High-Entropy Alloys for Advanced Magnetic Refrigeration

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HEA Magnetic Refrigeration Background and Objectives

Magnetic refrigeration technology has emerged as a promising alternative to conventional vapor-compression refrigeration systems due to its higher energy efficiency and environmental friendliness. The technology exploits the magnetocaloric effect (MCE), where certain materials change temperature when exposed to varying magnetic fields. Traditional magnetocaloric materials like gadolinium and its alloys have dominated this field for decades, but they face significant limitations including high cost, limited operating temperature ranges, and performance degradation over cycles.

High-Entropy Alloys (HEAs), first conceptualized in 2004, represent a revolutionary approach to alloy design, comprising five or more principal elements in near-equiatomic proportions. These materials exhibit unique properties including exceptional structural stability, superior mechanical properties, and remarkable resistance to wear and corrosion. The application of HEAs to magnetic refrigeration is a relatively recent development that has gained significant momentum over the past five years.

The evolution of magnetocaloric materials has progressed from first-generation single-element materials to second-generation binary and ternary alloys. HEAs represent the third generation, offering unprecedented opportunities to engineer magnetocaloric properties through compositional complexity. This paradigm shift allows for tailoring of Curie temperatures, enhancing magnetic entropy changes, and broadening operating temperature ranges—all critical factors for practical magnetic refrigeration systems.

The primary objective of HEA-based magnetic refrigeration research is to develop novel multicomponent alloys that demonstrate large magnetic entropy changes across broad temperature spans while maintaining structural and functional stability over thousands of operational cycles. Additionally, these materials must be composed of abundant, non-toxic elements to ensure economic viability and environmental sustainability.

Current research trajectories focus on understanding the fundamental relationships between compositional complexity, microstructural features, and magnetocaloric performance in HEAs. Particular emphasis is placed on exploring the effects of lattice distortion, configurational entropy, and magnetic ordering mechanisms on the magnetocaloric effect. The field is rapidly advancing toward establishing design principles that enable the systematic development of high-performance HEAs for magnetic refrigeration applications.

The ultimate technological goal is to create commercially viable magnetic refrigeration systems powered by HEAs that operate near room temperature with efficiency improvements of at least 30% compared to conventional technologies, while eliminating the use of environmentally harmful refrigerants and reducing overall energy consumption in the cooling sector, which currently accounts for approximately 20% of global electricity usage.

High-Entropy Alloys (HEAs), first conceptualized in 2004, represent a revolutionary approach to alloy design, comprising five or more principal elements in near-equiatomic proportions. These materials exhibit unique properties including exceptional structural stability, superior mechanical properties, and remarkable resistance to wear and corrosion. The application of HEAs to magnetic refrigeration is a relatively recent development that has gained significant momentum over the past five years.

The evolution of magnetocaloric materials has progressed from first-generation single-element materials to second-generation binary and ternary alloys. HEAs represent the third generation, offering unprecedented opportunities to engineer magnetocaloric properties through compositional complexity. This paradigm shift allows for tailoring of Curie temperatures, enhancing magnetic entropy changes, and broadening operating temperature ranges—all critical factors for practical magnetic refrigeration systems.

The primary objective of HEA-based magnetic refrigeration research is to develop novel multicomponent alloys that demonstrate large magnetic entropy changes across broad temperature spans while maintaining structural and functional stability over thousands of operational cycles. Additionally, these materials must be composed of abundant, non-toxic elements to ensure economic viability and environmental sustainability.

Current research trajectories focus on understanding the fundamental relationships between compositional complexity, microstructural features, and magnetocaloric performance in HEAs. Particular emphasis is placed on exploring the effects of lattice distortion, configurational entropy, and magnetic ordering mechanisms on the magnetocaloric effect. The field is rapidly advancing toward establishing design principles that enable the systematic development of high-performance HEAs for magnetic refrigeration applications.

