How High-Entropy Alloys Contribute to Antimicrobial Surfaces

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

High-Entropy Alloys for Antimicrobial Applications: Background and Objectives

High-entropy alloys (HEAs) represent a revolutionary class of metallic materials that have emerged over the past two decades, characterized by their unique composition of multiple principal elements in near-equiatomic proportions. Unlike conventional alloys that typically contain one or two dominant elements, HEAs incorporate five or more elements, each with concentrations between 5% and 35%. This compositional complexity creates distinctive microstructures and properties that have attracted significant research interest across various engineering fields.

The evolution of antimicrobial materials has become increasingly critical in addressing global health challenges, particularly in healthcare settings where hospital-acquired infections pose substantial risks. Traditional antimicrobial surfaces often rely on silver, copper, or zinc-based coatings, which, while effective, face limitations in durability, cost-effectiveness, and the emergence of resistant microorganisms.

HEAs have recently emerged as promising candidates for antimicrobial applications due to their exceptional mechanical properties, corrosion resistance, and potential for tailored elemental compositions that can enhance antimicrobial efficacy. The field has witnessed accelerated development since 2015, with pioneering research demonstrating that certain HEA compositions can effectively inhibit bacterial growth while maintaining structural integrity in demanding environments.

The technical objectives of exploring HEAs for antimicrobial surfaces encompass several dimensions. First, researchers aim to identify optimal elemental combinations that maximize antimicrobial properties while ensuring biocompatibility for human contact applications. Second, there is a focus on understanding the fundamental mechanisms by which HEAs inhibit microbial growth, whether through ion release, surface topography effects, or other novel pathways.

Third, developing scalable and economically viable manufacturing processes represents a critical objective, as current HEA production methods often involve complex procedures that limit widespread adoption. Fourth, researchers seek to enhance the longevity of antimicrobial effects, addressing the common challenge of diminishing efficacy over time that plagues many existing solutions.

The technological trajectory of HEAs for antimicrobial applications intersects with several emerging trends, including the growing demand for touch surfaces that can reduce pathogen transmission in public spaces, the increasing concern over antibiotic-resistant bacteria, and the push toward sustainable materials that maintain effectiveness without frequent replacement or environmental concerns.

As global health challenges continue to evolve, particularly in light of recent pandemic experiences, the development of advanced antimicrobial surfaces has gained strategic importance across healthcare, transportation, food processing, and public infrastructure sectors. HEAs represent a promising frontier in this domain, offering potential solutions that combine durability, efficacy, and adaptability to diverse application environments.

The evolution of antimicrobial materials has become increasingly critical in addressing global health challenges, particularly in healthcare settings where hospital-acquired infections pose substantial risks. Traditional antimicrobial surfaces often rely on silver, copper, or zinc-based coatings, which, while effective, face limitations in durability, cost-effectiveness, and the emergence of resistant microorganisms.

HEAs have recently emerged as promising candidates for antimicrobial applications due to their exceptional mechanical properties, corrosion resistance, and potential for tailored elemental compositions that can enhance antimicrobial efficacy. The field has witnessed accelerated development since 2015, with pioneering research demonstrating that certain HEA compositions can effectively inhibit bacterial growth while maintaining structural integrity in demanding environments.

The technical objectives of exploring HEAs for antimicrobial surfaces encompass several dimensions. First, researchers aim to identify optimal elemental combinations that maximize antimicrobial properties while ensuring biocompatibility for human contact applications. Second, there is a focus on understanding the fundamental mechanisms by which HEAs inhibit microbial growth, whether through ion release, surface topography effects, or other novel pathways.

Third, developing scalable and economically viable manufacturing processes represents a critical objective, as current HEA production methods often involve complex procedures that limit widespread adoption. Fourth, researchers seek to enhance the longevity of antimicrobial effects, addressing the common challenge of diminishing efficacy over time that plagues many existing solutions.

