Role of High-Entropy Alloy Coatings in Tribological Applications

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

High-Entropy Alloy Coating Evolution and Objectives

High-entropy alloy (HEA) coatings represent a revolutionary advancement in materials science, emerging from the broader development of high-entropy alloys first conceptualized in the early 2000s. These novel materials, composed of five or more principal elements in near-equiatomic proportions, have evolved from theoretical concepts to practical applications over the past two decades, particularly in tribological contexts where wear, friction, and lubrication are critical considerations.

The evolution of HEA coatings began with fundamental research into multi-principal element alloys, which demonstrated exceptional mechanical properties including high hardness, excellent wear resistance, and superior thermal stability compared to conventional alloys. This initial research phase focused primarily on bulk HEAs, with coating applications emerging as researchers recognized the potential to apply these beneficial properties to surface engineering.

By the mid-2010s, various deposition techniques including magnetron sputtering, laser cladding, and thermal spraying were adapted specifically for HEA coating production, marking a significant technological milestone. These advancements enabled the precise control of coating microstructure and composition, facilitating the tailoring of tribological properties for specific applications.

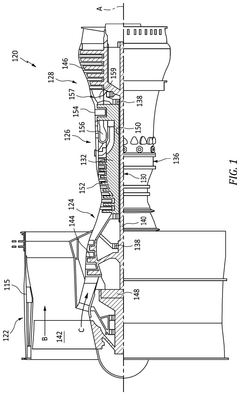

The tribological applications of HEA coatings have expanded considerably, from initial implementations in cutting tools and aerospace components to more diverse applications in automotive parts, biomedical implants, and energy systems. This expansion reflects growing recognition of their superior performance in extreme environments characterized by high temperatures, corrosive media, and severe mechanical stresses.

Current research objectives in HEA coating development focus on several key areas. First, establishing comprehensive structure-property relationships to enable predictive design rather than empirical development. Second, optimizing deposition parameters to enhance coating adhesion, density, and homogeneity while minimizing production costs. Third, exploring novel element combinations and microstructural designs to further improve tribological performance under specific operating conditions.

Long-term objectives include the development of computational models capable of accurately predicting HEA coating performance, standardization of testing methodologies to facilitate industry adoption, and scaling up production techniques for commercial viability. Additionally, researchers aim to integrate HEA coatings with other advanced materials and technologies, such as self-healing capabilities or smart sensing functions, to create multifunctional tribological systems.

The ultimate goal is to establish HEA coatings as a mainstream solution for extreme tribological challenges, where conventional materials fail to deliver adequate performance, thereby extending component lifespans, reducing maintenance requirements, and improving overall system efficiency across multiple industries.

The evolution of HEA coatings began with fundamental research into multi-principal element alloys, which demonstrated exceptional mechanical properties including high hardness, excellent wear resistance, and superior thermal stability compared to conventional alloys. This initial research phase focused primarily on bulk HEAs, with coating applications emerging as researchers recognized the potential to apply these beneficial properties to surface engineering.

By the mid-2010s, various deposition techniques including magnetron sputtering, laser cladding, and thermal spraying were adapted specifically for HEA coating production, marking a significant technological milestone. These advancements enabled the precise control of coating microstructure and composition, facilitating the tailoring of tribological properties for specific applications.

The tribological applications of HEA coatings have expanded considerably, from initial implementations in cutting tools and aerospace components to more diverse applications in automotive parts, biomedical implants, and energy systems. This expansion reflects growing recognition of their superior performance in extreme environments characterized by high temperatures, corrosive media, and severe mechanical stresses.

Current research objectives in HEA coating development focus on several key areas. First, establishing comprehensive structure-property relationships to enable predictive design rather than empirical development. Second, optimizing deposition parameters to enhance coating adhesion, density, and homogeneity while minimizing production costs. Third, exploring novel element combinations and microstructural designs to further improve tribological performance under specific operating conditions.

