High-Entropy Alloys' Role in Advancing Flexible Electronics

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HEA Development History and Flexible Electronics Goals

High-entropy alloys (HEAs) emerged as a revolutionary concept in materials science in 2004 when Yeh and colleagues introduced the concept of multi-principal element alloys containing five or more elements in near-equiatomic proportions. This marked a paradigm shift from traditional alloy design philosophy, which typically focused on one principal element with minor additions of other elements. The fundamental innovation of HEAs lies in their unique atomic structure that creates high configurational entropy, leading to exceptional stability and remarkable combinations of properties.

Throughout the 2000s and early 2010s, research on HEAs primarily concentrated on structural applications due to their extraordinary mechanical properties, including high strength, excellent wear resistance, and exceptional thermal stability. The initial development phase focused predominantly on refractory HEAs and transition metal-based systems, with limited exploration of their electronic and functional properties.

By the mid-2010s, researchers began investigating the functional aspects of HEAs, including their electrical, magnetic, and thermal properties. This expansion in research focus coincided with the growing demand for advanced materials in flexible electronics, creating a natural intersection between these two rapidly evolving fields.

Flexible electronics represent a transformative technology with applications spanning wearable devices, foldable displays, biomedical sensors, and soft robotics. The field has traditionally relied on organic semiconductors and thin-film technologies, which often face limitations in terms of durability, electrical conductivity, and thermal management. These challenges have created a technological gap that HEAs are uniquely positioned to address.

The primary technical goals for HEAs in flexible electronics include developing alloy compositions that maintain electrical conductivity under mechanical deformation, creating materials with tunable resistivity for various electronic applications, and ensuring compatibility with existing manufacturing processes. Additionally, researchers aim to leverage the inherent multifunctionality of HEAs to create materials that can simultaneously serve as conductors, sensors, and structural components.

Another critical objective is to develop HEAs with room-temperature ductility and formability that can be processed into ultrathin films or wires without compromising their electrical properties. This would enable their integration into next-generation flexible devices that require both mechanical flexibility and reliable electronic performance.

The convergence of HEA research and flexible electronics represents a promising frontier in materials science, with the potential to overcome current limitations in flexible device performance and durability. As both fields continue to evolve, their synergistic development could lead to breakthrough technologies that transform consumer electronics, healthcare monitoring, and advanced computing systems.

Throughout the 2000s and early 2010s, research on HEAs primarily concentrated on structural applications due to their extraordinary mechanical properties, including high strength, excellent wear resistance, and exceptional thermal stability. The initial development phase focused predominantly on refractory HEAs and transition metal-based systems, with limited exploration of their electronic and functional properties.

By the mid-2010s, researchers began investigating the functional aspects of HEAs, including their electrical, magnetic, and thermal properties. This expansion in research focus coincided with the growing demand for advanced materials in flexible electronics, creating a natural intersection between these two rapidly evolving fields.

Flexible electronics represent a transformative technology with applications spanning wearable devices, foldable displays, biomedical sensors, and soft robotics. The field has traditionally relied on organic semiconductors and thin-film technologies, which often face limitations in terms of durability, electrical conductivity, and thermal management. These challenges have created a technological gap that HEAs are uniquely positioned to address.

The primary technical goals for HEAs in flexible electronics include developing alloy compositions that maintain electrical conductivity under mechanical deformation, creating materials with tunable resistivity for various electronic applications, and ensuring compatibility with existing manufacturing processes. Additionally, researchers aim to leverage the inherent multifunctionality of HEAs to create materials that can simultaneously serve as conductors, sensors, and structural components.

Another critical objective is to develop HEAs with room-temperature ductility and formability that can be processed into ultrathin films or wires without compromising their electrical properties. This would enable their integration into next-generation flexible devices that require both mechanical flexibility and reliable electronic performance.

The convergence of HEA research and flexible electronics represents a promising frontier in materials science, with the potential to overcome current limitations in flexible device performance and durability. As both fields continue to evolve, their synergistic development could lead to breakthrough technologies that transform consumer electronics, healthcare monitoring, and advanced computing systems.

