Assessing Mini LED Integration in Aerospace Displays

SEP 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mini LED Aerospace Display Background and Objectives

Mini LED technology represents a significant advancement in display technology, positioned between traditional LED and micro LED solutions. Since its emergence in the early 2010s, Mini LED has evolved from experimental prototypes to commercial applications, with aerospace displays representing one of its most demanding and promising implementation environments. The technology utilizes LED chips typically ranging from 100 to 200 micrometers, offering substantial improvements in brightness, contrast ratio, and energy efficiency compared to conventional LCD displays.

The aerospace industry has historically been at the forefront of display technology adoption, transitioning from early cathode ray tubes to LCD and AMOLED displays. This evolution has been driven by the unique requirements of aerospace environments, including extreme temperature variations, high ambient light conditions, and the critical need for reliability and longevity. The integration of Mini LED technology represents the next logical progression in this technological trajectory.

The primary objective of Mini LED integration in aerospace displays is to enhance visual performance while maintaining or improving reliability metrics. Specific goals include achieving higher brightness levels exceeding 1,000 nits to ensure readability in direct sunlight conditions, improving contrast ratios to better than 1,000,000:1 for enhanced detail visibility, and reducing power consumption by at least 30% compared to current-generation displays to extend operational capabilities.

Additionally, Mini LED technology aims to address several persistent challenges in aerospace displays, including reducing weight by at least 15% compared to existing solutions, enhancing durability to withstand the rigorous vibration and shock conditions of aerospace environments, and extending operational lifespans to 50,000+ hours to align with aircraft service intervals.

The technology evolution trend indicates a progressive miniaturization of LED components, with corresponding improvements in pixel density and local dimming zones. Current research suggests that Mini LED represents an optimal balance between manufacturing feasibility and performance enhancement for the near to medium term, while serving as a stepping stone toward eventual Micro LED implementation in aerospace applications.

Market forecasts project that the aerospace display sector will grow at a CAGR of approximately 5.7% through 2030, with Mini LED technology potentially capturing up to 40% of this market by 2027. This growth is supported by increasing aircraft production rates and the ongoing modernization of existing fleets, creating substantial opportunities for advanced display technologies that can deliver improved performance while meeting stringent aerospace certification requirements.

The aerospace industry has historically been at the forefront of display technology adoption, transitioning from early cathode ray tubes to LCD and AMOLED displays. This evolution has been driven by the unique requirements of aerospace environments, including extreme temperature variations, high ambient light conditions, and the critical need for reliability and longevity. The integration of Mini LED technology represents the next logical progression in this technological trajectory.

The primary objective of Mini LED integration in aerospace displays is to enhance visual performance while maintaining or improving reliability metrics. Specific goals include achieving higher brightness levels exceeding 1,000 nits to ensure readability in direct sunlight conditions, improving contrast ratios to better than 1,000,000:1 for enhanced detail visibility, and reducing power consumption by at least 30% compared to current-generation displays to extend operational capabilities.

Additionally, Mini LED technology aims to address several persistent challenges in aerospace displays, including reducing weight by at least 15% compared to existing solutions, enhancing durability to withstand the rigorous vibration and shock conditions of aerospace environments, and extending operational lifespans to 50,000+ hours to align with aircraft service intervals.

The technology evolution trend indicates a progressive miniaturization of LED components, with corresponding improvements in pixel density and local dimming zones. Current research suggests that Mini LED represents an optimal balance between manufacturing feasibility and performance enhancement for the near to medium term, while serving as a stepping stone toward eventual Micro LED implementation in aerospace applications.

Market forecasts project that the aerospace display sector will grow at a CAGR of approximately 5.7% through 2030, with Mini LED technology potentially capturing up to 40% of this market by 2027. This growth is supported by increasing aircraft production rates and the ongoing modernization of existing fleets, creating substantial opportunities for advanced display technologies that can deliver improved performance while meeting stringent aerospace certification requirements.

Aerospace Display Market Requirements Analysis

The aerospace display market is characterized by stringent requirements that significantly exceed those of consumer electronics. Primary among these is reliability, as aerospace displays must maintain functionality under extreme conditions including temperature variations from -65°C to +85°C, altitudes up to 40,000 feet, and high vibration environments. These displays must demonstrate mean time between failures (MTBF) exceeding 50,000 hours, substantially higher than the 10,000-20,000 hours typical for commercial displays.