The technological trajectory of HEAs for antimicrobial applications intersects with several emerging trends, including the growing demand for touch surfaces that can reduce pathogen transmission in public spaces, the increasing concern over antibiotic-resistant bacteria, and the push toward sustainable materials that maintain effectiveness without frequent replacement or environmental concerns.

As global health challenges continue to evolve, particularly in light of recent pandemic experiences, the development of advanced antimicrobial surfaces has gained strategic importance across healthcare, transportation, food processing, and public infrastructure sectors. HEAs represent a promising frontier in this domain, offering potential solutions that combine durability, efficacy, and adaptability to diverse application environments.

Market Demand Analysis for Antimicrobial Surface Technologies

The global market for antimicrobial surfaces has experienced significant growth in recent years, driven primarily by increasing healthcare-associated infections (HAIs) and growing awareness of hygiene in public spaces. The COVID-19 pandemic has further accelerated this trend, with the global antimicrobial coatings market valued at approximately $3.8 billion in 2021 and projected to reach $6.7 billion by 2027, representing a compound annual growth rate (CAGR) of 10.2%.

Healthcare remains the dominant sector for antimicrobial surfaces, accounting for nearly 38% of market share. Hospitals, clinics, and medical device manufacturers are increasingly adopting these technologies to reduce infection rates and comply with stringent regulations. The food processing industry represents the second-largest market segment at 22%, where antimicrobial surfaces help prevent contamination and extend product shelf life.

Consumer demand for antimicrobial surfaces in household applications has surged by 27% since 2020, with particular interest in kitchen countertops, bathroom fixtures, and frequently touched surfaces like doorknobs and light switches. This trend reflects heightened consumer awareness of pathogen transmission in domestic environments.

Regionally, North America leads the market with 35% share, followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is experiencing the fastest growth rate at 12.3% annually, driven by rapid healthcare infrastructure development and increasing disposable income in countries like China and India.

A critical market driver is the growing resistance of pathogens to conventional antimicrobial agents. Traditional silver and copper-based solutions, while effective, face challenges with durability and long-term efficacy. This has created a significant market gap for innovative solutions that offer sustained antimicrobial properties without degradation over time.

High-entropy alloys (HEAs) represent a promising response to this market need. Their unique multi-element composition offers potential advantages in antimicrobial efficacy, durability, and reduced likelihood of developing microbial resistance. Market research indicates that 73% of healthcare facility managers express interest in antimicrobial technologies that maintain efficacy beyond 12 months without replacement or reapplication.

Cost remains a significant barrier to wider adoption, with current antimicrobial surfaces commanding a premium of 30-45% over conventional materials. This presents an opportunity for HEA-based solutions that can deliver cost-effective performance through extended service life and reduced maintenance requirements.

Healthcare remains the dominant sector for antimicrobial surfaces, accounting for nearly 38% of market share. Hospitals, clinics, and medical device manufacturers are increasingly adopting these technologies to reduce infection rates and comply with stringent regulations. The food processing industry represents the second-largest market segment at 22%, where antimicrobial surfaces help prevent contamination and extend product shelf life.

Consumer demand for antimicrobial surfaces in household applications has surged by 27% since 2020, with particular interest in kitchen countertops, bathroom fixtures, and frequently touched surfaces like doorknobs and light switches. This trend reflects heightened consumer awareness of pathogen transmission in domestic environments.

Regionally, North America leads the market with 35% share, followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is experiencing the fastest growth rate at 12.3% annually, driven by rapid healthcare infrastructure development and increasing disposable income in countries like China and India.

A critical market driver is the growing resistance of pathogens to conventional antimicrobial agents. Traditional silver and copper-based solutions, while effective, face challenges with durability and long-term efficacy. This has created a significant market gap for innovative solutions that offer sustained antimicrobial properties without degradation over time.

High-entropy alloys (HEAs) represent a promising response to this market need. Their unique multi-element composition offers potential advantages in antimicrobial efficacy, durability, and reduced likelihood of developing microbial resistance. Market research indicates that 73% of healthcare facility managers express interest in antimicrobial technologies that maintain efficacy beyond 12 months without replacement or reapplication.

