Comparison of thermal management in solid oxide electrolysis cells

OCT 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SOEC Thermal Management Background and Objectives

Solid Oxide Electrolysis Cells (SOECs) have emerged as a promising technology for clean hydrogen production through water electrolysis, offering significant advantages in energy efficiency and integration potential with renewable energy sources. The thermal management of SOECs represents a critical aspect of their operation, directly impacting performance, durability, and overall system efficiency.

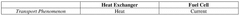

The evolution of SOEC thermal management strategies can be traced back to the early 2000s when research primarily focused on understanding basic heat transfer mechanisms within high-temperature electrolysis systems. Initial designs relied heavily on concepts borrowed from Solid Oxide Fuel Cell (SOFC) technology, with limited consideration for the unique thermal challenges posed by the endothermic nature of electrolysis operations.

By the mid-2010s, researchers began recognizing the distinct thermal management requirements of SOECs, particularly the need to balance heat generation from ohmic resistance with heat consumption from electrochemical reactions. This realization prompted more sophisticated approaches to thermal control, including advanced heat exchanger designs and strategic thermal integration with external heat sources.

Current technological trends indicate a shift toward more precise and dynamic thermal management systems that can adapt to varying operational conditions and load profiles. The integration of advanced materials with enhanced thermal conductivity and stability at high temperatures has become a focal point of recent developments, enabling more efficient heat distribution and reduced thermal gradients across cell components.

The primary objective of SOEC thermal management research is to develop systems capable of maintaining optimal temperature distributions throughout the cell stack while minimizing energy losses and thermal stress. This includes achieving thermal self-sustainability under various operating conditions, extending cell lifetime through reduced thermal degradation, and enhancing overall system efficiency through effective heat recovery and utilization.

Additional goals include the development of scalable thermal management solutions that remain effective across different system sizes, from laboratory-scale demonstrations to industrial-scale implementations. Researchers also aim to establish standardized methodologies for thermal characterization and performance evaluation, facilitating meaningful comparisons between different thermal management approaches.

The ultimate technological objective is to enable SOECs that can operate efficiently across a wide temperature range with minimal external thermal input, thereby improving system flexibility and economic viability. This would significantly enhance the potential for SOECs to serve as a cornerstone technology in future hydrogen economies and renewable energy systems, particularly in scenarios involving variable renewable energy sources and grid balancing applications.

The evolution of SOEC thermal management strategies can be traced back to the early 2000s when research primarily focused on understanding basic heat transfer mechanisms within high-temperature electrolysis systems. Initial designs relied heavily on concepts borrowed from Solid Oxide Fuel Cell (SOFC) technology, with limited consideration for the unique thermal challenges posed by the endothermic nature of electrolysis operations.

By the mid-2010s, researchers began recognizing the distinct thermal management requirements of SOECs, particularly the need to balance heat generation from ohmic resistance with heat consumption from electrochemical reactions. This realization prompted more sophisticated approaches to thermal control, including advanced heat exchanger designs and strategic thermal integration with external heat sources.

Current technological trends indicate a shift toward more precise and dynamic thermal management systems that can adapt to varying operational conditions and load profiles. The integration of advanced materials with enhanced thermal conductivity and stability at high temperatures has become a focal point of recent developments, enabling more efficient heat distribution and reduced thermal gradients across cell components.

The primary objective of SOEC thermal management research is to develop systems capable of maintaining optimal temperature distributions throughout the cell stack while minimizing energy losses and thermal stress. This includes achieving thermal self-sustainability under various operating conditions, extending cell lifetime through reduced thermal degradation, and enhancing overall system efficiency through effective heat recovery and utilization.

Additional goals include the development of scalable thermal management solutions that remain effective across different system sizes, from laboratory-scale demonstrations to industrial-scale implementations. Researchers also aim to establish standardized methodologies for thermal characterization and performance evaluation, facilitating meaningful comparisons between different thermal management approaches.

The ultimate technological objective is to enable SOECs that can operate efficiently across a wide temperature range with minimal external thermal input, thereby improving system flexibility and economic viability. This would significantly enhance the potential for SOECs to serve as a cornerstone technology in future hydrogen economies and renewable energy systems, particularly in scenarios involving variable renewable energy sources and grid balancing applications.