Visual performance requirements are equally demanding. Aerospace displays must deliver brightness levels of 200-800 nits for cockpit displays and up to 2,000 nits for head-up displays to ensure readability in direct sunlight conditions. Contrast ratios must exceed 1000:1, with wide viewing angles of at least 170 degrees to accommodate multiple crew member perspectives. Color accuracy must conform to ARINC 801 standards, with precise color calibration maintained throughout the operational lifetime.

Power efficiency represents another critical requirement, as aerospace systems operate within strict power budgets. Displays typically must function within 28V DC aircraft power systems while consuming minimal power to reduce heat generation in the confined cockpit environment. Weight considerations are paramount, with every gram saved translating to fuel efficiency improvements over the aircraft's operational lifetime.

Regulatory compliance adds another layer of complexity, with displays required to meet DO-160 environmental standards, DO-254 for hardware certification, and DO-178C for associated software. Military applications impose additional requirements including MIL-STD-810 for environmental testing and MIL-STD-461 for electromagnetic compatibility.

Market analysis reveals growing demand for advanced display technologies in both commercial and military aerospace sectors. The commercial aircraft display market segment is projected to grow steadily as fleet modernization continues, while military aerospace displays are seeing increased demand driven by situational awareness requirements and cockpit digitalization initiatives.

Key market drivers include the transition toward glass cockpits, increased data visualization requirements, and enhanced pilot-machine interfaces. The retrofit market represents a significant opportunity, as older aircraft are upgraded with modern display systems to extend operational lifespans and improve safety profiles.

The integration of Mini LED technology must address these aerospace-specific requirements while offering tangible improvements over existing LCD and AMOLED solutions currently dominating the market. Particular attention must be paid to certification pathways, as new display technologies face rigorous qualification processes before aerospace adoption.

Visual performance requirements are equally demanding. Aerospace displays must deliver brightness levels of 200-800 nits for cockpit displays and up to 2,000 nits for head-up displays to ensure readability in direct sunlight conditions. Contrast ratios must exceed 1000:1, with wide viewing angles of at least 170 degrees to accommodate multiple crew member perspectives. Color accuracy must conform to ARINC 801 standards, with precise color calibration maintained throughout the operational lifetime.

Power efficiency represents another critical requirement, as aerospace systems operate within strict power budgets. Displays typically must function within 28V DC aircraft power systems while consuming minimal power to reduce heat generation in the confined cockpit environment. Weight considerations are paramount, with every gram saved translating to fuel efficiency improvements over the aircraft's operational lifetime.

Regulatory compliance adds another layer of complexity, with displays required to meet DO-160 environmental standards, DO-254 for hardware certification, and DO-178C for associated software. Military applications impose additional requirements including MIL-STD-810 for environmental testing and MIL-STD-461 for electromagnetic compatibility.

Market analysis reveals growing demand for advanced display technologies in both commercial and military aerospace sectors. The commercial aircraft display market segment is projected to grow steadily as fleet modernization continues, while military aerospace displays are seeing increased demand driven by situational awareness requirements and cockpit digitalization initiatives.

Key market drivers include the transition toward glass cockpits, increased data visualization requirements, and enhanced pilot-machine interfaces. The retrofit market represents a significant opportunity, as older aircraft are upgraded with modern display systems to extend operational lifespans and improve safety profiles.

The integration of Mini LED technology must address these aerospace-specific requirements while offering tangible improvements over existing LCD and AMOLED solutions currently dominating the market. Particular attention must be paid to certification pathways, as new display technologies face rigorous qualification processes before aerospace adoption.

Mini LED Technology Status and Integration Challenges

Mini LED technology represents a significant advancement in display technology, positioned between traditional LED and micro LED solutions. In aerospace applications, Mini LEDs offer enhanced brightness, contrast ratios, and power efficiency - critical factors for cockpit displays and passenger entertainment systems operating in variable lighting conditions. Current implementation status shows Mini LEDs with dimensions typically ranging from 100 to 200 micrometers, allowing for more precise local dimming zones compared to conventional LED backlighting.

The aerospace industry has begun limited adoption of Mini LED technology, primarily in next-generation commercial aircraft display systems. Major avionics manufacturers including Honeywell, Thales, and Collins Aerospace have active development programs, with several prototype systems undergoing flight certification testing. Market penetration remains below 15% of new aerospace display installations, indicating significant growth potential as the technology matures.

