How High-Entropy Alloys Aid in Thermal Barrier Coatings

SEP 4, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HEA Thermal Barrier Coating Background & Objectives

High-entropy alloys (HEAs) represent a revolutionary paradigm shift in materials science that emerged in the early 2000s, diverging from traditional alloy design principles that typically focus on one principal element with minor additions. HEAs consist of five or more principal elements in near-equiatomic proportions, creating unique atomic structures with exceptional properties. The evolution of these materials has progressed rapidly over the past two decades, with significant breakthroughs in understanding their formation mechanisms, microstructural characteristics, and performance attributes.

The thermal barrier coating (TBC) field has traditionally relied on conventional materials like yttria-stabilized zirconia (YSZ) for protecting components in high-temperature environments such as gas turbine engines. However, these conventional TBCs face limitations in increasingly demanding operational conditions, particularly as industries push for higher efficiency through elevated operating temperatures.

The convergence of HEA technology with thermal barrier coating applications represents a promising frontier in materials engineering. This intersection aims to overcome the inherent limitations of traditional TBCs by leveraging the unique properties of HEAs, including their exceptional phase stability, reduced thermal conductivity, and superior mechanical properties at elevated temperatures.

The technical evolution trajectory shows a clear progression from early theoretical explorations of HEAs to their practical implementation in coating technologies. Initial research focused primarily on understanding the fundamental principles governing HEA formation and stability, while recent developments have increasingly targeted specific applications, with thermal protection systems emerging as a particularly promising domain.

The primary technical objective of HEA-based thermal barrier coatings is to develop next-generation protective systems capable of withstanding more extreme thermal conditions while maintaining structural integrity over extended operational lifetimes. This includes achieving lower thermal conductivity than conventional YSZ coatings, enhanced resistance to sintering at elevated temperatures, improved strain tolerance, and superior resistance to CMAS (calcium-magnesium-alumino-silicate) infiltration.

Secondary objectives include developing scalable and economically viable manufacturing processes for HEA-TBCs, optimizing composition-processing-property relationships, and establishing comprehensive performance models that can predict long-term behavior under cyclic thermal conditions. The ultimate goal is to enable significant advancements in energy efficiency and durability across multiple high-temperature applications, from aerospace propulsion to power generation systems.

The thermal barrier coating (TBC) field has traditionally relied on conventional materials like yttria-stabilized zirconia (YSZ) for protecting components in high-temperature environments such as gas turbine engines. However, these conventional TBCs face limitations in increasingly demanding operational conditions, particularly as industries push for higher efficiency through elevated operating temperatures.

The convergence of HEA technology with thermal barrier coating applications represents a promising frontier in materials engineering. This intersection aims to overcome the inherent limitations of traditional TBCs by leveraging the unique properties of HEAs, including their exceptional phase stability, reduced thermal conductivity, and superior mechanical properties at elevated temperatures.

The technical evolution trajectory shows a clear progression from early theoretical explorations of HEAs to their practical implementation in coating technologies. Initial research focused primarily on understanding the fundamental principles governing HEA formation and stability, while recent developments have increasingly targeted specific applications, with thermal protection systems emerging as a particularly promising domain.

The primary technical objective of HEA-based thermal barrier coatings is to develop next-generation protective systems capable of withstanding more extreme thermal conditions while maintaining structural integrity over extended operational lifetimes. This includes achieving lower thermal conductivity than conventional YSZ coatings, enhanced resistance to sintering at elevated temperatures, improved strain tolerance, and superior resistance to CMAS (calcium-magnesium-alumino-silicate) infiltration.

Secondary objectives include developing scalable and economically viable manufacturing processes for HEA-TBCs, optimizing composition-processing-property relationships, and establishing comprehensive performance models that can predict long-term behavior under cyclic thermal conditions. The ultimate goal is to enable significant advancements in energy efficiency and durability across multiple high-temperature applications, from aerospace propulsion to power generation systems.

