High-Entropy Alloys' Contribution to Tribocorrosion Resistance

SEP 4, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

High-Entropy Alloys Evolution and Research Objectives

High-entropy alloys (HEAs) represent a paradigm shift in metallurgical engineering, emerging as a revolutionary concept in the early 2000s when traditional alloy design principles were challenged. Unlike conventional alloys that rely on one principal element with minor additions, HEAs incorporate multiple principal elements (typically five or more) in near-equiatomic proportions, creating unique atomic structures with exceptional properties. This fundamental departure from traditional metallurgy has opened new avenues for material design and performance optimization.

The evolution of HEAs can be traced through several distinct phases. The initial conceptualization phase (2004-2010) established the theoretical foundation, with pioneering work by Yeh and Cantor demonstrating the stability of multi-principal element systems. The exploration phase (2010-2015) witnessed rapid expansion in research activity, with scientists investigating compositional effects on microstructure and basic mechanical properties. The current application-focused phase (2015-present) has seen increasing emphasis on tailoring HEAs for specific industrial challenges, including tribocorrosion resistance.

Tribocorrosion—the synergistic degradation resulting from simultaneous mechanical wear and electrochemical corrosion—represents a critical failure mechanism in numerous industrial applications. Traditional materials often struggle to withstand these combined destructive forces, creating a significant technological gap that HEAs are uniquely positioned to address.

The exceptional properties of HEAs that contribute to tribocorrosion resistance include their high entropy of mixing, which promotes the formation of simple solid solutions; severe lattice distortion that impedes dislocation movement; sluggish diffusion kinetics that enhance thermal stability; and the cocktail effect that enables property combinations unattainable in conventional alloys. These intrinsic characteristics provide HEAs with superior hardness, excellent work hardening capability, and remarkable corrosion resistance—all critical factors in tribocorrosion environments.

Research objectives in this field are increasingly focused on understanding the fundamental mechanisms by which HEAs resist tribocorrosion, developing predictive models for composition-property relationships, and establishing design principles for application-specific HEA formulations. Particular emphasis is being placed on elucidating the role of passive film formation and stability under mechanical stress, the influence of microstructural features on wear-corrosion synergy, and the development of cost-effective processing routes for industrial-scale production.

The ultimate goal is to develop next-generation HEAs with optimized tribocorrosion resistance for critical applications in chemical processing, marine environments, biomedical implants, and advanced energy systems, where material longevity under harsh conditions directly impacts system performance, safety, and economic viability.

The evolution of HEAs can be traced through several distinct phases. The initial conceptualization phase (2004-2010) established the theoretical foundation, with pioneering work by Yeh and Cantor demonstrating the stability of multi-principal element systems. The exploration phase (2010-2015) witnessed rapid expansion in research activity, with scientists investigating compositional effects on microstructure and basic mechanical properties. The current application-focused phase (2015-present) has seen increasing emphasis on tailoring HEAs for specific industrial challenges, including tribocorrosion resistance.

Tribocorrosion—the synergistic degradation resulting from simultaneous mechanical wear and electrochemical corrosion—represents a critical failure mechanism in numerous industrial applications. Traditional materials often struggle to withstand these combined destructive forces, creating a significant technological gap that HEAs are uniquely positioned to address.

The exceptional properties of HEAs that contribute to tribocorrosion resistance include their high entropy of mixing, which promotes the formation of simple solid solutions; severe lattice distortion that impedes dislocation movement; sluggish diffusion kinetics that enhance thermal stability; and the cocktail effect that enables property combinations unattainable in conventional alloys. These intrinsic characteristics provide HEAs with superior hardness, excellent work hardening capability, and remarkable corrosion resistance—all critical factors in tribocorrosion environments.

Research objectives in this field are increasingly focused on understanding the fundamental mechanisms by which HEAs resist tribocorrosion, developing predictive models for composition-property relationships, and establishing design principles for application-specific HEA formulations. Particular emphasis is being placed on elucidating the role of passive film formation and stability under mechanical stress, the influence of microstructural features on wear-corrosion synergy, and the development of cost-effective processing routes for industrial-scale production.

The ultimate goal is to develop next-generation HEAs with optimized tribocorrosion resistance for critical applications in chemical processing, marine environments, biomedical implants, and advanced energy systems, where material longevity under harsh conditions directly impacts system performance, safety, and economic viability.

