Assessing standards compliance for solid oxide electrolysis cells

OCT 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SOEC Technology Background and Objectives

Solid Oxide Electrolysis Cells (SOECs) represent a transformative technology in the realm of renewable energy conversion and storage. Emerging from solid oxide fuel cell (SOFC) research in the 1980s, SOECs operate on the reverse principle, using electricity to split water or carbon dioxide into hydrogen or carbon monoxide respectively. This technology has gained significant attention over the past decade as a promising solution for large-scale energy storage and sector coupling in renewable energy systems.

The evolution of SOEC technology has been marked by progressive improvements in materials science, particularly in electrolyte and electrode development. Early systems utilized yttria-stabilized zirconia (YSZ) electrolytes operating at temperatures exceeding 800°C, while contemporary research focuses on intermediate-temperature SOECs (600-750°C) using advanced materials such as gadolinium-doped ceria (GDC) and lanthanum strontium cobalt ferrite (LSCF).

Standards compliance assessment for SOECs has become increasingly critical as the technology transitions from laboratory research to commercial deployment. Currently, the field lacks comprehensive, universally accepted standards specifically designed for SOECs, often borrowing frameworks from adjacent technologies like SOFCs or conventional electrolyzers, which presents significant challenges for technology validation and market acceptance.

The primary technical objectives in SOEC development include enhancing durability beyond the current 10,000-20,000 operating hours, reducing degradation rates below 0.5% per 1000 hours, improving electrical efficiency to exceed 90% (HHV basis), and developing cost-effective manufacturing processes to achieve capital costs below $500/kW. These targets are essential for SOECs to compete with alternative hydrogen production technologies.

Recent technological trends indicate a growing focus on reversible solid oxide cells (rSOCs) capable of operating in both fuel cell and electrolysis modes, offering enhanced flexibility for grid balancing and energy storage applications. Additionally, co-electrolysis of H2O and CO2 to produce syngas directly has emerged as a promising pathway for carbon utilization and synthetic fuel production.

The global research landscape shows concentrated efforts in Europe, particularly Denmark, Germany and France, alongside significant programs in the United States, Japan, and increasingly China. Academic-industrial partnerships have accelerated in recent years, with notable collaborations between research institutions and energy companies seeking to commercialize SOEC technology for green hydrogen production and industrial decarbonization applications.

The evolution of SOEC technology has been marked by progressive improvements in materials science, particularly in electrolyte and electrode development. Early systems utilized yttria-stabilized zirconia (YSZ) electrolytes operating at temperatures exceeding 800°C, while contemporary research focuses on intermediate-temperature SOECs (600-750°C) using advanced materials such as gadolinium-doped ceria (GDC) and lanthanum strontium cobalt ferrite (LSCF).

Standards compliance assessment for SOECs has become increasingly critical as the technology transitions from laboratory research to commercial deployment. Currently, the field lacks comprehensive, universally accepted standards specifically designed for SOECs, often borrowing frameworks from adjacent technologies like SOFCs or conventional electrolyzers, which presents significant challenges for technology validation and market acceptance.

The primary technical objectives in SOEC development include enhancing durability beyond the current 10,000-20,000 operating hours, reducing degradation rates below 0.5% per 1000 hours, improving electrical efficiency to exceed 90% (HHV basis), and developing cost-effective manufacturing processes to achieve capital costs below $500/kW. These targets are essential for SOECs to compete with alternative hydrogen production technologies.

Recent technological trends indicate a growing focus on reversible solid oxide cells (rSOCs) capable of operating in both fuel cell and electrolysis modes, offering enhanced flexibility for grid balancing and energy storage applications. Additionally, co-electrolysis of H2O and CO2 to produce syngas directly has emerged as a promising pathway for carbon utilization and synthetic fuel production.

The global research landscape shows concentrated efforts in Europe, particularly Denmark, Germany and France, alongside significant programs in the United States, Japan, and increasingly China. Academic-industrial partnerships have accelerated in recent years, with notable collaborations between research institutions and energy companies seeking to commercialize SOEC technology for green hydrogen production and industrial decarbonization applications.