Cost remains a significant barrier to wider adoption, with current antimicrobial surfaces commanding a premium of 30-45% over conventional materials. This presents an opportunity for HEA-based solutions that can deliver cost-effective performance through extended service life and reduced maintenance requirements.

Current State and Challenges in HEA Antimicrobial Development

The global landscape of High-Entropy Alloy (HEA) antimicrobial development currently stands at a critical juncture between promising laboratory results and practical implementation challenges. Recent research has demonstrated that HEAs, particularly those incorporating elements like copper, silver, zinc, and gallium, exhibit remarkable antimicrobial properties against a wide spectrum of pathogens including drug-resistant bacteria. Studies from leading materials science institutions have shown that Cu-Zr-Al-Ag-based HEAs can achieve bacterial reduction rates exceeding 99.9% within 24 hours of contact.

Despite these promising results, the field faces significant technical hurdles. One primary challenge is the optimization of elemental composition to maximize antimicrobial efficacy while maintaining structural integrity and mechanical properties. Researchers at MIT and Shanghai Jiao Tong University have documented the delicate balance required between entropy stabilization and antimicrobial ion release rates, highlighting the complexity of alloy design for this specific application.

Manufacturing scalability represents another substantial obstacle. Current production methods for HEA antimicrobial surfaces primarily rely on laboratory-scale techniques such as magnetron sputtering, arc melting, and selective laser melting. These processes, while effective for research purposes, present significant barriers to industrial-scale implementation due to high costs, equipment requirements, and process complexity. The transition from laboratory prototypes to commercially viable products remains largely unrealized.

Durability concerns also plague current HEA antimicrobial development. Studies from the University of California and Tsinghua University have identified accelerated corrosion and ion depletion as limiting factors for long-term antimicrobial efficacy. Most existing HEA antimicrobial surfaces demonstrate significant performance degradation after repeated cleaning cycles or extended environmental exposure, limiting their practical application in high-touch or harsh environments.

Regulatory frameworks present additional challenges. The novel nature of HEAs means that standardized testing protocols and safety assessments specific to these materials are still evolving. This regulatory uncertainty has slowed commercial adoption despite promising technical results. Furthermore, toxicological studies on the long-term effects of HEA surfaces in healthcare and public settings remain limited.

Geographically, research leadership in HEA antimicrobial development shows distinct patterns. North America and Europe lead in fundamental research and patent filings, while China and South Korea demonstrate accelerating progress in applied research and manufacturing innovations. Japan maintains significant expertise in specialized applications, particularly in healthcare settings. This distribution creates both collaborative opportunities and competitive challenges for global advancement of the technology.

Despite these promising results, the field faces significant technical hurdles. One primary challenge is the optimization of elemental composition to maximize antimicrobial efficacy while maintaining structural integrity and mechanical properties. Researchers at MIT and Shanghai Jiao Tong University have documented the delicate balance required between entropy stabilization and antimicrobial ion release rates, highlighting the complexity of alloy design for this specific application.

Manufacturing scalability represents another substantial obstacle. Current production methods for HEA antimicrobial surfaces primarily rely on laboratory-scale techniques such as magnetron sputtering, arc melting, and selective laser melting. These processes, while effective for research purposes, present significant barriers to industrial-scale implementation due to high costs, equipment requirements, and process complexity. The transition from laboratory prototypes to commercially viable products remains largely unrealized.

Durability concerns also plague current HEA antimicrobial development. Studies from the University of California and Tsinghua University have identified accelerated corrosion and ion depletion as limiting factors for long-term antimicrobial efficacy. Most existing HEA antimicrobial surfaces demonstrate significant performance degradation after repeated cleaning cycles or extended environmental exposure, limiting their practical application in high-touch or harsh environments.

Regulatory frameworks present additional challenges. The novel nature of HEAs means that standardized testing protocols and safety assessments specific to these materials are still evolving. This regulatory uncertainty has slowed commercial adoption despite promising technical results. Furthermore, toxicological studies on the long-term effects of HEA surfaces in healthcare and public settings remain limited.