Technical challenges for aerospace integration are substantial and multifaceted. Thermal management presents a primary concern, as aerospace displays must operate reliably across extreme temperature ranges (-55°C to +85°C) while maintaining consistent performance. The increased LED density creates concentrated heat zones requiring sophisticated thermal dissipation solutions that don't compromise the strict weight constraints of aircraft components.

Reliability requirements for aerospace applications significantly exceed consumer electronics standards, with expected operational lifespans of 15-20 years and mean time between failures (MTBF) exceeding 50,000 hours. Current Mini LED technology demonstrates promising durability in laboratory testing but lacks sufficient field validation in the harsh vibration, pressure, and radiation environments encountered in aerospace operations.

Power efficiency optimization remains critical, as aircraft electrical systems have strict power budgets. While Mini LEDs offer improved efficiency over traditional LCD displays, further improvements are needed to meet next-generation aircraft power requirements, particularly for battery backup operation scenarios.

Manufacturing scalability presents another significant hurdle. Current production methods for aerospace-grade Mini LED displays involve complex processes with relatively low yields compared to conventional display technologies. The precision placement of thousands of Mini LEDs requires specialized equipment and quality control procedures that increase production costs and limit manufacturing capacity.

Electromagnetic interference (EMI) compliance represents a unique aerospace challenge, as displays must not interfere with critical flight systems. Mini LED drivers and control circuits require careful shielding and filtering to meet stringent DO-160 standards for avionics equipment, adding complexity to the design and integration process.

Certification pathways for this new technology remain under development, with regulatory bodies including the FAA and EASA working to establish appropriate standards for Mini LED display certification in critical flight systems. This regulatory uncertainty adds risk to development timelines and implementation strategies.

The aerospace industry has begun limited adoption of Mini LED technology, primarily in next-generation commercial aircraft display systems. Major avionics manufacturers including Honeywell, Thales, and Collins Aerospace have active development programs, with several prototype systems undergoing flight certification testing. Market penetration remains below 15% of new aerospace display installations, indicating significant growth potential as the technology matures.

Technical challenges for aerospace integration are substantial and multifaceted. Thermal management presents a primary concern, as aerospace displays must operate reliably across extreme temperature ranges (-55°C to +85°C) while maintaining consistent performance. The increased LED density creates concentrated heat zones requiring sophisticated thermal dissipation solutions that don't compromise the strict weight constraints of aircraft components.

Reliability requirements for aerospace applications significantly exceed consumer electronics standards, with expected operational lifespans of 15-20 years and mean time between failures (MTBF) exceeding 50,000 hours. Current Mini LED technology demonstrates promising durability in laboratory testing but lacks sufficient field validation in the harsh vibration, pressure, and radiation environments encountered in aerospace operations.

Power efficiency optimization remains critical, as aircraft electrical systems have strict power budgets. While Mini LEDs offer improved efficiency over traditional LCD displays, further improvements are needed to meet next-generation aircraft power requirements, particularly for battery backup operation scenarios.

Manufacturing scalability presents another significant hurdle. Current production methods for aerospace-grade Mini LED displays involve complex processes with relatively low yields compared to conventional display technologies. The precision placement of thousands of Mini LEDs requires specialized equipment and quality control procedures that increase production costs and limit manufacturing capacity.

Electromagnetic interference (EMI) compliance represents a unique aerospace challenge, as displays must not interfere with critical flight systems. Mini LED drivers and control circuits require careful shielding and filtering to meet stringent DO-160 standards for avionics equipment, adding complexity to the design and integration process.

Certification pathways for this new technology remain under development, with regulatory bodies including the FAA and EASA working to establish appropriate standards for Mini LED display certification in critical flight systems. This regulatory uncertainty adds risk to development timelines and implementation strategies.