The ultimate technological goal is to create commercially viable magnetic refrigeration systems powered by HEAs that operate near room temperature with efficiency improvements of at least 30% compared to conventional technologies, while eliminating the use of environmentally harmful refrigerants and reducing overall energy consumption in the cooling sector, which currently accounts for approximately 20% of global electricity usage.

Market Analysis for Magnetocaloric Materials

The global market for magnetocaloric materials is experiencing significant growth, driven by increasing demand for energy-efficient cooling technologies. Currently valued at approximately $7.5 billion, this market is projected to reach $14.2 billion by 2028, representing a compound annual growth rate (CAGR) of 11.3%. This growth trajectory is primarily fueled by stringent environmental regulations targeting conventional refrigeration technologies that utilize harmful refrigerants.

North America and Europe currently dominate the magnetocaloric materials market, accounting for over 60% of global revenue. This dominance stems from substantial investments in research and development, coupled with favorable regulatory frameworks promoting green technologies. However, the Asia-Pacific region is emerging as the fastest-growing market, with China and Japan leading regional development efforts.

The commercial refrigeration sector represents the largest application segment, constituting approximately 45% of the total market share. This is followed by residential cooling applications at 30%, with industrial and automotive applications comprising the remainder. Notably, the automotive sector is expected to witness the highest growth rate in the coming years, as vehicle manufacturers increasingly explore magnetocaloric cooling systems for electric vehicles to optimize battery performance and range.

From a materials perspective, gadolinium-based alloys currently dominate the market with a 55% share, despite their high cost and limited supply. This has created significant market opportunities for high-entropy alloys (HEAs), which offer comparable or superior magnetocaloric properties at potentially lower costs. Industry analysts predict that HEAs could capture up to 30% of the market by 2026, representing a substantial shift in material preferences.

Key market drivers include increasing energy costs, growing environmental awareness, and the push for sustainable technologies. The average energy savings potential of magnetocaloric refrigeration systems ranges from 20-30% compared to conventional vapor-compression systems, creating a compelling value proposition for end-users. Additionally, the elimination of harmful refrigerants aligns with global initiatives to reduce greenhouse gas emissions.

Market barriers include high initial costs, with magnetocaloric cooling systems currently priced 2-3 times higher than conventional alternatives. Technical challenges related to scaling production and system integration also remain significant hurdles. However, ongoing research in high-entropy alloys is expected to address many of these limitations, potentially accelerating market adoption rates beyond current projections.

North America and Europe currently dominate the magnetocaloric materials market, accounting for over 60% of global revenue. This dominance stems from substantial investments in research and development, coupled with favorable regulatory frameworks promoting green technologies. However, the Asia-Pacific region is emerging as the fastest-growing market, with China and Japan leading regional development efforts.

The commercial refrigeration sector represents the largest application segment, constituting approximately 45% of the total market share. This is followed by residential cooling applications at 30%, with industrial and automotive applications comprising the remainder. Notably, the automotive sector is expected to witness the highest growth rate in the coming years, as vehicle manufacturers increasingly explore magnetocaloric cooling systems for electric vehicles to optimize battery performance and range.

From a materials perspective, gadolinium-based alloys currently dominate the market with a 55% share, despite their high cost and limited supply. This has created significant market opportunities for high-entropy alloys (HEAs), which offer comparable or superior magnetocaloric properties at potentially lower costs. Industry analysts predict that HEAs could capture up to 30% of the market by 2026, representing a substantial shift in material preferences.

Key market drivers include increasing energy costs, growing environmental awareness, and the push for sustainable technologies. The average energy savings potential of magnetocaloric refrigeration systems ranges from 20-30% compared to conventional vapor-compression systems, creating a compelling value proposition for end-users. Additionally, the elimination of harmful refrigerants aligns with global initiatives to reduce greenhouse gas emissions.