Long-term objectives include the development of computational models capable of accurately predicting HEA coating performance, standardization of testing methodologies to facilitate industry adoption, and scaling up production techniques for commercial viability. Additionally, researchers aim to integrate HEA coatings with other advanced materials and technologies, such as self-healing capabilities or smart sensing functions, to create multifunctional tribological systems.

The ultimate goal is to establish HEA coatings as a mainstream solution for extreme tribological challenges, where conventional materials fail to deliver adequate performance, thereby extending component lifespans, reducing maintenance requirements, and improving overall system efficiency across multiple industries.

Tribological Market Demand Analysis

The tribological market is experiencing significant growth driven by increasing demands across multiple industrial sectors. The global tribology market, encompassing lubricants, coatings, and related technologies, is projected to reach $24.5 billion by 2025, growing at a CAGR of 3.5%. This growth is primarily fueled by the automotive, aerospace, and industrial manufacturing sectors, where the need for enhanced wear resistance and reduced friction is paramount.

High-Entropy Alloy (HEA) coatings represent an emerging segment within this market, addressing critical challenges in extreme operating conditions. Industries are increasingly seeking materials that can withstand high temperatures, corrosive environments, and heavy mechanical loads while maintaining structural integrity and performance. Traditional coatings often fail under these demanding conditions, creating a substantial market gap that HEA coatings are positioned to fill.

The aerospace industry demonstrates particularly strong demand, with requirements for components that can withstand extreme temperatures and mechanical stress in turbine engines and landing gear systems. Market research indicates that aerospace tribological applications alone account for approximately 18% of the specialty coatings market, with a growing portion allocated to advanced solutions like HEAs.

Similarly, the automotive sector shows increasing interest in HEA coatings for engine components, transmission systems, and brake mechanisms. As vehicle manufacturers push toward higher efficiency and extended component lifespans, the demand for superior tribological solutions continues to rise. This sector's tribological coating demand is growing at 4.2% annually, outpacing the overall market.

Energy production represents another significant market opportunity, particularly in renewable energy systems. Wind turbines, for instance, require exceptional wear resistance in gearboxes and bearings, creating a specialized niche for HEA coatings. The renewable energy sector's demand for advanced tribological solutions is growing at 5.7% annually, reflecting the rapid expansion of this industry.

Manufacturing equipment represents a substantial market segment, with cutting tools, dies, and high-wear components requiring increasingly sophisticated surface treatments. The industrial machinery sector accounts for 27% of the total tribological coatings market, with specialized applications showing even stronger growth trajectories.

Market analysis reveals a clear trend toward customized tribological solutions rather than one-size-fits-all approaches. End users increasingly demand coatings tailored to specific operating conditions, creating opportunities for HEA technologies that can be precisely engineered for particular applications. This shift toward application-specific solutions is expected to accelerate, with the customized coatings segment growing at 6.3% annually.

High-Entropy Alloy (HEA) coatings represent an emerging segment within this market, addressing critical challenges in extreme operating conditions. Industries are increasingly seeking materials that can withstand high temperatures, corrosive environments, and heavy mechanical loads while maintaining structural integrity and performance. Traditional coatings often fail under these demanding conditions, creating a substantial market gap that HEA coatings are positioned to fill.

The aerospace industry demonstrates particularly strong demand, with requirements for components that can withstand extreme temperatures and mechanical stress in turbine engines and landing gear systems. Market research indicates that aerospace tribological applications alone account for approximately 18% of the specialty coatings market, with a growing portion allocated to advanced solutions like HEAs.

Similarly, the automotive sector shows increasing interest in HEA coatings for engine components, transmission systems, and brake mechanisms. As vehicle manufacturers push toward higher efficiency and extended component lifespans, the demand for superior tribological solutions continues to rise. This sector's tribological coating demand is growing at 4.2% annually, outpacing the overall market.

Energy production represents another significant market opportunity, particularly in renewable energy systems. Wind turbines, for instance, require exceptional wear resistance in gearboxes and bearings, creating a specialized niche for HEA coatings. The renewable energy sector's demand for advanced tribological solutions is growing at 5.7% annually, reflecting the rapid expansion of this industry.

