Research on the cost-effectiveness of solid oxide electrolysis cells

OCT 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SOEC Technology Background and Objectives

Solid Oxide Electrolysis Cells (SOECs) represent a transformative technology in the realm of energy conversion, with roots dating back to the 1980s. Initially developed as a reverse application of solid oxide fuel cells (SOFCs), SOECs have evolved significantly over the past four decades. The fundamental principle involves using electrical energy to split water molecules into hydrogen and oxygen at high temperatures (700-900°C), offering theoretical efficiency advantages over low-temperature electrolysis technologies.

The evolution of SOEC technology has been marked by several key milestones, including the development of more durable ceramic materials, improved cell designs, and enhanced manufacturing techniques. Early research focused primarily on proof-of-concept demonstrations, while recent advancements have shifted toward addressing durability, scalability, and cost-effectiveness challenges that have historically limited widespread adoption.

Current technological trends in SOEC development include the pursuit of intermediate-temperature operation (500-700°C), which could significantly reduce material degradation while maintaining reasonable efficiency. Additionally, there is growing interest in co-electrolysis applications, where SOECs simultaneously convert water and carbon dioxide into syngas, providing a pathway for renewable energy storage and carbon utilization.

The primary technical objectives for SOEC research center on achieving economic viability through cost reduction while maintaining or improving performance metrics. Specific goals include extending cell lifetime beyond 40,000 hours of operation, reducing degradation rates to less than 0.5% per 1000 hours, and decreasing capital costs to under $500/kW. These improvements are essential for SOECs to compete with alternative hydrogen production technologies, particularly low-temperature electrolysis and steam methane reforming.

From a broader perspective, SOEC technology aligns with global decarbonization efforts and the transition toward hydrogen-based economies. The ability to efficiently convert renewable electricity into storable chemical energy addresses the intermittency challenges associated with wind and solar power generation. Furthermore, high-temperature electrolysis offers theoretical efficiency advantages that could ultimately translate to lower hydrogen production costs compared to alternative technologies.

The anticipated trajectory for SOEC technology involves progressive improvements in materials science, manufacturing processes, and system integration. Research institutions and industrial partners worldwide are collaborating to overcome existing technical barriers, with particular emphasis on developing cost-effective materials that can withstand the harsh operating conditions while maintaining performance over extended periods.

The evolution of SOEC technology has been marked by several key milestones, including the development of more durable ceramic materials, improved cell designs, and enhanced manufacturing techniques. Early research focused primarily on proof-of-concept demonstrations, while recent advancements have shifted toward addressing durability, scalability, and cost-effectiveness challenges that have historically limited widespread adoption.

Current technological trends in SOEC development include the pursuit of intermediate-temperature operation (500-700°C), which could significantly reduce material degradation while maintaining reasonable efficiency. Additionally, there is growing interest in co-electrolysis applications, where SOECs simultaneously convert water and carbon dioxide into syngas, providing a pathway for renewable energy storage and carbon utilization.

The primary technical objectives for SOEC research center on achieving economic viability through cost reduction while maintaining or improving performance metrics. Specific goals include extending cell lifetime beyond 40,000 hours of operation, reducing degradation rates to less than 0.5% per 1000 hours, and decreasing capital costs to under $500/kW. These improvements are essential for SOECs to compete with alternative hydrogen production technologies, particularly low-temperature electrolysis and steam methane reforming.

From a broader perspective, SOEC technology aligns with global decarbonization efforts and the transition toward hydrogen-based economies. The ability to efficiently convert renewable electricity into storable chemical energy addresses the intermittency challenges associated with wind and solar power generation. Furthermore, high-temperature electrolysis offers theoretical efficiency advantages that could ultimately translate to lower hydrogen production costs compared to alternative technologies.

The anticipated trajectory for SOEC technology involves progressive improvements in materials science, manufacturing processes, and system integration. Research institutions and industrial partners worldwide are collaborating to overcome existing technical barriers, with particular emphasis on developing cost-effective materials that can withstand the harsh operating conditions while maintaining performance over extended periods.

