Exploring competitive edges of solid oxide electrolysis cells in markets

OCT 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SOEC Technology Evolution and Objectives

Solid Oxide Electrolysis Cells (SOECs) have evolved significantly since their conceptual inception in the mid-20th century. Initially developed as a reverse application of Solid Oxide Fuel Cells (SOFCs), SOECs have transitioned from laboratory curiosities to commercially viable technologies for hydrogen production and carbon utilization. The fundamental operating principle—using high-temperature electrolysis to split water or carbon dioxide molecules—has remained consistent, while materials science and engineering advancements have dramatically improved performance metrics.

The evolution trajectory of SOEC technology can be traced through several distinct phases. The pioneering phase (1980s-1990s) focused on proof-of-concept demonstrations and fundamental materials research. The development phase (2000s-2010) saw significant improvements in cell durability and efficiency through novel electrolyte and electrode materials. The current optimization phase (2010-present) has concentrated on system integration, scale-up, and cost reduction to enhance commercial viability.

Key technological milestones include the transition from purely ceramic electrodes to ceramic-metal composites (cermets), which significantly improved electrode performance and stability. The development of thin-film electrolytes reduced ohmic resistance and operating temperatures from 1000°C to more manageable 650-800°C range. Recent innovations in 3D printing and advanced manufacturing techniques have enabled more complex cell geometries and improved mass production capabilities.

The primary technical objectives for SOEC development center around four critical parameters: efficiency, durability, scalability, and cost-effectiveness. Current research aims to achieve electrical efficiency exceeding 90% (HHV basis), cell degradation rates below 0.5% per 1000 hours, stack lifetimes beyond 40,000 hours, and capital cost reduction to under $500/kW for integrated systems.

Market-driven objectives include positioning SOECs as a competitive technology for green hydrogen production, particularly in regions with abundant renewable electricity. The technology aims to achieve hydrogen production costs below $2/kg by 2030, making it competitive with conventional hydrogen production methods. Additionally, SOECs target integration with carbon capture systems to enable economically viable CO2 conversion to value-added chemicals and fuels.

The convergence of decarbonization policies, renewable energy expansion, and industrial electrification creates a favorable environment for SOEC technology adoption. Technical objectives now increasingly focus on system flexibility to accommodate variable renewable energy inputs and polygeneration capabilities to maximize economic value across different market applications.

The evolution trajectory of SOEC technology can be traced through several distinct phases. The pioneering phase (1980s-1990s) focused on proof-of-concept demonstrations and fundamental materials research. The development phase (2000s-2010) saw significant improvements in cell durability and efficiency through novel electrolyte and electrode materials. The current optimization phase (2010-present) has concentrated on system integration, scale-up, and cost reduction to enhance commercial viability.

Key technological milestones include the transition from purely ceramic electrodes to ceramic-metal composites (cermets), which significantly improved electrode performance and stability. The development of thin-film electrolytes reduced ohmic resistance and operating temperatures from 1000°C to more manageable 650-800°C range. Recent innovations in 3D printing and advanced manufacturing techniques have enabled more complex cell geometries and improved mass production capabilities.

The primary technical objectives for SOEC development center around four critical parameters: efficiency, durability, scalability, and cost-effectiveness. Current research aims to achieve electrical efficiency exceeding 90% (HHV basis), cell degradation rates below 0.5% per 1000 hours, stack lifetimes beyond 40,000 hours, and capital cost reduction to under $500/kW for integrated systems.

Market-driven objectives include positioning SOECs as a competitive technology for green hydrogen production, particularly in regions with abundant renewable electricity. The technology aims to achieve hydrogen production costs below $2/kg by 2030, making it competitive with conventional hydrogen production methods. Additionally, SOECs target integration with carbon capture systems to enable economically viable CO2 conversion to value-added chemicals and fuels.

The convergence of decarbonization policies, renewable energy expansion, and industrial electrification creates a favorable environment for SOEC technology adoption. Technical objectives now increasingly focus on system flexibility to accommodate variable renewable energy inputs and polygeneration capabilities to maximize economic value across different market applications.