Market Analysis for SOEC Technology Applications

The global market for Solid Oxide Electrolysis Cell (SOEC) technology is experiencing significant growth, driven by increasing demand for clean hydrogen production and energy storage solutions. The SOEC market is projected to reach $500 million by 2026, with a compound annual growth rate of 15.7% from 2021 to 2026. This growth is primarily fueled by the global push towards decarbonization and the transition to renewable energy sources.

Thermal management solutions for SOECs represent a critical segment within this market, as efficient heat management directly impacts system performance, durability, and cost-effectiveness. The market for specialized thermal management components and systems for SOECs is estimated to account for approximately 20% of the overall SOEC market value.

Regionally, Europe leads the SOEC market with substantial investments in hydrogen infrastructure and research initiatives. Countries like Germany, Denmark, and France have established ambitious hydrogen strategies that specifically mention SOEC technology. The European market benefits from supportive policy frameworks and substantial public funding for clean energy technologies.

North America follows closely, with significant research activities and commercial deployments primarily in the United States and Canada. The Asia-Pacific region, particularly China, Japan, and South Korea, is showing the fastest growth rate in SOEC adoption, driven by national hydrogen strategies and industrial decarbonization efforts.

By application sector, industrial hydrogen production represents the largest market segment for SOEC technology at 45% of total deployments. Power-to-gas applications for grid balancing and energy storage account for approximately 30%, while synthetic fuel production comprises about 15% of the market. The remaining 10% includes niche applications such as oxygen production and distributed energy systems.

End-user industries showing the strongest interest in SOEC technology include chemical manufacturing, steel production, refining, and renewable energy integration. These sectors value the high-temperature operation of SOECs, which provides synergies with existing industrial processes and waste heat utilization opportunities.

Market analysis indicates that thermal management solutions that can effectively handle the high operating temperatures of SOECs (700-850°C) while minimizing energy losses are particularly valued by customers. There is growing demand for integrated thermal management systems that can recover and repurpose waste heat, thereby improving overall system efficiency and reducing operational costs.

Thermal management solutions for SOECs represent a critical segment within this market, as efficient heat management directly impacts system performance, durability, and cost-effectiveness. The market for specialized thermal management components and systems for SOECs is estimated to account for approximately 20% of the overall SOEC market value.

Regionally, Europe leads the SOEC market with substantial investments in hydrogen infrastructure and research initiatives. Countries like Germany, Denmark, and France have established ambitious hydrogen strategies that specifically mention SOEC technology. The European market benefits from supportive policy frameworks and substantial public funding for clean energy technologies.

North America follows closely, with significant research activities and commercial deployments primarily in the United States and Canada. The Asia-Pacific region, particularly China, Japan, and South Korea, is showing the fastest growth rate in SOEC adoption, driven by national hydrogen strategies and industrial decarbonization efforts.

By application sector, industrial hydrogen production represents the largest market segment for SOEC technology at 45% of total deployments. Power-to-gas applications for grid balancing and energy storage account for approximately 30%, while synthetic fuel production comprises about 15% of the market. The remaining 10% includes niche applications such as oxygen production and distributed energy systems.

End-user industries showing the strongest interest in SOEC technology include chemical manufacturing, steel production, refining, and renewable energy integration. These sectors value the high-temperature operation of SOECs, which provides synergies with existing industrial processes and waste heat utilization opportunities.

Market analysis indicates that thermal management solutions that can effectively handle the high operating temperatures of SOECs (700-850°C) while minimizing energy losses are particularly valued by customers. There is growing demand for integrated thermal management systems that can recover and repurpose waste heat, thereby improving overall system efficiency and reducing operational costs.

Current Thermal Management Challenges in SOECs

Solid Oxide Electrolysis Cells (SOECs) face significant thermal management challenges that currently limit their widespread commercial deployment. The high operating temperatures (700-900°C) necessary for optimal ionic conductivity create complex thermal gradients across cell components, leading to mechanical stress and potential material degradation. These thermal gradients are particularly problematic during transient operations, such as startup, shutdown, and load changes, where rapid temperature fluctuations can induce thermal shock and accelerate cell degradation.

