Effects of Rapid Solidification on High-Entropy Alloys

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

High-Entropy Alloys Background and Research Objectives

High-entropy alloys (HEAs) represent a revolutionary paradigm shift in metallurgical science that emerged in the early 2000s. Unlike conventional alloys that are based on one principal element with minor additions, HEAs consist of five or more principal elements in near-equiatomic proportions. This fundamental departure from traditional alloy design has opened new avenues for developing materials with exceptional combinations of properties, including high strength, excellent thermal stability, superior corrosion resistance, and remarkable wear resistance.

The evolution of HEAs can be traced back to the pioneering work of Yeh et al. and Cantor et al. in 2004, who independently proposed the concept of multi-principal element alloys. Since then, the field has experienced exponential growth, with researchers worldwide exploring various compositional spaces and processing techniques to tailor the microstructure and properties of these novel materials.

Recent technological trends in HEA development have focused on expanding beyond the original definition to include compositionally complex alloys with non-equiatomic compositions, as well as incorporating interstitial elements to further enhance specific properties. The integration of computational methods, including CALPHAD (CALculation of PHAse Diagrams) and machine learning approaches, has accelerated the discovery and optimization of new HEA compositions.

Rapid solidification processes represent a critical frontier in HEA research, as they can induce non-equilibrium phases, refined microstructures, and extended solid solubility limits. These processes include techniques such as melt spinning, laser additive manufacturing, and splat quenching, which impose cooling rates ranging from 10³ to 10⁸ K/s.

The primary research objectives of this technical investigation are multifaceted. First, we aim to comprehensively understand the fundamental mechanisms governing phase formation and microstructural evolution during rapid solidification of HEAs. Second, we seek to establish quantitative relationships between processing parameters, cooling rates, and resultant microstructures. Third, we intend to explore how rapid solidification affects the mechanical, thermal, and functional properties of various HEA systems.

Additionally, this research aims to identify promising HEA compositions that exhibit enhanced performance under rapid solidification conditions, potentially leading to new materials for extreme environment applications. The investigation will also evaluate the scalability of rapid solidification techniques for industrial production of HEAs, addressing challenges related to process control, reproducibility, and cost-effectiveness.

Through this technical exploration, we expect to contribute to the broader understanding of non-equilibrium processing of complex alloy systems and establish design principles for next-generation HEAs with tailored properties for specific technological applications.

The evolution of HEAs can be traced back to the pioneering work of Yeh et al. and Cantor et al. in 2004, who independently proposed the concept of multi-principal element alloys. Since then, the field has experienced exponential growth, with researchers worldwide exploring various compositional spaces and processing techniques to tailor the microstructure and properties of these novel materials.

Recent technological trends in HEA development have focused on expanding beyond the original definition to include compositionally complex alloys with non-equiatomic compositions, as well as incorporating interstitial elements to further enhance specific properties. The integration of computational methods, including CALPHAD (CALculation of PHAse Diagrams) and machine learning approaches, has accelerated the discovery and optimization of new HEA compositions.

Rapid solidification processes represent a critical frontier in HEA research, as they can induce non-equilibrium phases, refined microstructures, and extended solid solubility limits. These processes include techniques such as melt spinning, laser additive manufacturing, and splat quenching, which impose cooling rates ranging from 10³ to 10⁸ K/s.

The primary research objectives of this technical investigation are multifaceted. First, we aim to comprehensively understand the fundamental mechanisms governing phase formation and microstructural evolution during rapid solidification of HEAs. Second, we seek to establish quantitative relationships between processing parameters, cooling rates, and resultant microstructures. Third, we intend to explore how rapid solidification affects the mechanical, thermal, and functional properties of various HEA systems.

Additionally, this research aims to identify promising HEA compositions that exhibit enhanced performance under rapid solidification conditions, potentially leading to new materials for extreme environment applications. The investigation will also evaluate the scalability of rapid solidification techniques for industrial production of HEAs, addressing challenges related to process control, reproducibility, and cost-effectiveness.