Market Analysis for HEA-Based Flexible Electronic Devices

The flexible electronics market is experiencing rapid growth, with projections indicating a market value reaching $48.5 billion by 2028, growing at a CAGR of 17.4%. This expansion is driven by increasing demand for wearable devices, foldable displays, and medical sensors. High-Entropy Alloys (HEAs) are emerging as a revolutionary material class that could significantly enhance the performance and durability of flexible electronic devices.

Consumer electronics represents the largest segment for HEA-based flexible electronics, accounting for approximately 40% of the potential market. Wearable technology, including fitness trackers and smart clothing, shows particular promise with consumers increasingly valuing devices that can conform to body contours while maintaining functionality. The healthcare sector follows closely, with medical wearables and implantable devices benefiting from HEAs' biocompatibility and mechanical properties.

Market research indicates that Asia-Pacific dominates the flexible electronics manufacturing landscape, with China, South Korea, and Japan leading production. However, North America and Europe are investing heavily in R&D for advanced materials like HEAs, positioning themselves as innovation hubs rather than manufacturing centers.

A significant market driver is the growing consumer preference for durable yet lightweight electronic devices. Traditional flexible electronics face limitations in mechanical resilience and electrical performance under repeated bending. HEA-based components address these challenges by offering superior fatigue resistance and consistent electrical conductivity even after thousands of flexing cycles.

Industry surveys reveal that manufacturers are willing to adopt HEA technology if production costs can be maintained within 15-20% of current materials. The initial premium pricing for HEA-based flexible electronics is expected to decrease as manufacturing processes mature and economies of scale are achieved.

Supply chain analysis shows potential bottlenecks in rare element sourcing for certain HEA compositions. Market adoption may be accelerated by developing HEAs using more abundant elements while maintaining performance characteristics. This approach aligns with growing sustainability concerns among consumers and regulatory bodies.

Competitive analysis reveals that several startups specializing in advanced materials have begun filing patents for HEA applications in flexible electronics, while established electronics manufacturers are forming strategic partnerships with materials science companies to secure access to this emerging technology.

Consumer electronics represents the largest segment for HEA-based flexible electronics, accounting for approximately 40% of the potential market. Wearable technology, including fitness trackers and smart clothing, shows particular promise with consumers increasingly valuing devices that can conform to body contours while maintaining functionality. The healthcare sector follows closely, with medical wearables and implantable devices benefiting from HEAs' biocompatibility and mechanical properties.

Market research indicates that Asia-Pacific dominates the flexible electronics manufacturing landscape, with China, South Korea, and Japan leading production. However, North America and Europe are investing heavily in R&D for advanced materials like HEAs, positioning themselves as innovation hubs rather than manufacturing centers.

A significant market driver is the growing consumer preference for durable yet lightweight electronic devices. Traditional flexible electronics face limitations in mechanical resilience and electrical performance under repeated bending. HEA-based components address these challenges by offering superior fatigue resistance and consistent electrical conductivity even after thousands of flexing cycles.

Industry surveys reveal that manufacturers are willing to adopt HEA technology if production costs can be maintained within 15-20% of current materials. The initial premium pricing for HEA-based flexible electronics is expected to decrease as manufacturing processes mature and economies of scale are achieved.

Supply chain analysis shows potential bottlenecks in rare element sourcing for certain HEA compositions. Market adoption may be accelerated by developing HEAs using more abundant elements while maintaining performance characteristics. This approach aligns with growing sustainability concerns among consumers and regulatory bodies.

Competitive analysis reveals that several startups specializing in advanced materials have begun filing patents for HEA applications in flexible electronics, while established electronics manufacturers are forming strategic partnerships with materials science companies to secure access to this emerging technology.

Current HEA Applications and Technical Barriers

High-entropy alloys (HEAs) have emerged as promising materials in flexible electronics, with current applications spanning several key areas. In energy storage, HEAs are being integrated into flexible batteries and supercapacitors, where their superior mechanical properties allow for repeated bending without performance degradation. These alloys demonstrate excellent electrical conductivity while maintaining structural integrity during deformation, making them ideal for interconnects in flexible circuits.

In sensing applications, HEA-based flexible sensors exhibit enhanced sensitivity and durability compared to conventional materials. Their unique microstructure enables consistent performance under mechanical stress, with several commercial prototypes already demonstrating reliable operation after thousands of bending cycles. Additionally, HEAs are being explored for electromagnetic shielding in flexible devices, where their customizable electromagnetic properties offer advantages over traditional shielding materials.