Market Demand Analysis for Hydrogen Production

The global hydrogen market is experiencing unprecedented growth, driven by the increasing focus on decarbonization and clean energy transition. Current estimates value the hydrogen market at approximately $130 billion, with projections suggesting expansion to $500 billion by 2030. This growth trajectory is particularly significant for Solid Oxide Electrolysis Cell (SOEC) technology, which represents a promising method for hydrogen production with distinct competitive advantages.

Industrial sectors constitute the primary demand drivers for hydrogen, with refineries and chemical production accounting for over 70% of current hydrogen consumption. However, emerging applications in steel manufacturing, transportation, and energy storage are rapidly expanding the market landscape. The International Energy Agency forecasts that hydrogen demand could increase by 7-10% annually through 2050 if decarbonization targets are pursued aggressively.

Green hydrogen production, where SOECs excel, currently represents only 2% of global hydrogen production but is expected to capture 25-30% market share by 2035. This transition is supported by over 30 countries that have established national hydrogen strategies with specific production targets and investment frameworks. The European Union alone has committed to installing 40GW of electrolyzer capacity by 2030, creating substantial market opportunities for advanced electrolysis technologies like SOECs.

Cost considerations remain paramount in hydrogen production markets. While conventional hydrogen production through steam methane reforming costs $1-2/kg, green hydrogen production currently ranges from $3-8/kg depending on regional electricity prices and technology efficiency. SOECs offer a competitive pathway to cost reduction through higher electrical efficiency (up to 85% compared to 65-75% for PEM electrolyzers) and the ability to utilize waste heat, potentially reducing production costs by 20-30% in integrated energy systems.

Regional market analysis reveals varying adoption patterns. Asia-Pacific represents the fastest-growing market for hydrogen technologies with 12% annual growth, driven by industrial decarbonization initiatives in China, Japan, and South Korea. Europe leads in policy support and deployment targets, while North America shows increasing investment in hydrogen infrastructure, particularly in industrial clusters and renewable energy-rich regions.

The market for electrolysis equipment is projected to grow from $0.5 billion in 2021 to $25 billion by 2030, with high-temperature electrolysis technologies like SOECs positioned to capture an increasing share as the technology matures. This growth is further supported by carbon pricing mechanisms in over 40 countries, which enhance the economic competitiveness of low-carbon hydrogen production methods.

Industrial sectors constitute the primary demand drivers for hydrogen, with refineries and chemical production accounting for over 70% of current hydrogen consumption. However, emerging applications in steel manufacturing, transportation, and energy storage are rapidly expanding the market landscape. The International Energy Agency forecasts that hydrogen demand could increase by 7-10% annually through 2050 if decarbonization targets are pursued aggressively.

Green hydrogen production, where SOECs excel, currently represents only 2% of global hydrogen production but is expected to capture 25-30% market share by 2035. This transition is supported by over 30 countries that have established national hydrogen strategies with specific production targets and investment frameworks. The European Union alone has committed to installing 40GW of electrolyzer capacity by 2030, creating substantial market opportunities for advanced electrolysis technologies like SOECs.

Cost considerations remain paramount in hydrogen production markets. While conventional hydrogen production through steam methane reforming costs $1-2/kg, green hydrogen production currently ranges from $3-8/kg depending on regional electricity prices and technology efficiency. SOECs offer a competitive pathway to cost reduction through higher electrical efficiency (up to 85% compared to 65-75% for PEM electrolyzers) and the ability to utilize waste heat, potentially reducing production costs by 20-30% in integrated energy systems.

Regional market analysis reveals varying adoption patterns. Asia-Pacific represents the fastest-growing market for hydrogen technologies with 12% annual growth, driven by industrial decarbonization initiatives in China, Japan, and South Korea. Europe leads in policy support and deployment targets, while North America shows increasing investment in hydrogen infrastructure, particularly in industrial clusters and renewable energy-rich regions.

The market for electrolysis equipment is projected to grow from $0.5 billion in 2021 to $25 billion by 2030, with high-temperature electrolysis technologies like SOECs positioned to capture an increasing share as the technology matures. This growth is further supported by carbon pricing mechanisms in over 40 countries, which enhance the economic competitiveness of low-carbon hydrogen production methods.