Market Analysis for Hydrogen Production via Electrolysis

The global hydrogen market is experiencing significant growth, driven by the increasing focus on decarbonization and clean energy transitions. The market for hydrogen produced via electrolysis, particularly using solid oxide electrolysis cells (SOECs), represents a rapidly expanding segment within this broader landscape. Current estimates value the global green hydrogen market at approximately $2.5 billion in 2022, with projections suggesting growth to reach $89.2 billion by 2030, representing a compound annual growth rate (CAGR) of 54.7%.

Electrolytic hydrogen production technologies, including SOECs, are gaining traction due to their potential to produce hydrogen with minimal carbon emissions when powered by renewable energy sources. The market demand is primarily driven by industrial applications, which currently account for about 70% of hydrogen consumption globally. These applications include ammonia production, petroleum refining, and methanol synthesis.

Transportation represents another significant growth sector, with hydrogen fuel cell vehicles emerging as a promising alternative to battery electric vehicles, particularly for heavy-duty transport, long-haul shipping, and aviation. The market for hydrogen in transportation is expected to grow at a CAGR of 66.9% through 2030.

Regional analysis reveals that Europe currently leads in electrolysis deployment, with approximately 40% of global installed capacity, followed by Asia-Pacific at 35% and North America at 20%. Countries like Germany, Japan, South Korea, and China have established ambitious hydrogen strategies with substantial funding commitments, creating favorable market conditions for SOEC technology adoption.

The economic viability of hydrogen produced via SOECs is improving as technology advances and scales. Current production costs range from $4-6 per kilogram, with projections suggesting potential reduction to $2-3 per kilogram by 2030 as manufacturing scales and efficiency improves. This cost trajectory is critical for market expansion, as price parity with conventional hydrogen production methods (currently $1-2 per kilogram) remains a key adoption barrier.

Market barriers include high capital costs, limited infrastructure for hydrogen storage and distribution, and regulatory uncertainties regarding standards and certification. The lack of universally accepted standards for SOEC performance, durability, and safety represents a significant challenge that directly impacts market growth potential.

Customer segments show varying adoption patterns, with early adopters primarily in industrial applications where hydrogen is already utilized. Emerging segments include energy storage applications, where hydrogen produced during periods of excess renewable generation can be stored for later use, addressing intermittency challenges in renewable energy systems.

Electrolytic hydrogen production technologies, including SOECs, are gaining traction due to their potential to produce hydrogen with minimal carbon emissions when powered by renewable energy sources. The market demand is primarily driven by industrial applications, which currently account for about 70% of hydrogen consumption globally. These applications include ammonia production, petroleum refining, and methanol synthesis.

Transportation represents another significant growth sector, with hydrogen fuel cell vehicles emerging as a promising alternative to battery electric vehicles, particularly for heavy-duty transport, long-haul shipping, and aviation. The market for hydrogen in transportation is expected to grow at a CAGR of 66.9% through 2030.

Regional analysis reveals that Europe currently leads in electrolysis deployment, with approximately 40% of global installed capacity, followed by Asia-Pacific at 35% and North America at 20%. Countries like Germany, Japan, South Korea, and China have established ambitious hydrogen strategies with substantial funding commitments, creating favorable market conditions for SOEC technology adoption.

The economic viability of hydrogen produced via SOECs is improving as technology advances and scales. Current production costs range from $4-6 per kilogram, with projections suggesting potential reduction to $2-3 per kilogram by 2030 as manufacturing scales and efficiency improves. This cost trajectory is critical for market expansion, as price parity with conventional hydrogen production methods (currently $1-2 per kilogram) remains a key adoption barrier.

Market barriers include high capital costs, limited infrastructure for hydrogen storage and distribution, and regulatory uncertainties regarding standards and certification. The lack of universally accepted standards for SOEC performance, durability, and safety represents a significant challenge that directly impacts market growth potential.

Customer segments show varying adoption patterns, with early adopters primarily in industrial applications where hydrogen is already utilized. Emerging segments include energy storage applications, where hydrogen produced during periods of excess renewable generation can be stored for later use, addressing intermittency challenges in renewable energy systems.