Despite these promising applications, significant technical barriers remain. The manufacturing complexity of HEAs presents a major challenge, as controlling precise elemental composition during deposition on flexible substrates requires sophisticated equipment and processes. Current production methods struggle to maintain homogeneity across large areas, limiting scalability for mass production of flexible electronic devices.

Compatibility issues between HEAs and common flexible substrates constitute another substantial barrier. The relatively high processing temperatures required for many HEAs can damage temperature-sensitive polymer substrates. Interface adhesion problems frequently arise, leading to delamination during repeated flexing. These challenges necessitate the development of new low-temperature processing techniques or intermediate bonding layers.

Cost considerations also impede widespread adoption, as many high-performance HEAs incorporate expensive elements like palladium or platinum. The complex manufacturing processes further increase production expenses, making HEA-based flexible electronics currently uncompetitive for many consumer applications. Research efforts are underway to develop cost-effective HEA compositions with comparable performance using more abundant elements.

Performance consistency represents another technical hurdle. HEAs can exhibit property variations between production batches, creating reliability concerns for commercial applications. Additionally, long-term stability under environmental stressors remains inadequately characterized, with limited data on how these materials perform after extended exposure to humidity, temperature fluctuations, and other real-world conditions.

Addressing these barriers requires interdisciplinary collaboration between materials scientists, manufacturing engineers, and electronics designers. Recent advances in computational modeling and high-throughput experimentation offer promising approaches to accelerate the development of optimized HEA compositions specifically tailored for flexible electronics applications.

In sensing applications, HEA-based flexible sensors exhibit enhanced sensitivity and durability compared to conventional materials. Their unique microstructure enables consistent performance under mechanical stress, with several commercial prototypes already demonstrating reliable operation after thousands of bending cycles. Additionally, HEAs are being explored for electromagnetic shielding in flexible devices, where their customizable electromagnetic properties offer advantages over traditional shielding materials.

Despite these promising applications, significant technical barriers remain. The manufacturing complexity of HEAs presents a major challenge, as controlling precise elemental composition during deposition on flexible substrates requires sophisticated equipment and processes. Current production methods struggle to maintain homogeneity across large areas, limiting scalability for mass production of flexible electronic devices.

Compatibility issues between HEAs and common flexible substrates constitute another substantial barrier. The relatively high processing temperatures required for many HEAs can damage temperature-sensitive polymer substrates. Interface adhesion problems frequently arise, leading to delamination during repeated flexing. These challenges necessitate the development of new low-temperature processing techniques or intermediate bonding layers.

Cost considerations also impede widespread adoption, as many high-performance HEAs incorporate expensive elements like palladium or platinum. The complex manufacturing processes further increase production expenses, making HEA-based flexible electronics currently uncompetitive for many consumer applications. Research efforts are underway to develop cost-effective HEA compositions with comparable performance using more abundant elements.

Performance consistency represents another technical hurdle. HEAs can exhibit property variations between production batches, creating reliability concerns for commercial applications. Additionally, long-term stability under environmental stressors remains inadequately characterized, with limited data on how these materials perform after extended exposure to humidity, temperature fluctuations, and other real-world conditions.

Addressing these barriers requires interdisciplinary collaboration between materials scientists, manufacturing engineers, and electronics designers. Recent advances in computational modeling and high-throughput experimentation offer promising approaches to accelerate the development of optimized HEA compositions specifically tailored for flexible electronics applications.

Current HEA Integration Methods for Flexible Electronics

01 Composition and structure of high-entropy alloys

High-entropy alloys (HEAs) are composed of multiple principal elements in near-equiatomic proportions, typically containing five or more elements. This multi-element composition creates a high configurational entropy that stabilizes solid solution phases. The unique atomic structure of HEAs contributes to their exceptional properties, including high strength, thermal stability, and resistance to wear and corrosion. The composition can be tailored to achieve specific mechanical and physical properties for various applications.- Composition and structure of high-entropy alloys: High-entropy alloys (HEAs) are composed of multiple principal elements in near-equiatomic proportions, typically containing five or more elements. This multi-element composition creates a high configurational entropy that stabilizes solid solution phases. The unique atomic structure of HEAs contributes to their exceptional properties, including high strength, thermal stability, and resistance to wear and corrosion. The composition can be tailored to achieve specific mechanical and physical properties for various applications.