Current Mini LED Solutions for Aerospace Applications

01 Mini LED display technology and structure

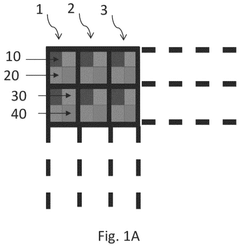

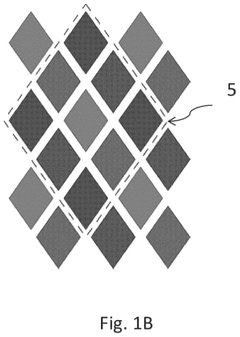

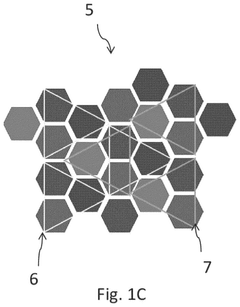

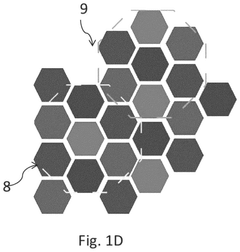

Mini LED technology involves the use of miniaturized LED chips in display panels, offering improved brightness, contrast ratio, and energy efficiency compared to traditional LED displays. These displays typically consist of arrays of small LED chips arranged in a matrix pattern, with each LED serving as a pixel or subpixel. The structure often includes a substrate, LED chips, driving circuits, and optical components to enhance light distribution and visual performance.- Mini LED display technology and structure: Mini LED technology involves the use of miniaturized LED chips in display panels, offering improved brightness, contrast ratio, and energy efficiency compared to traditional LED displays. These displays typically consist of a backlight module with thousands of tiny LED chips arranged in arrays, allowing for more precise local dimming zones and better control over light distribution. The structure often includes a substrate, multiple mini LED chips, and various optical films to enhance performance.

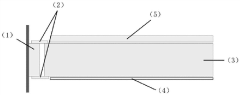

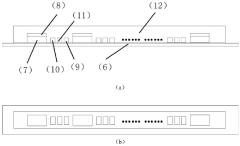

- Mini LED backlight modules and light control: Backlight modules for Mini LED displays incorporate advanced light control mechanisms to enhance display quality. These modules often feature specialized light guide plates, reflective films, and diffusion sheets that work together to distribute light evenly across the display surface. Innovations in this area focus on reducing light leakage, improving uniformity, and enabling more precise control over local dimming zones, which significantly enhances contrast ratio and reduces power consumption.

- Manufacturing processes for Mini LED displays: Manufacturing techniques for Mini LED displays involve specialized processes for chip placement, bonding, and integration. These processes include transfer printing methods, mass transfer technologies, and automated assembly techniques that enable the precise positioning of thousands of tiny LED chips. Innovations in this area focus on improving yield rates, reducing production costs, and enabling higher density LED arrangements to achieve better display performance.

- Mini LED thermal management solutions: Thermal management is critical for Mini LED displays to ensure optimal performance and longevity. Various solutions have been developed to address heat dissipation challenges, including specialized heat sinks, thermal interface materials, and cooling structures integrated into the display panel. These thermal management systems help maintain consistent brightness, prevent color shift, and extend the lifespan of the Mini LED components by efficiently removing excess heat generated during operation.

- Mini LED driving circuits and control systems: Advanced driving circuits and control systems are essential components of Mini LED displays, enabling precise control over thousands of individual LED zones. These systems incorporate specialized integrated circuits, power management solutions, and control algorithms that optimize brightness levels, reduce power consumption, and enable features like local dimming. Innovations in this area focus on improving response time, reducing electromagnetic interference, and enabling more granular control over display parameters.

02 Mini LED backlight solutions for LCD displays

Mini LEDs are increasingly used as backlighting solutions for LCD displays, providing local dimming capabilities that significantly improve contrast and black levels. These backlight modules typically feature thousands of mini LED chips arranged in multiple dimming zones, allowing for precise control of brightness in different areas of the screen. This technology bridges the gap between traditional LED backlighting and OLED displays, offering enhanced HDR performance and reduced blooming effects.Expand Specific Solutions03 Manufacturing processes and assembly methods for Mini LED displays

Advanced manufacturing techniques for Mini LED displays include transfer printing, pick-and-place methods, and mass transfer technologies to precisely position thousands of tiny LED chips. These processes often involve specialized equipment for handling the miniature components, substrate preparation, and electrical connections. Innovations in manufacturing focus on improving yield rates, reducing production costs, and enabling higher density LED placement for increased resolution displays.Expand Specific Solutions04 Thermal management and reliability solutions for Mini LED devices

Thermal management is critical for Mini LED displays due to the high density of light-emitting components. Solutions include specialized heat dissipation structures, thermal interface materials, and cooling systems designed to maintain optimal operating temperatures. These thermal management approaches help extend the lifespan of Mini LED displays, maintain consistent brightness levels, and prevent color shift issues that can occur with temperature fluctuations.Expand Specific Solutions05 Mini LED driving circuits and control systems

