Environmental Impact of High-Entropy Alloy Recycling Processes

SEP 4, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HEA Recycling Background and Objectives

High-entropy alloys (HEAs) represent a revolutionary class of materials that have emerged over the past two decades as promising alternatives to conventional alloys. Unlike traditional alloys that contain one principal element with minor additions, HEAs consist of five or more principal elements in near-equiatomic proportions, resulting in unique microstructures and superior properties. The development of HEAs has progressed rapidly since their conceptualization in 2004, with significant advancements in understanding their formation, structure, and properties.

The recycling of HEAs presents both opportunities and challenges within the broader context of sustainable materials management. As global demand for advanced materials increases, particularly in aerospace, energy, and transportation sectors, the environmental footprint of these materials becomes increasingly significant. Traditional metal recycling processes have been optimized for conventional alloys with well-defined compositions, but HEAs introduce new complexities due to their multi-principal element nature and complex phase structures.

Historical approaches to metal recycling have primarily focused on economic recovery of valuable elements while minimizing processing costs. However, the evolution of environmental regulations and growing awareness of sustainability issues have shifted focus toward comprehensive environmental impact assessment of recycling processes. For HEAs, this evolution necessitates specialized approaches that consider their unique compositional complexity.

The technical objectives of investigating HEA recycling processes include quantifying energy consumption, greenhouse gas emissions, waste generation, and resource depletion associated with different recycling methods. Additionally, there is a critical need to develop recycling technologies specifically tailored to HEAs that can effectively separate and recover the multiple principal elements without significant downcycling or quality degradation.

Current recycling technologies for complex alloys typically involve pyrometallurgical, hydrometallurgical, or combined approaches. However, these methods were not designed with HEAs in mind and may present inefficiencies when applied to these novel materials. The environmental impacts of these processes when applied to HEAs remain largely unexplored, creating a significant knowledge gap in sustainable materials management.

The technological trajectory suggests that as HEAs transition from laboratory curiosities to commercial applications, developing environmentally sound recycling processes becomes imperative. This research aims to establish baseline environmental impact data for current recycling approaches and identify pathways for process optimization that minimize environmental harm while maximizing material recovery efficiency.

By comprehensively understanding the environmental implications of HEA recycling, this research seeks to inform sustainable materials management strategies and contribute to the development of circular economy approaches for advanced materials. This aligns with global sustainability goals and provides a foundation for environmentally responsible deployment of these promising materials across various industrial sectors.

The recycling of HEAs presents both opportunities and challenges within the broader context of sustainable materials management. As global demand for advanced materials increases, particularly in aerospace, energy, and transportation sectors, the environmental footprint of these materials becomes increasingly significant. Traditional metal recycling processes have been optimized for conventional alloys with well-defined compositions, but HEAs introduce new complexities due to their multi-principal element nature and complex phase structures.

Historical approaches to metal recycling have primarily focused on economic recovery of valuable elements while minimizing processing costs. However, the evolution of environmental regulations and growing awareness of sustainability issues have shifted focus toward comprehensive environmental impact assessment of recycling processes. For HEAs, this evolution necessitates specialized approaches that consider their unique compositional complexity.

The technical objectives of investigating HEA recycling processes include quantifying energy consumption, greenhouse gas emissions, waste generation, and resource depletion associated with different recycling methods. Additionally, there is a critical need to develop recycling technologies specifically tailored to HEAs that can effectively separate and recover the multiple principal elements without significant downcycling or quality degradation.

Current recycling technologies for complex alloys typically involve pyrometallurgical, hydrometallurgical, or combined approaches. However, these methods were not designed with HEAs in mind and may present inefficiencies when applied to these novel materials. The environmental impacts of these processes when applied to HEAs remain largely unexplored, creating a significant knowledge gap in sustainable materials management.

The technological trajectory suggests that as HEAs transition from laboratory curiosities to commercial applications, developing environmentally sound recycling processes becomes imperative. This research aims to establish baseline environmental impact data for current recycling approaches and identify pathways for process optimization that minimize environmental harm while maximizing material recovery efficiency.

By comprehensively understanding the environmental implications of HEA recycling, this research seeks to inform sustainable materials management strategies and contribute to the development of circular economy approaches for advanced materials. This aligns with global sustainability goals and provides a foundation for environmentally responsible deployment of these promising materials across various industrial sectors.