Current Standards and Technical Challenges for SOECs

The current landscape of standards for Solid Oxide Electrolysis Cells (SOECs) remains fragmented and underdeveloped compared to more mature energy technologies. While SOECs share similarities with Solid Oxide Fuel Cells (SOFCs), they operate under different conditions and face unique challenges that require specific standardization approaches. Existing standards primarily focus on performance metrics, safety protocols, and durability testing, but lack comprehensive coverage of all operational aspects.

IEC 62282 series provides some applicable standards for solid oxide cells, though primarily developed for fuel cell applications. The adaptation of these standards for electrolysis operation requires significant modifications to account for different operating parameters, degradation mechanisms, and performance metrics. ISO/TC 197 offers standards related to hydrogen technologies, but with limited specific guidance for high-temperature electrolysis systems.

Technical challenges in standardization stem from the diverse materials and designs employed in SOEC development. The high operating temperatures (700-900°C) create unique testing challenges that conventional electrochemical testing protocols cannot adequately address. Current standards struggle to account for accelerated degradation testing that accurately predicts long-term performance under various operating conditions.

Measurement protocols present another significant challenge. The industry lacks consensus on standardized testing conditions, making cross-comparison between different SOEC technologies difficult. Parameters such as current density, temperature distribution, steam conversion rates, and impurity tolerance require standardized measurement approaches to enable meaningful benchmarking across research institutions and manufacturers.

Durability assessment remains particularly problematic. The correlation between accelerated stress tests and real-world degradation is not well established for SOECs. Standards must address various degradation mechanisms including chromium poisoning, nickel agglomeration, and electrolyte degradation under electrolysis conditions, which differ significantly from fuel cell operation.

Safety standards for high-temperature hydrogen production systems are still evolving. The combination of high temperatures, steam management, and hydrogen handling creates unique safety considerations that current standards do not fully address. Integration with downstream processes and grid interaction protocols also lack standardized approaches.

International harmonization efforts are underway through organizations like IEA, IRENA and the International Partnership for Hydrogen and Fuel Cells in the Economy (IPHE), but progress remains slow due to the emerging nature of the technology and varying regional priorities. The development of universally accepted testing protocols and performance metrics represents a critical path forward for enabling commercial deployment and market acceptance of SOEC technology.

IEC 62282 series provides some applicable standards for solid oxide cells, though primarily developed for fuel cell applications. The adaptation of these standards for electrolysis operation requires significant modifications to account for different operating parameters, degradation mechanisms, and performance metrics. ISO/TC 197 offers standards related to hydrogen technologies, but with limited specific guidance for high-temperature electrolysis systems.

Technical challenges in standardization stem from the diverse materials and designs employed in SOEC development. The high operating temperatures (700-900°C) create unique testing challenges that conventional electrochemical testing protocols cannot adequately address. Current standards struggle to account for accelerated degradation testing that accurately predicts long-term performance under various operating conditions.

Measurement protocols present another significant challenge. The industry lacks consensus on standardized testing conditions, making cross-comparison between different SOEC technologies difficult. Parameters such as current density, temperature distribution, steam conversion rates, and impurity tolerance require standardized measurement approaches to enable meaningful benchmarking across research institutions and manufacturers.

Durability assessment remains particularly problematic. The correlation between accelerated stress tests and real-world degradation is not well established for SOECs. Standards must address various degradation mechanisms including chromium poisoning, nickel agglomeration, and electrolyte degradation under electrolysis conditions, which differ significantly from fuel cell operation.

Safety standards for high-temperature hydrogen production systems are still evolving. The combination of high temperatures, steam management, and hydrogen handling creates unique safety considerations that current standards do not fully address. Integration with downstream processes and grid interaction protocols also lack standardized approaches.

International harmonization efforts are underway through organizations like IEA, IRENA and the International Partnership for Hydrogen and Fuel Cells in the Economy (IPHE), but progress remains slow due to the emerging nature of the technology and varying regional priorities. The development of universally accepted testing protocols and performance metrics represents a critical path forward for enabling commercial deployment and market acceptance of SOEC technology.