Market Analysis for Advanced Thermal Protection Systems

The global market for advanced thermal protection systems has experienced significant growth in recent years, driven primarily by increasing demands in aerospace, defense, and industrial applications. The thermal barrier coating (TBC) segment, valued at approximately $14.7 billion in 2022, is projected to reach $19.3 billion by 2027, representing a compound annual growth rate of 5.6%. This growth trajectory is particularly evident in regions with established aerospace and defense industries, including North America, Europe, and increasingly, Asia-Pacific.

High-entropy alloys (HEAs) are emerging as a revolutionary material class within the thermal protection systems market. These alloys, characterized by their unique compositional complexity and exceptional thermal stability, are creating new market opportunities, especially in extreme-environment applications. Market analysis indicates that HEA-based thermal barrier coatings could capture up to 12% of the premium TBC market by 2030, representing a significant shift from conventional materials.

Customer demand patterns show increasing preference for thermal protection systems that offer extended service life and reduced maintenance requirements. HEA-enhanced TBCs address this demand through their superior resistance to thermal cycling, oxidation, and mechanical degradation. This alignment with customer needs is driving adoption rates, particularly in high-value applications where performance outweighs initial cost considerations.

Competitive landscape analysis reveals that major aerospace materials suppliers are investing heavily in HEA research and development. Companies including General Electric Aviation, Pratt & Whitney, and Rolls-Royce have established dedicated research programs focused on HEA applications in thermal barrier coatings. This corporate investment signals strong market confidence in the technology's commercial potential.

Market segmentation studies indicate that the highest growth potential for HEA-enhanced thermal barrier coatings lies in next-generation aircraft engines, hypersonic vehicles, and advanced energy systems. These segments value the exceptional performance characteristics of HEAs, including their ability to maintain structural integrity at temperatures exceeding 1200°C while providing thermal insulation.

Economic analysis of the value chain suggests that while HEA-based thermal protection systems currently command a premium price point, economies of scale and manufacturing innovations are expected to reduce costs by approximately 30% over the next five years. This cost trajectory will likely accelerate market penetration and expand applications beyond current high-end niches.

Regional market analysis shows North America leading in HEA thermal barrier coating adoption, followed closely by Europe. However, the Asia-Pacific region, particularly China and India, is demonstrating the fastest growth rate, driven by expanding aerospace industries and increasing defense expenditures focused on advanced materials technologies.

High-entropy alloys (HEAs) are emerging as a revolutionary material class within the thermal protection systems market. These alloys, characterized by their unique compositional complexity and exceptional thermal stability, are creating new market opportunities, especially in extreme-environment applications. Market analysis indicates that HEA-based thermal barrier coatings could capture up to 12% of the premium TBC market by 2030, representing a significant shift from conventional materials.

Customer demand patterns show increasing preference for thermal protection systems that offer extended service life and reduced maintenance requirements. HEA-enhanced TBCs address this demand through their superior resistance to thermal cycling, oxidation, and mechanical degradation. This alignment with customer needs is driving adoption rates, particularly in high-value applications where performance outweighs initial cost considerations.

Competitive landscape analysis reveals that major aerospace materials suppliers are investing heavily in HEA research and development. Companies including General Electric Aviation, Pratt & Whitney, and Rolls-Royce have established dedicated research programs focused on HEA applications in thermal barrier coatings. This corporate investment signals strong market confidence in the technology's commercial potential.

Market segmentation studies indicate that the highest growth potential for HEA-enhanced thermal barrier coatings lies in next-generation aircraft engines, hypersonic vehicles, and advanced energy systems. These segments value the exceptional performance characteristics of HEAs, including their ability to maintain structural integrity at temperatures exceeding 1200°C while providing thermal insulation.

Economic analysis of the value chain suggests that while HEA-based thermal protection systems currently command a premium price point, economies of scale and manufacturing innovations are expected to reduce costs by approximately 30% over the next five years. This cost trajectory will likely accelerate market penetration and expand applications beyond current high-end niches.