Manufacturing equipment represents a substantial market segment, with cutting tools, dies, and high-wear components requiring increasingly sophisticated surface treatments. The industrial machinery sector accounts for 27% of the total tribological coatings market, with specialized applications showing even stronger growth trajectories.

Market analysis reveals a clear trend toward customized tribological solutions rather than one-size-fits-all approaches. End users increasingly demand coatings tailored to specific operating conditions, creating opportunities for HEA technologies that can be precisely engineered for particular applications. This shift toward application-specific solutions is expected to accelerate, with the customized coatings segment growing at 6.3% annually.

Current Status and Challenges in HEA Coating Technology

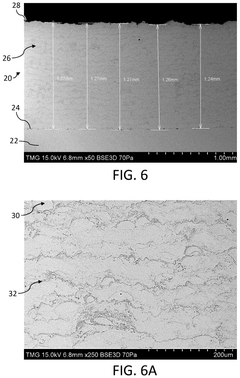

High-entropy alloy (HEA) coatings represent a significant advancement in materials science, with current global research efforts intensifying across North America, Europe, and Asia. These coatings, characterized by five or more principal elements in near-equiatomic proportions, have demonstrated remarkable tribological properties including superior wear resistance, high hardness, and excellent thermal stability. However, despite promising laboratory results, widespread industrial implementation remains limited due to several critical challenges.

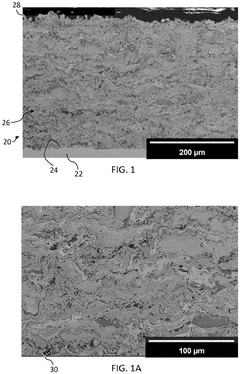

The fabrication of HEA coatings currently relies primarily on physical vapor deposition (PVD) techniques, particularly magnetron sputtering, which offers precise compositional control but suffers from low deposition rates and high equipment costs. Alternative methods such as thermal spraying and laser cladding show promise for thicker coatings but struggle with compositional homogeneity and phase stability. Electrodeposition has emerged as a cost-effective approach but faces challenges in achieving consistent multi-element deposition.

A fundamental challenge in HEA coating technology lies in the complex phase formation mechanisms, which remain incompletely understood. The interplay between entropy stabilization, enthalpy effects, and kinetic factors during deposition significantly impacts coating microstructure and properties. This knowledge gap hinders the development of predictive models for rational coating design, forcing researchers to rely heavily on empirical approaches.

Scalability presents another major obstacle, as most successful HEA coating demonstrations remain confined to laboratory scales. The transition to industrial-scale production faces issues of process reliability, coating uniformity over large areas, and cost-effectiveness. Additionally, quality control methods for these complex alloy systems are still evolving, with limited standardized testing protocols for tribological performance evaluation.

The long-term stability of HEA coatings under extreme service conditions represents a critical concern. While initial performance often appears promising, degradation mechanisms under combined thermal, mechanical, and chemical stresses require further investigation. This is particularly relevant for applications in aerospace, automotive, and energy sectors where component lifespans of decades may be expected.

Environmental considerations also pose challenges, as many current HEA coating formulations contain critical raw materials with supply chain vulnerabilities. The incorporation of toxic elements like chromium and cobalt in some compositions raises sustainability concerns, driving research toward more environmentally benign alternatives while maintaining performance standards.

Computational modeling capabilities, though advancing rapidly, still struggle to accurately predict the tribological behavior of these complex multi-element systems. The gap between theoretical predictions and experimental results highlights the need for improved simulation tools that can account for the unique characteristics of HEA coatings under various wear conditions.

The fabrication of HEA coatings currently relies primarily on physical vapor deposition (PVD) techniques, particularly magnetron sputtering, which offers precise compositional control but suffers from low deposition rates and high equipment costs. Alternative methods such as thermal spraying and laser cladding show promise for thicker coatings but struggle with compositional homogeneity and phase stability. Electrodeposition has emerged as a cost-effective approach but faces challenges in achieving consistent multi-element deposition.