One of the primary thermal management challenges is heat distribution uniformity. Uneven temperature distribution across the cell area results in localized hot spots that accelerate material degradation and can lead to delamination of cell components. This non-uniform heating also contributes to differential thermal expansion between materials with varying thermal expansion coefficients, creating mechanical stresses that compromise structural integrity over time.

Heat removal presents another significant challenge, particularly in high-current density operations. The exothermic nature of the hydrogen evolution reaction at the cathode generates substantial heat that must be efficiently removed to prevent overheating. Conversely, the endothermic oxygen evolution reaction at the anode requires heat input. Balancing these competing thermal requirements across the cell represents a fundamental engineering challenge.

Current thermal management systems often rely on complex heat exchanger designs that add significant weight, volume, and cost to SOEC systems. These systems typically utilize air or steam as heat transfer media, but their relatively low heat capacity necessitates high flow rates, increasing parasitic power consumption and reducing overall system efficiency. The integration of thermal management components with the electrochemical stack also presents design challenges related to sealing, thermal expansion matching, and flow distribution.

Material limitations further complicate thermal management strategies. High-temperature insulation materials with sufficient durability and low thermal conductivity are essential but add to system complexity and cost. Additionally, the thermal cycling resistance of cell materials remains a critical concern, as repeated heating and cooling cycles accelerate degradation mechanisms such as nickel agglomeration in fuel electrodes and chromium poisoning in air electrodes.

Monitoring and control of temperature profiles present additional challenges. Current temperature sensing technologies often lack the spatial resolution needed to detect localized hot spots, while the harsh operating environment limits sensor durability. Advanced thermal modeling approaches are being developed but require validation against experimental data under realistic operating conditions.

One of the primary thermal management challenges is heat distribution uniformity. Uneven temperature distribution across the cell area results in localized hot spots that accelerate material degradation and can lead to delamination of cell components. This non-uniform heating also contributes to differential thermal expansion between materials with varying thermal expansion coefficients, creating mechanical stresses that compromise structural integrity over time.

Heat removal presents another significant challenge, particularly in high-current density operations. The exothermic nature of the hydrogen evolution reaction at the cathode generates substantial heat that must be efficiently removed to prevent overheating. Conversely, the endothermic oxygen evolution reaction at the anode requires heat input. Balancing these competing thermal requirements across the cell represents a fundamental engineering challenge.

Current thermal management systems often rely on complex heat exchanger designs that add significant weight, volume, and cost to SOEC systems. These systems typically utilize air or steam as heat transfer media, but their relatively low heat capacity necessitates high flow rates, increasing parasitic power consumption and reducing overall system efficiency. The integration of thermal management components with the electrochemical stack also presents design challenges related to sealing, thermal expansion matching, and flow distribution.

Material limitations further complicate thermal management strategies. High-temperature insulation materials with sufficient durability and low thermal conductivity are essential but add to system complexity and cost. Additionally, the thermal cycling resistance of cell materials remains a critical concern, as repeated heating and cooling cycles accelerate degradation mechanisms such as nickel agglomeration in fuel electrodes and chromium poisoning in air electrodes.

Monitoring and control of temperature profiles present additional challenges. Current temperature sensing technologies often lack the spatial resolution needed to detect localized hot spots, while the harsh operating environment limits sensor durability. Advanced thermal modeling approaches are being developed but require validation against experimental data under realistic operating conditions.

Comparative Analysis of Existing Thermal Solutions

01 Heat management systems for SOEC operation

Solid oxide electrolysis cells (SOECs) require effective heat management systems to maintain optimal operating temperatures. These systems often include heat exchangers, insulation materials, and cooling mechanisms to prevent overheating during operation. Proper thermal management ensures stable electrochemical performance, extends cell lifetime, and improves overall system efficiency by controlling temperature gradients across the cell stack.- Heat management systems for SOEC operation: Solid oxide electrolysis cells (SOECs) require effective heat management systems to maintain optimal operating temperatures. These systems often include heat exchangers, insulation materials, and thermal barriers to control heat distribution within the cell stack. Proper thermal management prevents thermal stress, improves efficiency, and extends the operational lifespan of the cells by maintaining temperature uniformity across the stack.