Market barriers include high initial costs, with magnetocaloric cooling systems currently priced 2-3 times higher than conventional alternatives. Technical challenges related to scaling production and system integration also remain significant hurdles. However, ongoing research in high-entropy alloys is expected to address many of these limitations, potentially accelerating market adoption rates beyond current projections.

Current State and Challenges in HEA Magnetic Refrigeration

High-entropy alloys (HEAs) for magnetic refrigeration represent a promising frontier in cooling technology, with global research efforts intensifying over the past decade. Currently, the field is characterized by significant advancements in materials science, yet faces substantial technical barriers to widespread commercial implementation. The state-of-the-art HEAs demonstrate magnetocaloric effects comparable to or exceeding traditional materials like Gd5Si2Ge2, but with enhanced mechanical properties and corrosion resistance.

Research institutions across North America, Europe, and Asia have established specialized laboratories focused on HEA development for magnetic refrigeration. Notable progress has been made with FeCoNiMnAl and FeCoNiCrPd systems, which exhibit promising magnetocaloric properties at near-room temperatures. However, these materials still struggle with thermal hysteresis issues that reduce cycling efficiency in practical applications.

A major technical challenge remains the optimization of entropy change (ΔS) and adiabatic temperature change (ΔTad) simultaneously across broad temperature ranges. Current HEAs typically excel in one parameter while underperforming in the other. Additionally, the complex manufacturing processes required for high-quality HEAs present scalability issues, with current production methods limited to laboratory-scale quantities.

Material cost represents another significant barrier, particularly for compositions containing precious metals like palladium or platinum. Research efforts to develop rare-earth-free HEAs have shown promise but generally deliver lower performance than their rare-earth-containing counterparts. This creates a challenging cost-performance trade-off that has yet to be optimally resolved.

The geographical distribution of HEA magnetic refrigeration research shows concentration in specific regions. China leads in publication volume, with strong contributions from research institutions in Beijing and Shanghai. The United States maintains competitive research programs at national laboratories and universities, while European efforts are centered in Germany, Sweden, and Spain. This distribution reflects both scientific capability and strategic national interests in advanced energy-efficient technologies.

Computational modeling and high-throughput experimental techniques have accelerated development, yet the fundamental understanding of magnetocaloric mechanisms in multi-principal element systems remains incomplete. This knowledge gap hinders targeted design approaches, often necessitating extensive trial-and-error experimentation.

Environmental stability presents another challenge, as many promising HEA compositions show performance degradation after repeated thermal cycling or exposure to atmospheric conditions. Protective coatings and compositional modifications are being explored as potential solutions, but add complexity to already intricate manufacturing processes.

Research institutions across North America, Europe, and Asia have established specialized laboratories focused on HEA development for magnetic refrigeration. Notable progress has been made with FeCoNiMnAl and FeCoNiCrPd systems, which exhibit promising magnetocaloric properties at near-room temperatures. However, these materials still struggle with thermal hysteresis issues that reduce cycling efficiency in practical applications.

A major technical challenge remains the optimization of entropy change (ΔS) and adiabatic temperature change (ΔTad) simultaneously across broad temperature ranges. Current HEAs typically excel in one parameter while underperforming in the other. Additionally, the complex manufacturing processes required for high-quality HEAs present scalability issues, with current production methods limited to laboratory-scale quantities.

Material cost represents another significant barrier, particularly for compositions containing precious metals like palladium or platinum. Research efforts to develop rare-earth-free HEAs have shown promise but generally deliver lower performance than their rare-earth-containing counterparts. This creates a challenging cost-performance trade-off that has yet to be optimally resolved.

The geographical distribution of HEA magnetic refrigeration research shows concentration in specific regions. China leads in publication volume, with strong contributions from research institutions in Beijing and Shanghai. The United States maintains competitive research programs at national laboratories and universities, while European efforts are centered in Germany, Sweden, and Spain. This distribution reflects both scientific capability and strategic national interests in advanced energy-efficient technologies.