A fundamental challenge in HEA coating technology lies in the complex phase formation mechanisms, which remain incompletely understood. The interplay between entropy stabilization, enthalpy effects, and kinetic factors during deposition significantly impacts coating microstructure and properties. This knowledge gap hinders the development of predictive models for rational coating design, forcing researchers to rely heavily on empirical approaches.

Scalability presents another major obstacle, as most successful HEA coating demonstrations remain confined to laboratory scales. The transition to industrial-scale production faces issues of process reliability, coating uniformity over large areas, and cost-effectiveness. Additionally, quality control methods for these complex alloy systems are still evolving, with limited standardized testing protocols for tribological performance evaluation.

The long-term stability of HEA coatings under extreme service conditions represents a critical concern. While initial performance often appears promising, degradation mechanisms under combined thermal, mechanical, and chemical stresses require further investigation. This is particularly relevant for applications in aerospace, automotive, and energy sectors where component lifespans of decades may be expected.

Environmental considerations also pose challenges, as many current HEA coating formulations contain critical raw materials with supply chain vulnerabilities. The incorporation of toxic elements like chromium and cobalt in some compositions raises sustainability concerns, driving research toward more environmentally benign alternatives while maintaining performance standards.

Computational modeling capabilities, though advancing rapidly, still struggle to accurately predict the tribological behavior of these complex multi-element systems. The gap between theoretical predictions and experimental results highlights the need for improved simulation tools that can account for the unique characteristics of HEA coatings under various wear conditions.

Current HEA Coating Solutions for Tribological Applications

01 Composition and structure of high-entropy alloy coatings

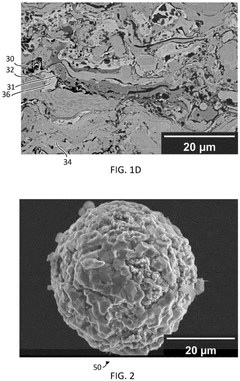

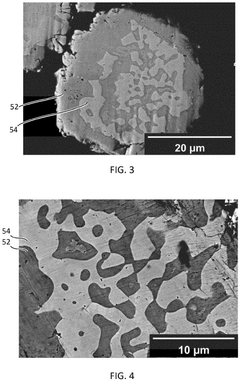

High-entropy alloy coatings are composed of multiple principal elements (typically five or more) in near-equiatomic proportions. This multi-element composition creates a high entropy of mixing, which promotes the formation of simple solid solution phases rather than complex intermetallic compounds. The unique structure of these coatings contributes to their exceptional properties, including high hardness, excellent wear resistance, and good thermal stability. The composition can be tailored to achieve specific performance characteristics for various applications.- Composition and structure of high-entropy alloy coatings: High-entropy alloy coatings are composed of multiple principal elements (typically five or more) in near-equiatomic proportions. This multi-element composition creates a high entropy of mixing, which promotes the formation of simple solid solution phases rather than complex intermetallic compounds. The unique structure of these coatings contributes to their exceptional properties, including high hardness, excellent wear resistance, and superior corrosion resistance. The composition can be tailored to achieve specific performance requirements for various applications.

- Deposition methods for high-entropy alloy coatings: Various deposition techniques are employed to fabricate high-entropy alloy coatings, including magnetron sputtering, laser cladding, thermal spraying, and electrodeposition. Each method offers distinct advantages in terms of coating quality, adhesion, thickness control, and microstructure development. Magnetron sputtering allows for precise composition control and dense coatings, while laser cladding provides thick coatings with metallurgical bonding to the substrate. Thermal spraying offers cost-effective solutions for large-area applications, and electrodeposition enables coating of complex geometries at relatively low temperatures.

- Performance enhancement and property optimization: The performance of high-entropy alloy coatings can be enhanced through various strategies, including heat treatment, addition of reinforcing phases, and microstructure control. Post-deposition heat treatments can promote phase transformation, grain refinement, and stress relief, leading to improved mechanical properties. Incorporation of ceramic particles, carbon nanotubes, or other reinforcing phases can significantly enhance hardness, wear resistance, and thermal stability. Optimization of processing parameters allows for tailored microstructures that balance strength, ductility, and other functional properties for specific applications.