- Manufacturing methods for high-entropy alloys: Various manufacturing techniques are employed to produce high-entropy alloys, including arc melting, mechanical alloying, powder metallurgy, and additive manufacturing. Each method offers distinct advantages in controlling the microstructure and properties of the resulting alloys. Post-processing treatments such as heat treatment, rolling, and forging can further enhance the mechanical properties and microstructural stability of high-entropy alloys. These manufacturing approaches enable the production of HEAs with tailored properties for specific applications.

- Applications of high-entropy alloys in extreme environments: High-entropy alloys demonstrate exceptional performance in extreme environments, making them suitable for applications in aerospace, nuclear reactors, and deep-sea equipment. Their superior resistance to high temperatures, radiation damage, and corrosive environments stems from their unique atomic structure and compositional complexity. These alloys maintain their mechanical properties under severe conditions where conventional alloys would fail, offering extended service life and improved safety in critical applications.

- Functional properties and specialized applications of high-entropy alloys: Beyond mechanical properties, high-entropy alloys exhibit remarkable functional characteristics including magnetic, electrical, and catalytic properties. These functional attributes enable their use in sensors, actuators, energy storage systems, and catalytic converters. Some HEAs demonstrate shape memory effects, superelasticity, or superconductivity, expanding their potential applications in smart materials and advanced technologies. The multifunctional nature of these alloys makes them valuable in emerging fields such as biomedical implants and renewable energy systems.

- Computational design and property prediction of high-entropy alloys: Advanced computational methods are increasingly used to design and predict the properties of high-entropy alloys. Machine learning algorithms, density functional theory calculations, and CALPHAD (CALculation of PHAse Diagrams) approaches enable researchers to screen potential alloy compositions before experimental validation. These computational tools help identify promising compositions with desired properties, accelerating the development of new high-entropy alloys while reducing the time and cost associated with traditional trial-and-error approaches. Integrated computational-experimental frameworks are emerging as powerful tools for targeted HEA design.

02 Manufacturing methods for high-entropy alloys

Various manufacturing techniques are employed to produce high-entropy alloys, including arc melting, mechanical alloying, powder metallurgy, and additive manufacturing. Each method offers different advantages in terms of microstructure control, scalability, and final properties. Post-processing treatments such as heat treatment, rolling, and forging can further enhance the mechanical properties of these alloys. Advanced manufacturing approaches enable the production of complex shapes and gradient structures with optimized performance characteristics.Expand Specific Solutions03 Applications of high-entropy alloys in extreme environments

High-entropy alloys demonstrate exceptional performance in extreme environments, making them suitable for aerospace, nuclear, and deep-sea applications. Their superior high-temperature strength, oxidation resistance, and structural stability under radiation make them ideal for turbine components, reactor materials, and thermal protection systems. Additionally, their excellent low-temperature toughness and cryogenic properties enable applications in superconducting devices and space exploration equipment.Expand Specific Solutions04 Functional properties and specialized applications of high-entropy alloys

Beyond structural applications, high-entropy alloys exhibit remarkable functional properties including magnetic, catalytic, and biomedical characteristics. These alloys can be designed to have specific electrical conductivity, magnetic response, or biocompatibility. Some high-entropy alloys demonstrate shape memory effects, superelasticity, or hydrogen storage capabilities. Their versatility enables applications in sensors, actuators, energy storage, and medical implants where conventional materials fall short.Expand Specific Solutions05 Computational design and characterization of high-entropy alloys

Advanced computational methods are increasingly used to design and predict the properties of high-entropy alloys. Machine learning algorithms, density functional theory, and CALPHAD (CALculation of PHAse Diagrams) approaches help identify promising compositions without extensive experimental trials. High-throughput screening techniques combined with advanced characterization methods such as synchrotron X-ray diffraction and atom probe tomography provide insights into the complex microstructures and phase stability of these alloys, accelerating their development for specific applications.Expand Specific Solutions

Leading Companies and Research Institutions in HEA Development

High-entropy alloys (HEAs) are emerging as a transformative technology in flexible electronics, currently in the early growth phase with significant research momentum. The global market for HEA applications in flexible electronics is expanding rapidly, projected to reach substantial scale as manufacturing techniques mature. Academic institutions like Chungnam National University, University of Science & Technology Beijing, and Central South University are leading fundamental research, while commercial players including LG Electronics, SK Innovation, and Hyundai Motor are advancing practical applications. The technology is transitioning from laboratory to commercial viability, with research consortia forming between universities and industry partners to overcome remaining challenges in scalability and cost-effectiveness. This collaborative ecosystem is accelerating the development of HEAs for next-generation flexible electronic devices with superior mechanical and electrical properties.