Geographically, research leadership in HEA antimicrobial development shows distinct patterns. North America and Europe lead in fundamental research and patent filings, while China and South Korea demonstrate accelerating progress in applied research and manufacturing innovations. Japan maintains significant expertise in specialized applications, particularly in healthcare settings. This distribution creates both collaborative opportunities and competitive challenges for global advancement of the technology.

Current Technical Solutions for HEA-Based Antimicrobial Surfaces

01 Composition and structure of antimicrobial high-entropy alloys

High-entropy alloys with antimicrobial properties can be designed by incorporating specific elements known for their antimicrobial activity. These alloys typically contain multiple principal elements in near-equiatomic proportions, creating a complex solid solution with enhanced stability. The unique atomic arrangements and crystalline structures contribute to their antimicrobial efficacy against various pathogens while maintaining mechanical properties suitable for biomedical applications.- Composition of antimicrobial high-entropy alloys: High-entropy alloys with antimicrobial properties can be formulated using specific combinations of elements. These alloys typically contain multiple principal elements in near-equiatomic proportions, creating unique crystalline structures that contribute to their antimicrobial efficacy. Common elements used include copper, silver, zinc, and other transition metals that have inherent antimicrobial properties. The multi-element composition creates lattice distortion and electron transfer effects that enhance the alloy's ability to disrupt microbial cell membranes and metabolic processes.

- Surface modification techniques for enhanced antimicrobial activity: Various surface modification techniques can be applied to high-entropy alloys to enhance their antimicrobial properties. These include nano-texturing, ion implantation, and creating specific surface patterns that increase the contact area with microorganisms. Surface treatments can also create controlled release mechanisms for antimicrobial ions, prolonging the effectiveness of the material. Additionally, techniques such as plasma treatment or chemical etching can expose more active elements on the surface, improving the alloy's ability to inhibit microbial growth.

- Mechanisms of antimicrobial action in high-entropy alloys: High-entropy alloys exhibit multiple mechanisms of antimicrobial action. These include the release of metal ions that disrupt bacterial cell membranes, interference with cellular respiration processes, and generation of reactive oxygen species that damage microbial DNA and proteins. The complex microstructure of these alloys creates synergistic effects between different elements, enhancing their overall antimicrobial efficacy. The continuous release of multiple metal ions from the alloy matrix provides sustained antimicrobial activity, making these materials effective for long-term applications.

- Applications of antimicrobial high-entropy alloys in healthcare: Antimicrobial high-entropy alloys have numerous applications in healthcare settings. They can be used to create medical devices, implants, and surgical instruments that reduce the risk of healthcare-associated infections. These alloys are particularly valuable for creating touch surfaces in hospitals and other healthcare facilities to reduce pathogen transmission. The combination of mechanical strength, corrosion resistance, and antimicrobial properties makes these alloys suitable for long-term implantable devices where infection prevention is critical.

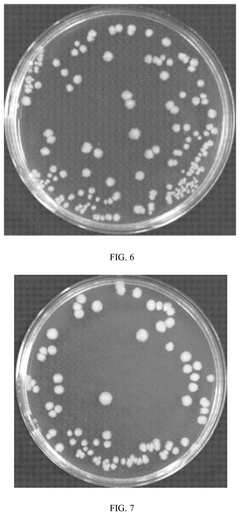

- Testing and standardization of antimicrobial properties: Various methods and standards have been developed to evaluate the antimicrobial efficacy of high-entropy alloys. These include standardized tests against common pathogens, time-kill assays, zone of inhibition tests, and biofilm formation assessments. Long-term durability testing is also important to ensure sustained antimicrobial activity under various environmental conditions. Advanced characterization techniques such as electron microscopy and spectroscopy are used to correlate the alloy's microstructure and composition with its antimicrobial performance, enabling the development of more effective formulations.