Market Analysis for Hydrogen Production

The global hydrogen market is experiencing significant growth, driven by increasing focus on decarbonization and clean energy transitions. Currently valued at approximately $130 billion, the hydrogen market is projected to reach $500 billion by 2030, with annual growth rates exceeding 9.2% through the decade. Green hydrogen, produced through electrolysis powered by renewable energy, represents the fastest-growing segment within this market.

Solid Oxide Electrolysis Cells (SOECs) are positioned as a promising technology for hydrogen production, particularly in the green hydrogen sector. While alkaline and PEM electrolyzers currently dominate the market with over 85% market share, SOECs are gaining attention due to their higher theoretical efficiency and potential for cost reduction at scale. The current market penetration of SOECs remains below 5%, presenting significant growth opportunities.

Industrial applications constitute the largest demand segment for hydrogen, accounting for 72% of current consumption, primarily in refining, ammonia production, and methanol synthesis. Transportation represents the fastest-growing application sector, with 27% annual growth expected through 2030 as fuel cell vehicles gain traction in commercial transportation fleets. Energy storage applications utilizing hydrogen are projected to grow at 23% annually as grid-scale storage solutions become more prevalent.

Regional analysis reveals that Asia-Pacific currently leads hydrogen consumption at 41% of global demand, followed by Europe (27%) and North America (22%). However, Europe is making the most aggressive investments in green hydrogen infrastructure, with over €40 billion committed through various national hydrogen strategies and the European Green Deal. China's latest five-year plan allocates substantial resources toward hydrogen production technologies, including advanced electrolysis methods.

The cost structure of hydrogen production varies significantly by production method. While grey hydrogen (from natural gas) costs $1-2/kg, blue hydrogen (with carbon capture) ranges from $2-3/kg, and green hydrogen currently averages $4-6/kg. For SOEC-based hydrogen production specifically, current costs range between $5-7/kg, with projections suggesting potential reduction to $2-3/kg by 2030 as technology matures and economies of scale are realized.

Market barriers for SOEC adoption include high capital costs (currently $1,000-1,500/kW versus $700-900/kW for PEM systems), durability concerns, and limited manufacturing scale. However, the technology's higher efficiency, particularly when integrated with industrial waste heat, presents a compelling value proposition for certain applications where high-temperature processes are already present.

Solid Oxide Electrolysis Cells (SOECs) are positioned as a promising technology for hydrogen production, particularly in the green hydrogen sector. While alkaline and PEM electrolyzers currently dominate the market with over 85% market share, SOECs are gaining attention due to their higher theoretical efficiency and potential for cost reduction at scale. The current market penetration of SOECs remains below 5%, presenting significant growth opportunities.

Industrial applications constitute the largest demand segment for hydrogen, accounting for 72% of current consumption, primarily in refining, ammonia production, and methanol synthesis. Transportation represents the fastest-growing application sector, with 27% annual growth expected through 2030 as fuel cell vehicles gain traction in commercial transportation fleets. Energy storage applications utilizing hydrogen are projected to grow at 23% annually as grid-scale storage solutions become more prevalent.

Regional analysis reveals that Asia-Pacific currently leads hydrogen consumption at 41% of global demand, followed by Europe (27%) and North America (22%). However, Europe is making the most aggressive investments in green hydrogen infrastructure, with over €40 billion committed through various national hydrogen strategies and the European Green Deal. China's latest five-year plan allocates substantial resources toward hydrogen production technologies, including advanced electrolysis methods.

The cost structure of hydrogen production varies significantly by production method. While grey hydrogen (from natural gas) costs $1-2/kg, blue hydrogen (with carbon capture) ranges from $2-3/kg, and green hydrogen currently averages $4-6/kg. For SOEC-based hydrogen production specifically, current costs range between $5-7/kg, with projections suggesting potential reduction to $2-3/kg by 2030 as technology matures and economies of scale are realized.