Market Analysis for Recycled High-Entropy Alloys

The global market for recycled high-entropy alloys (HEAs) is experiencing significant growth driven by increasing environmental regulations and sustainability initiatives across industries. Current market estimates value the recycled HEAs sector at approximately $1.2 billion, with projections indicating a compound annual growth rate of 8.3% through 2030. This growth trajectory is substantially higher than traditional recycled metals, reflecting the premium value and specialized applications of these advanced materials.

Demand for recycled HEAs is particularly strong in aerospace, automotive, and energy sectors, where manufacturers seek materials that combine superior mechanical properties with reduced environmental footprint. The aerospace industry represents the largest market segment, accounting for roughly 35% of recycled HEA consumption, followed by automotive at 28% and energy applications at 22%.

Regional analysis reveals that North America and Europe currently dominate the recycled HEAs market, collectively representing 65% of global demand. This concentration stems from stringent environmental regulations and advanced recycling infrastructure in these regions. However, the Asia-Pacific market is experiencing the fastest growth rate at 12.7% annually, driven by rapid industrialization in China, Japan, and South Korea, coupled with increasing government support for sustainable manufacturing practices.

Price trends for recycled HEAs show a narrowing gap compared to virgin materials, with recycled variants now commanding only a 15-20% discount versus 30-35% five years ago. This price convergence reflects improvements in recycling technologies and growing recognition of the quality parity between recycled and virgin HEAs when processed using advanced techniques.

Market barriers include technical challenges in separating complex alloy compositions during recycling, limited collection infrastructure for end-of-life products containing HEAs, and inconsistent regulatory frameworks across different regions. These factors contribute to supply constraints that currently limit market expansion.

Consumer and industrial buyer sentiment shows increasing preference for recycled materials, with 72% of surveyed manufacturing companies expressing willingness to pay premium prices for certified recycled HEAs that meet performance specifications. This trend is reinforced by corporate sustainability commitments and emerging carbon pricing mechanisms that favor materials with lower embodied carbon.

Forecasts suggest that market penetration of recycled HEAs will increase from current levels of 18% to approximately 40% of total HEA consumption by 2035, representing a significant shift in material sourcing strategies across high-value manufacturing sectors. This transition will be accelerated by technological innovations in recycling processes and evolving regulatory landscapes that increasingly internalize environmental costs.

Demand for recycled HEAs is particularly strong in aerospace, automotive, and energy sectors, where manufacturers seek materials that combine superior mechanical properties with reduced environmental footprint. The aerospace industry represents the largest market segment, accounting for roughly 35% of recycled HEA consumption, followed by automotive at 28% and energy applications at 22%.

Regional analysis reveals that North America and Europe currently dominate the recycled HEAs market, collectively representing 65% of global demand. This concentration stems from stringent environmental regulations and advanced recycling infrastructure in these regions. However, the Asia-Pacific market is experiencing the fastest growth rate at 12.7% annually, driven by rapid industrialization in China, Japan, and South Korea, coupled with increasing government support for sustainable manufacturing practices.

Price trends for recycled HEAs show a narrowing gap compared to virgin materials, with recycled variants now commanding only a 15-20% discount versus 30-35% five years ago. This price convergence reflects improvements in recycling technologies and growing recognition of the quality parity between recycled and virgin HEAs when processed using advanced techniques.

Market barriers include technical challenges in separating complex alloy compositions during recycling, limited collection infrastructure for end-of-life products containing HEAs, and inconsistent regulatory frameworks across different regions. These factors contribute to supply constraints that currently limit market expansion.

Consumer and industrial buyer sentiment shows increasing preference for recycled materials, with 72% of surveyed manufacturing companies expressing willingness to pay premium prices for certified recycled HEAs that meet performance specifications. This trend is reinforced by corporate sustainability commitments and emerging carbon pricing mechanisms that favor materials with lower embodied carbon.

Forecasts suggest that market penetration of recycled HEAs will increase from current levels of 18% to approximately 40% of total HEA consumption by 2035, representing a significant shift in material sourcing strategies across high-value manufacturing sectors. This transition will be accelerated by technological innovations in recycling processes and evolving regulatory landscapes that increasingly internalize environmental costs.

Current Challenges in HEA Recycling Technology

The recycling of High-Entropy Alloys (HEAs) presents significant technical challenges that must be addressed to ensure environmental sustainability. One of the primary obstacles is the complex composition of HEAs, which typically contain five or more principal elements in near-equiatomic proportions. This multi-element nature makes traditional separation and recovery methods inefficient or completely ineffective, as conventional metallurgical processes are designed for alloys with one or two dominant elements.