Current Compliance Assessment Methodologies

01 Safety and operational standards for solid oxide electrolysis cells

Solid oxide electrolysis cells must comply with safety and operational standards that govern their performance, durability, and safe operation. These standards include specifications for operating temperatures, pressure tolerances, and electrical safety requirements. Compliance with these standards ensures that the cells can operate safely under high-temperature conditions while maintaining performance efficiency and preventing hazardous situations.- Safety and operational standards for solid oxide electrolysis cells: Solid oxide electrolysis cells must comply with specific safety and operational standards to ensure reliable performance and prevent hazards. These standards cover aspects such as temperature resistance, pressure tolerance, and electrical safety requirements. Compliance with these standards ensures that the cells can operate safely under high-temperature conditions typical for solid oxide systems while maintaining structural integrity and preventing leakage of gases or electrolytes.

- Material composition and purity standards: Standards for solid oxide electrolysis cells specify requirements for material composition and purity levels of components such as electrolytes, electrodes, and interconnects. These standards ensure that materials used can withstand high operating temperatures while maintaining electrochemical performance. Specifications typically include acceptable impurity levels, grain size distributions, and phase composition requirements that affect cell durability and efficiency.

- Performance testing and certification protocols: Standardized testing protocols are established to evaluate and certify the performance of solid oxide electrolysis cells. These protocols include methods for measuring electrochemical performance, efficiency, durability, and degradation rates under various operating conditions. Certification requires demonstration of consistent performance over specified operating ranges and time periods, with standardized reporting of key performance indicators such as current density, gas conversion efficiency, and thermal cycling resistance.

- Environmental and sustainability compliance: Environmental standards for solid oxide electrolysis cells address sustainability aspects including carbon footprint, resource utilization, and end-of-life management. These standards specify acceptable emissions levels during manufacturing and operation, requirements for recyclability of components, and restrictions on hazardous materials. Compliance with these standards ensures that solid oxide electrolysis technology contributes positively to environmental goals while minimizing negative impacts throughout the product lifecycle.

- Integration and system-level standards: System-level standards govern how solid oxide electrolysis cells integrate with broader energy systems and infrastructure. These standards specify requirements for interfaces, control systems, monitoring capabilities, and grid connectivity. They ensure interoperability between components from different manufacturers and compatibility with existing energy infrastructure. Standards also address system-level safety features, emergency shutdown procedures, and requirements for balance-of-plant components that support cell operation.

02 Material composition and quality standards

Standards for solid oxide electrolysis cells specify requirements for material composition, purity, and quality. These standards cover electrolyte materials, electrode compositions, and interconnect materials to ensure optimal performance and longevity. Compliance with material standards is essential for achieving consistent cell performance, minimizing degradation, and ensuring compatibility between different components of the electrolysis system.Expand Specific Solutions03 Performance testing and certification protocols

Specific testing protocols and certification procedures are established for solid oxide electrolysis cells to verify their performance against industry standards. These protocols include methods for measuring efficiency, durability, degradation rates, and electrochemical performance. Standardized testing enables comparison between different cell designs and ensures that cells meet minimum performance requirements before commercial deployment.Expand Specific Solutions04 Environmental and sustainability compliance

Solid oxide electrolysis cells must adhere to environmental standards related to emissions, resource utilization, and end-of-life disposal. These standards address the environmental impact of manufacturing processes, operation, and decommissioning of cells. Compliance with these standards ensures that solid oxide electrolysis technology contributes to sustainable energy production with minimal environmental footprint.Expand Specific Solutions05 Integration and system-level standards

Standards for the integration of solid oxide electrolysis cells into larger energy systems specify requirements for interfaces, controls, and system-level performance. These standards ensure compatibility with power sources, hydrogen processing equipment, and grid connections. Compliance with integration standards facilitates the deployment of solid oxide electrolysis technology in various applications including renewable energy storage, industrial hydrogen production, and power-to-gas systems.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The solid oxide electrolysis cell (SOEC) standards compliance landscape is currently in a growth phase, with the market expanding as clean hydrogen production gains importance in decarbonization efforts. The global market is projected to grow significantly, driven by increasing investments in green hydrogen technologies. Technical maturity varies across players, with established research institutions like Technical University of Denmark, Tsinghua University, and Kyoto University leading fundamental research. Among commercial entities, Topsoe Fuel Cell, Convion Oy, and Versa Power Systems demonstrate advanced technological capabilities, while industrial giants like Toshiba, Hyundai, and Kia are investing to scale up manufacturing. Chinese institutions including Dalian Institute of Chemical Physics and PetroChina are rapidly advancing their technological capabilities, particularly in standards development and compliance frameworks.