Market Applications and Demand for Tribocorrosion-Resistant Materials

The global market for tribocorrosion-resistant materials has witnessed significant growth in recent years, driven primarily by increasing demands in industries where components operate in harsh environments combining mechanical wear and corrosive conditions. The estimated market value for specialized corrosion-resistant materials reached $29.4 billion in 2022, with tribocorrosion-resistant solutions representing approximately 18% of this segment.

Industries such as aerospace, marine engineering, biomedical implants, chemical processing, and oil and gas extraction demonstrate particularly strong demand for advanced tribocorrosion-resistant materials. In aerospace applications, components operating in extreme conditions require materials that can withstand both mechanical stress and corrosive environments, with the market for these specialized materials growing at 7.2% annually since 2018.

The biomedical sector presents one of the most promising growth areas, with the global market for tribocorrosion-resistant implant materials projected to reach $5.7 billion by 2027. This growth is fueled by increasing implant procedures worldwide and stricter regulatory requirements regarding implant longevity and biocompatibility. High-entropy alloys (HEAs) are positioned to capture a significant portion of this market due to their superior performance characteristics.

In the energy sector, particularly oil and gas extraction, equipment operating in deep-sea environments faces severe tribocorrosion challenges. The market for specialized materials in this segment was valued at $3.8 billion in 2022, with annual replacement costs due to tribocorrosion damage estimated at $1.2 billion globally. HEAs offer potential cost savings through extended component lifespans and reduced maintenance requirements.

Chemical processing industries represent another major market, where equipment degradation due to combined wear and corrosion accounts for approximately 5% of annual maintenance budgets. Companies are increasingly willing to invest in premium materials that offer superior tribocorrosion resistance to reduce downtime and extend equipment life cycles.

Geographically, North America and Europe currently dominate the market for advanced tribocorrosion-resistant materials, accounting for 58% of global demand. However, the Asia-Pacific region, particularly China and India, is experiencing the fastest growth rate at 9.3% annually, driven by rapid industrialization and increasing adoption of advanced materials in manufacturing processes.

Market analysis indicates that customers are increasingly prioritizing total lifecycle costs over initial acquisition expenses, creating favorable conditions for the adoption of HEAs despite their potentially higher upfront costs. This shift in purchasing behavior is supported by growing awareness of the long-term economic benefits of tribocorrosion-resistant materials in reducing maintenance requirements and extending component lifespans.

Industries such as aerospace, marine engineering, biomedical implants, chemical processing, and oil and gas extraction demonstrate particularly strong demand for advanced tribocorrosion-resistant materials. In aerospace applications, components operating in extreme conditions require materials that can withstand both mechanical stress and corrosive environments, with the market for these specialized materials growing at 7.2% annually since 2018.

The biomedical sector presents one of the most promising growth areas, with the global market for tribocorrosion-resistant implant materials projected to reach $5.7 billion by 2027. This growth is fueled by increasing implant procedures worldwide and stricter regulatory requirements regarding implant longevity and biocompatibility. High-entropy alloys (HEAs) are positioned to capture a significant portion of this market due to their superior performance characteristics.

In the energy sector, particularly oil and gas extraction, equipment operating in deep-sea environments faces severe tribocorrosion challenges. The market for specialized materials in this segment was valued at $3.8 billion in 2022, with annual replacement costs due to tribocorrosion damage estimated at $1.2 billion globally. HEAs offer potential cost savings through extended component lifespans and reduced maintenance requirements.

Chemical processing industries represent another major market, where equipment degradation due to combined wear and corrosion accounts for approximately 5% of annual maintenance budgets. Companies are increasingly willing to invest in premium materials that offer superior tribocorrosion resistance to reduce downtime and extend equipment life cycles.

Geographically, North America and Europe currently dominate the market for advanced tribocorrosion-resistant materials, accounting for 58% of global demand. However, the Asia-Pacific region, particularly China and India, is experiencing the fastest growth rate at 9.3% annually, driven by rapid industrialization and increasing adoption of advanced materials in manufacturing processes.

Market analysis indicates that customers are increasingly prioritizing total lifecycle costs over initial acquisition expenses, creating favorable conditions for the adoption of HEAs despite their potentially higher upfront costs. This shift in purchasing behavior is supported by growing awareness of the long-term economic benefits of tribocorrosion-resistant materials in reducing maintenance requirements and extending component lifespans.