Computational modeling and high-throughput experimental techniques have accelerated development, yet the fundamental understanding of magnetocaloric mechanisms in multi-principal element systems remains incomplete. This knowledge gap hinders targeted design approaches, often necessitating extensive trial-and-error experimentation.

Environmental stability presents another challenge, as many promising HEA compositions show performance degradation after repeated thermal cycling or exposure to atmospheric conditions. Protective coatings and compositional modifications are being explored as potential solutions, but add complexity to already intricate manufacturing processes.

Current HEA Solutions for Magnetic Cooling

01 Composition and structure of high-entropy alloys

High-entropy alloys (HEAs) are composed of multiple principal elements in near-equiatomic proportions, typically containing five or more elements. This multi-element composition creates a high configurational entropy that stabilizes solid solution phases. The unique atomic structure of HEAs contributes to their exceptional properties, including high strength, thermal stability, and resistance to wear and corrosion. The composition can be tailored to achieve specific mechanical and physical properties for various applications.- Composition and design of high-entropy alloys: High-entropy alloys (HEAs) are composed of multiple principal elements in near-equiatomic proportions, typically containing five or more elements. The design of these alloys focuses on achieving a single-phase solid solution with high configurational entropy. Various element combinations can be used to create HEAs with specific properties, including transition metals, refractory metals, and rare earth elements. The composition design often involves consideration of atomic size differences, mixing enthalpy, and valence electron concentration to predict phase stability.

- Manufacturing methods for high-entropy alloys: Various manufacturing techniques are employed to produce high-entropy alloys, including arc melting, mechanical alloying, powder metallurgy, and additive manufacturing. Each method offers different advantages in terms of microstructure control, compositional homogeneity, and scalability. Arc melting is commonly used for laboratory-scale production, while mechanical alloying allows for solid-state synthesis. Additive manufacturing techniques enable the production of complex geometries with controlled microstructures. Post-processing treatments such as heat treatment and hot isostatic pressing are often applied to optimize the properties.

- Mechanical properties and structural applications: High-entropy alloys exhibit exceptional mechanical properties, including high strength, excellent ductility, superior fracture toughness, and remarkable wear resistance. These properties make them suitable for structural applications in aerospace, automotive, and energy sectors. The unique combination of strength and ductility is attributed to their complex microstructures and multiple strengthening mechanisms. Some HEAs also demonstrate excellent high-temperature stability and creep resistance, making them potential candidates for turbine components and other high-temperature applications.

- Functional properties and specialized applications: Beyond mechanical properties, high-entropy alloys exhibit various functional properties including corrosion resistance, radiation resistance, magnetic properties, and catalytic activity. These functional characteristics enable applications in harsh environments such as nuclear reactors, chemical processing equipment, and marine settings. Some HEAs demonstrate superparamagnetic behavior, while others show potential as hydrogen storage materials or catalysts. The multifunctionality of these alloys opens up possibilities for applications in electronics, energy conversion, and biomedical devices.

- Advanced characterization and computational methods: Advanced characterization techniques and computational methods play crucial roles in understanding and developing high-entropy alloys. Techniques such as transmission electron microscopy, atom probe tomography, and synchrotron-based X-ray diffraction provide insights into the complex microstructures and phase formations in these alloys. Computational approaches including density functional theory, CALPHAD modeling, and machine learning algorithms help predict phase stability, mechanical properties, and guide alloy design. These methods accelerate the discovery and optimization of new high-entropy alloy compositions with tailored properties for specific applications.