Technical University of Denmark

Technical Solution: Technical University of Denmark (DTU) has developed a comprehensive standards compliance framework for solid oxide electrolysis cells (SOECs) that integrates both electrochemical performance and durability testing protocols. Their approach includes accelerated stress testing methodologies to evaluate long-term degradation mechanisms under various operating conditions. DTU's compliance assessment system incorporates impedance spectroscopy techniques for in-situ monitoring of cell degradation, allowing for real-time evaluation against IEC and ISO standards. Their framework particularly focuses on quantifying performance metrics such as area-specific resistance, current density thresholds, and thermal cycling resilience. DTU has also pioneered standardized testing protocols for evaluating hydrogen production efficiency and steam electrolysis performance that have been adopted by multiple international certification bodies.

Strengths: Strong academic research foundation with extensive laboratory facilities for comprehensive testing; collaborative approach with industry partners ensures practical applicability. Weaknesses: Academic focus may sometimes prioritize research novelty over commercial implementation requirements.

Dalian Institute of Chemical Physics of CAS

Technical Solution: Dalian Institute of Chemical Physics (DICP) has established an advanced standards compliance assessment system for solid oxide electrolysis cells that emphasizes material characterization and performance validation. Their methodology incorporates multi-scale testing from micro-structural analysis to full-stack evaluation, ensuring compliance with both Chinese national standards and international benchmarks. DICP's approach features specialized high-temperature testing facilities capable of simulating various industrial operating environments up to 1000°C, allowing for precise evaluation of electrolyte conductivity, electrode activity, and overall cell efficiency. Their compliance framework includes detailed protocols for evaluating impurity tolerance, thermal expansion compatibility, and mechanical strength parameters critical for long-term operation. DICP has also developed specialized techniques for evaluating the interface stability between different cell components during extended operation periods.

Strengths: Exceptional materials science expertise with state-of-the-art characterization equipment; strong connections to Chinese manufacturing sector for implementation. Weaknesses: Some testing protocols may be more aligned with Chinese national standards than international requirements.

Critical Standards and Certification Requirements

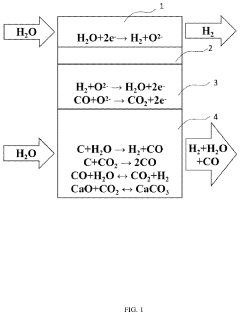

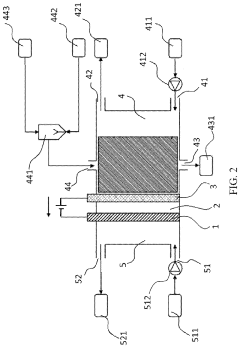

Carbon-assisted solid oxide electrolysis cell

PatentInactiveUS20230167562A1

Innovation

- The introduction of a CO2 absorber in the anode chamber, where water is used as an in situ gasification agent to enhance carbon gasification, promoting steam-carbon gasification and suppressing the Boudouard reaction, thereby increasing carbon gasification rates and generating more hydrogen fuel, which improves electrochemical kinetics and reduces energy consumption.

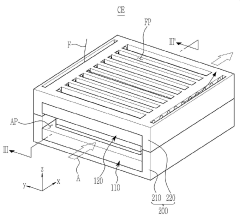

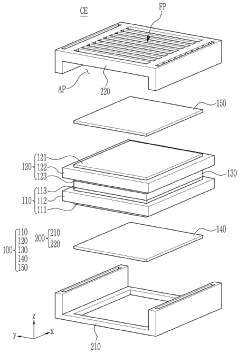

Solid oxide electrolysis cell and cell assembly including the same

PatentPendingKR1020240085112A

Innovation

- A solid oxide electrolysis cell design that combines two unit cells with mirror-symmetrical stacking and reduced separator plates, along with parallel electrical connections and circuit breakers, to prevent local high voltage and minimize thickness.