Through this technical exploration, we expect to contribute to the broader understanding of non-equilibrium processing of complex alloy systems and establish design principles for next-generation HEAs with tailored properties for specific technological applications.

Market Applications and Demand Analysis for HEAs

The global market for High-Entropy Alloys (HEAs) is experiencing significant growth driven by their exceptional mechanical properties, corrosion resistance, and thermal stability. These characteristics make HEAs particularly valuable in aerospace, defense, automotive, and energy sectors where traditional alloys reach their performance limits. The market size for advanced alloys including HEAs was valued at approximately $2.5 billion in 2022, with projections indicating a compound annual growth rate of 11.7% through 2030.

Rapid solidification processing has emerged as a critical manufacturing technique that enhances HEAs' properties, creating substantial market opportunities. Industries requiring materials that can withstand extreme conditions show the strongest demand. The aerospace sector represents the largest market segment, with HEAs being evaluated for turbine blades, structural components, and heat shields where their superior high-temperature strength and oxidation resistance provide significant advantages over conventional superalloys.

The automotive industry presents another substantial market, particularly in electric vehicles where lightweight, high-strength materials can improve energy efficiency. Rapidly solidified HEAs offer potential weight reduction while maintaining structural integrity under thermal cycling conditions. This sector's demand is expected to grow at 13.5% annually as manufacturers seek to meet increasingly stringent emissions standards.

Energy generation applications constitute a rapidly expanding market segment, especially in nuclear and renewable energy systems. HEAs processed through rapid solidification demonstrate enhanced radiation resistance and thermal stability, making them candidates for next-generation nuclear reactors and concentrated solar power systems. The market value in this segment is projected to reach $1.2 billion by 2028.

Medical device manufacturing represents an emerging application area with significant growth potential. Rapidly solidified HEAs exhibit excellent biocompatibility combined with wear resistance and antimicrobial properties, creating opportunities for orthopedic implants and surgical instruments. This segment is growing at 15.2% annually, driven by aging populations in developed economies.

Regional analysis indicates North America and Europe currently dominate HEA market consumption, accounting for 65% of global demand. However, the Asia-Pacific region, particularly China, Japan, and South Korea, is experiencing the fastest growth rate at 14.3% annually due to expanding manufacturing capabilities and increasing R&D investments in advanced materials.

Market challenges include high production costs, limited standardization, and scaling difficulties for rapid solidification techniques. Despite these barriers, the unique property combinations achieved through rapid solidification of HEAs continue to drive market expansion as industries seek materials capable of meeting increasingly demanding performance requirements.

Rapid solidification processing has emerged as a critical manufacturing technique that enhances HEAs' properties, creating substantial market opportunities. Industries requiring materials that can withstand extreme conditions show the strongest demand. The aerospace sector represents the largest market segment, with HEAs being evaluated for turbine blades, structural components, and heat shields where their superior high-temperature strength and oxidation resistance provide significant advantages over conventional superalloys.

The automotive industry presents another substantial market, particularly in electric vehicles where lightweight, high-strength materials can improve energy efficiency. Rapidly solidified HEAs offer potential weight reduction while maintaining structural integrity under thermal cycling conditions. This sector's demand is expected to grow at 13.5% annually as manufacturers seek to meet increasingly stringent emissions standards.

Energy generation applications constitute a rapidly expanding market segment, especially in nuclear and renewable energy systems. HEAs processed through rapid solidification demonstrate enhanced radiation resistance and thermal stability, making them candidates for next-generation nuclear reactors and concentrated solar power systems. The market value in this segment is projected to reach $1.2 billion by 2028.

Medical device manufacturing represents an emerging application area with significant growth potential. Rapidly solidified HEAs exhibit excellent biocompatibility combined with wear resistance and antimicrobial properties, creating opportunities for orthopedic implants and surgical instruments. This segment is growing at 15.2% annually, driven by aging populations in developed economies.