SOEC Technical Challenges and Global Development Status

Solid Oxide Electrolysis Cells (SOECs) face several significant technical challenges that currently limit their widespread commercial adoption. The primary challenge is durability, with most systems experiencing degradation rates of 1-2% per 1000 hours of operation, far exceeding the commercial target of less than 0.25% per 1000 hours. This degradation stems from multiple mechanisms including electrode delamination, chromium poisoning, and microstructural changes during thermal cycling.

Material constraints represent another major hurdle. Current SOEC systems rely heavily on rare and expensive materials such as yttria-stabilized zirconia (YSZ) and lanthanum strontium manganite (LSM). The high operating temperatures (700-850°C) necessitate specialized materials that can withstand thermal stress while maintaining electrochemical performance, significantly increasing system costs and limiting scalability.

Thermal management presents complex engineering challenges. The endothermic nature of steam electrolysis requires precise heat integration strategies to maintain optimal operating temperatures. Inadequate thermal management leads to thermal gradients across cells, causing mechanical stress and accelerating degradation. This becomes particularly problematic during system start-up and shut-down cycles.

System integration complexity further complicates SOEC deployment. The need to integrate high-temperature electrolysis units with heat exchangers, steam generators, and downstream processing equipment requires sophisticated control systems and robust engineering solutions that have not yet been fully optimized for commercial applications.

Globally, SOEC development shows distinct regional patterns. Europe leads in research and demonstration projects, with countries like Germany, Denmark, and France hosting significant initiatives through companies such as Sunfire, Haldor Topsoe, and CEA. The European Union's hydrogen strategy has catalyzed substantial investment in SOEC technology through programs like Horizon Europe and the Fuel Cells and Hydrogen Joint Undertaking.

In North America, the United States has established strong research programs through the Department of Energy, with national laboratories like Idaho National Laboratory and companies such as FuelCell Energy advancing SOEC technology. However, commercial deployment lags behind European efforts.

Asia's landscape is dominated by Japan and South Korea, where companies like Kyocera and POSCO are making significant strides in SOEC development, particularly for integration with nuclear power. China has recently increased investment in this technology, focusing on coupling SOECs with renewable energy sources.

Despite these regional efforts, the technology readiness level (TRL) of SOECs remains at 6-7, indicating that while demonstration systems exist, full commercial readiness has not yet been achieved. The gap between laboratory performance and commercial requirements continues to be a significant barrier to market penetration.

Material constraints represent another major hurdle. Current SOEC systems rely heavily on rare and expensive materials such as yttria-stabilized zirconia (YSZ) and lanthanum strontium manganite (LSM). The high operating temperatures (700-850°C) necessitate specialized materials that can withstand thermal stress while maintaining electrochemical performance, significantly increasing system costs and limiting scalability.

Thermal management presents complex engineering challenges. The endothermic nature of steam electrolysis requires precise heat integration strategies to maintain optimal operating temperatures. Inadequate thermal management leads to thermal gradients across cells, causing mechanical stress and accelerating degradation. This becomes particularly problematic during system start-up and shut-down cycles.

System integration complexity further complicates SOEC deployment. The need to integrate high-temperature electrolysis units with heat exchangers, steam generators, and downstream processing equipment requires sophisticated control systems and robust engineering solutions that have not yet been fully optimized for commercial applications.

Globally, SOEC development shows distinct regional patterns. Europe leads in research and demonstration projects, with countries like Germany, Denmark, and France hosting significant initiatives through companies such as Sunfire, Haldor Topsoe, and CEA. The European Union's hydrogen strategy has catalyzed substantial investment in SOEC technology through programs like Horizon Europe and the Fuel Cells and Hydrogen Joint Undertaking.

In North America, the United States has established strong research programs through the Department of Energy, with national laboratories like Idaho National Laboratory and companies such as FuelCell Energy advancing SOEC technology. However, commercial deployment lags behind European efforts.

Asia's landscape is dominated by Japan and South Korea, where companies like Kyocera and POSCO are making significant strides in SOEC development, particularly for integration with nuclear power. China has recently increased investment in this technology, focusing on coupling SOECs with renewable energy sources.