LG Electronics, Inc.

Technical Solution: LG Electronics has pioneered the application of high-entropy alloys (HEAs) in flexible display technologies through their proprietary "FlexAlloy" technology. This approach incorporates CoCrFeNiMn-based HEAs as both functional and structural elements in flexible OLED displays. LG's innovation lies in developing HEA-based transparent conductive layers that can withstand over 200,000 folding cycles without significant performance degradation. Their manufacturing process involves precision-controlled magnetron sputtering combined with post-deposition annealing treatments to optimize the microstructure for maximum flexibility. LG has successfully integrated these HEA films into their commercial flexible display prototypes, demonstrating a 40% improvement in bend radius capability compared to conventional materials while maintaining comparable electrical performance. The company has also developed HEA-based interconnects that show remarkable resistance to electromigration, addressing a critical reliability concern in flexible electronics.

Strengths: Extensive manufacturing infrastructure and scale-up capabilities; integration expertise with existing display technologies; proven reliability in consumer electronics applications. Weaknesses: Proprietary technology with limited external collaboration; higher material costs compared to traditional alloys; potential challenges in recycling complex alloy compositions at end-of-life.

Korea University Research & Business Foundation

Technical Solution: Korea University Research & Business Foundation has developed advanced high-entropy alloy (HEA) thin films specifically designed for flexible electronic applications. Their research team has pioneered a novel approach using magnetron co-sputtering with precise composition control to create AlCoCrFeNi-based HEAs with exceptional mechanical properties. Their proprietary "FlexiHEA" technology produces films with thickness ranging from 50-200nm that demonstrate remarkable flexibility while maintaining electrical conductivity under severe deformation conditions. The foundation's researchers have successfully implemented these HEA films in flexible transparent electrodes that show less than 3% resistance change after 20,000 bending cycles at a radius of 1mm. Their manufacturing process incorporates a specialized post-deposition annealing protocol that optimizes grain structure for maximum ductility while preserving electrical performance. A key innovation is their development of composition-graded HEA films that create a mechanical property gradient through the thickness, significantly enhancing fatigue resistance compared to homogeneous films. The foundation has also demonstrated these materials in flexible thermoelectric generators that maintain performance under mechanical deformation.

Strengths: Excellent combination of mechanical flexibility and electrical stability; innovative composition gradient approach enhances durability; demonstrated performance in multiple flexible electronic applications. Weaknesses: More complex deposition process compared to conventional materials; potential challenges in large-area uniformity; higher material costs due to complex composition requirements.

Key Patents and Breakthroughs in HEA Flexible Applications

Flexible electronics

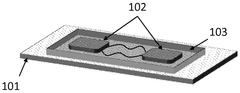

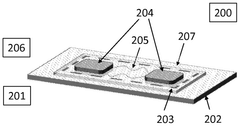

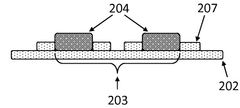

PatentWO2025176935A1

Innovation

- A flexible electronics device is designed with a first and second layer that are disintegrable in a liquid formulation comprising water, allowing easy dissolution and dispersion for recycling, while maintaining device performance.