02 Manufacturing methods for high-entropy alloys

Various manufacturing techniques are employed to produce high-entropy alloys, including arc melting, mechanical alloying, powder metallurgy, and additive manufacturing. Each method offers different advantages in terms of microstructure control, scalability, and final properties. Post-processing treatments such as heat treatment, rolling, and forging can further enhance the mechanical properties of these alloys. Advanced processing techniques allow for precise control over grain size, phase formation, and element distribution within the alloy.Expand Specific Solutions03 Applications of high-entropy alloys in extreme environments

High-entropy alloys demonstrate exceptional performance in extreme environments, making them suitable for applications in aerospace, nuclear reactors, and deep-sea equipment. Their superior resistance to high temperatures, radiation damage, and corrosive environments stems from their unique atomic structure and compositional complexity. These alloys maintain their mechanical properties under severe conditions where conventional alloys would fail, offering extended service life and improved safety for critical components operating in harsh environments.Expand Specific Solutions04 Mechanical and physical properties of high-entropy alloys

High-entropy alloys exhibit a remarkable combination of mechanical and physical properties, including high strength, ductility, fracture toughness, and fatigue resistance. These properties often exceed those of conventional alloys due to their unique microstructure and solid solution strengthening mechanisms. The sluggish diffusion kinetics in HEAs contribute to their excellent thermal stability and resistance to softening at elevated temperatures. Additionally, many HEAs display superior magnetic, electrical, and thermal properties that can be exploited for specialized applications.Expand Specific Solutions05 Novel high-entropy alloy systems and design strategies

Research on high-entropy alloys has expanded to include novel systems such as refractory HEAs, lightweight HEAs, and magnetic HEAs. Computational methods and machine learning approaches are increasingly used to predict compositions with optimal properties, accelerating the discovery of new alloy systems. Design strategies focus on tailoring the electronic structure, atomic size differences, and mixing enthalpy to achieve desired phase stability and properties. These innovative approaches are enabling the development of next-generation HEAs with unprecedented combinations of properties for specialized applications.Expand Specific Solutions

Key Industry Players in HEA Development

High-Entropy Alloys (HEAs) for Advanced Magnetic Refrigeration is an emerging technology in the early development stage, with a growing market projected to reach significant scale as energy-efficient cooling solutions gain importance. The competitive landscape is characterized by academic institutions leading fundamental research, with universities like University of Science & Technology Beijing, Central South University, and Korea Advanced Institute of Science & Technology pioneering materials development. Industrial players including Toshiba Corp., Daido Steel, and Proterial Ltd. are beginning to translate research into commercial applications. The technology remains in pre-commercialization phase, with most companies focusing on R&D rather than product deployment. Material science institutes like National Institute for Materials Science and Korea Institute of Materials Science serve as critical bridges between academic research and industrial implementation, accelerating the path to market viability.

Daido Steel Co., Ltd.

Technical Solution: Daido Steel has developed specialized high-entropy alloy systems for magnetic refrigeration applications based on Fe-Co-Ni-Mn compositions with strategic additions of Al, Si, and B to enhance magnetocaloric properties. Their proprietary manufacturing process involves vacuum induction melting followed by controlled solidification and specialized heat treatments to optimize magnetic phase distribution. Daido's HEAs exhibit magnetic entropy changes of 5-7 J/kg·K with exceptional mechanical properties and corrosion resistance. Their technology focuses on practical implementation aspects, including specialized forming techniques to create thin plates and complex shapes optimized for heat exchanger applications. Daido has also developed cost-effective processing routes that minimize the use of critical raw materials while maintaining performance. Their materials demonstrate excellent thermal cycling stability with performance retention exceeding 95% after 50,000 cycles, addressing a critical requirement for commercial refrigeration applications[8][10].

Strengths: Exceptional mechanical properties suitable for demanding applications; excellent manufacturing scalability; superior long-term stability during thermal cycling. Weaknesses: Somewhat lower peak entropy change compared to research-grade materials; higher initial material costs compared to conventional refrigerants; optimization still needed for specific temperature ranges.