- Corrosion and oxidation resistance mechanisms: High-entropy alloy coatings exhibit exceptional corrosion and oxidation resistance due to several mechanisms. The cocktail effect from multiple elements creates a complex electrochemical environment that inhibits corrosion initiation. The sluggish diffusion effect in these alloys slows down the kinetics of corrosion and oxidation processes. Formation of stable passive films containing multiple metal oxides provides enhanced protection against aggressive environments. The lattice distortion caused by atoms of different sizes increases the energy barrier for diffusion of corrosive species, further improving resistance to environmental degradation.

- Applications and industrial implementation: High-entropy alloy coatings find applications across various industries due to their superior properties. In aerospace, they serve as thermal barrier coatings and wear-resistant surfaces for turbine components. In automotive applications, they enhance the durability of engine components and provide corrosion protection. For biomedical implants, specific compositions offer biocompatibility combined with mechanical strength. In energy sectors, these coatings protect components exposed to extreme environments in power generation systems. The industrial implementation involves scaling up production processes, quality control measures, and cost-effective solutions for widespread adoption of these advanced coating systems.

02 Deposition methods for high-entropy alloy coatings

Various deposition techniques can be employed to fabricate high-entropy alloy coatings, including magnetron sputtering, laser cladding, plasma spraying, and electrodeposition. Each method offers distinct advantages in terms of coating quality, adhesion, thickness control, and microstructure development. The processing parameters during deposition significantly influence the phase formation, grain size, and overall performance of the coatings. Advanced deposition methods allow for precise control over composition gradients and layered structures to optimize coating properties.Expand Specific Solutions03 Corrosion and oxidation resistance of high-entropy alloy coatings

High-entropy alloy coatings exhibit exceptional corrosion and oxidation resistance due to their unique microstructure and composition. The formation of stable passive films on the surface provides protection against aggressive environments. The cocktail effect from multiple elements contributes to enhanced electrochemical stability. These coatings can maintain their protective properties at elevated temperatures and in harsh chemical environments, making them suitable for applications in marine, chemical processing, and high-temperature industries.Expand Specific Solutions04 Mechanical properties and wear resistance of high-entropy alloy coatings

High-entropy alloy coatings demonstrate superior mechanical properties, including high hardness, excellent wear resistance, and good toughness. The solid solution strengthening and lattice distortion effects contribute to their enhanced mechanical performance. These coatings can withstand severe tribological conditions while maintaining structural integrity. The combination of hardness and toughness makes them ideal for protective coatings in applications subjected to mechanical wear, erosion, and impact loading.Expand Specific Solutions05 Functional applications of high-entropy alloy coatings

High-entropy alloy coatings find applications in various functional areas beyond traditional protective purposes. These include electromagnetic shielding, catalytic applications, biomedical implants, and thermal barrier coatings. The tunable properties of these coatings allow for customization to meet specific functional requirements. Some high-entropy alloy coatings also exhibit interesting magnetic, electrical, and thermal properties that can be exploited for specialized applications in electronics, energy conversion, and sensing technologies.Expand Specific Solutions

Leading Companies and Research Institutions in HEA Coatings

The high-entropy alloy (HEA) coatings market for tribological applications is in a growth phase, characterized by increasing research intensity and emerging commercial applications. The global market is expanding as industries seek advanced wear-resistant solutions, with projections indicating significant growth potential. Technologically, HEA coatings are transitioning from laboratory research to industrial implementation, with varying maturity levels across different players. Leading companies like Oerlikon Surface Solutions and Halliburton are developing commercial applications, while academic institutions such as McGill University and National Cheng Kung University are advancing fundamental research. Industrial players including Pratt & Whitney Canada and LG Electronics are exploring specialized applications, creating a competitive landscape balanced between established coating manufacturers and emerging technology developers.