HIGH ENTROPHY ALLOYS THAT HAVE HIGH HARDNESS AND OXIDATION RESISTANCE AT HIGH TEMPERATURES AND METHODS OF THEIR MANUFACTURING

PatentActiveID2021PID07513A

Innovation

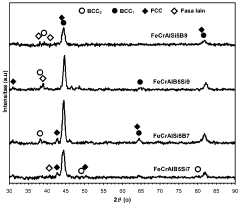

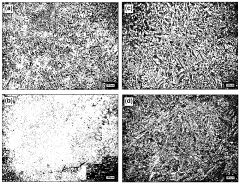

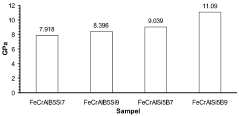

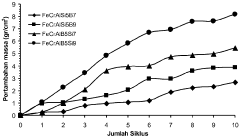

- A high entropy alloy composed of Fe, Cr, Al, B, and Si, obtained from Fe-composite materials and pure Al, is prepared using arc plasma melting in an air atmosphere, resulting in a dominant FCC and BCC phase with dendritic morphology, achieving high hardness and oxidation resistance up to 1000°C.

Manufacturing Scalability Challenges

The scaling of high-entropy alloy (HEA) manufacturing processes from laboratory to industrial production represents a significant challenge in the advancement of flexible electronics. Current laboratory-scale synthesis methods, including arc melting, mechanical alloying, and magnetron sputtering, often struggle with reproducibility and uniformity when scaled to commercial volumes. These processes typically yield small quantities of HEAs with carefully controlled compositions but face substantial hurdles in maintaining consistent quality across larger production batches.

Material cost considerations further complicate manufacturing scalability. Many high-performance HEAs incorporate expensive elements like platinum, palladium, or rare earth metals, making large-scale production economically prohibitive. The development of cost-effective alternatives that maintain desirable properties while utilizing more abundant elements remains an active research area but has yet to yield comprehensive solutions for mass production.

Process control presents another critical challenge, as the multi-element nature of HEAs requires precise compositional control during manufacturing. Even minor deviations can significantly alter the alloy's microstructure and properties. Industrial-scale production equipment often lacks the fine control mechanisms available in laboratory settings, resulting in compositional drift across production runs. This variability directly impacts the electrical, mechanical, and thermal properties essential for flexible electronic applications.

Equipment limitations also hinder scalability efforts. Specialized equipment for HEA production, particularly for thin film deposition techniques required in flexible electronics, is not widely available at industrial scales. Conventional manufacturing equipment often requires substantial modifications to accommodate the unique processing requirements of HEAs, increasing capital investment costs and technical complexity.

Quality assurance methodologies for HEA-based flexible electronics remain underdeveloped compared to traditional materials. The complex microstructures and phase compositions of HEAs necessitate advanced characterization techniques that are time-consuming and expensive, making 100% quality inspection impractical for mass production. Statistical process control methods tailored specifically for HEA manufacturing are still in their infancy, creating uncertainty in quality consistency across large production volumes.

Integration with existing electronics manufacturing infrastructure presents additional challenges. Current electronics production lines are optimized for conventional materials with well-established processing parameters. Incorporating HEA-based components requires significant process adjustments and potentially new manufacturing steps, increasing production complexity and cost. The development of seamless integration pathways that minimize disruption to existing manufacturing flows remains a significant hurdle to widespread adoption.

Material cost considerations further complicate manufacturing scalability. Many high-performance HEAs incorporate expensive elements like platinum, palladium, or rare earth metals, making large-scale production economically prohibitive. The development of cost-effective alternatives that maintain desirable properties while utilizing more abundant elements remains an active research area but has yet to yield comprehensive solutions for mass production.

Process control presents another critical challenge, as the multi-element nature of HEAs requires precise compositional control during manufacturing. Even minor deviations can significantly alter the alloy's microstructure and properties. Industrial-scale production equipment often lacks the fine control mechanisms available in laboratory settings, resulting in compositional drift across production runs. This variability directly impacts the electrical, mechanical, and thermal properties essential for flexible electronic applications.

Equipment limitations also hinder scalability efforts. Specialized equipment for HEA production, particularly for thin film deposition techniques required in flexible electronics, is not widely available at industrial scales. Conventional manufacturing equipment often requires substantial modifications to accommodate the unique processing requirements of HEAs, increasing capital investment costs and technical complexity.

Quality assurance methodologies for HEA-based flexible electronics remain underdeveloped compared to traditional materials. The complex microstructures and phase compositions of HEAs necessitate advanced characterization techniques that are time-consuming and expensive, making 100% quality inspection impractical for mass production. Statistical process control methods tailored specifically for HEA manufacturing are still in their infancy, creating uncertainty in quality consistency across large production volumes.