- Temperature control strategies for SOEC efficiency: Various temperature control strategies are employed to optimize SOEC efficiency. These include active cooling systems, temperature monitoring sensors, and automated control mechanisms that adjust operating parameters based on thermal feedback. Maintaining precise temperature control is crucial for balancing electrochemical reaction rates, preventing material degradation, and ensuring consistent hydrogen production efficiency across varying load conditions.

- Thermal insulation and material selection for SOECs: The selection of appropriate thermal insulation materials and cell components is critical for effective thermal management in SOECs. Advanced ceramic materials, composite structures, and specialized coatings are used to withstand high operating temperatures while providing necessary insulation properties. These materials help minimize heat loss, reduce energy consumption, and protect surrounding components from thermal damage during operation.

- Thermal cycling and durability enhancement: Thermal cycling management is essential for enhancing the durability and longevity of SOECs. Specialized designs and operational protocols are implemented to minimize thermal stress during startup, shutdown, and load fluctuations. Gradual heating and cooling procedures, along with stress-relieving components, help prevent thermal shock, reduce material fatigue, and extend the operational lifetime of the electrolysis cells.

- Integration of thermal recovery systems: Advanced SOEC systems incorporate thermal recovery mechanisms to capture and utilize waste heat, improving overall system efficiency. Heat recovery systems, such as regenerative heat exchangers and thermal energy storage units, recycle excess heat from the electrolysis process for preheating incoming gases or generating additional power. This integration optimizes energy utilization, reduces operating costs, and enhances the environmental sustainability of hydrogen production.

02 Temperature control strategies for SOEC stacks

Various temperature control strategies are employed in SOEC stacks to maintain uniform temperature distribution. These include active cooling systems, thermal barriers, and strategic placement of temperature sensors. Advanced control algorithms monitor and adjust operating parameters in real-time to prevent hotspots and thermal stress. These strategies help optimize electrolysis efficiency while preventing thermal degradation of cell components.Expand Specific Solutions03 Thermal insulation and materials for high-temperature operation

Specialized thermal insulation materials and designs are crucial for SOEC systems operating at high temperatures (700-900°C). These materials must withstand extreme thermal conditions while providing effective insulation to minimize heat loss and energy consumption. Advanced ceramic materials, composite structures, and multi-layer insulation designs help maintain temperature stability while protecting surrounding components from thermal damage.Expand Specific Solutions04 Integration of thermal recovery systems

Thermal recovery systems capture and utilize waste heat generated during SOEC operation, improving overall system efficiency. These systems may include heat exchangers, thermal storage units, and integrated cogeneration capabilities. By recovering thermal energy that would otherwise be lost, these systems reduce energy consumption, lower operating costs, and improve the environmental footprint of SOEC technology.Expand Specific Solutions05 Thermal cycling and durability enhancement

Thermal cycling management is essential for enhancing the durability and lifespan of SOECs. Controlled heating and cooling rates during startup and shutdown prevent thermal shock and mechanical stress on cell components. Advanced materials and structural designs that accommodate thermal expansion and contraction help maintain cell integrity during temperature fluctuations. These approaches significantly extend operational lifetime and reduce maintenance requirements for SOEC systems.Expand Specific Solutions

Leading Organizations in SOEC Thermal Technology

The thermal management in solid oxide electrolysis cells (SOECs) market is currently in a growth phase, with increasing adoption driven by clean energy transitions. The global market is expanding as SOECs become critical for hydrogen production and energy storage applications. Technologically, the field shows varying maturity levels among key players. Companies like Topsoe A/S, Sunfire GmbH, and Elcogen AS are leading commercial development with advanced thermal management solutions, while research institutions such as CEA, Northwestern University, and Technical University of Denmark are pushing fundamental innovations. Traditional industrial players including Robert Bosch GmbH and Toshiba Corp. are leveraging their manufacturing expertise to address thermal challenges, creating a competitive landscape balancing specialized SOEC developers and established engineering corporations.