Regional analysis indicates North America and Europe currently dominate HEA market consumption, accounting for 65% of global demand. However, the Asia-Pacific region, particularly China, Japan, and South Korea, is experiencing the fastest growth rate at 14.3% annually due to expanding manufacturing capabilities and increasing R&D investments in advanced materials.

Market challenges include high production costs, limited standardization, and scaling difficulties for rapid solidification techniques. Despite these barriers, the unique property combinations achieved through rapid solidification of HEAs continue to drive market expansion as industries seek materials capable of meeting increasingly demanding performance requirements.

Current Rapid Solidification Techniques and Challenges

Rapid solidification techniques have evolved significantly over the past few decades, offering unique advantages for processing high-entropy alloys (HEAs). Currently, several established methods dominate the field, each with distinct capabilities and limitations. Melt spinning represents one of the most widely employed techniques, capable of achieving cooling rates of 10^4-10^6 K/s by ejecting molten alloy onto a rapidly rotating copper wheel. This method produces thin ribbons or flakes with exceptionally fine microstructures, though sample size limitations restrict industrial scalability.

Laser surface melting and laser additive manufacturing have gained prominence for their precision and flexibility. These techniques can achieve cooling rates of 10^3-10^7 K/s while enabling complex geometries. However, they often introduce thermal gradients that create heterogeneous microstructures across processed components, presenting challenges for maintaining consistent properties throughout HEA parts.

Gas atomization produces spherical powder particles with cooling rates of 10^2-10^4 K/s, making it valuable for powder metallurgy applications. While offering good scalability, the technique struggles with precise control of particle size distribution and occasional satellite formation, which can affect subsequent consolidation processes.

Splat quenching achieves extreme cooling rates (10^6-10^8 K/s) by impacting molten droplets against cold substrates, but suffers from poor reproducibility and limited sample dimensions, restricting its application primarily to laboratory research rather than industrial production.

Several critical challenges persist across these techniques. Maintaining compositional homogeneity during rapid solidification remains difficult, as preferential solidification of certain elements can lead to segregation and compromise the core HEA concept of single-phase solid solutions. The formation of metastable phases, while sometimes beneficial, introduces unpredictability in mechanical properties and thermal stability during service.

Equipment limitations also present significant hurdles. Most rapid solidification technologies require sophisticated control systems and precise parameter optimization to achieve desired microstructures. The high capital costs and specialized expertise needed for these systems create barriers to widespread industrial adoption.

Scale-up challenges further complicate commercial implementation. Many techniques that excel at laboratory scale encounter difficulties when adapted to industrial production volumes. The trade-off between cooling rate and sample dimensions remains a fundamental constraint, with higher cooling rates typically achievable only in smaller samples.

Characterization of rapidly solidified HEAs presents another challenge, as conventional metallographic techniques may not adequately capture the ultrafine features and metastable phases formed during extreme cooling. Advanced analytical methods like high-resolution transmission electron microscopy and atom probe tomography are often necessary but add complexity and cost to material development efforts.

Laser surface melting and laser additive manufacturing have gained prominence for their precision and flexibility. These techniques can achieve cooling rates of 10^3-10^7 K/s while enabling complex geometries. However, they often introduce thermal gradients that create heterogeneous microstructures across processed components, presenting challenges for maintaining consistent properties throughout HEA parts.

Gas atomization produces spherical powder particles with cooling rates of 10^2-10^4 K/s, making it valuable for powder metallurgy applications. While offering good scalability, the technique struggles with precise control of particle size distribution and occasional satellite formation, which can affect subsequent consolidation processes.

Splat quenching achieves extreme cooling rates (10^6-10^8 K/s) by impacting molten droplets against cold substrates, but suffers from poor reproducibility and limited sample dimensions, restricting its application primarily to laboratory research rather than industrial production.

Several critical challenges persist across these techniques. Maintaining compositional homogeneity during rapid solidification remains difficult, as preferential solidification of certain elements can lead to segregation and compromise the core HEA concept of single-phase solid solutions. The formation of metastable phases, while sometimes beneficial, introduces unpredictability in mechanical properties and thermal stability during service.