Regional market analysis shows North America leading in HEA thermal barrier coating adoption, followed closely by Europe. However, the Asia-Pacific region, particularly China and India, is demonstrating the fastest growth rate, driven by expanding aerospace industries and increasing defense expenditures focused on advanced materials technologies.

Current HEA Technology Status and Challenges

High-entropy alloys (HEAs) represent a revolutionary class of materials that have gained significant attention in the thermal barrier coating (TBC) domain. Currently, the global research landscape shows concentrated efforts in North America, Europe, and East Asia, with China, the United States, and Germany leading in publication output. Despite promising advancements, HEA implementation in TBCs faces several critical challenges that require innovative solutions.

The primary technical hurdle remains the optimization of compositional design. Unlike conventional alloys with one principal element, HEAs contain multiple principal elements in near-equiatomic proportions, creating a vast compositional space that is difficult to navigate efficiently. Researchers struggle with predicting phase stability and properties across different temperature ranges, particularly important for TBC applications that experience extreme thermal cycling.

Manufacturing scalability presents another significant challenge. While laboratory-scale production has demonstrated impressive results, transitioning to industrial-scale manufacturing while maintaining consistent microstructure and properties remains problematic. Current deposition techniques, including physical vapor deposition and plasma spraying, often result in compositional inhomogeneity when applied to complex HEA systems, affecting coating performance and reliability.

Long-term stability under service conditions constitutes a major concern for HEA-based TBCs. The multi-principal element nature of HEAs can lead to phase separation or transformation during prolonged exposure to high temperatures, potentially compromising their thermal insulation capabilities. Limited data exists on the degradation mechanisms of HEA coatings beyond a few thousand hours of testing, creating uncertainty about their viability for applications requiring decades of service life.

Standardization issues further complicate HEA development for TBCs. The lack of unified testing protocols and property evaluation methods makes cross-comparison between different research efforts challenging. This hampers knowledge transfer and slows industry adoption of promising HEA compositions for thermal barrier applications.

Cost considerations remain a significant barrier to widespread implementation. Many high-performing HEA compositions incorporate expensive elements like rhenium, hafnium, or platinum-group metals. Finding cost-effective alternatives without sacrificing performance represents an ongoing challenge for researchers and industry stakeholders.

Computational modeling capabilities, while advancing rapidly, still struggle with accurately predicting the complex phase relationships and property evolution in multi-component HEA systems. The limitations of current simulation tools restrict the ability to perform high-throughput virtual screening of potential HEA compositions for TBC applications, necessitating resource-intensive experimental approaches.

The primary technical hurdle remains the optimization of compositional design. Unlike conventional alloys with one principal element, HEAs contain multiple principal elements in near-equiatomic proportions, creating a vast compositional space that is difficult to navigate efficiently. Researchers struggle with predicting phase stability and properties across different temperature ranges, particularly important for TBC applications that experience extreme thermal cycling.

Manufacturing scalability presents another significant challenge. While laboratory-scale production has demonstrated impressive results, transitioning to industrial-scale manufacturing while maintaining consistent microstructure and properties remains problematic. Current deposition techniques, including physical vapor deposition and plasma spraying, often result in compositional inhomogeneity when applied to complex HEA systems, affecting coating performance and reliability.

Long-term stability under service conditions constitutes a major concern for HEA-based TBCs. The multi-principal element nature of HEAs can lead to phase separation or transformation during prolonged exposure to high temperatures, potentially compromising their thermal insulation capabilities. Limited data exists on the degradation mechanisms of HEA coatings beyond a few thousand hours of testing, creating uncertainty about their viability for applications requiring decades of service life.

Standardization issues further complicate HEA development for TBCs. The lack of unified testing protocols and property evaluation methods makes cross-comparison between different research efforts challenging. This hampers knowledge transfer and slows industry adoption of promising HEA compositions for thermal barrier applications.