Commissariat à l´énergie atomique et aux énergies Alternatives

Technical Solution: CEA has developed advanced thermal management solutions for solid oxide electrolysis cells (SOECs) focusing on optimized heat distribution through innovative cell architecture. Their approach incorporates specialized thermal barrier coatings and structured flow channels that enable precise temperature control across the cell surface. CEA's thermal management system utilizes a combination of active and passive cooling strategies, including integrated heat exchangers that recover waste heat to improve overall system efficiency. Their research has demonstrated that proper thermal gradient management can extend SOEC lifetime by up to 40% while maintaining high hydrogen production rates. CEA has also pioneered computational fluid dynamics modeling specifically tailored for SOEC thermal behavior prediction, allowing for rapid design iterations and performance optimization before physical prototyping.

Strengths: Superior heat distribution technology resulting in extended cell lifetime and reduced thermal stress. Advanced modeling capabilities enable precise thermal prediction and optimization. Weaknesses: Solutions may require complex manufacturing processes, potentially increasing production costs. Some thermal management approaches may add system complexity and weight.

Topsoe A/S

Technical Solution: Topsoe has developed a proprietary thermal management system for SOECs called eCOs™, which incorporates advanced ceramic materials with tailored thermal expansion coefficients to minimize thermal stress during operation. Their system features a unique stack design with integrated thermal monitoring sensors that provide real-time temperature distribution data across the cell. Topsoe's approach includes specialized edge sealing technology that prevents thermal leakage while maintaining electrical isolation between cells. Their thermal management solution incorporates dynamic load response capabilities, allowing the system to adjust operational parameters based on thermal conditions to prevent hotspot formation. Topsoe has demonstrated stable operation under thermal cycling conditions with degradation rates below 0.5% per 1000 hours, significantly outperforming conventional designs. Their technology also includes specialized gas distribution channels that ensure uniform temperature profiles even at high current densities.

Strengths: Industry-leading thermal cycling capability with minimal degradation rates. Integrated monitoring system allows for proactive thermal management. Weaknesses: Higher initial system cost compared to conventional designs. Proprietary materials may create supply chain dependencies and limit manufacturing flexibility.

Key Thermal Management Patents and Research

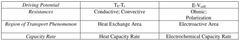

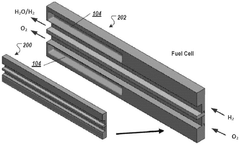

Solid oxide cell system with thermally tolerant cells with passive thermal management structures

PatentWO2025058674A9

Innovation

- A passive thermal management structure is integrated into the interconnects of solid oxide cells, redistributing thermal conductance to regions with the largest temperature gradients, maintaining overall interconnect mass while reducing temperature variations and stress.

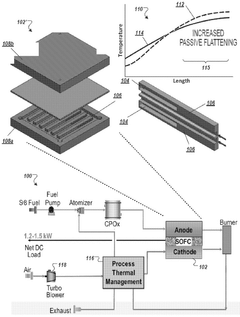

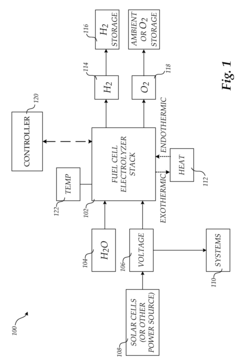

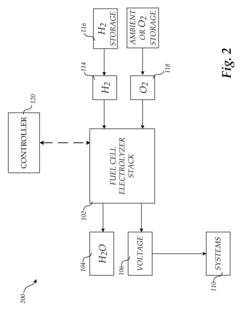

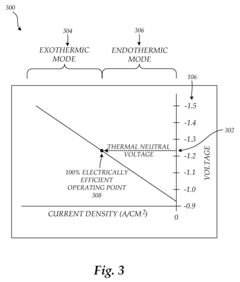

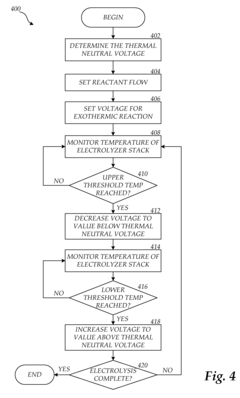

Thermal management of a high temperature fuel cell electrolyzer

PatentActiveUS8231774B2

Innovation

- A thermal control system that monitors the temperature of a high temperature electrolyzer cell and adjusts the voltage above and below the thermal neutral voltage to cycle the cell between endothermic and exothermic modes, eliminating the need for additional cooling systems.