Current Status and Challenges in HEA Tribocorrosion Research

The global research landscape of High-Entropy Alloys (HEAs) for tribocorrosion resistance has witnessed significant advancement in recent years, yet remains in a relatively nascent stage compared to conventional alloy systems. Current research indicates that HEAs exhibit promising tribocorrosion resistance due to their unique microstructural characteristics and compositional complexity, which can simultaneously address wear and corrosion challenges in aggressive environments.

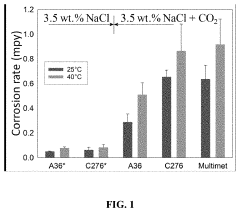

Laboratory investigations across major research institutions in the United States, China, Europe, and Japan have demonstrated that certain HEA compositions can outperform traditional alloys like stainless steels and nickel-based superalloys in combined wear-corrosion conditions. Particularly, CoCrFeMnNi (Cantor alloy) derivatives and refractory HEAs containing elements like Mo, Nb, and Ta have shown exceptional performance in simulated industrial environments.

Despite these promising results, several significant challenges persist in HEA tribocorrosion research. The first major obstacle is the lack of standardized testing protocols specifically designed for evaluating tribocorrosion behavior of HEAs. Current methodologies are largely adapted from conventional alloy testing, potentially overlooking unique degradation mechanisms specific to HEAs.

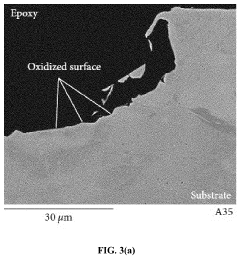

Another critical challenge is the limited understanding of the synergistic effects between mechanical wear and electrochemical corrosion in these complex alloy systems. The interaction between multiple principal elements creates unique passive films and tribological interfaces whose behavior under simultaneous mechanical and chemical attack remains poorly characterized.

The prohibitive cost of manufacturing HEAs at industrial scale represents another significant barrier. Current production methods, primarily arc melting and mechanical alloying, face challenges in scaling up while maintaining compositional homogeneity and microstructural control, limiting widespread industrial adoption and comprehensive testing.

Data inconsistency across research groups further complicates progress in this field. Variations in testing conditions, sample preparation, and reporting standards make direct comparisons between studies difficult, hindering the development of comprehensive design principles for tribocorrosion-resistant HEAs.

Geographically, research concentration shows distinct patterns with China leading in publication volume, while the United States and European institutions (particularly in Germany and Sweden) focus on fundamental mechanistic studies. Japanese and South Korean research groups have made notable contributions in specialized applications like biomedical implants and nuclear materials.

The integration of computational methods with experimental approaches remains underdeveloped, with limited predictive models capable of accurately forecasting tribocorrosion behavior based on alloy composition and microstructure. This gap significantly slows the discovery process, which currently relies heavily on resource-intensive trial-and-error experimentation.

Laboratory investigations across major research institutions in the United States, China, Europe, and Japan have demonstrated that certain HEA compositions can outperform traditional alloys like stainless steels and nickel-based superalloys in combined wear-corrosion conditions. Particularly, CoCrFeMnNi (Cantor alloy) derivatives and refractory HEAs containing elements like Mo, Nb, and Ta have shown exceptional performance in simulated industrial environments.

Despite these promising results, several significant challenges persist in HEA tribocorrosion research. The first major obstacle is the lack of standardized testing protocols specifically designed for evaluating tribocorrosion behavior of HEAs. Current methodologies are largely adapted from conventional alloy testing, potentially overlooking unique degradation mechanisms specific to HEAs.

Another critical challenge is the limited understanding of the synergistic effects between mechanical wear and electrochemical corrosion in these complex alloy systems. The interaction between multiple principal elements creates unique passive films and tribological interfaces whose behavior under simultaneous mechanical and chemical attack remains poorly characterized.

The prohibitive cost of manufacturing HEAs at industrial scale represents another significant barrier. Current production methods, primarily arc melting and mechanical alloying, face challenges in scaling up while maintaining compositional homogeneity and microstructural control, limiting widespread industrial adoption and comprehensive testing.

Data inconsistency across research groups further complicates progress in this field. Variations in testing conditions, sample preparation, and reporting standards make direct comparisons between studies difficult, hindering the development of comprehensive design principles for tribocorrosion-resistant HEAs.