Equipment limitations also present significant hurdles. Most rapid solidification technologies require sophisticated control systems and precise parameter optimization to achieve desired microstructures. The high capital costs and specialized expertise needed for these systems create barriers to widespread industrial adoption.

Scale-up challenges further complicate commercial implementation. Many techniques that excel at laboratory scale encounter difficulties when adapted to industrial production volumes. The trade-off between cooling rate and sample dimensions remains a fundamental constraint, with higher cooling rates typically achievable only in smaller samples.

Characterization of rapidly solidified HEAs presents another challenge, as conventional metallographic techniques may not adequately capture the ultrafine features and metastable phases formed during extreme cooling. Advanced analytical methods like high-resolution transmission electron microscopy and atom probe tomography are often necessary but add complexity and cost to material development efforts.

Established Rapid Solidification Methods for HEAs

01 Composition and structure of high-entropy alloys

High-entropy alloys (HEAs) are composed of multiple principal elements in near-equiatomic proportions, which leads to high configurational entropy. These alloys exhibit unique microstructures and properties due to their complex compositions. Rapid solidification techniques can be employed to produce HEAs with refined grain structures, enhanced solid solubility, and improved mechanical properties. The composition typically includes elements with similar atomic sizes to minimize lattice distortion while maximizing entropy effects.- Composition and structure of high-entropy alloys for rapid solidification: High-entropy alloys (HEAs) are composed of multiple principal elements in near-equiatomic proportions, which can form solid solutions with simple crystal structures. These alloys exhibit unique properties when processed through rapid solidification techniques, including enhanced mechanical properties, improved corrosion resistance, and superior thermal stability. The composition typically includes elements with similar atomic sizes to minimize lattice distortion while maximizing entropy effects during solidification.

- Rapid solidification techniques for high-entropy alloys: Various rapid solidification techniques are employed to process high-entropy alloys, including melt spinning, gas atomization, laser melting, and splat quenching. These methods achieve cooling rates of 10^3 to 10^6 K/s, which prevents phase separation and promotes the formation of metastable phases. Rapid solidification suppresses the formation of intermetallic compounds and segregation, resulting in refined microstructures with enhanced properties compared to conventionally cast alloys.

- Microstructural evolution during rapid solidification of high-entropy alloys: The microstructure of rapidly solidified high-entropy alloys is characterized by ultrafine grains, supersaturated solid solutions, and metastable phases. The high cooling rates suppress diffusion processes, leading to extended solid solubility and the formation of nanocrystalline or amorphous structures. The resulting microstructure often exhibits unique features such as cellular or dendritic patterns, core-shell structures, and compositional fluctuations at the nanoscale, which contribute to the exceptional properties of these materials.

- Mechanical and functional properties of rapidly solidified high-entropy alloys: Rapidly solidified high-entropy alloys exhibit superior mechanical properties including high strength, hardness, and wear resistance while maintaining good ductility. The unique microstructure resulting from rapid solidification contributes to exceptional thermal stability, corrosion resistance, and magnetic properties. These alloys often show reduced thermal conductivity and enhanced radiation resistance compared to conventional alloys, making them suitable for extreme environment applications. The combination of these properties can be tailored through composition and processing parameters to meet specific application requirements.

- Applications and manufacturing processes for rapidly solidified high-entropy alloys: Rapidly solidified high-entropy alloys find applications in aerospace components, cutting tools, wear-resistant coatings, and high-temperature structural materials. Manufacturing processes include powder metallurgy routes where rapidly solidified powders are consolidated through hot isostatic pressing, spark plasma sintering, or additive manufacturing techniques. These processing routes allow for near-net-shape manufacturing while preserving the beneficial microstructures obtained through rapid solidification. The scalability of these processes enables industrial production of high-entropy alloy components with complex geometries and tailored properties.