Materials Science Advancements for SOEC Systems

Recent advancements in materials science have significantly enhanced the performance and durability of Solid Oxide Electrolysis Cell (SOEC) systems. The development of novel materials with improved thermal properties has been crucial in addressing the thermal management challenges that have historically limited SOEC efficiency and lifespan.

Ceramic-based electrolytes have evolved from traditional yttria-stabilized zirconia (YSZ) to more advanced compositions incorporating gadolinium-doped ceria (GDC) and lanthanum strontium gallium magnesium oxide (LSGM). These newer materials demonstrate superior ionic conductivity at intermediate temperatures (600-800°C), allowing for more efficient operation while reducing thermal stress on system components.

Electrode materials have similarly progressed, with perovskite-structured materials gaining prominence for their exceptional catalytic activity and thermal stability. Lanthanum strontium cobalt ferrite (LSCF) and barium strontium cobalt ferrite (BSCF) cathodes exhibit remarkable oxygen reduction reaction (ORR) kinetics while maintaining structural integrity across operational temperature ranges.

Interconnect materials have transitioned from ceramic-based options to metallic alloys with specialized coatings. Chromium-based ferritic stainless steels with protective manganese cobalt oxide spinel coatings now provide excellent electrical conductivity while resisting oxidation and chromium volatilization at elevated temperatures, significantly enhancing thermal management capabilities.

Thermal barrier coatings (TBCs) represent another critical advancement, with yttria-partially stabilized zirconia (YSZ) and lanthanum zirconate-based coatings providing effective thermal insulation. These materials help maintain temperature gradients within acceptable limits, preventing thermal shock and extending cell lifespans.

Nanostructured composite materials have emerged as particularly promising for SOEC applications. By incorporating nanoscale features, researchers have created materials with tailored thermal expansion coefficients and enhanced thermal conductivity properties. These composites often combine conventional ceramics with novel additives such as graphene, carbon nanotubes, or metallic nanoparticles to achieve specific thermal management characteristics.

Sealing materials have also evolved significantly, with glass-ceramic composites now offering both hermetic sealing capabilities and thermal expansion compatibility with other cell components. These advanced sealants maintain integrity across the wide temperature ranges experienced during SOEC startup, operation, and shutdown cycles, addressing a historically problematic aspect of thermal management.

Ceramic-based electrolytes have evolved from traditional yttria-stabilized zirconia (YSZ) to more advanced compositions incorporating gadolinium-doped ceria (GDC) and lanthanum strontium gallium magnesium oxide (LSGM). These newer materials demonstrate superior ionic conductivity at intermediate temperatures (600-800°C), allowing for more efficient operation while reducing thermal stress on system components.

Electrode materials have similarly progressed, with perovskite-structured materials gaining prominence for their exceptional catalytic activity and thermal stability. Lanthanum strontium cobalt ferrite (LSCF) and barium strontium cobalt ferrite (BSCF) cathodes exhibit remarkable oxygen reduction reaction (ORR) kinetics while maintaining structural integrity across operational temperature ranges.

Interconnect materials have transitioned from ceramic-based options to metallic alloys with specialized coatings. Chromium-based ferritic stainless steels with protective manganese cobalt oxide spinel coatings now provide excellent electrical conductivity while resisting oxidation and chromium volatilization at elevated temperatures, significantly enhancing thermal management capabilities.

Thermal barrier coatings (TBCs) represent another critical advancement, with yttria-partially stabilized zirconia (YSZ) and lanthanum zirconate-based coatings providing effective thermal insulation. These materials help maintain temperature gradients within acceptable limits, preventing thermal shock and extending cell lifespans.

Nanostructured composite materials have emerged as particularly promising for SOEC applications. By incorporating nanoscale features, researchers have created materials with tailored thermal expansion coefficients and enhanced thermal conductivity properties. These composites often combine conventional ceramics with novel additives such as graphene, carbon nanotubes, or metallic nanoparticles to achieve specific thermal management characteristics.

Sealing materials have also evolved significantly, with glass-ceramic composites now offering both hermetic sealing capabilities and thermal expansion compatibility with other cell components. These advanced sealants maintain integrity across the wide temperature ranges experienced during SOEC startup, operation, and shutdown cycles, addressing a historically problematic aspect of thermal management.