Geographically, research concentration shows distinct patterns with China leading in publication volume, while the United States and European institutions (particularly in Germany and Sweden) focus on fundamental mechanistic studies. Japanese and South Korean research groups have made notable contributions in specialized applications like biomedical implants and nuclear materials.

The integration of computational methods with experimental approaches remains underdeveloped, with limited predictive models capable of accurately forecasting tribocorrosion behavior based on alloy composition and microstructure. This gap significantly slows the discovery process, which currently relies heavily on resource-intensive trial-and-error experimentation.

Current HEA Compositions and Processing Techniques

01 Composition design of high-entropy alloys for tribocorrosion resistance

High-entropy alloys with specific elemental compositions can be designed to enhance tribocorrosion resistance. These alloys typically contain multiple principal elements in near-equiatomic proportions, creating complex solid solutions with unique properties. The careful selection and balancing of elements such as Cr, Ni, Co, Fe, and Al can lead to improved hardness, passivation behavior, and corrosion resistance, which collectively contribute to superior tribocorrosion performance in aggressive environments.- Composition design of high-entropy alloys for enhanced tribocorrosion resistance: High-entropy alloys with specific elemental compositions can be designed to enhance tribocorrosion resistance. These alloys typically contain multiple principal elements in near-equiatomic proportions, creating unique microstructures that resist both mechanical wear and corrosion simultaneously. The careful selection and balancing of elements such as Cr, Ni, Co, Fe, and others can create synergistic effects that improve overall tribocorrosion performance compared to conventional alloys.

- Surface modification techniques for improved tribocorrosion resistance: Various surface modification techniques can be applied to high-entropy alloys to further enhance their tribocorrosion resistance. These include laser surface treatment, plasma nitriding, physical vapor deposition, and other coating methods. These treatments create protective layers or modify the surface microstructure to improve hardness, reduce friction coefficients, and enhance corrosion resistance, resulting in superior tribocorrosion performance in aggressive environments.

- Microstructural engineering for optimized tribocorrosion properties: The microstructure of high-entropy alloys plays a crucial role in determining their tribocorrosion resistance. Engineering approaches such as grain refinement, phase control, and precipitation hardening can be employed to optimize the microstructure. Creating nanocrystalline structures, controlling phase stability, and inducing beneficial precipitates can significantly enhance both mechanical properties and corrosion resistance, leading to superior tribocorrosion performance in various environments.

- Testing and evaluation methods for tribocorrosion resistance: Specialized testing methodologies have been developed to evaluate the tribocorrosion resistance of high-entropy alloys. These include electrochemical tests combined with tribological measurements, potentiodynamic polarization during sliding wear tests, and advanced surface characterization techniques. These methods allow for comprehensive assessment of material performance under simultaneous mechanical and electrochemical stresses, enabling the development of alloys with optimized tribocorrosion resistance for specific applications.

- Application-specific high-entropy alloy development for tribocorrosive environments: High-entropy alloys can be tailored for specific applications that require excellent tribocorrosion resistance, such as marine environments, biomedical implants, chemical processing equipment, and energy production systems. By adjusting composition, processing parameters, and surface treatments based on the specific tribocorrosive conditions of the intended application, these alloys can be optimized to provide superior performance and extended service life compared to traditional materials in challenging operational environments.

02 Surface modification techniques for improved tribocorrosion resistance

Various surface modification techniques can be applied to high-entropy alloys to enhance their tribocorrosion resistance. These include nitriding, carburizing, laser surface treatment, and the application of protective coatings. Such treatments modify the surface properties by creating hard, corrosion-resistant layers that can withstand both mechanical wear and chemical attack simultaneously, thereby extending the service life of components operating in harsh environments.Expand Specific Solutions03 Microstructural engineering for enhanced tribocorrosion performance

The microstructure of high-entropy alloys plays a crucial role in determining their tribocorrosion resistance. Engineering approaches such as grain refinement, precipitation hardening, and controlled phase formation can significantly improve mechanical properties and corrosion resistance. Techniques like heat treatment, thermomechanical processing, and rapid solidification can be employed to develop optimized microstructures that provide a balance between hardness, ductility, and corrosion resistance for superior tribocorrosion performance.Expand Specific Solutions04 Testing and evaluation methods for tribocorrosion resistance