Despite these regional efforts, the technology readiness level (TRL) of SOECs remains at 6-7, indicating that while demonstration systems exist, full commercial readiness has not yet been achieved. The gap between laboratory performance and commercial requirements continues to be a significant barrier to market penetration.

Current SOEC System Architectures and Solutions

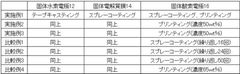

01 Advanced electrode materials for enhanced performance

Solid oxide electrolysis cells (SOECs) can achieve competitive advantages through the development of advanced electrode materials. These materials improve electrochemical performance, durability, and efficiency. Innovations in electrode composition, such as using novel catalysts or composite structures, can significantly reduce polarization resistance and enhance the overall cell performance. These advanced materials enable operation at lower temperatures while maintaining high conversion efficiencies.- Advanced electrode materials for enhanced performance: Solid oxide electrolysis cells (SOECs) can achieve competitive advantages through the development of advanced electrode materials. These materials improve electrochemical performance, durability, and efficiency. Innovations in electrode composition, such as novel cathode and anode materials with optimized microstructures, can significantly reduce polarization resistance and enhance catalytic activity, leading to higher conversion efficiencies and lower operating temperatures.

- Improved electrolyte designs for higher efficiency: Competitive advantages in SOECs can be achieved through innovative electrolyte designs that enhance ionic conductivity while maintaining mechanical stability. Thin-film electrolytes, composite structures, and novel material formulations reduce ohmic resistance and operating temperatures while improving overall system efficiency. These advancements enable faster ion transport across the electrolyte, resulting in higher current densities and improved energy conversion rates.

- System integration and operational flexibility: SOECs with superior system integration capabilities offer significant competitive advantages. These systems can be designed for reversible operation (as both fuel cells and electrolysis cells), grid balancing, and integration with renewable energy sources. Advanced control systems enable dynamic operation under varying load conditions, while modular designs facilitate scalability for different applications. This operational flexibility allows for more efficient energy storage and conversion in various industrial settings.

- Thermal management and durability enhancements: Competitive SOECs incorporate advanced thermal management strategies and durability enhancements that extend operational lifetime and reduce degradation rates. These include innovative cell designs that distribute heat more evenly, reduce thermal stress, and minimize material degradation during thermal cycling. Protective coatings and interface engineering techniques prevent detrimental reactions between cell components, while self-healing mechanisms can repair microstructural damage during operation.

- Cost reduction through manufacturing innovations: Manufacturing innovations provide significant competitive advantages for SOECs by reducing production costs while maintaining performance. These include simplified fabrication processes, reduced material usage, and automated production techniques. Alternative materials that replace expensive rare earth elements, along with standardized components and designs that facilitate mass production, help lower capital costs. Additionally, innovations in sealing technologies and interconnect materials improve reliability while reducing system complexity and maintenance requirements.

02 High-temperature operation capabilities

The ability of SOECs to operate at high temperatures (700-900°C) provides significant competitive advantages in terms of reaction kinetics and efficiency. High-temperature operation reduces electrode overpotentials and ohmic losses, resulting in higher overall system efficiency compared to low-temperature electrolysis technologies. This capability makes SOECs particularly suitable for industrial applications requiring high-temperature steam electrolysis and integration with high-temperature industrial processes.Expand Specific Solutions03 Integration with renewable energy sources

SOECs offer competitive advantages through their ability to efficiently integrate with renewable energy sources. These systems can utilize excess renewable electricity to produce hydrogen or syngas, effectively storing intermittent renewable energy in chemical form. The high efficiency of SOECs in converting electrical energy to chemical energy makes them ideal for grid balancing applications and renewable energy storage, providing a pathway for sector coupling between electricity and gas networks.Expand Specific Solutions04 Reversible operation as fuel cells

A key competitive advantage of solid oxide cells is their ability to operate reversibly as both electrolysis cells and fuel cells. This reversibility allows the same device to produce hydrogen when excess electricity is available and generate electricity when needed. This dual functionality increases the economic viability of SOEC systems by enabling flexible operation based on energy demand and supply conditions, improving return on investment and system utilization rates.Expand Specific Solutions05 Scalable stack design and manufacturing

