications in marine environments demonstrate favorable environmental profiles when compared to conventional solutions. The reduced need for maintenance translates to lower lifetime energy consumption and decreased emissions associated with repair operations. Additionally, the elimination of biocide leaching prevents bioaccumulation of toxic substances in marine food chains, protecting ecosystem health and potentially safeguarding human health through seafood consumption.

Regulatory frameworks worldwide are increasingly restricting the use of environmentally harmful antifouling technologies. HEAs align well with these evolving regulations, positioning them as compliant solutions for future maritime applications. Their development supports international sustainability goals, including several UN Sustainable Development Goals related to marine conservation, responsible consumption, and climate action.

Economic sustainability also factors prominently in HEA implementation. While initial production costs may exceed traditional materials, the extended service life and reduced maintenance requirements create favorable total cost of ownership profiles. This economic viability enhances adoption potential across various maritime sectors, from commercial shipping to offshore renewable energy installations, amplifying the cumulative environmental benefits.

Regulatory Framework for Marine Anti-Biofouling Technologies

The regulatory landscape governing marine anti-biofouling technologies has evolved significantly in response to environmental concerns about traditional biocidal approaches. The International Maritime Organization (IMO) established a pivotal framework through the International Convention on the Control of Harmful Anti-fouling Systems on Ships (AFS Convention), which came into force in 2008. This convention specifically banned the use of tributyltin (TBT)-based coatings due to their severe environmental impacts on marine ecosystems and non-target organisms.

The European Union has implemented additional regulations through the Biocidal Products Regulation (BPR, Regulation EU 528/2012), which controls the marketing and use of biocidal products, including anti-fouling paints. This regulation requires extensive environmental and toxicological data before approval, creating significant barriers for new biocidal solutions while encouraging the development of non-biocidal alternatives like high-entropy alloys (HEAs).

In the United States, the Environmental Protection Agency (EPA) regulates anti-fouling technologies under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA) and the Toxic Substances Control Act (TSCA). The EPA has established specific registration requirements for anti-fouling paints and coatings, with increasing scrutiny on copper-based formulations in certain coastal states like Washington and California.

The regulatory framework has created a tiered approach to compliance, with different requirements based on the mechanism of action. Biocidal anti-fouling systems face the most stringent regulations, while physical deterrents and surface modification technologies like HEAs may face fewer regulatory hurdles if they can demonstrate minimal environmental impact and leaching characteristics.

International standards organizations, including ISO and ASTM, have developed testing protocols for evaluating the performance and environmental impact of anti-fouling technologies. These standards provide important benchmarks for comparing traditional biocidal approaches with emerging solutions like HEAs, particularly regarding long-term effectiveness and environmental footprint.

The regulatory trend clearly favors technologies with reduced environmental impact, creating market opportunities for innovative solutions like HEAs that can demonstrate biofouling resistance without relying on toxic biocides. However, novel materials must still navigate complex approval processes that vary by jurisdiction, with particular attention to potential nanomaterial regulations as some HEA applications may involve nanoscale engineering.

The European Union has implemented additional regulations through the Biocidal Products Regulation (BPR, Regulation EU 528/2012), which controls the marketing and use of biocidal products, including anti-fouling paints. This regulation requires extensive environmental and toxicological data before approval, creating significant barriers for new biocidal solutions while encouraging the development of non-biocidal alternatives like high-entropy alloys (HEAs).

In the United States, the Environmental Protection Agency (EPA) regulates anti-fouling technologies under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA) and the Toxic Substances Control Act (TSCA). The EPA has established specific registration requirements for anti-fouling paints and coatings, with increasing scrutiny on copper-based formulations in certain coastal states like Washington and California.

The regulatory framework has created a tiered approach to compliance, with different requirements based on the mechanism of action. Biocidal anti-fouling systems face the most stringent regulations, while physical deterrents and surface modification technologies like HEAs may face fewer regulatory hurdles if they can demonstrate minimal environmental impact and leaching characteristics.

International standards organizations, including ISO and ASTM, have developed testing protocols for evaluating the performance and environmental impact of anti-fouling technologies. These standards provide important benchmarks for comparing traditional biocidal approaches with emerging solutions like HEAs, particularly regarding long-term effectiveness and environmental footprint.

The regulatory trend clearly favors technologies with reduced environmental impact, creating market opportunities for innovative solutions like HEAs that can demonstrate biofouling resistance without relying on toxic biocides. However, novel materials must still navigate complex approval processes that vary by jurisdiction, with particular attention to potential nanomaterial regulations as some HEA applications may involve nanoscale engineering.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!