02 Rapid solidification techniques for high-entropy alloys

Various rapid solidification techniques can be applied to produce high-entropy alloys with enhanced properties. These techniques include melt spinning, splat quenching, gas atomization, and laser melting, which achieve cooling rates of 10^3-10^6 K/s. Rapid solidification prevents phase separation and promotes the formation of supersaturated solid solutions or metastable phases. These processes result in refined microstructures with improved mechanical properties and corrosion resistance compared to conventionally cast alloys.Expand Specific Solutions03 Mechanical properties of rapidly solidified high-entropy alloys

Rapidly solidified high-entropy alloys exhibit superior mechanical properties compared to their conventionally processed counterparts. These properties include enhanced hardness, strength, wear resistance, and fatigue life. The improved properties result from grain refinement, solid solution strengthening, and the formation of nanoscale precipitates during rapid solidification. The combination of multiple principal elements in these alloys creates complex strain fields that impede dislocation movement, further enhancing strength while maintaining reasonable ductility.Expand Specific Solutions04 Thermal stability and phase transformation in rapidly solidified HEAs

Rapidly solidified high-entropy alloys demonstrate unique thermal stability and phase transformation behaviors. The high configurational entropy stabilizes solid solution phases and suppresses the formation of intermetallic compounds. During rapid solidification, metastable phases may form that transform upon subsequent heat treatment. Understanding these phase transformations is crucial for designing HEAs with tailored properties. The sluggish diffusion kinetics in these multi-component systems further contributes to their exceptional thermal stability at elevated temperatures.Expand Specific Solutions05 Applications of rapidly solidified high-entropy alloys

Rapidly solidified high-entropy alloys find applications in various industries due to their exceptional properties. These applications include high-temperature structural components, wear-resistant coatings, corrosion-resistant materials, and functional materials for electronic and magnetic applications. The unique combination of strength, thermal stability, and corrosion resistance makes these alloys particularly suitable for extreme environments. Additionally, their biocompatibility properties enable potential applications in medical implants and devices.Expand Specific Solutions

Leading Research Institutions and Industrial Players

The high-entropy alloy (HEA) market is currently in its growth phase, characterized by increasing research intensity and emerging commercial applications. The global market size is estimated to reach $12-15 billion by 2030, driven by aerospace, automotive, and energy sector demands. From a technological maturity perspective, rapid solidification techniques for HEAs are transitioning from laboratory to industrial implementation. Leading players include established aerospace corporations like Lockheed Martin developing advanced HEAs for extreme environments, materials specialists such as Kobe Steel and Sanyo Special Steel commercializing production processes, and academic institutions (Central South University, Harbin Institute of Technology) pioneering fundamental research. Research collaborations between industry leaders like Hyundai Motor, Samsung Display, and academic partners are accelerating the technology's advancement toward commercial viability.

Harbin Institute of Technology

Technical Solution: Harbin Institute of Technology has developed an advanced rapid solidification technique for high-entropy alloys (HEAs) using melt spinning and laser surface melting. Their approach focuses on creating non-equilibrium microstructures with refined grains down to nanoscale dimensions. The institute has pioneered methods to achieve cooling rates exceeding 10^6 K/s, which significantly alters phase formation and stability in HEAs. Their research demonstrates that rapid solidification can effectively suppress phase separation and promote the formation of supersaturated solid solutions with enhanced mechanical properties. They've successfully applied this technique to Al-containing HEAs, which traditionally suffer from brittle intermetallic formation under conventional processing. Their work has shown that rapidly solidified HEAs exhibit superior hardness, wear resistance, and corrosion resistance compared to conventionally cast counterparts.

Strengths: Achieves exceptional grain refinement and metastable phase formation that enhances mechanical properties; enables incorporation of elements with limited equilibrium solubility. Weaknesses: Scale-up challenges for industrial production; potential thermal instability of metastable structures during service at elevated temperatures.