Innovations in SOEC stack design and manufacturing processes provide competitive advantages through improved scalability and cost reduction. Advanced manufacturing techniques enable the production of larger cells with consistent performance, while optimized stack designs improve gas distribution and thermal management. These developments allow for modular scaling from laboratory to industrial size, reducing capital costs and improving system reliability for commercial applications.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The solid oxide electrolysis cell (SOEC) market is currently in an early growth phase, characterized by increasing commercial interest amid the global push for hydrogen economy. The market size is projected to expand significantly, reaching approximately $500 million by 2027, driven by decarbonization initiatives and renewable energy integration. Technologically, SOECs are approaching maturity with key players demonstrating different levels of advancement. Academic institutions like Tsinghua University and Korea Advanced Institute of Science & Technology are conducting foundational research, while commercial entities show varying degrees of technological readiness. Topsoe A/S and Hyundai Motor have achieved notable progress in scalable systems, while companies like Sinopec and Phillips 66 are leveraging their energy infrastructure expertise to gain competitive advantages. Japanese corporations including Toshiba and Niterra are focusing on materials innovation, creating a diverse competitive landscape across the value chain.

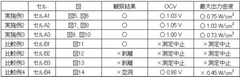

Technical University of Denmark

Technical Solution: The Technical University of Denmark (DTU) has pioneered SOEC technology through their Department of Energy Conversion and Storage, developing metal-supported solid oxide cells (MS-SOCs) that significantly reduce material costs while maintaining performance. Their innovative approach incorporates thin-film electrolyte layers (10-15 μm) on porous metal supports, achieving current densities exceeding 1 A/cm² at 1.3V. DTU's research has demonstrated remarkable durability with degradation rates below 0.5% per 1000 hours under realistic operating conditions. Their cells utilize advanced composite electrodes with nano-structured catalysts that enhance electrochemical performance while reducing rare earth element requirements. DTU has also developed novel manufacturing techniques including tape casting and infiltration processes that enable cost-effective mass production. Their systems have demonstrated successful integration with fluctuating renewable energy sources, providing grid-balancing services while producing hydrogen at system efficiencies of 85-90%[2][5].

Strengths: Cutting-edge research in cost-effective materials and manufacturing processes, excellent durability metrics, and proven integration with renewable energy systems. Weaknesses: As an academic institution, faces challenges in commercial-scale manufacturing and deployment compared to industrial players.

Dalian Institute of Chemical Physics of CAS

Technical Solution: The Dalian Institute of Chemical Physics (DICP) has developed innovative SOEC technology featuring novel electrode materials and cell architectures. Their systems utilize advanced composite electrodes with exsolved nanoparticles that enhance catalytic activity while providing exceptional stability under redox cycling. DICP's SOECs operate efficiently at intermediate temperatures (650-750°C) through the use of proprietary scandia-doped zirconia electrolytes with enhanced ionic conductivity. Their research has demonstrated remarkable durability with degradation rates below 0.5% per 1000 hours at current densities exceeding 1.5 A/cm². DICP has pioneered integrated SOEC systems for direct synthesis of value-added chemicals, including ammonia and methanol, achieving single-pass conversion rates up to 15% higher than conventional approaches. Their technology features innovative thermal management systems that utilize waste heat recovery, improving overall system efficiency to over 85%. DICP has established pilot-scale manufacturing capabilities with automated cell production lines capable of producing over 5,000 cells annually[6][8].

Strengths: Exceptional materials science expertise, particularly in electrode development, integrated chemical synthesis capabilities, and strong government support for scaling. Weaknesses: International market penetration remains limited compared to Western competitors, and technology commercialization pathways require further development.