Halliburton Energy Services, Inc.

Technical Solution: Halliburton Energy Services has pioneered the application of high-entropy alloy (HEA) coatings specifically for oil and gas drilling equipment operating in extreme tribological environments. Their proprietary HEA coating systems utilize a combination of transition metals (typically including Cr, Ni, Co, Fe) along with refractory elements (Mo, W, Nb) to create exceptionally wear-resistant surfaces for downhole tools. Halliburton employs both thermal spray and laser cladding deposition techniques to apply these multi-principal element coatings to drilling components that experience severe abrasive, erosive, and corrosive conditions. Their HEA coatings demonstrate superior performance in high-temperature, high-pressure environments with H2S and CO2 exposure. Testing has shown that Halliburton's HEA-coated drill bits and stabilizers exhibit 40-50% longer service life compared to conventional hard-facing materials. The company has developed specialized HEA compositions that maintain their tribological properties at temperatures exceeding 800°C while resisting sulfide stress cracking. Recent innovations include self-healing HEA coating variants that can partially restore damaged surfaces during operation through controlled oxidation mechanisms.

Strengths: Extensive field testing capabilities in actual downhole conditions; specialized compositions tailored for oil and gas tribological challenges; robust application methods suitable for large and complex components. Weaknesses: Higher initial cost compared to traditional hardfacing; potential for thermal mismatch with substrate materials in certain applications; limited standardization across different product lines.

Oerlikon Surface Solutions AG

Technical Solution: Oerlikon Surface Solutions AG has developed advanced high-entropy alloy (HEA) coating solutions specifically designed for extreme tribological applications. Their proprietary BALIQ™ technology utilizes physical vapor deposition (PVD) processes to create multi-element HEA coatings with exceptional wear resistance. These coatings typically contain 5-7 principal elements in near-equiatomic proportions, creating a single-phase solid solution with high configurational entropy. The company's HEA coatings demonstrate superior hardness (>25 GPa) and elastic modulus values while maintaining excellent thermal stability up to 1000°C. Their recent innovations include incorporating nitrogen into HEA structures to form high-entropy nitride coatings with enhanced tribological performance. Oerlikon's HEA coatings have shown up to 60% reduction in friction coefficients and 3-5 times longer service life compared to conventional coatings in high-temperature sliding wear applications. The company has successfully implemented these coatings in automotive components, cutting tools, and aerospace applications where extreme wear conditions prevail.

Strengths: Industry-leading PVD technology allowing precise control of coating composition and microstructure; extensive industrial application experience; comprehensive testing facilities for tribological performance validation. Weaknesses: Higher production costs compared to conventional coatings; limited thickness capability (typically <10μm) which may restrict applications requiring thicker protective layers.

Key Patents and Innovations in HEA Coating Technology

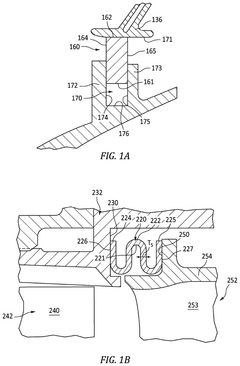

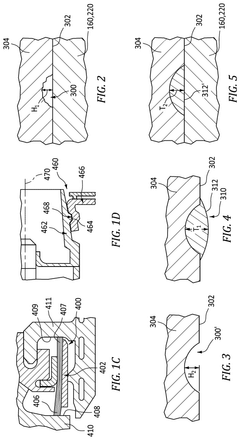

Seal with high entropy alloy coating

PatentPendingEP4474617A2

Innovation

- A high-entropy alloy (HEA) coating with specific atomic percentages of Al, Fe, Co, Cr, Mn, and Ni is applied using HVOF spraying, providing enhanced tribological performance and resistance to hot corrosion by forming a lubricious oxide layer.