Market barriers for SOEC adoption include high capital costs (currently $1,000-1,500/kW versus $700-900/kW for PEM systems), durability concerns, and limited manufacturing scale. However, the technology's higher efficiency, particularly when integrated with industrial waste heat, presents a compelling value proposition for certain applications where high-temperature processes are already present.

Current SOEC Cost Challenges

Solid Oxide Electrolysis Cells (SOECs) face significant cost challenges that currently limit their widespread commercial adoption despite their promising efficiency in hydrogen production. The capital expenditure (CAPEX) for SOEC systems remains prohibitively high, ranging from $800-1,500/kW, substantially exceeding the U.S. Department of Energy's target of $300/kW for economically viable hydrogen production. This cost barrier represents one of the primary obstacles to market penetration.

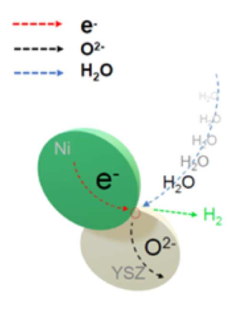

Material costs constitute approximately 60-70% of total SOEC stack expenses. The ceramic electrolytes, typically yttria-stabilized zirconia (YSZ), require high-purity raw materials and complex manufacturing processes. Additionally, electrode materials such as nickel-based anodes and lanthanum strontium manganite (LSM) cathodes incorporate expensive rare earth elements. The interconnects, often made from specialized chromium alloys with protective coatings, further contribute to material expenses.

Manufacturing complexity presents another significant cost challenge. The production of SOECs demands precise control over multiple high-temperature processes, including tape casting, screen printing, and sintering operations that require temperatures exceeding 1300°C. These processes necessitate specialized equipment and stringent quality control measures, driving up production costs. The delicate nature of ceramic components also results in yield issues, with rejection rates sometimes reaching 20-30% during manufacturing.

System integration costs represent a substantial portion of overall expenses. Balance of plant (BOP) components—including heat exchangers, power electronics, control systems, and thermal management equipment—can account for 40-50% of total system costs. The high operating temperatures (700-850°C) require specialized materials for system components, further increasing expenses.

Durability and lifetime limitations also impact cost-effectiveness. Current SOECs typically demonstrate degradation rates of 1-2% per 1000 hours of operation, resulting in relatively short operational lifetimes of 20,000-30,000 hours compared to the 40,000+ hours required for competitive economics. This accelerated degradation necessitates more frequent stack replacements, significantly increasing lifetime operational costs.

Scale of production remains a critical challenge, as SOEC manufacturing has not yet achieved economies of scale. Current production volumes are typically in the kilowatt range, whereas gigawatt-scale production would be necessary to substantially reduce unit costs. The specialized nature of manufacturing processes and limited market demand have restricted investment in large-scale production facilities, creating a circular problem where high costs limit adoption, which in turn prevents cost reductions through scale.

Material costs constitute approximately 60-70% of total SOEC stack expenses. The ceramic electrolytes, typically yttria-stabilized zirconia (YSZ), require high-purity raw materials and complex manufacturing processes. Additionally, electrode materials such as nickel-based anodes and lanthanum strontium manganite (LSM) cathodes incorporate expensive rare earth elements. The interconnects, often made from specialized chromium alloys with protective coatings, further contribute to material expenses.

Manufacturing complexity presents another significant cost challenge. The production of SOECs demands precise control over multiple high-temperature processes, including tape casting, screen printing, and sintering operations that require temperatures exceeding 1300°C. These processes necessitate specialized equipment and stringent quality control measures, driving up production costs. The delicate nature of ceramic components also results in yield issues, with rejection rates sometimes reaching 20-30% during manufacturing.