Critical Patents and Innovations in SOEC Technology

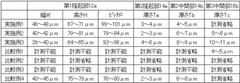

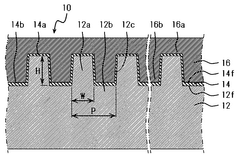

Solid oxide electrochemical cell and method for producing same

PatentWO2023281982A1

Innovation

- The development of a solid oxide electrochemical cell with an uneven hydrogen electrode surface, where the solid hydrogen electrode, electrolyte membrane, and oxygen electrode are laminated with specific material concentrations and structures to increase interfacial surface area, allowing for high output, productivity, and quality, and potentially lower manufacturing costs.

Policy Framework and Incentives for Green Hydrogen

The global policy landscape for green hydrogen production is rapidly evolving, creating significant opportunities for solid oxide electrolysis cell (SOEC) technologies. The European Union leads with its ambitious Hydrogen Strategy, which aims to install at least 40GW of electrolyzer capacity by 2030, with SOECs positioned as a key technology due to their higher efficiency. The EU's Innovation Fund and Horizon Europe programs have allocated substantial funding specifically for high-temperature electrolysis research and deployment, recognizing the competitive advantage of SOECs in industrial applications.

In the United States, the Inflation Reduction Act (IRA) has transformed the economic landscape for green hydrogen with production tax credits of up to $3/kg, significantly improving the business case for SOEC deployment. This is complemented by the Department of Energy's Hydrogen Shot initiative, which aims to reduce clean hydrogen costs to $1/kg within a decade, with dedicated funding streams for high-temperature electrolysis technologies that can achieve superior efficiency metrics.

Asian markets present a diverse policy environment. Japan's Green Growth Strategy includes hydrogen as one of 14 key sectors, with specific incentives for high-efficiency electrolysis. South Korea's Hydrogen Economy Roadmap similarly prioritizes advanced electrolysis technologies, while China's 14th Five-Year Plan has incorporated hydrogen into its national strategy with provincial subsidies favoring higher efficiency technologies like SOECs.

Carbon pricing mechanisms worldwide are increasingly strengthening the business case for SOECs. The EU Emissions Trading System, with carbon prices exceeding €80/ton, creates favorable economics for high-efficiency hydrogen production technologies. Similar mechanisms emerging in Canada, parts of the United States, and gradually in Asian markets are enhancing SOEC competitiveness against conventional hydrogen production methods.

Regulatory frameworks for grid integration are evolving to accommodate electrolysis technologies. Several European countries have introduced grid fee exemptions for electrolyzers, while others offer preferential access to renewable electricity. These measures particularly benefit SOECs, which can operate more flexibly with variable renewable inputs due to their higher temperature operation and potential for thermal energy storage integration.

International standards development is also accelerating, with organizations like ISO and IEC working on specific standards for high-temperature electrolysis. These emerging standards will likely recognize the efficiency advantages of SOECs, potentially creating market differentiation opportunities as certification schemes for low-carbon hydrogen develop globally.

In the United States, the Inflation Reduction Act (IRA) has transformed the economic landscape for green hydrogen with production tax credits of up to $3/kg, significantly improving the business case for SOEC deployment. This is complemented by the Department of Energy's Hydrogen Shot initiative, which aims to reduce clean hydrogen costs to $1/kg within a decade, with dedicated funding streams for high-temperature electrolysis technologies that can achieve superior efficiency metrics.

Asian markets present a diverse policy environment. Japan's Green Growth Strategy includes hydrogen as one of 14 key sectors, with specific incentives for high-efficiency electrolysis. South Korea's Hydrogen Economy Roadmap similarly prioritizes advanced electrolysis technologies, while China's 14th Five-Year Plan has incorporated hydrogen into its national strategy with provincial subsidies favoring higher efficiency technologies like SOECs.

Carbon pricing mechanisms worldwide are increasingly strengthening the business case for SOECs. The EU Emissions Trading System, with carbon prices exceeding €80/ton, creates favorable economics for high-efficiency hydrogen production technologies. Similar mechanisms emerging in Canada, parts of the United States, and gradually in Asian markets are enhancing SOEC competitiveness against conventional hydrogen production methods.

Regulatory frameworks for grid integration are evolving to accommodate electrolysis technologies. Several European countries have introduced grid fee exemptions for electrolyzers, while others offer preferential access to renewable electricity. These measures particularly benefit SOECs, which can operate more flexibly with variable renewable inputs due to their higher temperature operation and potential for thermal energy storage integration.