High Entropy Alloy Repair of Nickel and Cobalt Superalloys

PatentPendingUS20240410312A1

Innovation

- A method involving the application of high entropy alloy (HEA) repair materials via high velocity oxy-fuel (HVOF) spray or other techniques to damaged nickel- or cobalt-based alloy components, providing a robust tribological interface with specific atomic compositions and surface finishing to enhance durability and resistance to corrosion and wear.

Environmental Impact and Sustainability Considerations

The environmental impact of High-Entropy Alloy (HEA) coatings in tribological applications represents a critical consideration in their development and implementation. These advanced materials offer significant sustainability advantages compared to traditional coating solutions. HEA coatings typically demonstrate exceptional durability and wear resistance, which directly translates to extended service life for components and reduced replacement frequency. This longevity contributes substantially to resource conservation and waste reduction across various industrial sectors.

From a manufacturing perspective, HEA coatings can be produced through relatively energy-efficient processes compared to some conventional coating technologies. Physical vapor deposition (PVD) and other modern deposition techniques used for HEA coatings can be optimized for lower energy consumption, particularly when compared to traditional thermal spray processes that require higher temperatures and energy inputs.

The composition flexibility of HEAs presents another environmental advantage. These alloys can be designed to minimize or eliminate environmentally harmful elements such as lead, cadmium, and chromium that are commonly found in traditional tribological coatings. This reduction in toxic elements improves workplace safety during manufacturing and reduces environmental contamination risks throughout the product lifecycle.

Life cycle assessment (LCA) studies indicate that the environmental footprint of HEA-coated components is often lower than conventional alternatives when considering the entire product lifecycle. The extended service intervals and reduced maintenance requirements translate to fewer replacement parts, less maintenance-related waste, and lower overall resource consumption.

In industrial applications, HEA coatings contribute to energy efficiency improvements through reduced friction coefficients. Lower friction in mechanical systems directly correlates with decreased energy consumption in operational equipment, potentially offering significant energy savings in large-scale industrial operations and transportation systems.

End-of-life considerations also favor HEA coatings, as their complex multi-element composition may create opportunities for valuable metal recovery through advanced recycling processes. Research is ongoing to develop specific recycling methodologies for these complex alloys to ensure maximum material recovery and minimize landfill waste.

Future sustainability improvements in HEA coating technology are focusing on developing water-based or solvent-free deposition methods, further reducing volatile organic compound (VOC) emissions during manufacturing. Additionally, researchers are exploring bio-inspired HEA compositions that mimic natural wear-resistant structures while maintaining environmental compatibility.

From a manufacturing perspective, HEA coatings can be produced through relatively energy-efficient processes compared to some conventional coating technologies. Physical vapor deposition (PVD) and other modern deposition techniques used for HEA coatings can be optimized for lower energy consumption, particularly when compared to traditional thermal spray processes that require higher temperatures and energy inputs.

The composition flexibility of HEAs presents another environmental advantage. These alloys can be designed to minimize or eliminate environmentally harmful elements such as lead, cadmium, and chromium that are commonly found in traditional tribological coatings. This reduction in toxic elements improves workplace safety during manufacturing and reduces environmental contamination risks throughout the product lifecycle.

Life cycle assessment (LCA) studies indicate that the environmental footprint of HEA-coated components is often lower than conventional alternatives when considering the entire product lifecycle. The extended service intervals and reduced maintenance requirements translate to fewer replacement parts, less maintenance-related waste, and lower overall resource consumption.

In industrial applications, HEA coatings contribute to energy efficiency improvements through reduced friction coefficients. Lower friction in mechanical systems directly correlates with decreased energy consumption in operational equipment, potentially offering significant energy savings in large-scale industrial operations and transportation systems.

End-of-life considerations also favor HEA coatings, as their complex multi-element composition may create opportunities for valuable metal recovery through advanced recycling processes. Research is ongoing to develop specific recycling methodologies for these complex alloys to ensure maximum material recovery and minimize landfill waste.

Future sustainability improvements in HEA coating technology are focusing on developing water-based or solvent-free deposition methods, further reducing volatile organic compound (VOC) emissions during manufacturing. Additionally, researchers are exploring bio-inspired HEA compositions that mimic natural wear-resistant structures while maintaining environmental compatibility.