System integration costs represent a substantial portion of overall expenses. Balance of plant (BOP) components—including heat exchangers, power electronics, control systems, and thermal management equipment—can account for 40-50% of total system costs. The high operating temperatures (700-850°C) require specialized materials for system components, further increasing expenses.

Durability and lifetime limitations also impact cost-effectiveness. Current SOECs typically demonstrate degradation rates of 1-2% per 1000 hours of operation, resulting in relatively short operational lifetimes of 20,000-30,000 hours compared to the 40,000+ hours required for competitive economics. This accelerated degradation necessitates more frequent stack replacements, significantly increasing lifetime operational costs.

Scale of production remains a critical challenge, as SOEC manufacturing has not yet achieved economies of scale. Current production volumes are typically in the kilowatt range, whereas gigawatt-scale production would be necessary to substantially reduce unit costs. The specialized nature of manufacturing processes and limited market demand have restricted investment in large-scale production facilities, creating a circular problem where high costs limit adoption, which in turn prevents cost reductions through scale.

Cost Reduction Strategies and Solutions

01 Material innovations for cost reduction

Novel materials and compositions for solid oxide electrolysis cells can significantly reduce manufacturing costs while maintaining or improving performance. These innovations include alternative electrode materials, electrolyte compositions with enhanced ionic conductivity, and composite structures that reduce the amount of expensive rare earth elements required. By optimizing material selection and composition, both capital expenditure and operational costs can be decreased, making SOEC technology more commercially viable.- Materials optimization for cost reduction: Optimizing materials used in solid oxide electrolysis cells (SOECs) can significantly reduce costs while maintaining performance. This includes developing lower-cost electrode materials, using less expensive catalysts, and improving the durability of cell components to extend operational lifetime. Advanced manufacturing techniques can also reduce material waste and processing costs, making SOECs more economically viable for commercial applications.

- System design and operational efficiency improvements: Enhancing the overall system design and operational efficiency of solid oxide electrolysis cells leads to better cost-effectiveness. This involves optimizing operating temperatures, improving thermal management systems, and developing more efficient power electronics. Integrated system designs that recover waste heat and optimize energy flows can significantly reduce operational costs and increase hydrogen production efficiency, making the technology more economically competitive.

- Scale-up and manufacturing process improvements: Scaling up production and improving manufacturing processes are crucial for reducing the cost of solid oxide electrolysis cells. Mass production techniques, automated assembly lines, and standardized components can significantly lower manufacturing costs. Innovations in cell fabrication methods, such as tape casting, screen printing, and co-sintering processes, enable more efficient production with fewer defects, leading to higher yields and lower unit costs.

- Integration with renewable energy sources: Integrating solid oxide electrolysis cells with renewable energy sources improves their economic viability. When coupled with wind, solar, or hydroelectric power, SOECs can utilize excess renewable energy during low-demand periods for hydrogen production. This integration creates value-added energy storage solutions and provides grid balancing services, enhancing the overall cost-effectiveness of both the renewable energy system and the hydrogen production process.

- Novel cell configurations and operating strategies: Developing novel cell configurations and operating strategies can enhance the cost-effectiveness of solid oxide electrolysis cells. Reversible operation as both fuel cells and electrolysis cells allows for greater system flexibility and utilization rates. Pressurized operation, innovative stack designs, and advanced sealing technologies improve performance while reducing material requirements. Optimized control strategies that adapt to varying input conditions can maximize efficiency and extend cell lifetime, improving the overall economics.