Sophisticated driving circuits and control systems are essential for Mini LED displays to achieve precise brightness control, uniform illumination, and energy efficiency. These systems typically include integrated circuits for current regulation, pulse width modulation controllers for dimming, and addressing schemes for individual or grouped LED control. Advanced driver designs focus on reducing power consumption while maintaining display performance and supporting features like high refresh rates and HDR content rendering.Expand Specific Solutions

Key Aerospace Display and Mini LED Manufacturers

The Mini LED integration in aerospace displays market is currently in a growth phase, with increasing adoption driven by the technology's superior brightness, contrast, and energy efficiency. The market size is expanding as aerospace manufacturers seek advanced display solutions for cockpit instrumentation and passenger entertainment systems. Technologically, Mini LED sits between conventional LED and emerging Micro LED, with companies at varying maturity levels. Industry leaders like Rockwell Collins, Honeywell, Thales, and Airbus are advancing integration in critical aerospace applications, while display specialists including BOE Technology, TCL, LG Electronics, and OSRAM are developing specialized Mini LED solutions optimized for the demanding aerospace environment. Chinese manufacturers like Absen Optoelectronics are also emerging as significant players in this competitive landscape.

Rockwell Collins, Inc.

Technical Solution: Rockwell Collins has developed advanced Mini LED integration solutions specifically for aerospace displays, focusing on their Pro Line Fusion and Pro Line 21 avionics suites. Their technology utilizes a matrix of thousands of individually controlled Mini LEDs with sizes ranging from 50-200 micrometers, enabling precise local dimming capabilities. This allows for contrast ratios exceeding 1,000,000:1 and brightness levels up to 1,500 nits while maintaining power efficiency. The company's aerospace-grade Mini LED displays incorporate redundant LED arrays and specialized thermal management systems to meet stringent DO-160 environmental standards. Their displays feature anti-reflective coatings and wide viewing angles (>170°) specifically designed for cockpit environments where readability under direct sunlight is critical. Rockwell Collins has also implemented specialized dimming algorithms that adjust to ambient light conditions automatically while preserving color accuracy across the entire brightness range.

Strengths: Exceptional reliability with MTBF exceeding 30,000 hours; superior readability in variable lighting conditions; reduced power consumption compared to traditional LCD displays; meets stringent aerospace certification requirements. Weaknesses: Higher initial cost compared to conventional display technologies; increased complexity in manufacturing and quality control; requires specialized cooling solutions for high-brightness applications.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has pioneered Mini LED technology for aerospace applications through their Advanced Display System (ADS) platform. Their solution incorporates high-density Mini LED arrays with pixel pitches below 0.5mm, enabling ultra-high resolution displays for critical flight information. Honeywell's aerospace Mini LED displays utilize proprietary local dimming algorithms that divide the screen into over 1,000 independently controlled zones, achieving contrast ratios above 100,000:1 while maintaining brightness uniformity within ±5%. The displays are engineered to withstand extreme aerospace conditions, including temperature ranges from -55°C to +85°C, altitudes up to 40,000 feet, and vibration profiles matching commercial and military aircraft requirements. Honeywell has integrated their Mini LED technology with synthetic vision systems and enhanced flight vision systems, providing pilots with unprecedented situational awareness in all weather conditions. Their displays maintain color accuracy with Delta-E values below 2.0 across the entire operating temperature range, ensuring critical flight information is presented consistently.

Strengths: Exceptional durability in extreme aerospace environments; superior power efficiency compared to traditional backlight systems; enhanced readability in direct sunlight with anti-glare treatments; seamless integration with existing avionics systems. Weaknesses: Complex thermal management requirements; higher component cost compared to conventional LCD technologies; requires specialized manufacturing processes that limit production scalability.

Critical Patents and Technical Innovations in Aerospace Mini LED

Electronic display device offering a day display function, and a display function compatible with night-vision instruments

PatentPendingUS20250037647A1

Innovation

- The proposed electronic display device uses a compact assembly of micro-LEDs, including a red diode and one or more other diodes with a shifted emission spectrum, to create a color display compatible with both day and night-vision modes by adjusting the emission spectrum to reduce red and infrared light.