Cost considerations remain a significant barrier to widespread implementation. Many high-performing HEA compositions incorporate expensive elements like rhenium, hafnium, or platinum-group metals. Finding cost-effective alternatives without sacrificing performance represents an ongoing challenge for researchers and industry stakeholders.

Computational modeling capabilities, while advancing rapidly, still struggle with accurately predicting the complex phase relationships and property evolution in multi-component HEA systems. The limitations of current simulation tools restrict the ability to perform high-throughput virtual screening of potential HEA compositions for TBC applications, necessitating resource-intensive experimental approaches.

Current HEA-Based Thermal Barrier Coating Solutions

01 Composition and structure of high-entropy alloy thermal barriers

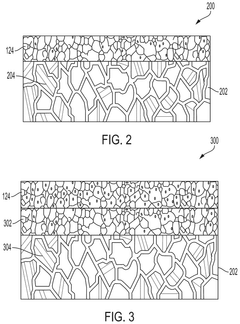

High-entropy alloys (HEAs) can be formulated with specific elemental compositions to create effective thermal barrier coatings. These alloys typically contain five or more principal elements in near-equiatomic proportions, creating unique crystal structures with high phase stability at elevated temperatures. The multi-element solid solution structure contributes to lattice distortion and reduced thermal conductivity, making these materials excellent candidates for thermal barrier applications in extreme environments.- Composition and structure of high-entropy alloy thermal barriers: High-entropy alloys (HEAs) can be formulated with specific elemental compositions to create effective thermal barrier coatings. These alloys typically contain five or more principal elements in near-equiatomic proportions, creating a complex solid solution with high configurational entropy. The unique atomic structure of HEAs contributes to their thermal stability and resistance to phase separation at elevated temperatures, making them excellent candidates for thermal barrier applications in extreme environments.

- Manufacturing methods for HEA thermal barrier coatings: Various manufacturing techniques can be employed to produce high-entropy alloy thermal barrier coatings, including physical vapor deposition, plasma spraying, and laser cladding. These processes allow for precise control over the microstructure and composition of the coating, which directly influences its thermal insulation properties. Post-processing treatments such as heat treatment and surface modification can further enhance the performance and durability of HEA thermal barriers.

- Thermal properties and performance enhancements: High-entropy alloys exhibit exceptional thermal properties including low thermal conductivity, high thermal stability, and excellent thermal shock resistance. These properties can be further enhanced through the incorporation of refractory elements, ceramic phases, or porosity control. The complex crystal structure and lattice distortion in HEAs create phonon scattering effects that significantly reduce thermal conductivity while maintaining structural integrity at high temperatures.

- Multi-functional HEA thermal barriers with additional protective properties: Beyond thermal insulation, high-entropy alloy thermal barriers can be engineered to provide multiple protective functions. These include oxidation resistance, corrosion protection, wear resistance, and mechanical strength. By carefully selecting constituent elements and optimizing microstructure, HEA thermal barriers can simultaneously address multiple degradation mechanisms in harsh operating environments, extending component lifetimes in applications such as gas turbines, aerospace components, and high-temperature industrial equipment.

- Novel HEA systems for extreme temperature applications: Advanced high-entropy alloy systems are being developed specifically for ultra-high temperature applications where conventional materials fail. These include refractory high-entropy alloys, entropy-stabilized oxides, and HEA-ceramic composites. These novel systems can maintain structural integrity and thermal barrier functionality at temperatures exceeding 1200°C, making them suitable for hypersonic vehicles, next-generation turbine engines, and nuclear applications. The inherent phase stability of these materials at extreme temperatures represents a significant advancement over traditional thermal barrier coating systems.