Energy Efficiency and Sustainability Considerations

Thermal management in solid oxide electrolysis cells (SOECs) represents a critical factor in determining overall system efficiency and environmental impact. The high operating temperatures of SOECs (typically 600-900°C) create both challenges and opportunities from an energy efficiency perspective. When properly managed, this thermal requirement can be integrated with other industrial processes, creating synergistic energy systems that significantly improve overall efficiency.

The energy balance of SOEC systems must be carefully considered, as the endothermic nature of electrolysis reactions requires substantial heat input. In thermoneutral operation modes, the electrical energy supplied precisely matches the enthalpy requirements of the reaction, optimizing efficiency. However, many systems operate in exothermic modes where excess heat must be effectively managed and, ideally, recovered for secondary applications.

Heat recovery systems integrated with SOECs can dramatically improve overall system efficiency. Waste heat can be captured and utilized for space heating, preheating reactants, or powering secondary processes. Advanced thermal integration approaches that couple SOECs with industrial processes requiring high temperatures show particular promise, with theoretical system efficiencies exceeding 80% when properly designed.

From a sustainability perspective, SOECs offer significant advantages over alternative hydrogen production methods. Life cycle assessments indicate that SOEC systems powered by renewable electricity sources can reduce greenhouse gas emissions by 90% compared to conventional steam methane reforming processes. The carbon footprint is primarily determined by the electricity source, highlighting the importance of renewable integration.

Material sustainability presents another critical consideration. Current SOEC designs rely on rare earth elements and precious metals that face supply constraints and environmental concerns during extraction. Research into alternative materials using earth-abundant elements shows promise for improving the sustainability profile while maintaining performance characteristics.

Water consumption represents an often-overlooked sustainability aspect of SOEC operation. While significantly lower than many alternative hydrogen production methods, water requirements must be considered in deployment planning, particularly in water-stressed regions. Closed-loop water recovery systems can mitigate this concern but add complexity and cost to system design.

The durability and operational lifetime of SOEC systems directly impact their sustainability profile. Thermal cycling and management significantly affect degradation rates, with poorly managed thermal profiles potentially reducing system lifetime by 50% or more. Advanced thermal management strategies that minimize thermal gradients and mechanical stress can extend operational lifetimes to 40,000+ hours, substantially improving lifecycle sustainability metrics.

The energy balance of SOEC systems must be carefully considered, as the endothermic nature of electrolysis reactions requires substantial heat input. In thermoneutral operation modes, the electrical energy supplied precisely matches the enthalpy requirements of the reaction, optimizing efficiency. However, many systems operate in exothermic modes where excess heat must be effectively managed and, ideally, recovered for secondary applications.

Heat recovery systems integrated with SOECs can dramatically improve overall system efficiency. Waste heat can be captured and utilized for space heating, preheating reactants, or powering secondary processes. Advanced thermal integration approaches that couple SOECs with industrial processes requiring high temperatures show particular promise, with theoretical system efficiencies exceeding 80% when properly designed.

From a sustainability perspective, SOECs offer significant advantages over alternative hydrogen production methods. Life cycle assessments indicate that SOEC systems powered by renewable electricity sources can reduce greenhouse gas emissions by 90% compared to conventional steam methane reforming processes. The carbon footprint is primarily determined by the electricity source, highlighting the importance of renewable integration.

Material sustainability presents another critical consideration. Current SOEC designs rely on rare earth elements and precious metals that face supply constraints and environmental concerns during extraction. Research into alternative materials using earth-abundant elements shows promise for improving the sustainability profile while maintaining performance characteristics.

Water consumption represents an often-overlooked sustainability aspect of SOEC operation. While significantly lower than many alternative hydrogen production methods, water requirements must be considered in deployment planning, particularly in water-stressed regions. Closed-loop water recovery systems can mitigate this concern but add complexity and cost to system design.

The durability and operational lifetime of SOEC systems directly impact their sustainability profile. Thermal cycling and management significantly affect degradation rates, with poorly managed thermal profiles potentially reducing system lifetime by 50% or more. Advanced thermal management strategies that minimize thermal gradients and mechanical stress can extend operational lifetimes to 40,000+ hours, substantially improving lifecycle sustainability metrics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!