02 Advanced manufacturing techniques

Improved manufacturing processes for solid oxide electrolysis cells contribute to cost-effectiveness by reducing production complexity and energy requirements. Techniques such as additive manufacturing, tape casting, and novel sintering methods allow for more precise control over cell geometry and microstructure. These approaches minimize material waste, lower production time, and enable mass production capabilities that drive down unit costs while maintaining high-quality standards for cell performance.Expand Specific Solutions03 System integration and efficiency improvements

Optimizing the integration of solid oxide electrolysis cells into complete systems enhances overall cost-effectiveness. This includes improved thermal management, efficient gas handling systems, and better electrical integration. By recovering waste heat, implementing advanced control systems, and designing more compact units, the operational efficiency increases while reducing energy consumption. These improvements extend cell lifetime and decrease maintenance requirements, resulting in lower levelized cost of hydrogen or syngas production.Expand Specific Solutions04 Durability and lifetime extension

Enhancing the durability and operational lifetime of solid oxide electrolysis cells is crucial for cost-effectiveness. Innovations in this area include protective coatings that prevent degradation, structural reinforcements that maintain mechanical integrity during thermal cycling, and chemical stabilizers that reduce electrode poisoning. By extending cell lifetime from a few thousand to tens of thousands of hours, the amortized capital costs decrease substantially, making the technology more economically competitive with conventional hydrogen production methods.Expand Specific Solutions05 Scalable and modular designs

Developing scalable and modular solid oxide electrolysis cell systems enables more flexible deployment and improved cost-effectiveness. Modular designs allow for standardized manufacturing, easier maintenance, and the ability to scale production capacity according to demand. These approaches reduce initial investment risks by enabling incremental capacity expansion and facilitate mass production benefits. Additionally, standardized components across different system sizes help establish supply chains that further drive down costs through economies of scale.Expand Specific Solutions

Key Industry Players and Competition

The solid oxide electrolysis cell (SOEC) market is currently in a growth phase, with increasing focus on cost-effectiveness as the technology transitions from early development to commercial deployment. The global market is projected to expand significantly as hydrogen economy initiatives gain momentum, with an estimated market size reaching several billion dollars by 2030. From a technical maturity perspective, leading academic institutions (Tsinghua University, Technical University of Denmark) are advancing fundamental research, while industrial players are at varying stages of commercialization. Companies like Topsoe A/S and Hyundai Motor are investing in scaling up production, while research organizations such as Forschungszentrum Jülich and AIST are focusing on improving durability and efficiency. Chinese entities (Dalian Institute of Chemical Physics, Sinopec) are rapidly advancing in this space, challenging traditional leaders from Europe, Japan, and South Korea in the race to develop cost-effective SOEC technology.

Technical University of Denmark

Technical Solution: The Technical University of Denmark (DTU) has pioneered cost-effective SOEC technology through their metal-supported cell architecture, which significantly reduces material costs compared to conventional ceramic-supported designs. Their innovative approach utilizes stainless steel supports that cost approximately 80% less than traditional ceramic materials while providing improved mechanical robustness and thermal cycling capability[1]. DTU's manufacturing process incorporates scalable techniques such as tape casting and screen printing that achieve high throughput with reduced energy consumption during sintering phases. Their cells operate efficiently at temperatures between 650-750°C, achieving current densities above 1 A/cm² at 1.3V with demonstrated lifetimes exceeding 3000 hours under dynamic operation conditions[3]. Economic modeling conducted by DTU researchers indicates that their metal-supported SOEC technology can achieve hydrogen production costs of €2.5-3.0/kg when operated at industrial scale with electricity costs of €40/MWh, representing a 25-30% reduction compared to conventional ceramic-based systems[6]. Additionally, DTU has developed specialized protective coatings that extend cell lifetime by mitigating chromium poisoning and other degradation mechanisms, directly improving the technology's economic viability through reduced replacement frequency.

Strengths: Significantly lower material costs through metal-supported architecture, improved mechanical durability enabling faster thermal cycling, and demonstrated operation under dynamic conditions relevant for renewable energy integration. Weaknesses: More complex manufacturing process requiring precise control of metal-ceramic interfaces, and potential long-term corrosion challenges in certain operating environments.