Regulatory Framework and Policy Implications

The regulatory landscape for solid oxide electrolysis cells (SOECs) is characterized by a complex interplay of international standards, national regulations, and industry-specific guidelines. Currently, key regulatory frameworks include IEC 62282 for fuel cell technologies, which partially covers SOECs, and ISO 14687 for hydrogen fuel quality specifications. These standards provide foundational requirements for safety, performance, and interoperability, though they remain insufficient for the unique operational characteristics of SOECs operating at high temperatures (700-900°C).

National regulatory bodies have adopted varying approaches to SOEC technology oversight. The European Union, through its Hydrogen Strategy and the European Green Deal, has established progressive regulatory pathways that incentivize SOEC deployment while maintaining stringent safety standards. In contrast, the United States relies on a combination of Department of Energy guidelines and state-level regulations, creating a more fragmented compliance environment. Asian markets, particularly Japan and South Korea, have implemented technology-specific standards that address the unique material degradation and thermal cycling challenges of SOECs.

Policy implications of SOEC standards compliance extend beyond technical considerations into economic and environmental domains. Carbon pricing mechanisms and renewable energy incentives significantly influence the economic viability of SOEC hydrogen production. Regions with robust carbon markets provide indirect regulatory support for SOEC technologies by improving their cost competitiveness against conventional hydrogen production methods.

Regulatory harmonization remains a critical challenge for global SOEC deployment. The International Partnership for Hydrogen and Fuel Cells in the Economy (IPHE) has initiated efforts to develop globally recognized testing protocols for electrolysis technologies, though SOEC-specific protocols remain underdeveloped. This regulatory fragmentation creates market entry barriers and increases compliance costs for manufacturers operating across multiple jurisdictions.

Future regulatory developments will likely focus on lifecycle assessment requirements, grid integration protocols, and durability standards specific to high-temperature electrolysis. The integration of SOECs with renewable energy sources introduces additional regulatory considerations regarding grid stability and energy storage, necessitating adaptive regulatory frameworks that can accommodate technological evolution while maintaining safety and performance standards.

Policy makers face the challenge of balancing innovation support with appropriate oversight. Regulatory sandboxes and technology-specific exemptions have emerged as promising approaches to facilitate SOEC commercialization while gathering operational data necessary for comprehensive standard development. These adaptive regulatory mechanisms will be essential for addressing the unique compliance challenges of this emerging clean energy technology.

National regulatory bodies have adopted varying approaches to SOEC technology oversight. The European Union, through its Hydrogen Strategy and the European Green Deal, has established progressive regulatory pathways that incentivize SOEC deployment while maintaining stringent safety standards. In contrast, the United States relies on a combination of Department of Energy guidelines and state-level regulations, creating a more fragmented compliance environment. Asian markets, particularly Japan and South Korea, have implemented technology-specific standards that address the unique material degradation and thermal cycling challenges of SOECs.

Policy implications of SOEC standards compliance extend beyond technical considerations into economic and environmental domains. Carbon pricing mechanisms and renewable energy incentives significantly influence the economic viability of SOEC hydrogen production. Regions with robust carbon markets provide indirect regulatory support for SOEC technologies by improving their cost competitiveness against conventional hydrogen production methods.

Regulatory harmonization remains a critical challenge for global SOEC deployment. The International Partnership for Hydrogen and Fuel Cells in the Economy (IPHE) has initiated efforts to develop globally recognized testing protocols for electrolysis technologies, though SOEC-specific protocols remain underdeveloped. This regulatory fragmentation creates market entry barriers and increases compliance costs for manufacturers operating across multiple jurisdictions.

Future regulatory developments will likely focus on lifecycle assessment requirements, grid integration protocols, and durability standards specific to high-temperature electrolysis. The integration of SOECs with renewable energy sources introduces additional regulatory considerations regarding grid stability and energy storage, necessitating adaptive regulatory frameworks that can accommodate technological evolution while maintaining safety and performance standards.