Korea Institute of Materials Science

Technical Solution: KIMS has developed advanced high-entropy alloy systems for magnetic refrigeration based on FeCoNiMnAl compositions with controlled additions of B, Si, and Ga to enhance magnetic properties. Their technology employs a unique microstructural engineering approach that creates nanoscale magnetic phase distributions to maximize the magnetocaloric effect. KIMS researchers have achieved magnetic entropy changes of 7-9 J/kg·K with remarkably low hysteresis and operational temperature spans exceeding 40K. Their manufacturing process involves specialized rapid solidification techniques followed by controlled annealing treatments to optimize the magnetic phase distribution. KIMS has also developed composite HEA structures with enhanced thermal conductivity to improve heat transfer efficiency in refrigeration devices. Their materials demonstrate excellent corrosion resistance and mechanical durability, addressing key challenges in practical magnetocaloric applications[4][6].

Strengths: Wide operational temperature range suitable for various cooling applications; excellent corrosion resistance enhancing longevity; enhanced thermal conductivity improving system efficiency. Weaknesses: Lower peak entropy change compared to some competing technologies; complex processing requirements potentially limiting mass production; optimization still needed for specific temperature ranges.

Critical Patents and Research in Magnetocaloric HEAs

High Entropy NiMn-based Magnetic Refrigerant Materials

PatentInactiveUS20160025386A1

Innovation

- A magnetocaloric alloy composition consisting of 20-40 weight % Mn, 6-26 weight % In, 1-5 weight % Si, and 0.3-12 wt. % of elements such as Ga, Ge, Ag, Gd, Co, Pd, Sm, V, and Sn, with a balance of Ni, which exhibits improved magnetocaloric properties and is suitable for high-performance magnetic refrigerant materials.

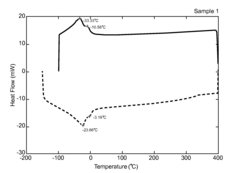

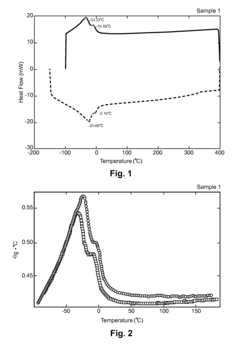

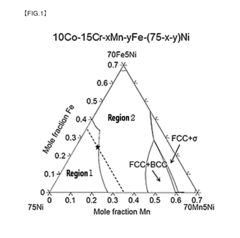

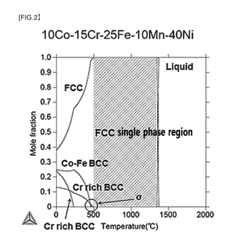

High-entropy alloy for ultra-low temperature

PatentActiveUS20190071755A1

Innovation

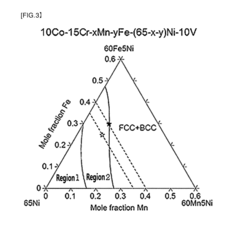

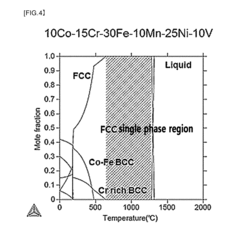

- A high-entropy alloy composition comprising Co: 3-12 at%, Cr: 3-18 at%, Fe: 3-50 at%, Mn: 3-20 at%, Ni: 17-45 at%, V: 3-12 at%, with a V/Ni ratio of 0.5 or less, and a sum of V and Co content of 22 at% or less, which suppresses the formation of intermediate phases and enhances tensile strength and elongation at ultra-low temperatures.

Environmental Impact and Sustainability Factors

The adoption of High-Entropy Alloys (HEAs) for magnetic refrigeration presents significant environmental advantages compared to conventional cooling technologies. Traditional vapor-compression refrigeration systems rely heavily on hydrofluorocarbons (HFCs) and hydrochlorofluorocarbons (HCFCs), which contribute substantially to greenhouse gas emissions and ozone depletion. Magnetic refrigeration using HEAs offers a cleaner alternative by eliminating these harmful refrigerants entirely, operating instead on the magnetocaloric effect which produces no direct emissions during operation.