Ultrathin Mini-LED backlight module capable of realizing night vision compatibility

PatentActiveCN113809056A

Innovation

- An ultra-thin Mini-LED backlight module is designed, which uses Mini-LED backlight strips, reflective dams, light guide plates, reflective films and optical modules. It achieves daytime mode by flipping blue LED chips and fluorescent films. Backlighting, flip-chip red, blue and green Mini-LED chips realize backlighting in night vision compatible mode, and use integrated packaging colloid to increase the number of LED arrangements and optimize the arrangement spacing, reducing power consumption and improving light efficiency. .

Aerospace Certification and Compliance Requirements

The integration of Mini LED technology into aerospace displays necessitates rigorous adherence to stringent certification and compliance requirements established by aviation regulatory bodies worldwide. The Federal Aviation Administration (FAA), European Union Aviation Safety Agency (EASA), and other international authorities maintain comprehensive frameworks that govern all aircraft components, with particular emphasis on display systems due to their critical role in flight operations.

Primary certification standards include DO-160 for environmental testing, which subjects Mini LED displays to extreme temperature variations, vibration, humidity, and electromagnetic interference testing. These tests ensure displays maintain functionality under the harsh conditions encountered during flight operations. Additionally, DO-254 compliance is mandatory for hardware development processes, establishing design assurance levels that correspond to the criticality of display functions.

For software components controlling Mini LED displays, DO-178C certification is required, with assurance levels ranging from E (least critical) to A (most critical). Cockpit displays typically require Level A or B certification, demanding extensive verification and validation procedures that significantly impact development timelines and costs for Mini LED integration projects.

Optical performance requirements present unique challenges for Mini LED aerospace displays. Standards such as MIL-STD-3009 govern critical parameters including luminance, contrast ratio, and color accuracy. Mini LED technology must demonstrate compliance with night vision imaging system (NVIS) compatibility requirements while maintaining readability across diverse lighting conditions from direct sunlight to night operations.

Power consumption and thermal management certifications are particularly relevant for Mini LED implementations. The technology must meet DO-311A standards for electrical power systems, with demonstrations of power stability during various aircraft operational modes and emergency scenarios. Heat dissipation characteristics must be thoroughly documented to prevent thermal issues that could compromise adjacent avionics systems.

Reliability testing represents another significant compliance hurdle, with aerospace displays typically requiring mean time between failure (MTBF) ratings exceeding 30,000 hours. Mini LED displays must undergo accelerated life testing and demonstrate resilience against single-point failures through redundancy mechanisms. Certification authorities increasingly require comprehensive reliability data specific to the novel aspects of Mini LED technology, including LED driver circuits and backlight control systems.

Human factors certification per MIL-STD-1472 and RTCA/DO-367 standards ensures that Mini LED displays support optimal pilot interaction and information processing. These requirements address aspects such as symbol legibility, color discrimination, and response times—all areas where Mini LED technology offers potential advantages but must provide quantifiable evidence of compliance.

Primary certification standards include DO-160 for environmental testing, which subjects Mini LED displays to extreme temperature variations, vibration, humidity, and electromagnetic interference testing. These tests ensure displays maintain functionality under the harsh conditions encountered during flight operations. Additionally, DO-254 compliance is mandatory for hardware development processes, establishing design assurance levels that correspond to the criticality of display functions.

For software components controlling Mini LED displays, DO-178C certification is required, with assurance levels ranging from E (least critical) to A (most critical). Cockpit displays typically require Level A or B certification, demanding extensive verification and validation procedures that significantly impact development timelines and costs for Mini LED integration projects.

Optical performance requirements present unique challenges for Mini LED aerospace displays. Standards such as MIL-STD-3009 govern critical parameters including luminance, contrast ratio, and color accuracy. Mini LED technology must demonstrate compliance with night vision imaging system (NVIS) compatibility requirements while maintaining readability across diverse lighting conditions from direct sunlight to night operations.

Power consumption and thermal management certifications are particularly relevant for Mini LED implementations. The technology must meet DO-311A standards for electrical power systems, with demonstrations of power stability during various aircraft operational modes and emergency scenarios. Heat dissipation characteristics must be thoroughly documented to prevent thermal issues that could compromise adjacent avionics systems.

Reliability testing represents another significant compliance hurdle, with aerospace displays typically requiring mean time between failure (MTBF) ratings exceeding 30,000 hours. Mini LED displays must undergo accelerated life testing and demonstrate resilience against single-point failures through redundancy mechanisms. Certification authorities increasingly require comprehensive reliability data specific to the novel aspects of Mini LED technology, including LED driver circuits and backlight control systems.