Specialized testing methodologies have been developed to evaluate the tribocorrosion resistance of high-entropy alloys. These include electrochemical tests combined with tribological measurements, such as potentiodynamic polarization during sliding wear tests, electrochemical impedance spectroscopy, and weight loss measurements. Advanced characterization techniques like scanning electron microscopy, X-ray photoelectron spectroscopy, and 3D profilometry are used to analyze wear tracks and corrosion products, providing insights into tribocorrosion mechanisms and material performance.Expand Specific Solutions05 Application-specific high-entropy alloy development

High-entropy alloys with enhanced tribocorrosion resistance are being developed for specific industrial applications. These include components for marine environments, chemical processing equipment, biomedical implants, and advanced energy systems. The alloy compositions and processing methods are tailored to meet the specific tribocorrosion challenges of each application, considering factors such as temperature, pH, electrolyte composition, and mechanical loading conditions to optimize performance in real-world operating environments.Expand Specific Solutions

Leading Research Institutions and Industrial Players in HEA Field

High-entropy alloys (HEAs) are emerging as a promising solution for tribocorrosion resistance, with the market currently in its growth phase. The global market for tribocorrosion-resistant materials is expanding, driven by increasing demands in aerospace, automotive, and energy sectors. Research institutions like Lanzhou Institute of Chemical Physics, Central South University, and Dartmouth College are leading fundamental research, while companies such as Proterial Ltd., LG Electronics, and Mitsubishi Heavy Industries are advancing commercial applications. The technology is approaching maturity in specialized applications but remains in development for broader implementation. Collaboration between academic institutions and industrial players is accelerating innovation, with significant progress in understanding how HEAs' unique microstructural characteristics contribute to superior tribocorrosion resistance in harsh environments.

Lanzhou Institute of Chemical Physics

Technical Solution: Lanzhou Institute of Chemical Physics has developed innovative high-entropy alloy (HEA) coatings with exceptional tribocorrosion resistance through a multi-element alloying approach. Their technical solution involves the synthesis of CoCrFeMnNi-based HEAs with controlled microstructure using magnetron co-sputtering techniques. These alloys form a stable passive film enriched with Cr and Mn oxides that significantly enhances corrosion resistance while maintaining excellent mechanical properties. The institute has pioneered the addition of nitrogen to create high-entropy nitride coatings that demonstrate superior hardness (25-35 GPa) and tribological performance in aggressive media. Their research has established that the severe lattice distortion and sluggish diffusion effects in HEAs contribute to enhanced tribocorrosion resistance by impeding dislocation movement and crack propagation during simultaneous mechanical and chemical attacks.

Strengths: Superior passive film formation capability; excellent combination of hardness and corrosion resistance; advanced characterization techniques for tribocorrosion mechanisms. Weaknesses: Potential high manufacturing costs; challenges in scaling up laboratory processes for industrial applications; limited long-term performance data in extreme environments.

Korea Institute of Materials Science

Technical Solution: The Korea Institute of Materials Science has developed a sophisticated approach to enhancing tribocorrosion resistance through high-entropy alloys (HEAs). Their technical solution centers on the development of CoCrFeMnNi-based HEAs with controlled additions of Al and Cu to optimize both mechanical properties and corrosion resistance. The institute employs advanced vacuum arc melting followed by precision controlled cooling to create HEAs with nanoscale precipitates that significantly enhance hardness while maintaining ductility. Their research has demonstrated that these HEAs form a stable passive layer in chloride-containing environments, with corrosion current densities reduced by an order of magnitude compared to conventional alloys. The institute has pioneered a novel surface modification technique using plasma nitriding at moderate temperatures (450-550°C) to create a gradient nanostructured surface layer that dramatically improves tribocorrosion performance. Testing in simulated seawater environments has shown their HEAs maintain structural integrity under simultaneous mechanical wear and electrochemical attack, with wear rates reduced by approximately 65% compared to 316L stainless steel.

Strengths: Excellent balance between mechanical properties and corrosion resistance; innovative surface modification techniques; comprehensive testing in realistic service environments. Weaknesses: Complex processing requirements; potential challenges in joining and welding; higher production costs compared to conventional alloys.

Key Mechanisms of Tribocorrosion Resistance in HEAs

High-performance corrosion-resistant high-entropy alloys

PatentActiveUS11466344B2

Innovation

- Development of high-entropy alloys with a face-centered cubic (FCC) crystal structure, composed of iron, nickel, cobalt, molybdenum, and chromium, with minor elements, providing high corrosion resistance and ductility, suitable for use as coatings or bulk components in extreme environments.