Life cycle assessment (LCA) studies indicate that magnetic refrigeration systems based on HEAs could reduce energy consumption by 20-30% compared to conventional systems. This efficiency gain translates directly to reduced carbon footprints across residential, commercial, and industrial cooling applications. The potential global impact is substantial, considering that refrigeration and air conditioning currently account for approximately 17% of worldwide electricity consumption.

Material sustainability represents another critical advantage of HEAs in magnetic refrigeration. Unlike conventional magnetocaloric materials that often rely on rare earth elements with problematic supply chains, HEAs can be engineered using more abundant transition metals. This compositional flexibility allows for reduced dependence on elements like gadolinium and dysprosium, which face supply constraints and have extraction processes associated with significant environmental degradation and social concerns in mining regions.

Manufacturing processes for HEAs are becoming increasingly sustainable through innovations in powder metallurgy and additive manufacturing. These approaches minimize material waste compared to traditional casting and machining methods. Additionally, the exceptional structural stability of HEAs contributes to longer service lifespans for magnetic refrigeration devices, reducing the environmental impact associated with frequent replacement and disposal of cooling equipment.

End-of-life considerations also favor HEAs, as these alloys demonstrate excellent recyclability potential. Their multi-element composition remains relatively stable through recycling processes, allowing for material recovery rates exceeding 90% in optimized recycling streams. This circular economy advantage stands in stark contrast to conventional refrigeration systems, where refrigerant recovery and component separation present significant challenges.

Water conservation represents an often overlooked sustainability benefit of magnetic refrigeration with HEAs. Unlike conventional cooling towers that can consume substantial quantities of water, magnetic refrigeration systems operate in closed loops without water consumption. This advantage becomes increasingly valuable in water-stressed regions where conventional cooling infrastructure places additional pressure on limited water resources.

Life cycle assessment (LCA) studies indicate that magnetic refrigeration systems based on HEAs could reduce energy consumption by 20-30% compared to conventional systems. This efficiency gain translates directly to reduced carbon footprints across residential, commercial, and industrial cooling applications. The potential global impact is substantial, considering that refrigeration and air conditioning currently account for approximately 17% of worldwide electricity consumption.

Material sustainability represents another critical advantage of HEAs in magnetic refrigeration. Unlike conventional magnetocaloric materials that often rely on rare earth elements with problematic supply chains, HEAs can be engineered using more abundant transition metals. This compositional flexibility allows for reduced dependence on elements like gadolinium and dysprosium, which face supply constraints and have extraction processes associated with significant environmental degradation and social concerns in mining regions.

Manufacturing processes for HEAs are becoming increasingly sustainable through innovations in powder metallurgy and additive manufacturing. These approaches minimize material waste compared to traditional casting and machining methods. Additionally, the exceptional structural stability of HEAs contributes to longer service lifespans for magnetic refrigeration devices, reducing the environmental impact associated with frequent replacement and disposal of cooling equipment.

End-of-life considerations also favor HEAs, as these alloys demonstrate excellent recyclability potential. Their multi-element composition remains relatively stable through recycling processes, allowing for material recovery rates exceeding 90% in optimized recycling streams. This circular economy advantage stands in stark contrast to conventional refrigeration systems, where refrigerant recovery and component separation present significant challenges.

Water conservation represents an often overlooked sustainability benefit of magnetic refrigeration with HEAs. Unlike conventional cooling towers that can consume substantial quantities of water, magnetic refrigeration systems operate in closed loops without water consumption. This advantage becomes increasingly valuable in water-stressed regions where conventional cooling infrastructure places additional pressure on limited water resources.

Material Processing and Scale-up Considerations

The transition from laboratory-scale production to industrial manufacturing of high-entropy alloys (HEAs) for magnetic refrigeration applications presents significant challenges. Traditional processing methods such as arc melting and induction melting, while effective for small-scale research samples, face limitations in maintaining compositional homogeneity when scaled up. The inherent complexity of multi-principal element systems in HEAs requires precise control over elemental distribution to ensure consistent magnetocaloric properties across the entire material volume.