Industrial Application Case Studies and Performance Metrics

High-entropy alloy (HEA) coatings have demonstrated remarkable performance in various industrial applications, particularly in sectors where tribological properties are critical. The aerospace industry has been at the forefront of adopting HEA coatings for turbine blades and engine components, where these materials have shown a 30-40% improvement in wear resistance compared to conventional nickel-based superalloys under high-temperature conditions (800-1000°C).

In automotive manufacturing, HEA coatings applied to engine pistons and cylinder liners have exhibited exceptional performance metrics, including a reduction in friction coefficient by up to 25% and an extension of component lifespan by 1.5-2 times compared to traditional chrome coatings. These improvements translate directly into enhanced fuel efficiency and reduced maintenance costs.

The cutting tool industry represents another significant application area, where AlCoCrFeNi and TiZrHfNbTa HEA coatings have demonstrated superior hardness (25-30 GPa) and oxidation resistance at elevated temperatures. Field tests conducted by major tool manufacturers indicate a 40-60% increase in tool life when using HEA-coated cutting inserts for machining hardened steels and titanium alloys.

Performance metrics for HEA coatings in marine applications are equally impressive. Studies conducted in simulated seawater environments show that CoCrFeMnNi-based coatings maintain structural integrity and tribological properties after 5000 hours of salt spray testing, outperforming conventional stainless steel coatings by a significant margin in terms of corrosion resistance and surface degradation.

In the oil and gas sector, pump components and drill bits coated with refractory HEAs (containing elements like Mo, W, and Nb) have demonstrated exceptional resistance to erosive wear under high-pressure, high-temperature conditions. Field data indicates a 3-4 fold increase in service intervals compared to components with conventional hard chrome or thermal spray coatings.

Quantitative performance assessments across these applications consistently highlight several key metrics: wear rates typically reduced by 30-70% compared to conventional coatings; friction coefficients commonly lowered by 15-30%; and operational temperature ranges extended by 100-300°C. Additionally, lifecycle cost analyses demonstrate that despite higher initial application costs (typically 40-80% more than conventional coatings), the extended service life and reduced maintenance requirements result in overall cost savings of 25-45% over the component lifecycle.

In automotive manufacturing, HEA coatings applied to engine pistons and cylinder liners have exhibited exceptional performance metrics, including a reduction in friction coefficient by up to 25% and an extension of component lifespan by 1.5-2 times compared to traditional chrome coatings. These improvements translate directly into enhanced fuel efficiency and reduced maintenance costs.

The cutting tool industry represents another significant application area, where AlCoCrFeNi and TiZrHfNbTa HEA coatings have demonstrated superior hardness (25-30 GPa) and oxidation resistance at elevated temperatures. Field tests conducted by major tool manufacturers indicate a 40-60% increase in tool life when using HEA-coated cutting inserts for machining hardened steels and titanium alloys.

Performance metrics for HEA coatings in marine applications are equally impressive. Studies conducted in simulated seawater environments show that CoCrFeMnNi-based coatings maintain structural integrity and tribological properties after 5000 hours of salt spray testing, outperforming conventional stainless steel coatings by a significant margin in terms of corrosion resistance and surface degradation.

In the oil and gas sector, pump components and drill bits coated with refractory HEAs (containing elements like Mo, W, and Nb) have demonstrated exceptional resistance to erosive wear under high-pressure, high-temperature conditions. Field data indicates a 3-4 fold increase in service intervals compared to components with conventional hard chrome or thermal spray coatings.

Quantitative performance assessments across these applications consistently highlight several key metrics: wear rates typically reduced by 30-70% compared to conventional coatings; friction coefficients commonly lowered by 15-30%; and operational temperature ranges extended by 100-300°C. Additionally, lifecycle cost analyses demonstrate that despite higher initial application costs (typically 40-80% more than conventional coatings), the extended service life and reduced maintenance requirements result in overall cost savings of 25-45% over the component lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!