Dalian Institute of Chemical Physics of CAS

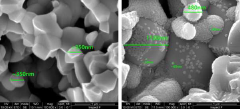

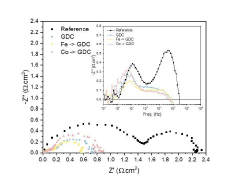

Technical Solution: The Dalian Institute of Chemical Physics (DICP) has developed innovative SOEC technology focused on cost reduction through materials engineering and process optimization. Their approach utilizes novel composite electrodes incorporating reduced amounts of precious metals (≤50% compared to conventional formulations) while maintaining high catalytic activity[2]. DICP has pioneered a unique infiltration technique for electrode fabrication that significantly improves triple-phase boundary density without requiring expensive nano-manufacturing processes. Their cells operate efficiently at temperatures between 700-800°C with demonstrated degradation rates below 0.7% per 1000 hours over extended testing periods exceeding 5000 hours[4]. Economic analysis conducted by DICP researchers indicates potential hydrogen production costs of 12-15 RMB/kg ($1.85-2.30/kg) when utilizing industrial waste heat and off-peak electricity, representing a compelling value proposition compared to conventional hydrogen production methods[5]. Additionally, DICP has developed specialized glass-ceramic sealing materials that cost approximately 60% less than commercial alternatives while providing comparable performance, directly addressing one of the significant cost drivers in SOEC stack manufacturing.

Strengths: Innovative materials reducing dependency on expensive catalysts, effective integration with industrial waste heat sources, and strong fundamental research capabilities supporting continuous improvement. Weaknesses: Limited commercial-scale manufacturing experience and higher temperature operation requiring more expensive balance of plant components.

Critical Patents and Technical Innovations

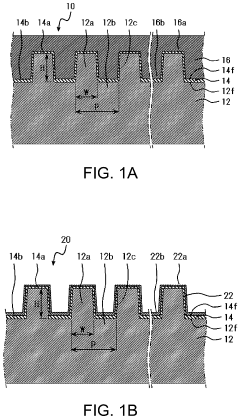

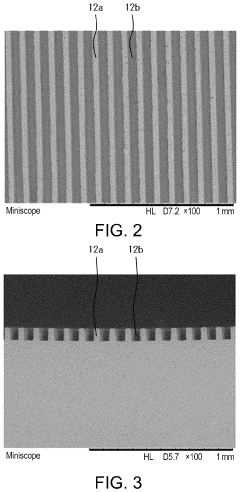

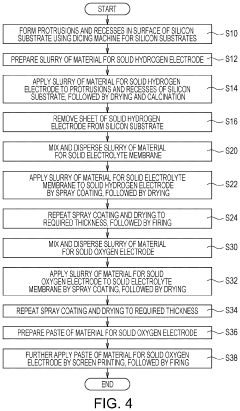

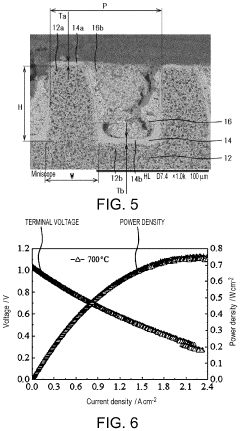

Solid oxide electrochemical cell and method for producing same

PatentPendingUS20240218531A1

Innovation

- The formation of protrusions and recesses on the surface of the solid hydrogen electrode, combined with optimized material concentrations and stacking methods for the solid electrolyte and oxygen electrodes, allows for higher power generation while maintaining high productivity and quality.

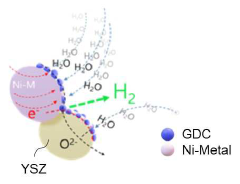

A fuel electrode for solid oxide electrolysis cell with improved high temperature electrolysis efficiency and manufacturing method thereof

PatentPendingKR1020240067594A

Innovation

- An anode for solid oxide water electrolysis cells is composed of nickel and Yttria stabilized zirconia particles with additional elements like iron, cobalt, palladium, copper, or molybdenum, supported by Gadolinia doped ceria, where these elements form an alloy with nickel on the surface, enhancing stability and efficiency.