Human factors certification per MIL-STD-1472 and RTCA/DO-367 standards ensures that Mini LED displays support optimal pilot interaction and information processing. These requirements address aspects such as symbol legibility, color discrimination, and response times—all areas where Mini LED technology offers potential advantages but must provide quantifiable evidence of compliance.

Reliability and Environmental Testing Methodologies

The integration of Mini LED technology into aerospace displays necessitates rigorous reliability and environmental testing methodologies to ensure performance under extreme conditions. Aerospace applications demand displays that can withstand temperature extremes ranging from -65°C to +85°C, requiring thermal cycling tests that simulate rapid temperature transitions. These tests typically involve 500-1000 cycles between temperature extremes with dwell times of 15-30 minutes to evaluate thermal stress resistance and identify potential failure modes in Mini LED arrays.

Vibration and mechanical shock testing represents another critical evaluation area, with aerospace displays subjected to random vibration profiles according to MIL-STD-810H standards. Mini LED displays must withstand vibration frequencies of 10-2000 Hz at varying power spectral densities and mechanical shocks up to 20G. These tests verify the structural integrity of Mini LED bonding and connection interfaces that are particularly vulnerable to mechanical stresses.

Altitude and pressure differential testing simulates rapid decompression scenarios and high-altitude operations up to 40,000 feet. Mini LED displays must maintain optical performance and structural integrity during pressure changes of 15 psi/minute. Specialized test chambers recreate these conditions while monitoring display functionality, pixel response, and potential delamination issues that could compromise display integrity.

Electromagnetic compatibility (EMC) testing follows DO-160G standards to ensure Mini LED displays neither emit excessive electromagnetic interference nor suffer performance degradation when exposed to external electromagnetic fields. This includes radiated susceptibility tests at field strengths up to 200 V/m across frequency ranges of 10 kHz to 18 GHz, critical for ensuring display reliability in complex avionics environments.

Accelerated life testing methodologies employ elevated stress conditions to predict long-term reliability. Mini LED displays undergo high-temperature operating life tests at 85°C for 1000+ hours with continuous operation cycles. Statistical analysis of failure rates enables the calculation of mean time between failures (MTBF) values, with aerospace applications typically requiring MTBF ratings exceeding 50,000 hours.

Humidity and corrosion resistance testing exposes displays to 95% relative humidity at 60°C for 240 hours, followed by salt fog exposure according to ASTM B117 standards. These tests evaluate the effectiveness of conformal coatings and encapsulation methods used to protect Mini LED components from moisture ingress and corrosive environments commonly encountered in aerospace applications.

Vibration and mechanical shock testing represents another critical evaluation area, with aerospace displays subjected to random vibration profiles according to MIL-STD-810H standards. Mini LED displays must withstand vibration frequencies of 10-2000 Hz at varying power spectral densities and mechanical shocks up to 20G. These tests verify the structural integrity of Mini LED bonding and connection interfaces that are particularly vulnerable to mechanical stresses.

Altitude and pressure differential testing simulates rapid decompression scenarios and high-altitude operations up to 40,000 feet. Mini LED displays must maintain optical performance and structural integrity during pressure changes of 15 psi/minute. Specialized test chambers recreate these conditions while monitoring display functionality, pixel response, and potential delamination issues that could compromise display integrity.

Electromagnetic compatibility (EMC) testing follows DO-160G standards to ensure Mini LED displays neither emit excessive electromagnetic interference nor suffer performance degradation when exposed to external electromagnetic fields. This includes radiated susceptibility tests at field strengths up to 200 V/m across frequency ranges of 10 kHz to 18 GHz, critical for ensuring display reliability in complex avionics environments.

Accelerated life testing methodologies employ elevated stress conditions to predict long-term reliability. Mini LED displays undergo high-temperature operating life tests at 85°C for 1000+ hours with continuous operation cycles. Statistical analysis of failure rates enables the calculation of mean time between failures (MTBF) values, with aerospace applications typically requiring MTBF ratings exceeding 50,000 hours.

Humidity and corrosion resistance testing exposes displays to 95% relative humidity at 60°C for 240 hours, followed by salt fog exposure according to ASTM B117 standards. These tests evaluate the effectiveness of conformal coatings and encapsulation methods used to protect Mini LED components from moisture ingress and corrosive environments commonly encountered in aerospace applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!