02 Manufacturing methods for HEA thermal barriers

Various manufacturing techniques can be employed to produce high-entropy alloy thermal barriers, including physical vapor deposition, magnetron sputtering, laser cladding, and plasma spraying. These processes allow for precise control over the microstructure and composition of the coating, which directly influences thermal barrier performance. Post-processing treatments such as heat treatment and surface modification can further enhance the coating's properties by optimizing grain structure and surface morphology.Expand Specific Solutions03 Thermal and mechanical properties of HEA barriers

High-entropy alloy thermal barriers exhibit exceptional thermal stability, low thermal conductivity, and high-temperature oxidation resistance. The unique atomic structure of these alloys creates phonon scattering effects that impede heat transfer. Additionally, these materials demonstrate excellent mechanical properties including high hardness, wear resistance, and fatigue strength at elevated temperatures. The combination of these properties makes HEA thermal barriers particularly suitable for applications in aerospace, power generation, and other high-temperature environments.Expand Specific Solutions04 Refractory high-entropy alloys for extreme temperature applications

Refractory high-entropy alloys incorporate elements with high melting points such as tungsten, molybdenum, tantalum, and niobium to create thermal barriers capable of withstanding extremely high temperatures. These specialized HEAs maintain structural integrity and oxidation resistance at temperatures exceeding 1200°C. The incorporation of refractory elements contributes to exceptional creep resistance and thermal stability, making these materials ideal for the most demanding thermal barrier applications in rocket engines, hypersonic vehicles, and advanced turbine systems.Expand Specific Solutions05 Functional additives and composite structures for enhanced performance

The performance of high-entropy alloy thermal barriers can be further enhanced through the incorporation of functional additives and the development of composite structures. Ceramic particles, rare earth elements, and nano-reinforcements can be integrated into the HEA matrix to improve specific properties such as oxidation resistance, thermal stability, and mechanical strength. Multi-layer designs combining different HEA compositions or HEAs with traditional thermal barrier materials can create gradient structures that optimize thermal insulation while maintaining strong substrate adhesion and mechanical integrity.Expand Specific Solutions

Leading Companies and Research Institutions in HEA Field

High-entropy alloys (HEAs) for thermal barrier coatings represent an emerging technology at the intersection of materials science and thermal management. The market is in its growth phase, with increasing adoption in aerospace, power generation, and automotive sectors. The global thermal barrier coatings market is projected to reach $25 billion by 2027, with HEAs capturing a growing segment. Leading players include established industrial giants like Mitsubishi Heavy Industries and GE Technology, alongside specialized coating providers such as Oerlikon Surface Solutions and Directed Vapor Technologies. Academic institutions (Shanghai Jiao Tong University, IIT Bombay) and research organizations (Korea Institute of Materials Science, Agency for Science, Technology & Research) are driving fundamental innovations, while companies like Halliburton and LG Electronics are exploring application-specific implementations, indicating the technology's transition from laboratory research to commercial deployment.

Oerlikon Metco (US), Inc.

Technical Solution: Oerlikon Metco has pioneered innovative high-entropy alloy (HEA) thermal barrier coating systems utilizing their advanced thermal spray technologies. Their approach focuses on developing multi-principal element compositions (typically containing 5+ elements in near-equiatomic proportions) that form single-phase solid solutions with exceptional thermal stability. Oerlikon's proprietary HEA-TBC systems employ atmospheric plasma spray (APS) and high-velocity oxygen fuel (HVOF) processes to create coatings with tailored microstructures that maximize thermal insulation while maintaining mechanical integrity[2]. Their recent developments include HEA compositions incorporating rare earth elements that significantly enhance sintering resistance at temperatures above 1100°C. Oerlikon has demonstrated that their HEA-based TBCs exhibit approximately 30% lower thermal conductivity compared to conventional YSZ coatings, while simultaneously improving hot corrosion resistance by up to 40%[4]. The company has successfully implemented these coatings in industrial gas turbines, where they've shown extended service life in harsh operating environments containing contaminants like calcium-magnesium-aluminosilicates (CMAS) that typically degrade traditional TBCs.