Policy makers face the challenge of balancing innovation support with appropriate oversight. Regulatory sandboxes and technology-specific exemptions have emerged as promising approaches to facilitate SOEC commercialization while gathering operational data necessary for comprehensive standard development. These adaptive regulatory mechanisms will be essential for addressing the unique compliance challenges of this emerging clean energy technology.

Environmental Impact and Sustainability Metrics

Solid oxide electrolysis cells (SOECs) represent a promising technology for clean hydrogen production, yet their environmental footprint and sustainability metrics require thorough assessment to ensure their alignment with global climate goals. The life cycle assessment (LCA) of SOECs reveals significant advantages over conventional hydrogen production methods, with potential greenhouse gas emission reductions of 60-90% when powered by renewable energy sources compared to steam methane reforming processes.

The carbon intensity of SOEC systems varies considerably based on electricity sources, with estimates ranging from 0.5-2.0 kg CO2eq/kg H2 when using renewable energy, compared to 9-12 kg CO2eq/kg H2 for conventional methods. This substantial difference underscores the importance of integrating SOECs with clean energy infrastructure to maximize environmental benefits. Material sustainability also presents challenges, as SOECs typically contain rare earth elements and precious metals that face supply constraints and environmental concerns during extraction and processing.

Water consumption metrics indicate that SOECs require approximately 9-10 liters of water per kg of hydrogen produced, which is significantly lower than biomass-based hydrogen production methods. However, water quality requirements for SOECs are stringent, necessitating energy-intensive purification processes that must be factored into overall sustainability assessments.

Energy return on investment (EROI) calculations for SOEC systems demonstrate improving efficiency, with current systems achieving 65-75% electrical-to-hydrogen conversion efficiency. This represents a critical sustainability metric that continues to improve as technology advances, approaching the theoretical maximum efficiency of approximately 85-90% under optimal operating conditions.

Land use impacts of SOEC deployment remain relatively minimal compared to other renewable energy technologies, requiring approximately 0.1-0.2 m²/MWh when integrated with solar or wind power generation. This favorable land-use profile enhances the overall sustainability proposition of SOEC technology in regions with land constraints.

Circular economy considerations for SOECs are gaining prominence in standards compliance frameworks, with emerging metrics focusing on material recovery rates, component reusability, and end-of-life management. Current recovery rates for critical materials from decommissioned SOECs range from 30-70%, presenting significant opportunities for improvement through advanced recycling technologies and design-for-disassembly approaches that are increasingly becoming standard requirements.

The carbon intensity of SOEC systems varies considerably based on electricity sources, with estimates ranging from 0.5-2.0 kg CO2eq/kg H2 when using renewable energy, compared to 9-12 kg CO2eq/kg H2 for conventional methods. This substantial difference underscores the importance of integrating SOECs with clean energy infrastructure to maximize environmental benefits. Material sustainability also presents challenges, as SOECs typically contain rare earth elements and precious metals that face supply constraints and environmental concerns during extraction and processing.

Water consumption metrics indicate that SOECs require approximately 9-10 liters of water per kg of hydrogen produced, which is significantly lower than biomass-based hydrogen production methods. However, water quality requirements for SOECs are stringent, necessitating energy-intensive purification processes that must be factored into overall sustainability assessments.

Energy return on investment (EROI) calculations for SOEC systems demonstrate improving efficiency, with current systems achieving 65-75% electrical-to-hydrogen conversion efficiency. This represents a critical sustainability metric that continues to improve as technology advances, approaching the theoretical maximum efficiency of approximately 85-90% under optimal operating conditions.

Land use impacts of SOEC deployment remain relatively minimal compared to other renewable energy technologies, requiring approximately 0.1-0.2 m²/MWh when integrated with solar or wind power generation. This favorable land-use profile enhances the overall sustainability proposition of SOEC technology in regions with land constraints.

Circular economy considerations for SOECs are gaining prominence in standards compliance frameworks, with emerging metrics focusing on material recovery rates, component reusability, and end-of-life management. Current recovery rates for critical materials from decommissioned SOECs range from 30-70%, presenting significant opportunities for improvement through advanced recycling technologies and design-for-disassembly approaches that are increasingly becoming standard requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!