University of Science & Technology Beijing

Technical Solution: University of Science & Technology Beijing has developed a comprehensive approach to rapid solidification of high-entropy alloys focusing on microstructural control and property enhancement. Their technique combines electromagnetic levitation melting with splat quenching to achieve cooling rates of 10^5-10^7 K/s. This method has been particularly successful with refractory high-entropy alloys (RHEAs) containing elements like Mo, Nb, Ta, and W, which are challenging to process conventionally due to their high melting points. Their research has revealed that rapid solidification can effectively suppress dendritic segregation and promote the formation of supersaturated BCC solid solutions with significantly improved homogeneity. The university has also pioneered the development of dual-phase HEAs through controlled rapid solidification, creating materials with an optimal balance of strength and ductility. Their studies have demonstrated that rapidly solidified HEAs exhibit superior oxidation resistance at high temperatures compared to conventionally processed alloys.

Strengths: Exceptional control over phase formation in refractory HEAs; ability to create dual-phase microstructures with balanced mechanical properties. Weaknesses: Energy-intensive processing requirements; limited sample sizes with current laboratory-scale equipment.

Critical Patents and Research on HEA Microstructure Control

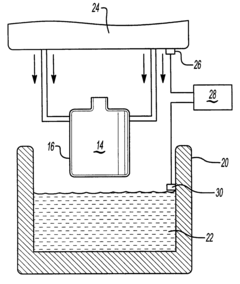

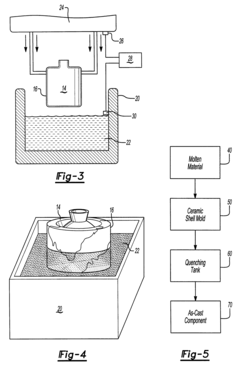

Rapid solidification investment casting

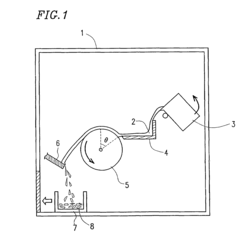

PatentInactiveUS6622774B2

Innovation

- The process involves rapid cooling of molten material in a pre-heated ceramic shell mold by quenching it in an oil bath, with controlled cooling rates achieved through varying immersion speeds, oil types, and temperatures, ensuring a uniform fine microstructure in the as-cast component.

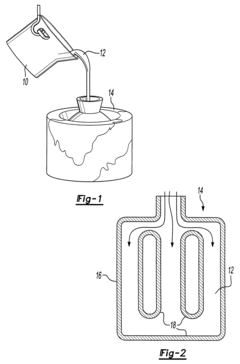

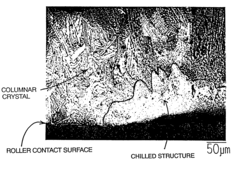

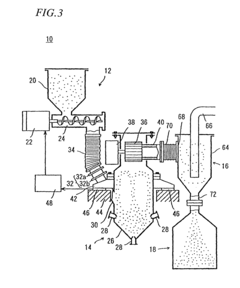

Rare earth magnet and method for producing the magnet

PatentInactiveUS7138017B2

Innovation

- The method involves preparing a material alloy with a chilled structure constituting 2-20 volume percent, coarsely pulverizing using hydrogen occlusion, finely pulverizing to remove particles smaller than 1 μm, and applying a lubricant to the powder, resulting in a particle size distribution with a single peak and mean particle size of 4 μm or less, enhancing compactibility and magnetic alignment.

Material Property Enhancement Through Processing Parameters

Processing parameters play a crucial role in determining the final properties of high-entropy alloys (HEAs) subjected to rapid solidification. The cooling rate, which can range from 10^3 to 10^8 K/s during rapid solidification processes, significantly influences microstructural evolution and consequently the mechanical properties of HEAs.

When optimizing cooling rates, researchers have observed that intermediate cooling rates (10^5-10^6 K/s) often produce the most favorable combination of strength and ductility in many HEA systems. This occurs because these rates allow for sufficient suppression of equilibrium phase formation while still enabling beneficial nanoscale precipitation or clustering.