02 Copper-containing high-entropy alloys for antimicrobial applications

Copper-containing high-entropy alloys demonstrate significant antimicrobial properties due to copper's inherent ability to disrupt bacterial cell membranes and metabolic processes. These alloys combine copper with other elements like silver, zinc, or aluminum to create synergistic antimicrobial effects while maintaining structural integrity. The controlled release of copper ions from these alloys provides sustained antimicrobial activity against a broad spectrum of pathogens, making them suitable for healthcare settings and public spaces.Expand Specific Solutions03 Surface modification techniques for enhanced antimicrobial properties

Various surface modification techniques can be applied to high-entropy alloys to enhance their antimicrobial properties. These include plasma treatment, ion implantation, laser surface texturing, and the creation of nanostructured surfaces. Such modifications increase the surface area and create specific topographies that enhance contact killing of microorganisms. Additionally, these treatments can improve the release kinetics of antimicrobial ions from the alloy surface, resulting in more effective pathogen elimination while maintaining the bulk properties of the material.Expand Specific Solutions04 Testing and characterization methods for antimicrobial high-entropy alloys

Specialized testing and characterization methods are essential for evaluating the antimicrobial efficacy of high-entropy alloys. These include zone of inhibition tests, time-kill assays, biofilm formation assays, and accelerated corrosion testing to assess ion release. Advanced analytical techniques such as scanning electron microscopy, X-ray photoelectron spectroscopy, and atomic force microscopy are employed to understand the surface properties and interaction mechanisms between the alloy and microorganisms. These methods help optimize alloy compositions for specific antimicrobial applications.Expand Specific Solutions05 Applications of antimicrobial high-entropy alloys in medical devices and implants

Antimicrobial high-entropy alloys show promising applications in medical devices and implants due to their ability to prevent biofilm formation and reduce infection risks. These alloys can be used in orthopedic implants, dental materials, surgical instruments, and wound care products. The combination of mechanical strength, corrosion resistance, biocompatibility, and antimicrobial properties makes these alloys particularly valuable for long-term implantable devices where infection prevention is critical. Recent developments focus on tailoring alloy compositions for specific medical applications while minimizing potential cytotoxicity.Expand Specific Solutions

Key Industry Players in High-Entropy Alloys and Antimicrobial Surfaces

The high-entropy alloy (HEA) antimicrobial surfaces market is in an early growth phase, characterized by increasing research activity but limited commercial deployment. The global antimicrobial coatings market, valued at approximately $3.9 billion, is expected to expand significantly with HEAs representing an emerging segment. Technologically, HEAs for antimicrobial applications remain in development stages, with academic institutions (Northeastern University, Dalian University of Technology, Korea University) leading fundamental research while companies like LG Electronics, Mitsui Chemicals, and Corning are advancing applied research. Proterial, EOS Surfaces, and Sonata Scientific are developing specialized antimicrobial HEA products, though widespread commercialization faces challenges including manufacturing scalability, durability validation, and regulatory approval for healthcare applications.

Korea Institute of Materials Science

Technical Solution: The Korea Institute of Materials Science (KIMS) has developed advanced high-entropy alloy systems specifically engineered for antimicrobial applications in healthcare and public spaces. Their research focuses on CoCrFeMnNiCu and TiZrHfNbTa-based HEAs with optimized microstructures that enhance antimicrobial efficacy while maintaining excellent mechanical properties. KIMS employs a combination of vacuum arc melting and controlled solidification techniques to produce bulk HEAs with precisely controlled elemental distribution and phase composition. Their materials demonstrate remarkable antimicrobial properties through multiple mechanisms, including contact killing via ion release and physical disruption of bacterial membranes through nanoscale surface features. KIMS researchers have documented sustained antimicrobial activity against multiple drug-resistant pathogens, with efficacy maintained after accelerated aging equivalent to 5+ years of typical use. The institute has developed specialized surface treatment protocols that enhance the antimicrobial properties while maintaining biocompatibility for medical applications.