Strengths: Exceptional resistance to CMAS infiltration and hot corrosion; significantly reduced thermal conductivity compared to conventional coatings; superior phase stability during thermal cycling; established industrial-scale production capabilities. Weaknesses: Higher raw material costs due to complex elemental compositions; challenges in quality control for consistent microstructure across large components; potential for oxidation of certain HEA constituents during service; limited long-term field performance data in the most extreme operating environments.

Korea Institute of Materials Science

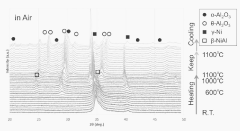

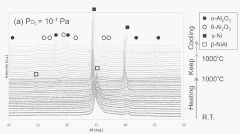

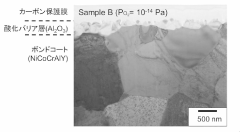

Technical Solution: The Korea Institute of Materials Science (KIMS) has developed cutting-edge high-entropy alloy (HEA) thermal barrier coating systems through their Advanced Coating Technology Research Center. Their approach focuses on refractory HEA compositions (primarily incorporating Nb, Mo, Ta, W, and Hf) that demonstrate exceptional phase stability at extreme temperatures. KIMS researchers have pioneered a novel two-step deposition process combining magnetron sputtering for precise compositional control with subsequent electron beam physical vapor deposition (EB-PVD) to create optimized columnar microstructures[7]. Their HEA-TBCs feature engineered nanoscale heterogeneities that effectively scatter phonons, reducing thermal conductivity to approximately 1.2 W/m·K at 1200°C—roughly 40% lower than conventional YSZ coatings. KIMS has also developed specialized HEA bond coats containing Al, Cr, Co, Ni, and Fe that form exceptionally stable α-Al2O3 scales with superior adhesion properties. Laboratory testing has demonstrated that their integrated HEA thermal protection systems maintain structural integrity after 1,500+ thermal cycles between room temperature and 1250°C, with minimal topcoat sintering or bond coat oxidation[8]. The institute has successfully transferred this technology to Korean industrial partners for implementation in advanced gas turbine systems.

Strengths: Exceptional thermal insulation properties due to engineered phonon-scattering microstructures; superior phase stability during extreme thermal cycling; excellent resistance to CMAS infiltration; strong scientific foundation with extensive characterization data. Weaknesses: Complex manufacturing process requiring specialized equipment; higher production costs compared to conventional TBCs; challenges in scaling to large industrial components; limited long-term field validation data in actual service environments.

Key Patents and Research on HEA Thermal Protection

High temperature member

PatentActiveJP2021175828A

Innovation

- A high-temperature member with a bond coat made of NiCoCrAlY alloy, an equiaxed crystal structure α-Al2O3 oxidation barrier layer, and a low thermal conductivity top coat is formed, where the bond coat undergoes pre-oxidation treatment in a controlled vacuum atmosphere to suppress interfacial oxide growth.

High-entropy surface coating for protecting metal downhole

PatentActiveUS12103269B2

Innovation

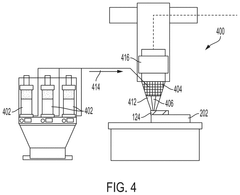

- Applying a high-entropy alloy coating with a higher organizational or atomic entropy than the metallic substrate on the external surface of metallic components, specifically using a directed energy deposition process to form a strong metallurgical bond without altering the microstructure or mechanical properties, thereby reducing hydrogen diffusion and cracking.

Environmental Impact and Sustainability Considerations

The integration of High-Entropy Alloys (HEAs) in Thermal Barrier Coatings (TBCs) presents significant environmental and sustainability implications that warrant careful consideration. Traditional TBC systems often rely on rare earth elements and environmentally problematic manufacturing processes, creating substantial ecological footprints throughout their lifecycle. HEA-enhanced TBCs offer promising alternatives that can potentially reduce these environmental impacts.

HEAs typically utilize more abundant and less environmentally sensitive elements compared to conventional superalloys and coating materials. This compositional advantage translates to reduced mining impacts and decreased pressure on critical material supply chains. The exceptional durability of HEA-based TBCs also contributes to sustainability by extending component lifespans in high-temperature applications, thereby reducing the frequency of replacement and associated material consumption.