Melt superheat temperature represents another critical parameter that affects the nucleation behavior during rapid solidification. Studies have shown that controlling the initial melt temperature 100-300°C above the liquidus can significantly refine grain structures in rapidly solidified HEAs, particularly in systems containing refractory elements like Mo, Nb, and Ta.

The atmosphere during processing also substantially impacts material properties. Inert gas environments (typically argon or helium) prevent oxidation during rapid solidification, while vacuum processing minimizes both oxidation and gas entrapment. Recent research demonstrates that controlled nitrogen atmospheres can induce beneficial nitride formation in certain HEA compositions, enhancing hardness without excessive embrittlement.

Substrate material selection and temperature control during melt spinning or splat quenching processes directly influence the thermal gradient and solidification direction. Copper substrates, due to their high thermal conductivity, promote more uniform cooling compared to steel substrates, resulting in more homogeneous microstructures in rapidly solidified HEA ribbons and flakes.

Post-solidification thermal treatments, even brief ones, can dramatically alter the property profile of rapidly solidified HEAs. Flash annealing treatments (5-30 seconds at temperatures 50-100°C below recrystallization) have been shown to relieve residual stresses while maintaining the metastable phases formed during rapid solidification, improving ductility without significant strength reduction.

The addition of inoculants or heterogeneous nucleation sites prior to rapid solidification represents an emerging approach for property enhancement. Nano-scale ceramic particles (TiC, TiB2) introduced at 0.1-0.5 wt% concentrations can serve as nucleation sites during solidification, resulting in refined microstructures with improved mechanical properties and thermal stability in HEAs processed through rapid solidification techniques.

When optimizing cooling rates, researchers have observed that intermediate cooling rates (10^5-10^6 K/s) often produce the most favorable combination of strength and ductility in many HEA systems. This occurs because these rates allow for sufficient suppression of equilibrium phase formation while still enabling beneficial nanoscale precipitation or clustering.

Melt superheat temperature represents another critical parameter that affects the nucleation behavior during rapid solidification. Studies have shown that controlling the initial melt temperature 100-300°C above the liquidus can significantly refine grain structures in rapidly solidified HEAs, particularly in systems containing refractory elements like Mo, Nb, and Ta.

The atmosphere during processing also substantially impacts material properties. Inert gas environments (typically argon or helium) prevent oxidation during rapid solidification, while vacuum processing minimizes both oxidation and gas entrapment. Recent research demonstrates that controlled nitrogen atmospheres can induce beneficial nitride formation in certain HEA compositions, enhancing hardness without excessive embrittlement.

Substrate material selection and temperature control during melt spinning or splat quenching processes directly influence the thermal gradient and solidification direction. Copper substrates, due to their high thermal conductivity, promote more uniform cooling compared to steel substrates, resulting in more homogeneous microstructures in rapidly solidified HEA ribbons and flakes.

Post-solidification thermal treatments, even brief ones, can dramatically alter the property profile of rapidly solidified HEAs. Flash annealing treatments (5-30 seconds at temperatures 50-100°C below recrystallization) have been shown to relieve residual stresses while maintaining the metastable phases formed during rapid solidification, improving ductility without significant strength reduction.

The addition of inoculants or heterogeneous nucleation sites prior to rapid solidification represents an emerging approach for property enhancement. Nano-scale ceramic particles (TiC, TiB2) introduced at 0.1-0.5 wt% concentrations can serve as nucleation sites during solidification, resulting in refined microstructures with improved mechanical properties and thermal stability in HEAs processed through rapid solidification techniques.

Sustainability and Cost Considerations in HEA Production

The production of high-entropy alloys (HEAs) through rapid solidification processes presents significant sustainability challenges and cost implications that must be carefully evaluated. Traditional manufacturing methods for HEAs often involve energy-intensive processes and expensive raw materials, leading to high production costs and considerable environmental footprints. Rapid solidification techniques, while offering microstructural advantages, require sophisticated equipment and precise control systems that further increase initial capital investments.