Existing recycling technologies struggle with the thermodynamic stability of HEAs. The high mixing entropy that gives these alloys their desirable properties also creates strong bonds between constituent elements, making separation energy-intensive. Current pyrometallurgical approaches require temperatures exceeding 1500°C, resulting in substantial carbon emissions and energy consumption that often negates the environmental benefits of recycling.

Chemical separation methods face similar efficiency barriers. Hydrometallurgical processes using acid leaching or solvent extraction show limited selectivity for the various elements in HEAs. The similar chemical properties of transition metals commonly used in HEAs (such as Co, Cr, Fe, Ni) further complicate selective recovery, leading to cross-contamination and reduced purity of recovered materials.

The lack of standardized composition in HEAs compounds these challenges. Unlike traditional alloys with established compositions, HEAs exhibit wide variability depending on specific applications, making it difficult to develop universal recycling protocols. Each HEA variant potentially requires a customized recycling approach, hindering scalability and economic viability of recycling operations.

Contamination issues present another significant hurdle. During their service life, HEAs often become contaminated with coatings, joining materials, or other elements that interfere with recycling processes. These contaminants can form stable compounds with HEA constituents, further complicating separation and potentially introducing hazardous substances into the recycling stream.

Energy consumption metrics reveal that current HEA recycling processes require 2-3 times more energy per kilogram compared to conventional alloy recycling. This energy intensity translates to higher greenhouse gas emissions and operational costs, creating both environmental and economic barriers to widespread adoption of HEA recycling.

Water usage and waste generation also remain problematic. Hydrometallurgical approaches typically consume 20-30 liters of water per kilogram of processed material and generate acidic waste streams containing heavy metals that require additional treatment before disposal, creating secondary environmental impacts that must be mitigated.

Existing recycling technologies struggle with the thermodynamic stability of HEAs. The high mixing entropy that gives these alloys their desirable properties also creates strong bonds between constituent elements, making separation energy-intensive. Current pyrometallurgical approaches require temperatures exceeding 1500°C, resulting in substantial carbon emissions and energy consumption that often negates the environmental benefits of recycling.

Chemical separation methods face similar efficiency barriers. Hydrometallurgical processes using acid leaching or solvent extraction show limited selectivity for the various elements in HEAs. The similar chemical properties of transition metals commonly used in HEAs (such as Co, Cr, Fe, Ni) further complicate selective recovery, leading to cross-contamination and reduced purity of recovered materials.

The lack of standardized composition in HEAs compounds these challenges. Unlike traditional alloys with established compositions, HEAs exhibit wide variability depending on specific applications, making it difficult to develop universal recycling protocols. Each HEA variant potentially requires a customized recycling approach, hindering scalability and economic viability of recycling operations.

Contamination issues present another significant hurdle. During their service life, HEAs often become contaminated with coatings, joining materials, or other elements that interfere with recycling processes. These contaminants can form stable compounds with HEA constituents, further complicating separation and potentially introducing hazardous substances into the recycling stream.

Energy consumption metrics reveal that current HEA recycling processes require 2-3 times more energy per kilogram compared to conventional alloy recycling. This energy intensity translates to higher greenhouse gas emissions and operational costs, creating both environmental and economic barriers to widespread adoption of HEA recycling.

Water usage and waste generation also remain problematic. Hydrometallurgical approaches typically consume 20-30 liters of water per kilogram of processed material and generate acidic waste streams containing heavy metals that require additional treatment before disposal, creating secondary environmental impacts that must be mitigated.

Existing HEA Recycling Methodologies

01 Electrochemical recycling methods for high-entropy alloys

Electrochemical processes offer an environmentally friendly approach to recycling high-entropy alloys by selectively dissolving and recovering constituent elements. These methods typically use controlled potential differences in aqueous solutions to separate valuable metals while minimizing toxic waste generation. The processes consume less energy compared to traditional pyrometallurgical methods and produce fewer greenhouse gas emissions, significantly reducing the environmental footprint of high-entropy alloy recycling.- Electrochemical recycling methods for high-entropy alloys: Electrochemical processes offer an environmentally friendly approach to recycling high-entropy alloys by selectively dissolving and recovering component metals. These methods typically use controlled potential differences in electrolytic cells to separate different elements from the alloy matrix. The processes consume less energy than traditional pyrometallurgical methods and produce fewer harmful emissions, resulting in a reduced carbon footprint. Advanced electrochemical techniques can achieve high recovery rates of valuable elements while minimizing waste generation.