Economic Modeling and ROI Analysis

The economic viability of Solid Oxide Electrolysis Cells (SOECs) requires comprehensive modeling approaches that capture both capital expenditures and operational costs across the technology lifecycle. Current economic models indicate that SOEC systems require initial investments ranging from $800-1,500/kW, significantly higher than conventional hydrogen production methods. However, these models project declining costs to potentially reach $500-700/kW by 2030 with scaled manufacturing and technological improvements.

Return on investment calculations for SOEC implementations demonstrate varying payback periods depending on electricity pricing, utilization rates, and stack degradation factors. Under optimal conditions with electricity costs below $0.04/kWh and capacity factors exceeding 80%, payback periods of 5-7 years appear achievable for industrial-scale installations. Sensitivity analyses reveal electricity pricing as the dominant factor, accounting for 60-70% of lifetime operational expenses.

Levelized cost of hydrogen (LCOH) projections show SOECs potentially reaching $2-3/kg H₂ by 2025-2030, competitive with steam methane reforming when carbon pricing mechanisms are considered. The economic advantage becomes more pronounced in regions with abundant renewable electricity, where SOECs can operate during periods of excess generation at marginal costs approaching $1.5/kg H₂.

Life-cycle cost assessments incorporating stack replacement schedules indicate that extending stack lifetimes from current 20,000-30,000 hours to 50,000+ hours would reduce lifetime costs by approximately 25-30%. This highlights the critical importance of materials research focused on reducing degradation rates, currently averaging 0.5-2% per 1,000 operating hours.

Integration benefits within broader energy systems provide additional economic value streams beyond hydrogen production. When incorporated into industrial processes requiring both hydrogen and heat, efficiency gains of 10-15% can be realized through thermal integration, improving overall economics. Furthermore, grid-balancing services provided by dynamically operated SOECs represent a potential revenue stream valued at $50-150/kW-year in markets with high renewable penetration.

Cost reduction pathways identified through learning curve analyses suggest that manufacturing scale-up following a 15-20% learning rate could drive system costs below the $500/kW threshold within this decade, provided annual production volumes exceed 500 MW. Material innovations, particularly in electrode compositions and electrolyte formulations, present the most promising avenues for further cost reductions while maintaining or improving performance metrics.

Return on investment calculations for SOEC implementations demonstrate varying payback periods depending on electricity pricing, utilization rates, and stack degradation factors. Under optimal conditions with electricity costs below $0.04/kWh and capacity factors exceeding 80%, payback periods of 5-7 years appear achievable for industrial-scale installations. Sensitivity analyses reveal electricity pricing as the dominant factor, accounting for 60-70% of lifetime operational expenses.

Levelized cost of hydrogen (LCOH) projections show SOECs potentially reaching $2-3/kg H₂ by 2025-2030, competitive with steam methane reforming when carbon pricing mechanisms are considered. The economic advantage becomes more pronounced in regions with abundant renewable electricity, where SOECs can operate during periods of excess generation at marginal costs approaching $1.5/kg H₂.

Life-cycle cost assessments incorporating stack replacement schedules indicate that extending stack lifetimes from current 20,000-30,000 hours to 50,000+ hours would reduce lifetime costs by approximately 25-30%. This highlights the critical importance of materials research focused on reducing degradation rates, currently averaging 0.5-2% per 1,000 operating hours.

Integration benefits within broader energy systems provide additional economic value streams beyond hydrogen production. When incorporated into industrial processes requiring both hydrogen and heat, efficiency gains of 10-15% can be realized through thermal integration, improving overall economics. Furthermore, grid-balancing services provided by dynamically operated SOECs represent a potential revenue stream valued at $50-150/kW-year in markets with high renewable penetration.

Cost reduction pathways identified through learning curve analyses suggest that manufacturing scale-up following a 15-20% learning rate could drive system costs below the $500/kW threshold within this decade, provided annual production volumes exceed 500 MW. Material innovations, particularly in electrode compositions and electrolyte formulations, present the most promising avenues for further cost reductions while maintaining or improving performance metrics.