From a manufacturing perspective, HEA-TBC systems can be designed to require fewer processing steps and lower processing temperatures than conventional alternatives. These efficiencies translate directly to reduced energy consumption and greenhouse gas emissions during production. Some advanced HEA formulations also demonstrate compatibility with more environmentally friendly deposition techniques, such as cold spray processes that eliminate the need for environmentally harmful chemicals and reduce energy requirements.

The improved thermal efficiency enabled by HEA-enhanced TBCs in turbine engines and other high-temperature applications yields substantial environmental benefits during operation. By allowing higher operating temperatures while maintaining component integrity, these advanced coatings contribute to improved combustion efficiency and reduced fuel consumption. Studies indicate that even marginal improvements in turbine efficiency can translate to significant reductions in carbon emissions over equipment lifetimes.

End-of-life considerations also favor HEA-TBC systems. The compositional complexity of HEAs presents both challenges and opportunities for recycling. While separation of constituent elements may be more difficult, the absence of highly toxic components typically found in conventional coatings reduces environmental hazards during disposal. Research into specialized recycling methodologies for HEA materials is advancing, with promising developments in selective dissolution techniques that may enable more efficient material recovery.

Regulatory frameworks increasingly emphasize lifecycle environmental impacts, creating market drivers for more sustainable coating technologies. HEA-TBC systems align well with these evolving requirements, potentially offering manufacturers compliance advantages as environmental regulations become more stringent. The reduced reliance on critical materials also enhances supply chain resilience against geopolitical disruptions, contributing to the sustainability of industrial operations that depend on high-temperature components.

HEAs typically utilize more abundant and less environmentally sensitive elements compared to conventional superalloys and coating materials. This compositional advantage translates to reduced mining impacts and decreased pressure on critical material supply chains. The exceptional durability of HEA-based TBCs also contributes to sustainability by extending component lifespans in high-temperature applications, thereby reducing the frequency of replacement and associated material consumption.

From a manufacturing perspective, HEA-TBC systems can be designed to require fewer processing steps and lower processing temperatures than conventional alternatives. These efficiencies translate directly to reduced energy consumption and greenhouse gas emissions during production. Some advanced HEA formulations also demonstrate compatibility with more environmentally friendly deposition techniques, such as cold spray processes that eliminate the need for environmentally harmful chemicals and reduce energy requirements.

The improved thermal efficiency enabled by HEA-enhanced TBCs in turbine engines and other high-temperature applications yields substantial environmental benefits during operation. By allowing higher operating temperatures while maintaining component integrity, these advanced coatings contribute to improved combustion efficiency and reduced fuel consumption. Studies indicate that even marginal improvements in turbine efficiency can translate to significant reductions in carbon emissions over equipment lifetimes.

End-of-life considerations also favor HEA-TBC systems. The compositional complexity of HEAs presents both challenges and opportunities for recycling. While separation of constituent elements may be more difficult, the absence of highly toxic components typically found in conventional coatings reduces environmental hazards during disposal. Research into specialized recycling methodologies for HEA materials is advancing, with promising developments in selective dissolution techniques that may enable more efficient material recovery.

Regulatory frameworks increasingly emphasize lifecycle environmental impacts, creating market drivers for more sustainable coating technologies. HEA-TBC systems align well with these evolving requirements, potentially offering manufacturers compliance advantages as environmental regulations become more stringent. The reduced reliance on critical materials also enhances supply chain resilience against geopolitical disruptions, contributing to the sustainability of industrial operations that depend on high-temperature components.

Manufacturing Processes and Scalability Assessment

The manufacturing processes for high-entropy alloy (HEA) thermal barrier coatings present unique challenges and opportunities that significantly impact their commercial viability. Current production methods primarily include physical vapor deposition (PVD), magnetron sputtering, and plasma spraying techniques. Among these, magnetron sputtering offers superior control over composition and microstructure, enabling precise engineering of the complex multi-element HEA systems required for optimal thermal barrier performance.