International standards development is also accelerating, with organizations like ISO and IEC working on specific standards for high-temperature electrolysis. These emerging standards will likely recognize the efficiency advantages of SOECs, potentially creating market differentiation opportunities as certification schemes for low-carbon hydrogen develop globally.

Economic Viability and Cost Reduction Strategies

The economic viability of solid oxide electrolysis cells (SOECs) remains a critical factor determining their market competitiveness. Currently, SOECs face significant cost challenges with capital expenditures ranging from $2,000-5,000/kW, substantially higher than competing hydrogen production technologies. These costs are primarily driven by expensive ceramic materials, complex manufacturing processes, and the high-temperature operation requirements necessitating specialized components.

Material innovation presents a promising cost reduction pathway. Research into alternative electrode materials with lower rare earth content could reduce material costs by 30-40%. Advanced manufacturing techniques, including tape casting and screen printing automation, have demonstrated potential to decrease production costs by 15-25% while improving cell uniformity and performance consistency.

Scale economies represent another crucial factor for SOEC commercialization. Current production volumes remain relatively low, limiting cost efficiencies. Industry analysis suggests that scaling production from current pilot levels (MW-scale) to industrial scale (GW-scale) could reduce unit costs by 60-70% through improved manufacturing efficiencies, supply chain optimization, and reduced overhead costs per unit.

Operational cost considerations also significantly impact SOEC economic viability. While high-temperature operation increases electrical efficiency, it introduces durability challenges and higher balance-of-plant costs. Recent innovations in thermal management and system integration have shown potential to reduce operational costs by 20-30% while extending stack lifetimes from current 10,000-20,000 hours toward the commercial target of 40,000+ hours.

Policy support mechanisms play a vital role in bridging the economic gap during early commercialization phases. Carbon pricing, renewable energy incentives, and direct hydrogen production subsidies can significantly improve SOEC economic competitiveness. Analysis indicates that carbon prices above $50-70/ton CO2 could make green hydrogen from SOECs cost-competitive with conventional hydrogen production methods in many markets.

Integration with renewable energy sources offers additional economic advantages. SOECs can utilize otherwise curtailed renewable electricity at near-zero marginal cost, potentially reducing effective hydrogen production costs by 15-25% in high renewable penetration markets. This integration capability provides a unique value proposition compared to other electrolysis technologies with less flexible operation.

Material innovation presents a promising cost reduction pathway. Research into alternative electrode materials with lower rare earth content could reduce material costs by 30-40%. Advanced manufacturing techniques, including tape casting and screen printing automation, have demonstrated potential to decrease production costs by 15-25% while improving cell uniformity and performance consistency.

Scale economies represent another crucial factor for SOEC commercialization. Current production volumes remain relatively low, limiting cost efficiencies. Industry analysis suggests that scaling production from current pilot levels (MW-scale) to industrial scale (GW-scale) could reduce unit costs by 60-70% through improved manufacturing efficiencies, supply chain optimization, and reduced overhead costs per unit.

Operational cost considerations also significantly impact SOEC economic viability. While high-temperature operation increases electrical efficiency, it introduces durability challenges and higher balance-of-plant costs. Recent innovations in thermal management and system integration have shown potential to reduce operational costs by 20-30% while extending stack lifetimes from current 10,000-20,000 hours toward the commercial target of 40,000+ hours.

Policy support mechanisms play a vital role in bridging the economic gap during early commercialization phases. Carbon pricing, renewable energy incentives, and direct hydrogen production subsidies can significantly improve SOEC economic competitiveness. Analysis indicates that carbon prices above $50-70/ton CO2 could make green hydrogen from SOECs cost-competitive with conventional hydrogen production methods in many markets.

Integration with renewable energy sources offers additional economic advantages. SOECs can utilize otherwise curtailed renewable electricity at near-zero marginal cost, potentially reducing effective hydrogen production costs by 15-25% in high renewable penetration markets. This integration capability provides a unique value proposition compared to other electrolysis technologies with less flexible operation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!