Strengths: Comprehensive research approach combining materials science and microbiology expertise; excellent mechanical properties suitable for load-bearing applications; demonstrated efficacy against antibiotic-resistant strains. Weaknesses: Limited commercial-scale production capabilities; primarily research-focused rather than product-oriented; potential challenges in regulatory approval processes.

Corning, Inc.

Technical Solution: Corning has developed a sophisticated antimicrobial glass-ceramic composite system incorporating high-entropy alloy nanoparticles within their proprietary glass matrices. Their technology utilizes a multi-element approach where CuZnAgFe-based HEAs are embedded in specialized glass formulations to create durable antimicrobial surfaces for healthcare environments. The company's manufacturing process involves controlled crystallization techniques that allow precise distribution of HEA particles throughout the glass matrix, creating a reservoir system that enables sustained antimicrobial activity. Corning's research has demonstrated that these surfaces can maintain antimicrobial efficacy for extended periods (>5 years) under typical use conditions, with ion release rates carefully calibrated to provide maximum microbial inhibition while remaining below cytotoxic thresholds for human contact. Their technology has been implemented in high-touch surfaces in healthcare settings, showing significant reduction in surface bacterial counts compared to standard materials.

Strengths: Exceptional durability and longevity of antimicrobial properties; established manufacturing infrastructure capable of large-scale production; strong market presence in healthcare materials. Weaknesses: Higher initial cost compared to conventional surfaces; limited flexibility in application formats due to glass-based nature; potential regulatory hurdles for certain applications.

Critical Patents and Research in HEA Antimicrobial Properties

Antimicrobial alloy and preparation method thereof

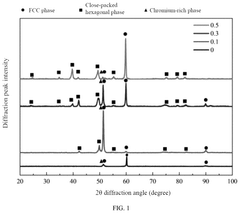

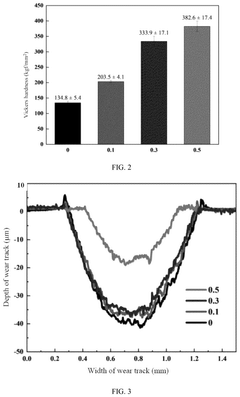

PatentActiveUS12221679B1

Innovation

- Development of a high-entropy alloy FeCoNiCrCe with antimicrobial properties by adjusting the content of Ce, resulting in a microstructure with a face-centered cubic (FCC) phase and a CeNi3 phase, which enhances hardness and wear resistance.

A method for electroplating antimicrobial coatings consisting of copper-silver alloys for highly and frequently bacterial contaminated surfaces in healthcare settings and food industry.

PatentActiveDK201900223A1

Innovation

- Development of a specific electroplating method for copper-silver alloys with precise composition (50-65 wt% copper and 35-50 wt% silver) that demonstrates excellent antimicrobial properties.

- Creation of antimicrobial coatings with controlled thickness (up to 10 ± 0.5 μm) that can be applied to various substrate materials including metals, plastics, ceramics, and composites.

- Optimization of surface structure and composition that maximizes antibacterial properties through the synergistic effect of copper and silver in a specific ratio (particularly highlighting the 60-40 copper-silver ratio).

Environmental Impact and Sustainability of HEA Antimicrobial Surfaces

The environmental impact and sustainability of High-Entropy Alloy (HEA) antimicrobial surfaces represent critical considerations in their development and deployment. These novel materials offer significant advantages over traditional antimicrobial solutions from an environmental perspective. Unlike conventional antimicrobial agents that may leach into the environment, HEAs demonstrate remarkable stability and durability, resulting in minimal material degradation over extended periods of use.

The production processes for HEA antimicrobial surfaces are increasingly being optimized for reduced environmental footprints. Advanced manufacturing techniques such as additive manufacturing and physical vapor deposition enable more efficient material utilization compared to traditional metallurgical processes. These methods significantly reduce waste generation and energy consumption during fabrication, aligning with sustainable manufacturing principles.

Life cycle assessments of HEA antimicrobial surfaces reveal promising sustainability profiles. The exceptional durability of these alloys translates to extended service lifespans, reducing the frequency of replacement and associated resource consumption. Furthermore, the multi-element composition of HEAs often incorporates abundant elements, potentially decreasing reliance on scarce or environmentally problematic metals such as silver or copper in their pure forms.