HIGH ENTROPY CORROSION RESISTANT alloy

PatentInactiveBR112019017951A2

Innovation

- A high-entropy, multi-principal alloy composition comprising Co, Ni, Fe, Mn, Cr, Mo, and N, with optional substitutions of W or V for Mo, is designed to achieve a stable FCC phase structure by optimizing enthalpy of mixing, atomic size difference, and valence electron concentration, thereby minimizing secondary phase formation and enhancing corrosion resistance.

Environmental Impact and Sustainability of HEA Materials

The environmental impact of High-Entropy Alloys (HEAs) represents a critical consideration in their development and application, particularly in tribocorrosion-resistant scenarios. These advanced materials demonstrate significant sustainability advantages compared to conventional alloys, primarily due to their enhanced durability and resistance to degradation in harsh environments. The extended service life of HEA components directly translates to reduced material consumption and waste generation over time, contributing to resource conservation efforts.

HEAs' superior tribocorrosion resistance enables a substantial reduction in maintenance frequency and replacement cycles for critical components in industrial applications. This operational efficiency minimizes the environmental footprint associated with manufacturing replacement parts and reduces the energy consumption linked to maintenance operations. Furthermore, the decreased need for protective coatings and surface treatments—often containing environmentally problematic substances—represents another ecological benefit of HEA implementation.

From a life cycle assessment perspective, HEAs demonstrate promising environmental credentials. While their initial production may require specialized processing techniques with potentially higher energy demands, this is typically offset by their significantly extended operational lifespan. The net environmental impact calculation favors HEAs when considering the complete product lifecycle, from raw material extraction through manufacturing, use phase, and end-of-life management.

The recyclability of HEAs presents both opportunities and challenges for sustainable materials management. Their complex multi-element composition can complicate traditional recycling processes, potentially requiring advanced separation technologies. However, research indicates that HEAs can be effectively recycled with appropriate methodologies, preserving valuable and sometimes critical raw materials within the circular economy framework.

Energy efficiency improvements represent another environmental benefit of HEA implementation. In tribological applications, the reduced friction coefficients of many HEA systems directly translate to energy savings in mechanical systems. This effect is particularly pronounced in transportation and industrial machinery applications, where even marginal efficiency improvements can yield significant cumulative energy conservation over operational lifetimes.

Looking forward, the environmental profile of HEAs continues to improve as manufacturing processes evolve and become more efficient. Emerging production techniques such as additive manufacturing offer pathways to reduce material waste during HEA component fabrication. Additionally, ongoing research into compositional optimization may yield HEA variants that maintain exceptional tribocorrosion resistance while minimizing reliance on rare or environmentally problematic elements, further enhancing their sustainability credentials.

HEAs' superior tribocorrosion resistance enables a substantial reduction in maintenance frequency and replacement cycles for critical components in industrial applications. This operational efficiency minimizes the environmental footprint associated with manufacturing replacement parts and reduces the energy consumption linked to maintenance operations. Furthermore, the decreased need for protective coatings and surface treatments—often containing environmentally problematic substances—represents another ecological benefit of HEA implementation.

From a life cycle assessment perspective, HEAs demonstrate promising environmental credentials. While their initial production may require specialized processing techniques with potentially higher energy demands, this is typically offset by their significantly extended operational lifespan. The net environmental impact calculation favors HEAs when considering the complete product lifecycle, from raw material extraction through manufacturing, use phase, and end-of-life management.

The recyclability of HEAs presents both opportunities and challenges for sustainable materials management. Their complex multi-element composition can complicate traditional recycling processes, potentially requiring advanced separation technologies. However, research indicates that HEAs can be effectively recycled with appropriate methodologies, preserving valuable and sometimes critical raw materials within the circular economy framework.

Energy efficiency improvements represent another environmental benefit of HEA implementation. In tribological applications, the reduced friction coefficients of many HEA systems directly translate to energy savings in mechanical systems. This effect is particularly pronounced in transportation and industrial machinery applications, where even marginal efficiency improvements can yield significant cumulative energy conservation over operational lifetimes.

Looking forward, the environmental profile of HEAs continues to improve as manufacturing processes evolve and become more efficient. Emerging production techniques such as additive manufacturing offer pathways to reduce material waste during HEA component fabrication. Additionally, ongoing research into compositional optimization may yield HEA variants that maintain exceptional tribocorrosion resistance while minimizing reliance on rare or environmentally problematic elements, further enhancing their sustainability credentials.