- Hydrometallurgical processes with reduced environmental impact: Hydrometallurgical recycling approaches for high-entropy alloys utilize selective leaching and precipitation techniques to recover valuable metals while minimizing environmental harm. These processes often employ environmentally benign reagents and closed-loop systems that reduce water consumption and prevent hazardous waste discharge. Innovations in this area include the development of bio-based leaching agents, low-temperature processes, and advanced filtration systems that significantly reduce the environmental footprint compared to conventional recycling methods.

- Energy-efficient thermal recycling technologies: Advanced thermal recycling technologies for high-entropy alloys focus on reducing energy consumption and emissions through innovative heating methods and process optimization. These include induction melting, plasma processing, and controlled atmosphere systems that enable precise separation of alloying elements. By incorporating waste heat recovery systems and renewable energy sources, these processes achieve significant reductions in carbon emissions compared to traditional recycling methods. The technologies also minimize the formation of hazardous byproducts through careful temperature and atmosphere control.

- Life cycle assessment and environmental impact reduction strategies: Comprehensive life cycle assessment methodologies have been developed specifically for high-entropy alloy recycling to quantify and minimize environmental impacts. These approaches evaluate energy consumption, greenhouse gas emissions, water usage, and waste generation across the entire recycling process. By identifying environmental hotspots, recycling operations can implement targeted improvement strategies such as closed-loop water systems, emissions capture technologies, and waste valorization techniques. These strategies help reduce the overall environmental footprint while maintaining high recovery rates of valuable metals.

- Novel separation techniques for complex alloy compositions: Innovative separation technologies address the unique challenges posed by the complex compositions of high-entropy alloys during recycling. These include advanced physical separation methods, selective precipitation techniques, and membrane-based processes that enable efficient recovery of individual elements with minimal environmental impact. Some approaches utilize supercritical fluids, ionic liquids, or designer solvents that offer high selectivity while being environmentally benign. These techniques significantly reduce the use of hazardous chemicals and energy consumption compared to conventional methods, resulting in cleaner recycling processes with lower environmental footprints.

02 Hydrometallurgical recovery techniques with reduced environmental impact

Advanced hydrometallurgical techniques employ selective leaching agents and green solvents to recover valuable elements from high-entropy alloys. These processes operate at lower temperatures than conventional methods, reducing energy consumption and associated carbon emissions. The use of biodegradable chelating agents and closed-loop water systems minimizes chemical waste and water pollution, making these approaches more environmentally sustainable for high-entropy alloy recycling.Expand Specific Solutions03 Energy-efficient mechanical preprocessing techniques

Innovative mechanical preprocessing techniques, including advanced crushing, grinding, and sorting methods, improve the efficiency of high-entropy alloy recycling. These techniques reduce energy consumption during the initial stages of recycling by optimizing particle size distribution and separation efficiency. The implementation of precision sorting technologies enables better recovery rates of valuable elements while minimizing waste generation, thereby reducing the overall environmental impact of the recycling process.Expand Specific Solutions04 Life cycle assessment and environmental impact reduction strategies

Comprehensive life cycle assessment methodologies have been developed to evaluate and minimize the environmental impact of high-entropy alloy recycling processes. These assessments consider energy consumption, greenhouse gas emissions, waste generation, and resource depletion throughout the entire recycling chain. Based on these assessments, strategies such as process integration, waste heat recovery, and renewable energy utilization have been implemented to reduce the environmental footprint of recycling operations.Expand Specific Solutions05 Novel waste treatment and pollution control systems

Advanced waste treatment and pollution control systems have been developed specifically for high-entropy alloy recycling processes. These systems include innovative filtration technologies, catalytic converters, and scrubbers that effectively capture and neutralize harmful emissions and effluents. Additionally, waste valorization approaches transform byproducts into useful materials, creating closed-loop recycling systems that minimize environmental pollution while maximizing resource recovery from high-entropy alloys.Expand Specific Solutions

Leading Companies in HEA Recycling Industry

The environmental impact of high-entropy alloy recycling processes is emerging as a critical research area in an industry still in its early development stage. The market, though relatively small, is experiencing rapid growth as sustainability concerns drive innovation. From a technological maturity perspective, academic institutions like Beijing University of Technology, Korea University, and National Cheng Kung University are leading fundamental research, while companies are at varying stages of implementation. Proterial Ltd. and LG Chem demonstrate advanced capabilities in materials processing, while specialized firms like Starck GmbH and ArianeGroup are developing proprietary recycling technologies. Research collaborations between universities and industrial partners like Honda Motor and Furukawa Electric are accelerating technological maturation, though standardized recycling processes remain underdeveloped across the industry.