Advanced powder metallurgy techniques offer promising pathways for large-scale HEA production. Mechanical alloying through high-energy ball milling enables the formation of homogeneous alloy powders with nanoscale structures, which can subsequently be consolidated through hot isostatic pressing or spark plasma sintering. These techniques allow for better control of grain size and phase formation, critical factors affecting the magnetocaloric effect in HEAs.

Rapid solidification processes, including melt spinning and gas atomization, represent another viable approach for scaling up HEA production. These methods achieve cooling rates of 10^4-10^6 K/s, effectively "freezing" the high-entropy state and minimizing segregation. The resulting microstructures often exhibit enhanced magnetic properties compared to conventionally cast materials, making them particularly suitable for magnetic refrigeration applications.

Cost considerations remain a significant barrier to widespread adoption of HEAs in commercial magnetic refrigeration systems. The use of rare earth elements in many magnetocaloric HEAs substantially increases material costs. Research into rare earth-free HEA compositions based on transition metals shows promise for cost reduction while maintaining acceptable performance metrics. Process optimization to reduce energy consumption during manufacturing also represents an important economic consideration.

Quality control protocols for scaled-up HEA production require sophisticated characterization techniques. X-ray diffraction analysis, scanning electron microscopy with energy-dispersive X-ray spectroscopy, and vibrating sample magnetometry must be implemented at various production stages to ensure compositional and structural uniformity. The development of in-line monitoring systems capable of detecting deviations in real-time would significantly enhance manufacturing reliability.

Environmental and safety considerations must also be addressed when scaling up HEA production. Many constituent elements in magnetocaloric HEAs can pose health and environmental risks if not properly handled. Closed-loop processing systems that minimize waste generation and worker exposure to potentially hazardous materials should be integrated into manufacturing facilities. Additionally, life cycle assessment of HEA-based magnetic refrigeration systems indicates potential for significant environmental benefits through energy savings during operation, offsetting manufacturing impacts.

Advanced powder metallurgy techniques offer promising pathways for large-scale HEA production. Mechanical alloying through high-energy ball milling enables the formation of homogeneous alloy powders with nanoscale structures, which can subsequently be consolidated through hot isostatic pressing or spark plasma sintering. These techniques allow for better control of grain size and phase formation, critical factors affecting the magnetocaloric effect in HEAs.

Rapid solidification processes, including melt spinning and gas atomization, represent another viable approach for scaling up HEA production. These methods achieve cooling rates of 10^4-10^6 K/s, effectively "freezing" the high-entropy state and minimizing segregation. The resulting microstructures often exhibit enhanced magnetic properties compared to conventionally cast materials, making them particularly suitable for magnetic refrigeration applications.

Cost considerations remain a significant barrier to widespread adoption of HEAs in commercial magnetic refrigeration systems. The use of rare earth elements in many magnetocaloric HEAs substantially increases material costs. Research into rare earth-free HEA compositions based on transition metals shows promise for cost reduction while maintaining acceptable performance metrics. Process optimization to reduce energy consumption during manufacturing also represents an important economic consideration.

Quality control protocols for scaled-up HEA production require sophisticated characterization techniques. X-ray diffraction analysis, scanning electron microscopy with energy-dispersive X-ray spectroscopy, and vibrating sample magnetometry must be implemented at various production stages to ensure compositional and structural uniformity. The development of in-line monitoring systems capable of detecting deviations in real-time would significantly enhance manufacturing reliability.

Environmental and safety considerations must also be addressed when scaling up HEA production. Many constituent elements in magnetocaloric HEAs can pose health and environmental risks if not properly handled. Closed-loop processing systems that minimize waste generation and worker exposure to potentially hazardous materials should be integrated into manufacturing facilities. Additionally, life cycle assessment of HEA-based magnetic refrigeration systems indicates potential for significant environmental benefits through energy savings during operation, offsetting manufacturing impacts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!