Standardization and Testing Protocols for HEA Tribocorrosion

The standardization of testing protocols for High-Entropy Alloys (HEAs) in tribocorrosion environments represents a critical challenge in advancing their industrial application. Currently, there exists significant variability in testing methodologies across research institutions and industries, hampering direct comparison of results and slowing technological progress in this field.

Established tribocorrosion testing standards such as ASTM G119 and ISO 20795 provide general frameworks but lack specific adaptations for the unique characteristics of HEAs, including their complex microstructures and compositional variations. This gap necessitates the development of HEA-specific protocols that account for their distinctive mechanical and electrochemical behaviors under combined wear and corrosion conditions.

Key parameters requiring standardization include electrochemical conditions (potential ranges, reference electrodes), mechanical parameters (load, sliding speed, contact geometry), and environmental factors (electrolyte composition, temperature, pH). The synergistic effects between mechanical wear and electrochemical degradation in HEAs demand carefully controlled testing environments to ensure reproducibility and meaningful data interpretation.

Advanced characterization techniques must be integrated into standardized protocols, including in-situ electrochemical impedance spectroscopy (EIS), post-test surface analysis via XPS and ToF-SIMS, and cross-sectional microstructural examination. These techniques provide critical insights into the tribocorrosion mechanisms specific to HEAs, such as selective element leaching and passive film dynamics under mechanical stress.

Round-robin testing initiatives involving multiple laboratories would significantly enhance protocol validation and refinement. Such collaborative efforts could establish benchmark HEA compositions for comparative studies and develop reference materials with known tribocorrosion responses, creating a foundation for consistent evaluation methodologies across the field.

Data reporting standards represent another crucial aspect requiring attention. Comprehensive documentation should include detailed alloy processing history, microstructural characterization, and precise testing conditions. Standardized metrics for quantifying tribocorrosion performance—such as synergy factors, wear-corrosion maps, and electrochemical noise analysis parameters—would facilitate meaningful comparisons between different HEA systems.

The development of accelerated testing protocols presents a significant opportunity to expedite HEA evaluation for industrial applications. Correlation studies between accelerated tests and long-term performance in actual service environments would provide valuable predictive capabilities, enabling more efficient material selection and optimization processes for specific tribocorrosion challenges.

Established tribocorrosion testing standards such as ASTM G119 and ISO 20795 provide general frameworks but lack specific adaptations for the unique characteristics of HEAs, including their complex microstructures and compositional variations. This gap necessitates the development of HEA-specific protocols that account for their distinctive mechanical and electrochemical behaviors under combined wear and corrosion conditions.

Key parameters requiring standardization include electrochemical conditions (potential ranges, reference electrodes), mechanical parameters (load, sliding speed, contact geometry), and environmental factors (electrolyte composition, temperature, pH). The synergistic effects between mechanical wear and electrochemical degradation in HEAs demand carefully controlled testing environments to ensure reproducibility and meaningful data interpretation.

Advanced characterization techniques must be integrated into standardized protocols, including in-situ electrochemical impedance spectroscopy (EIS), post-test surface analysis via XPS and ToF-SIMS, and cross-sectional microstructural examination. These techniques provide critical insights into the tribocorrosion mechanisms specific to HEAs, such as selective element leaching and passive film dynamics under mechanical stress.

Round-robin testing initiatives involving multiple laboratories would significantly enhance protocol validation and refinement. Such collaborative efforts could establish benchmark HEA compositions for comparative studies and develop reference materials with known tribocorrosion responses, creating a foundation for consistent evaluation methodologies across the field.

Data reporting standards represent another crucial aspect requiring attention. Comprehensive documentation should include detailed alloy processing history, microstructural characterization, and precise testing conditions. Standardized metrics for quantifying tribocorrosion performance—such as synergy factors, wear-corrosion maps, and electrochemical noise analysis parameters—would facilitate meaningful comparisons between different HEA systems.

The development of accelerated testing protocols presents a significant opportunity to expedite HEA evaluation for industrial applications. Correlation studies between accelerated tests and long-term performance in actual service environments would provide valuable predictive capabilities, enabling more efficient material selection and optimization processes for specific tribocorrosion challenges.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!