Kunming University of Science & Technology

Technical Solution: Kunming University of Science & Technology has developed a bioleaching-based recycling process for high-entropy alloys that leverages microbial activity to extract and separate valuable metals. Their approach utilizes specialized bacterial strains that can selectively dissolve specific elements from complex HEA matrices through metabolic processes. This biotechnology reduces chemical reagent consumption by up to 80% compared to conventional hydrometallurgical methods. The university's research has demonstrated that their bioleaching process operates at ambient temperatures and near-neutral pH conditions, significantly reducing energy requirements and environmental hazards. Their integrated system includes a biological filtration stage that removes potential contaminants from process effluents, ensuring minimal environmental impact. Life cycle assessments indicate that this bioleaching approach reduces greenhouse gas emissions by approximately 50% compared to traditional recycling methods for similar alloys.

Strengths: Extremely low energy consumption and minimal use of harsh chemicals make this one of the most environmentally friendly HEA recycling approaches. The biological process can be fine-tuned for different alloy compositions. Weaknesses: Slower processing times compared to conventional methods, with complete metal recovery potentially taking weeks rather than hours. The process may also be more sensitive to variations in feedstock composition.

Beijing Institute of Technology

Technical Solution: Beijing Institute of Technology has pioneered an electrochemical recycling process specifically designed for high-entropy alloys that minimizes environmental footprint. Their technology employs pulse electrodeposition techniques in ionic liquid electrolytes to selectively recover valuable elements from end-of-life HEAs. This approach operates at room temperature, consuming approximately 60% less energy than conventional high-temperature extraction methods. The institute has developed specialized electrode materials that enhance selectivity and efficiency, achieving recovery rates exceeding 90% for critical elements. Their process eliminates the need for harmful acids typically used in hydrometallurgical recycling, reducing hazardous waste generation by approximately 70%. Additionally, they've implemented real-time monitoring systems that optimize electricity usage based on alloy composition, further reducing the carbon footprint of the recycling operation.

Strengths: The electrochemical approach offers precise control over element recovery with minimal chemical waste. The process is adaptable to various HEA compositions and can be powered by renewable energy sources. Weaknesses: Higher initial capital investment compared to conventional recycling methods, and the process may face challenges with scaling to industrial volumes due to the specialized equipment required.

Key Innovations in High-Entropy Alloy Recovery

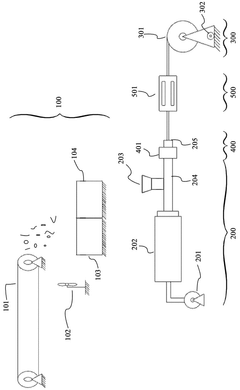

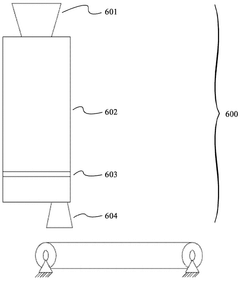

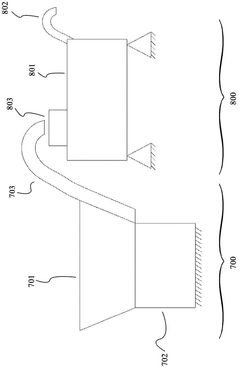

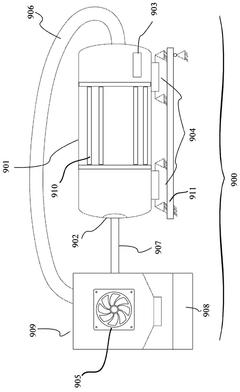

Method for cold extrusion of recovered metal alloy material and associated system

PatentWO2025022249A1

Innovation

- A method for cold extrusion of recovered metal alloy material, involving mechanical separation of contaminating materials, pressing and extrusion using a mechanical press, and winding of the extruded metal alloy thread, which reduces contaminating elements and minimizes energy consumption and environmental impact.