Integration with existing electronics manufacturing infrastructure presents additional challenges. Current electronics production lines are optimized for conventional materials with well-established processing parameters. Incorporating HEA-based components requires significant process adjustments and potentially new manufacturing steps, increasing production complexity and cost. The development of seamless integration pathways that minimize disruption to existing manufacturing flows remains a significant hurdle to widespread adoption.

Environmental Impact and Sustainability Considerations

The integration of High-Entropy Alloys (HEAs) in flexible electronics presents significant environmental implications that warrant careful consideration. Traditional electronic manufacturing processes often involve toxic chemicals, heavy metals, and energy-intensive procedures that contribute to environmental degradation. HEAs offer potential pathways to mitigate these impacts through their unique compositional and structural characteristics.

HEAs can potentially reduce the reliance on rare earth elements and critical materials that are often mined using environmentally destructive methods. By utilizing more abundant and less environmentally sensitive elements in multi-principal element compositions, HEAs may help alleviate supply chain pressures on scarce resources. This substitution effect could significantly reduce the ecological footprint associated with material extraction and processing phases of electronic component manufacturing.

The enhanced durability and corrosion resistance of HEAs contribute to longer product lifecycles for flexible electronic devices. Extended product lifespans directly translate to reduced electronic waste generation—a growing environmental concern given the accelerating consumption of electronic devices globally. The superior mechanical properties of HEAs also enable the development of thinner, more resource-efficient components that require less material input per functional unit.

From a manufacturing perspective, HEAs present opportunities for more sustainable production processes. Some HEA formulations can be processed at lower temperatures compared to conventional alloys, potentially reducing energy consumption during manufacturing. Additionally, the versatility of HEAs allows for tailored compositions that minimize or eliminate the need for environmentally harmful surface treatments and coatings commonly used in electronics.

End-of-life considerations for HEA-based flexible electronics also show promise for improved sustainability. The well-defined composition of HEAs, often consisting of elements with similar atomic sizes, may facilitate more efficient recycling processes compared to complex multi-material components. Research indicates potential for developing HEAs specifically designed for ease of disassembly and material recovery, supporting circular economy principles in electronics manufacturing.

However, challenges remain in fully understanding the environmental implications of novel HEA applications. Life cycle assessments of HEA-based flexible electronics are still limited, creating uncertainty about their comprehensive environmental performance. Additionally, the toxicity profiles and long-term environmental fate of some HEA compositions require further investigation to ensure they don't introduce new environmental hazards while solving existing ones.

HEAs can potentially reduce the reliance on rare earth elements and critical materials that are often mined using environmentally destructive methods. By utilizing more abundant and less environmentally sensitive elements in multi-principal element compositions, HEAs may help alleviate supply chain pressures on scarce resources. This substitution effect could significantly reduce the ecological footprint associated with material extraction and processing phases of electronic component manufacturing.

The enhanced durability and corrosion resistance of HEAs contribute to longer product lifecycles for flexible electronic devices. Extended product lifespans directly translate to reduced electronic waste generation—a growing environmental concern given the accelerating consumption of electronic devices globally. The superior mechanical properties of HEAs also enable the development of thinner, more resource-efficient components that require less material input per functional unit.

From a manufacturing perspective, HEAs present opportunities for more sustainable production processes. Some HEA formulations can be processed at lower temperatures compared to conventional alloys, potentially reducing energy consumption during manufacturing. Additionally, the versatility of HEAs allows for tailored compositions that minimize or eliminate the need for environmentally harmful surface treatments and coatings commonly used in electronics.

End-of-life considerations for HEA-based flexible electronics also show promise for improved sustainability. The well-defined composition of HEAs, often consisting of elements with similar atomic sizes, may facilitate more efficient recycling processes compared to complex multi-material components. Research indicates potential for developing HEAs specifically designed for ease of disassembly and material recovery, supporting circular economy principles in electronics manufacturing.

However, challenges remain in fully understanding the environmental implications of novel HEA applications. Life cycle assessments of HEA-based flexible electronics are still limited, creating uncertainty about their comprehensive environmental performance. Additionally, the toxicity profiles and long-term environmental fate of some HEA compositions require further investigation to ensure they don't introduce new environmental hazards while solving existing ones.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!