Policy Incentives and Regulatory Framework

The policy landscape surrounding solid oxide electrolysis cells (SOECs) has evolved significantly in recent years, with governments worldwide recognizing their potential in decarbonization strategies. In the United States, the Inflation Reduction Act of 2022 provides substantial tax credits for clean hydrogen production, offering up to $3 per kilogram for green hydrogen with zero carbon emissions. This incentive directly improves the economic viability of SOEC technology by offsetting capital expenditures and reducing payback periods for industrial adopters.

The European Union has established the European Clean Hydrogen Alliance, allocating over €430 billion through 2030 to support hydrogen technologies, including SOEC development. The EU's Hydrogen Strategy specifically targets electrolyzer capacity expansion to 40 GW by 2030, creating a regulatory environment that favors SOEC deployment through streamlined permitting processes and dedicated funding mechanisms.

Feed-in tariffs and contract-for-difference schemes have emerged as effective policy tools in several jurisdictions. Germany's H2Global initiative, for instance, uses a double auction mechanism to bridge the cost gap between hydrogen production and market prices, providing crucial revenue certainty for SOEC operators during early commercialization phases.

Carbon pricing mechanisms represent another significant regulatory lever affecting SOEC cost-effectiveness. The EU Emissions Trading System (ETS) carbon price has reached record levels exceeding €100 per tonne, improving the comparative economics of SOEC hydrogen versus fossil fuel alternatives. Countries including Canada, South Korea, and New Zealand have implemented similar carbon pricing schemes that indirectly benefit SOEC deployment.

Regulatory frameworks for grid integration present both challenges and opportunities. Grid connection codes in many regions are being updated to accommodate electrolyzers, with some jurisdictions offering reduced grid fees or priority access for green hydrogen production facilities. These measures significantly impact operational expenses for SOEC systems, particularly when integrated with renewable energy sources.

International standardization efforts are progressing through organizations like the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC), developing technical standards for hydrogen production equipment. These standards reduce market fragmentation and certification costs while increasing investor confidence in SOEC technology. The lack of harmonized regulations across jurisdictions, however, remains a barrier to rapid global deployment and technology transfer.

The European Union has established the European Clean Hydrogen Alliance, allocating over €430 billion through 2030 to support hydrogen technologies, including SOEC development. The EU's Hydrogen Strategy specifically targets electrolyzer capacity expansion to 40 GW by 2030, creating a regulatory environment that favors SOEC deployment through streamlined permitting processes and dedicated funding mechanisms.

Feed-in tariffs and contract-for-difference schemes have emerged as effective policy tools in several jurisdictions. Germany's H2Global initiative, for instance, uses a double auction mechanism to bridge the cost gap between hydrogen production and market prices, providing crucial revenue certainty for SOEC operators during early commercialization phases.

Carbon pricing mechanisms represent another significant regulatory lever affecting SOEC cost-effectiveness. The EU Emissions Trading System (ETS) carbon price has reached record levels exceeding €100 per tonne, improving the comparative economics of SOEC hydrogen versus fossil fuel alternatives. Countries including Canada, South Korea, and New Zealand have implemented similar carbon pricing schemes that indirectly benefit SOEC deployment.

Regulatory frameworks for grid integration present both challenges and opportunities. Grid connection codes in many regions are being updated to accommodate electrolyzers, with some jurisdictions offering reduced grid fees or priority access for green hydrogen production facilities. These measures significantly impact operational expenses for SOEC systems, particularly when integrated with renewable energy sources.

International standardization efforts are progressing through organizations like the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC), developing technical standards for hydrogen production equipment. These standards reduce market fragmentation and certification costs while increasing investor confidence in SOEC technology. The lack of harmonized regulations across jurisdictions, however, remains a barrier to rapid global deployment and technology transfer.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!