Energy consumption represents a major sustainability concern in HEA production. Rapid solidification methods such as melt spinning, splat quenching, and laser-based additive manufacturing demand substantial power inputs to achieve the necessary cooling rates (10^3-10^6 K/s). Recent studies indicate that energy requirements for these processes can range from 25-60 kWh per kilogram of produced material, significantly higher than conventional casting methods. However, the enhanced properties achieved through rapid solidification may offset these energy costs through improved product lifespans and performance efficiency.

Material utilization efficiency varies considerably across different rapid solidification techniques. Powder-based methods typically experience material losses of 15-30%, while melt spinning and similar processes can achieve utilization rates exceeding 90%. This variance directly impacts both production costs and sustainability metrics. Furthermore, the rare and strategic elements commonly incorporated in HEAs (such as cobalt, niobium, and scandium) raise concerns regarding resource scarcity and geopolitical supply risks.

Lifecycle assessment studies reveal that the environmental impact of rapidly solidified HEAs must be evaluated holistically. While production phases may have higher environmental burdens compared to conventional alloys, the superior mechanical properties, corrosion resistance, and thermal stability of HEAs can significantly extend component lifespans, potentially reducing lifetime environmental impacts by 30-50% in demanding applications.

Economic analyses indicate that current production costs for rapidly solidified HEAs range from $80-250 per kilogram, approximately 3-8 times higher than conventional structural alloys. These costs are primarily driven by raw material prices (40-60%), processing expenses (25-35%), and quality control requirements (10-20%). However, economies of scale and technological improvements are gradually reducing these figures, with projections suggesting potential cost reductions of 30-40% within the next decade.

Recycling considerations present both challenges and opportunities for HEA sustainability. The complex, multi-element compositions of HEAs complicate traditional recycling streams, potentially requiring specialized separation techniques. Conversely, the inherent compositional flexibility of HEAs may allow for greater tolerance of impurities in recycled feedstock, potentially creating new pathways for utilizing lower-grade recycled materials in high-performance applications.

Energy consumption represents a major sustainability concern in HEA production. Rapid solidification methods such as melt spinning, splat quenching, and laser-based additive manufacturing demand substantial power inputs to achieve the necessary cooling rates (10^3-10^6 K/s). Recent studies indicate that energy requirements for these processes can range from 25-60 kWh per kilogram of produced material, significantly higher than conventional casting methods. However, the enhanced properties achieved through rapid solidification may offset these energy costs through improved product lifespans and performance efficiency.

Material utilization efficiency varies considerably across different rapid solidification techniques. Powder-based methods typically experience material losses of 15-30%, while melt spinning and similar processes can achieve utilization rates exceeding 90%. This variance directly impacts both production costs and sustainability metrics. Furthermore, the rare and strategic elements commonly incorporated in HEAs (such as cobalt, niobium, and scandium) raise concerns regarding resource scarcity and geopolitical supply risks.

Lifecycle assessment studies reveal that the environmental impact of rapidly solidified HEAs must be evaluated holistically. While production phases may have higher environmental burdens compared to conventional alloys, the superior mechanical properties, corrosion resistance, and thermal stability of HEAs can significantly extend component lifespans, potentially reducing lifetime environmental impacts by 30-50% in demanding applications.

Economic analyses indicate that current production costs for rapidly solidified HEAs range from $80-250 per kilogram, approximately 3-8 times higher than conventional structural alloys. These costs are primarily driven by raw material prices (40-60%), processing expenses (25-35%), and quality control requirements (10-20%). However, economies of scale and technological improvements are gradually reducing these figures, with projections suggesting potential cost reductions of 30-40% within the next decade.

Recycling considerations present both challenges and opportunities for HEA sustainability. The complex, multi-element compositions of HEAs complicate traditional recycling streams, potentially requiring specialized separation techniques. Conversely, the inherent compositional flexibility of HEAs may allow for greater tolerance of impurities in recycled feedstock, potentially creating new pathways for utilizing lower-grade recycled materials in high-performance applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!