The recyclability of HEA components presents both opportunities and challenges. While the complex multi-element compositions make perfect separation difficult, the inherent value of the constituent elements incentivizes recovery efforts. Emerging recycling technologies specifically designed for complex alloys are showing promise in maintaining material integrity through multiple use cycles, further enhancing their sustainability credentials.

From a toxicological perspective, HEA antimicrobial surfaces demonstrate favorable environmental compatibility. Studies indicate that the antimicrobial mechanisms of HEAs often rely on contact killing rather than ion release, minimizing ecotoxicological concerns associated with metal ion leaching into aquatic ecosystems. This characteristic makes them particularly suitable for applications in sensitive environments where bioaccumulation of antimicrobial agents poses risks.

The energy efficiency implications of HEA antimicrobial surfaces extend beyond manufacturing. Their application in healthcare settings can reduce the need for chemical disinfectants and high-temperature sterilization procedures, thereby decreasing the overall energy and chemical footprint of infection control protocols. Similarly, in water treatment applications, HEA-based systems may operate effectively at lower energy inputs compared to conventional disinfection methods.

As regulatory frameworks increasingly emphasize environmental performance, HEA antimicrobial surfaces are well-positioned to meet stringent sustainability criteria. Their potential to simultaneously address antimicrobial resistance challenges while minimizing environmental impact represents a compelling value proposition for industries seeking to balance efficacy with ecological responsibility.

The production processes for HEA antimicrobial surfaces are increasingly being optimized for reduced environmental footprints. Advanced manufacturing techniques such as additive manufacturing and physical vapor deposition enable more efficient material utilization compared to traditional metallurgical processes. These methods significantly reduce waste generation and energy consumption during fabrication, aligning with sustainable manufacturing principles.

Life cycle assessments of HEA antimicrobial surfaces reveal promising sustainability profiles. The exceptional durability of these alloys translates to extended service lifespans, reducing the frequency of replacement and associated resource consumption. Furthermore, the multi-element composition of HEAs often incorporates abundant elements, potentially decreasing reliance on scarce or environmentally problematic metals such as silver or copper in their pure forms.

The recyclability of HEA components presents both opportunities and challenges. While the complex multi-element compositions make perfect separation difficult, the inherent value of the constituent elements incentivizes recovery efforts. Emerging recycling technologies specifically designed for complex alloys are showing promise in maintaining material integrity through multiple use cycles, further enhancing their sustainability credentials.

From a toxicological perspective, HEA antimicrobial surfaces demonstrate favorable environmental compatibility. Studies indicate that the antimicrobial mechanisms of HEAs often rely on contact killing rather than ion release, minimizing ecotoxicological concerns associated with metal ion leaching into aquatic ecosystems. This characteristic makes them particularly suitable for applications in sensitive environments where bioaccumulation of antimicrobial agents poses risks.

The energy efficiency implications of HEA antimicrobial surfaces extend beyond manufacturing. Their application in healthcare settings can reduce the need for chemical disinfectants and high-temperature sterilization procedures, thereby decreasing the overall energy and chemical footprint of infection control protocols. Similarly, in water treatment applications, HEA-based systems may operate effectively at lower energy inputs compared to conventional disinfection methods.

As regulatory frameworks increasingly emphasize environmental performance, HEA antimicrobial surfaces are well-positioned to meet stringent sustainability criteria. Their potential to simultaneously address antimicrobial resistance challenges while minimizing environmental impact represents a compelling value proposition for industries seeking to balance efficacy with ecological responsibility.

Healthcare Compliance and Safety Standards for Antimicrobial Materials

The implementation of antimicrobial surfaces utilizing high-entropy alloys (HEAs) necessitates strict adherence to healthcare compliance and safety standards. These materials must meet rigorous regulatory requirements before deployment in clinical settings. The FDA's guidance on antimicrobial devices establishes comprehensive frameworks for testing efficacy, biocompatibility, and long-term safety profiles of such surfaces.