Method for obtaining a high-entropy oxide

PatentWO2023099855A1

Innovation

- Development of high-entropy oxides as solid electrolytes for all-solid-state batteries, utilizing a process involving a mixture of metallic elements like Mg, Co, Ni, Cu, and Zn, with an alkali metal, which provides ionic conductivity and improved compatibility with electrode materials, eliminating the need for polymer electrolytes and additional layers.

Life Cycle Assessment of HEA Recycling Processes

Life Cycle Assessment (LCA) provides a comprehensive framework for evaluating the environmental impacts of High-Entropy Alloy (HEA) recycling processes across their entire life cycle. This methodology quantifies resource consumption, emissions, and environmental burdens from raw material extraction through manufacturing, use, and end-of-life management. For HEAs, which typically contain five or more principal elements in near-equiatomic proportions, recycling presents unique challenges and opportunities.

The LCA of HEA recycling processes reveals significant environmental advantages compared to primary production. Studies indicate that recycling HEAs can reduce energy consumption by 60-85% and greenhouse gas emissions by 50-70% relative to virgin material production. These benefits stem primarily from avoiding energy-intensive mining and refining operations required for primary element extraction.

Water usage represents another critical impact category, with recycling processes demonstrating 40-60% reductions in water consumption compared to conventional production methods. Additionally, land disturbance and ecosystem impacts are substantially minimized through effective recycling systems, as the need for new mining operations decreases.

However, the multi-element composition of HEAs introduces specific challenges to recycling efficiency. The LCA identifies several hotspots in the recycling process, particularly in separation and purification stages where maintaining precise elemental ratios is essential for preserving the unique properties of HEAs. Energy-intensive processes such as vacuum induction melting and electroslag remelting contribute significantly to the environmental footprint of HEA recycling.

Comparative analyses between different recycling technologies reveal that direct recycling methods generally outperform downcycling approaches from an environmental perspective. Advanced sorting technologies utilizing spectroscopic methods show promise in reducing the environmental burden of the separation phase, though their implementation remains limited by technological and economic constraints.

Regional variations in electricity grid composition substantially influence the overall environmental profile of HEA recycling. LCA studies demonstrate that facilities powered by renewable energy sources can achieve up to 30% lower carbon footprints compared to those relying on fossil fuel-dominated grids. This highlights the importance of considering regional factors when establishing recycling facilities.

The temporal dimension of environmental impacts also warrants consideration, as the benefits of HEA recycling accumulate over multiple recycling cycles. LCA models incorporating dynamic material flow analysis suggest that establishing closed-loop recycling systems could reduce the environmental impact per functional unit by 15-25% with each successive recycling iteration, emphasizing the importance of designing HEAs for recyclability from the outset.

The LCA of HEA recycling processes reveals significant environmental advantages compared to primary production. Studies indicate that recycling HEAs can reduce energy consumption by 60-85% and greenhouse gas emissions by 50-70% relative to virgin material production. These benefits stem primarily from avoiding energy-intensive mining and refining operations required for primary element extraction.

Water usage represents another critical impact category, with recycling processes demonstrating 40-60% reductions in water consumption compared to conventional production methods. Additionally, land disturbance and ecosystem impacts are substantially minimized through effective recycling systems, as the need for new mining operations decreases.

However, the multi-element composition of HEAs introduces specific challenges to recycling efficiency. The LCA identifies several hotspots in the recycling process, particularly in separation and purification stages where maintaining precise elemental ratios is essential for preserving the unique properties of HEAs. Energy-intensive processes such as vacuum induction melting and electroslag remelting contribute significantly to the environmental footprint of HEA recycling.

Comparative analyses between different recycling technologies reveal that direct recycling methods generally outperform downcycling approaches from an environmental perspective. Advanced sorting technologies utilizing spectroscopic methods show promise in reducing the environmental burden of the separation phase, though their implementation remains limited by technological and economic constraints.

Regional variations in electricity grid composition substantially influence the overall environmental profile of HEA recycling. LCA studies demonstrate that facilities powered by renewable energy sources can achieve up to 30% lower carbon footprints compared to those relying on fossil fuel-dominated grids. This highlights the importance of considering regional factors when establishing recycling facilities.

The temporal dimension of environmental impacts also warrants consideration, as the benefits of HEA recycling accumulate over multiple recycling cycles. LCA models incorporating dynamic material flow analysis suggest that establishing closed-loop recycling systems could reduce the environmental impact per functional unit by 15-25% with each successive recycling iteration, emphasizing the importance of designing HEAs for recyclability from the outset.