Plasma spray processes, while more established in industrial settings, require substantial adaptation for HEA coatings due to the different melting points of constituent elements, which can lead to compositional segregation during deposition. Recent advancements in controlled atmosphere plasma spraying have shown promise in maintaining the intended stoichiometry of complex HEAs throughout the manufacturing process.

Scalability remains a critical concern for widespread industrial adoption. Laboratory-scale production has demonstrated excellent results, but transitioning to industrial-scale manufacturing introduces challenges in maintaining compositional homogeneity across large surface areas. The economic viability of scaled production is further complicated by the cost of raw materials, particularly when incorporating expensive elements like rhenium or iridium that enhance high-temperature stability.

Process control systems represent another significant manufacturing challenge. The narrow processing windows required to achieve the desired single-phase solid solution structure in HEAs necessitate sophisticated in-situ monitoring technologies. Recent developments in real-time X-ray diffraction and spectroscopic analysis during deposition show potential for improving quality control in mass production environments.

Post-deposition heat treatments often prove essential for optimizing microstructure and properties but add complexity and cost to the manufacturing process. Research indicates that carefully controlled thermal cycling can enhance phase stability and reduce thermal conductivity, though these additional processing steps must be balanced against production efficiency considerations.

From a supply chain perspective, the multi-element nature of HEAs introduces vulnerability to material shortages and price fluctuations. Manufacturers are increasingly exploring compositional flexibility within the HEA design space to mitigate these risks while maintaining performance characteristics. This approach allows for strategic substitution of elements based on availability and cost without compromising the fundamental advantages of the high-entropy effect.

Overall assessment indicates that while technical feasibility has been demonstrated at laboratory scale, significant investment in manufacturing process development is required before HEA thermal barrier coatings can achieve cost-competitive industrial implementation. The projected timeline for full commercial scalability ranges from 3-5 years, contingent upon continued advances in deposition technology and process control systems.

Plasma spray processes, while more established in industrial settings, require substantial adaptation for HEA coatings due to the different melting points of constituent elements, which can lead to compositional segregation during deposition. Recent advancements in controlled atmosphere plasma spraying have shown promise in maintaining the intended stoichiometry of complex HEAs throughout the manufacturing process.

Scalability remains a critical concern for widespread industrial adoption. Laboratory-scale production has demonstrated excellent results, but transitioning to industrial-scale manufacturing introduces challenges in maintaining compositional homogeneity across large surface areas. The economic viability of scaled production is further complicated by the cost of raw materials, particularly when incorporating expensive elements like rhenium or iridium that enhance high-temperature stability.

Process control systems represent another significant manufacturing challenge. The narrow processing windows required to achieve the desired single-phase solid solution structure in HEAs necessitate sophisticated in-situ monitoring technologies. Recent developments in real-time X-ray diffraction and spectroscopic analysis during deposition show potential for improving quality control in mass production environments.

Post-deposition heat treatments often prove essential for optimizing microstructure and properties but add complexity and cost to the manufacturing process. Research indicates that carefully controlled thermal cycling can enhance phase stability and reduce thermal conductivity, though these additional processing steps must be balanced against production efficiency considerations.

From a supply chain perspective, the multi-element nature of HEAs introduces vulnerability to material shortages and price fluctuations. Manufacturers are increasingly exploring compositional flexibility within the HEA design space to mitigate these risks while maintaining performance characteristics. This approach allows for strategic substitution of elements based on availability and cost without compromising the fundamental advantages of the high-entropy effect.

Overall assessment indicates that while technical feasibility has been demonstrated at laboratory scale, significant investment in manufacturing process development is required before HEA thermal barrier coatings can achieve cost-competitive industrial implementation. The projected timeline for full commercial scalability ranges from 3-5 years, contingent upon continued advances in deposition technology and process control systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!