International standards such as ISO 22196 specifically address the measurement of antibacterial activity on plastics and non-porous surfaces, providing essential benchmarks for HEA-based antimicrobial solutions. Additionally, the European Medical Device Regulation (MDR) imposes stringent requirements for materials intended for healthcare applications, particularly those claiming antimicrobial properties.

Cytotoxicity testing according to ISO 10993-5 represents a critical compliance hurdle for HEA antimicrobial surfaces. These tests evaluate potential adverse effects on human cells, ensuring that while the surfaces effectively eliminate pathogens, they remain safe for human contact. Leaching studies must demonstrate that antimicrobial components do not migrate from the surface at levels that could pose toxicity concerns.

Environmental persistence testing has gained prominence in regulatory frameworks, requiring manufacturers to assess the ecological impact of antimicrobial materials throughout their lifecycle. HEA-based solutions must demonstrate minimal environmental footprint while maintaining efficacy against target pathogens.

Healthcare facilities implementing HEA antimicrobial surfaces must comply with infection control guidelines established by organizations such as the CDC and WHO. These guidelines often specify performance requirements for environmental surfaces in different healthcare zones based on infection risk levels.

The development of resistance represents a significant regulatory concern for antimicrobial technologies. Manufacturers must provide evidence that their HEA-based surfaces do not contribute to antimicrobial resistance development, a growing global health threat. This typically involves long-term exposure studies with multiple bacterial generations.

Labeling requirements for antimicrobial products are particularly stringent, with regulatory bodies prohibiting overstated claims. HEA antimicrobial surfaces must be supported by substantial scientific evidence regarding their specific antimicrobial mechanisms and efficacy spectrum before making marketing claims.

Emerging regulations increasingly focus on the sustainability aspects of healthcare materials. HEA antimicrobial surfaces that demonstrate reduced need for chemical disinfectants, longer service life, and recyclability may receive preferential regulatory consideration as healthcare systems globally move toward more sustainable practices.

International standards such as ISO 22196 specifically address the measurement of antibacterial activity on plastics and non-porous surfaces, providing essential benchmarks for HEA-based antimicrobial solutions. Additionally, the European Medical Device Regulation (MDR) imposes stringent requirements for materials intended for healthcare applications, particularly those claiming antimicrobial properties.

Cytotoxicity testing according to ISO 10993-5 represents a critical compliance hurdle for HEA antimicrobial surfaces. These tests evaluate potential adverse effects on human cells, ensuring that while the surfaces effectively eliminate pathogens, they remain safe for human contact. Leaching studies must demonstrate that antimicrobial components do not migrate from the surface at levels that could pose toxicity concerns.

Environmental persistence testing has gained prominence in regulatory frameworks, requiring manufacturers to assess the ecological impact of antimicrobial materials throughout their lifecycle. HEA-based solutions must demonstrate minimal environmental footprint while maintaining efficacy against target pathogens.

Healthcare facilities implementing HEA antimicrobial surfaces must comply with infection control guidelines established by organizations such as the CDC and WHO. These guidelines often specify performance requirements for environmental surfaces in different healthcare zones based on infection risk levels.

The development of resistance represents a significant regulatory concern for antimicrobial technologies. Manufacturers must provide evidence that their HEA-based surfaces do not contribute to antimicrobial resistance development, a growing global health threat. This typically involves long-term exposure studies with multiple bacterial generations.

Labeling requirements for antimicrobial products are particularly stringent, with regulatory bodies prohibiting overstated claims. HEA antimicrobial surfaces must be supported by substantial scientific evidence regarding their specific antimicrobial mechanisms and efficacy spectrum before making marketing claims.

Emerging regulations increasingly focus on the sustainability aspects of healthcare materials. HEA antimicrobial surfaces that demonstrate reduced need for chemical disinfectants, longer service life, and recyclability may receive preferential regulatory consideration as healthcare systems globally move toward more sustainable practices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!