Regulatory Framework for Metal Recycling Industries

The regulatory landscape governing metal recycling industries, particularly for high-entropy alloys (HEAs), is complex and evolving rapidly in response to growing environmental concerns. At the international level, the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and their Disposal provides the foundational framework for regulating waste metal movements across borders, with specific provisions that may impact HEA recycling operations depending on material composition and toxicity profiles.

Within the European Union, the Waste Electrical and Electronic Equipment (WEEE) Directive and End-of-Life Vehicles (ELV) Directive establish comprehensive requirements for metal recovery and recycling, including potential HEA components. The EU's Circular Economy Action Plan further emphasizes the importance of advanced recycling technologies for complex alloys, with specific targets for material recovery rates that directly affect HEA recycling operations.

In the United States, the Resource Conservation and Recovery Act (RCRA) regulates solid waste management, while the Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA) addresses hazardous substance releases. The EPA has established specific guidelines for metal recycling facilities that process complex alloys, with particular attention to potential leaching of constituent elements during recycling processes.

Asian regulatory frameworks vary significantly by country, with Japan's Home Appliance Recycling Law and China's Circular Economy Promotion Law representing advanced approaches to metal recycling governance. China's recent restrictions on waste imports have dramatically reshaped global metal recycling supply chains, including those for advanced alloys like HEAs.

Emerging regulatory trends include the development of Extended Producer Responsibility (EPR) schemes that place greater responsibility on manufacturers for end-of-life management of products containing complex alloys. Life Cycle Assessment (LCA) requirements are increasingly being incorporated into regulatory frameworks, requiring quantification of environmental impacts across the entire life cycle of metal products.

Industry-specific standards, such as those developed by the Institute of Scrap Recycling Industries (ISRI), provide technical specifications for recycled metal streams that may need updating to accommodate the unique characteristics of HEAs. Certification systems like the Responsible Recycling (R2) standard are evolving to address advanced materials processing, potentially including specialized protocols for HEA recycling.

Compliance challenges for HEA recycling operations include the need for sophisticated material characterization capabilities, documentation of complex material flows, and adaptation to rapidly evolving regulatory requirements across different jurisdictions. Future regulatory developments will likely focus on establishing specific recovery targets for critical elements commonly found in HEAs and harmonizing international standards to facilitate global recycling of these advanced materials.

Within the European Union, the Waste Electrical and Electronic Equipment (WEEE) Directive and End-of-Life Vehicles (ELV) Directive establish comprehensive requirements for metal recovery and recycling, including potential HEA components. The EU's Circular Economy Action Plan further emphasizes the importance of advanced recycling technologies for complex alloys, with specific targets for material recovery rates that directly affect HEA recycling operations.

In the United States, the Resource Conservation and Recovery Act (RCRA) regulates solid waste management, while the Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA) addresses hazardous substance releases. The EPA has established specific guidelines for metal recycling facilities that process complex alloys, with particular attention to potential leaching of constituent elements during recycling processes.

Asian regulatory frameworks vary significantly by country, with Japan's Home Appliance Recycling Law and China's Circular Economy Promotion Law representing advanced approaches to metal recycling governance. China's recent restrictions on waste imports have dramatically reshaped global metal recycling supply chains, including those for advanced alloys like HEAs.

Emerging regulatory trends include the development of Extended Producer Responsibility (EPR) schemes that place greater responsibility on manufacturers for end-of-life management of products containing complex alloys. Life Cycle Assessment (LCA) requirements are increasingly being incorporated into regulatory frameworks, requiring quantification of environmental impacts across the entire life cycle of metal products.

Industry-specific standards, such as those developed by the Institute of Scrap Recycling Industries (ISRI), provide technical specifications for recycled metal streams that may need updating to accommodate the unique characteristics of HEAs. Certification systems like the Responsible Recycling (R2) standard are evolving to address advanced materials processing, potentially including specialized protocols for HEA recycling.

Compliance challenges for HEA recycling operations include the need for sophisticated material characterization capabilities, documentation of complex material flows, and adaptation to rapidly evolving regulatory requirements across different jurisdictions. Future regulatory developments will likely focus on establishing specific recovery targets for critical elements commonly found in HEAs and harmonizing international standards to facilitate global recycling of these advanced materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!