Solid oxide electrolysis cells regulatory milestones and developments

OCT 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SOEC Technology Background and Objectives

Solid oxide electrolysis cells (SOECs) represent a transformative technology in the realm of renewable energy conversion and storage. Originating from solid oxide fuel cell (SOFC) research in the mid-20th century, SOECs have evolved significantly over the past decades. The fundamental principle behind SOECs involves the electrochemical conversion of water and/or carbon dioxide into hydrogen, carbon monoxide, or syngas using electricity, typically at high temperatures (700-900°C).

The technology's development trajectory has been marked by several key milestones. In the 1980s, initial proof-of-concept demonstrations established the viability of high-temperature electrolysis. The 1990s witnessed improvements in ceramic materials and manufacturing techniques, while the early 2000s saw increased research interest driven by growing concerns about climate change and energy security.

Recent technological advancements have focused on enhancing durability, reducing operating temperatures, and improving overall system efficiency. Current state-of-the-art SOECs can achieve electrical efficiencies exceeding 80% for hydrogen production, significantly outperforming low-temperature electrolysis technologies.

The primary objective of SOEC technology development is to establish a cost-effective, efficient, and scalable method for converting renewable electricity into storable chemical energy carriers. This addresses the intermittency challenge inherent in renewable energy sources such as wind and solar power. Additionally, SOECs offer a pathway for sector coupling, enabling the integration of electricity, heat, and chemical production systems.

From a regulatory perspective, SOEC development has been influenced by evolving policy frameworks related to hydrogen economy, carbon emissions reduction, and renewable energy integration. Major regulatory milestones include the EU Hydrogen Strategy (2020), which identified high-temperature electrolysis as a key technology for green hydrogen production, and various national hydrogen roadmaps that have established targets for electrolyzer deployment.

Looking forward, SOEC technology aims to achieve several critical objectives: reducing capital costs to below $500/kW, extending stack lifetimes beyond 40,000 hours, demonstrating multi-MW scale installations, and establishing integrated systems that can utilize various heat sources including industrial waste heat, nuclear, or concentrated solar power. These objectives align with broader energy transition goals and the increasing recognition of hydrogen as a versatile energy carrier in a decarbonized economy.

The technology's development trajectory has been marked by several key milestones. In the 1980s, initial proof-of-concept demonstrations established the viability of high-temperature electrolysis. The 1990s witnessed improvements in ceramic materials and manufacturing techniques, while the early 2000s saw increased research interest driven by growing concerns about climate change and energy security.

Recent technological advancements have focused on enhancing durability, reducing operating temperatures, and improving overall system efficiency. Current state-of-the-art SOECs can achieve electrical efficiencies exceeding 80% for hydrogen production, significantly outperforming low-temperature electrolysis technologies.

The primary objective of SOEC technology development is to establish a cost-effective, efficient, and scalable method for converting renewable electricity into storable chemical energy carriers. This addresses the intermittency challenge inherent in renewable energy sources such as wind and solar power. Additionally, SOECs offer a pathway for sector coupling, enabling the integration of electricity, heat, and chemical production systems.

From a regulatory perspective, SOEC development has been influenced by evolving policy frameworks related to hydrogen economy, carbon emissions reduction, and renewable energy integration. Major regulatory milestones include the EU Hydrogen Strategy (2020), which identified high-temperature electrolysis as a key technology for green hydrogen production, and various national hydrogen roadmaps that have established targets for electrolyzer deployment.

Looking forward, SOEC technology aims to achieve several critical objectives: reducing capital costs to below $500/kW, extending stack lifetimes beyond 40,000 hours, demonstrating multi-MW scale installations, and establishing integrated systems that can utilize various heat sources including industrial waste heat, nuclear, or concentrated solar power. These objectives align with broader energy transition goals and the increasing recognition of hydrogen as a versatile energy carrier in a decarbonized economy.

Market Demand Analysis for Hydrogen Production

The global hydrogen market is experiencing unprecedented growth, driven by the urgent need for clean energy solutions to combat climate change. Hydrogen produced via solid oxide electrolysis cells (SOECs) represents a particularly promising pathway for decarbonization across multiple sectors. Current market analysis indicates that green hydrogen demand could reach 530 million tons by 2050, with SOECs positioned to capture a significant portion of this expanding market.

Industrial applications constitute the largest demand segment for hydrogen produced via SOECs, particularly in sectors where direct electrification remains challenging. Steel manufacturing, which accounts for approximately 7-9% of global CO2 emissions, has begun pilot projects using hydrogen as a reducing agent instead of coal. Chemical manufacturing, especially ammonia and methanol production, represents another substantial market, with several major chemical companies announcing transitions to green hydrogen feedstock.

Transportation presents a growing demand vector, particularly in heavy-duty vehicles, shipping, and aviation where battery limitations persist. The fuel cell electric vehicle (FCEV) market is projected to grow substantially in regions with established hydrogen infrastructure, with commercial fleets leading adoption due to centralized refueling requirements and predictable routes.

Energy storage applications are emerging as a critical market driver for SOEC-produced hydrogen. As renewable energy penetration increases, grid operators face growing intermittency challenges. Hydrogen produced during excess renewable generation periods can be stored and later reconverted to electricity, providing seasonal storage capabilities that batteries cannot match.

Regional market analysis reveals significant variation in hydrogen demand growth. The European Union, through its Hydrogen Strategy, aims to install at least 40GW of electrolyzer capacity by 2030. Asia-Pacific markets, led by Japan, South Korea, and increasingly China, are developing substantial hydrogen economies focused on industrial applications and transportation. North America shows growing interest, particularly in industrial clusters where hydrogen infrastructure can be developed efficiently.

Cost considerations remain central to market expansion. Current green hydrogen production costs range from $3-8/kg depending on electricity prices and utilization rates. However, SOEC technology offers efficiency advantages over alternative electrolysis methods, potentially reducing costs as the technology matures and scales. Industry projections suggest green hydrogen could reach cost parity with fossil-based hydrogen in favorable regions by 2030, substantially expanding addressable markets.

Industrial applications constitute the largest demand segment for hydrogen produced via SOECs, particularly in sectors where direct electrification remains challenging. Steel manufacturing, which accounts for approximately 7-9% of global CO2 emissions, has begun pilot projects using hydrogen as a reducing agent instead of coal. Chemical manufacturing, especially ammonia and methanol production, represents another substantial market, with several major chemical companies announcing transitions to green hydrogen feedstock.

Transportation presents a growing demand vector, particularly in heavy-duty vehicles, shipping, and aviation where battery limitations persist. The fuel cell electric vehicle (FCEV) market is projected to grow substantially in regions with established hydrogen infrastructure, with commercial fleets leading adoption due to centralized refueling requirements and predictable routes.

Energy storage applications are emerging as a critical market driver for SOEC-produced hydrogen. As renewable energy penetration increases, grid operators face growing intermittency challenges. Hydrogen produced during excess renewable generation periods can be stored and later reconverted to electricity, providing seasonal storage capabilities that batteries cannot match.

Regional market analysis reveals significant variation in hydrogen demand growth. The European Union, through its Hydrogen Strategy, aims to install at least 40GW of electrolyzer capacity by 2030. Asia-Pacific markets, led by Japan, South Korea, and increasingly China, are developing substantial hydrogen economies focused on industrial applications and transportation. North America shows growing interest, particularly in industrial clusters where hydrogen infrastructure can be developed efficiently.

Cost considerations remain central to market expansion. Current green hydrogen production costs range from $3-8/kg depending on electricity prices and utilization rates. However, SOEC technology offers efficiency advantages over alternative electrolysis methods, potentially reducing costs as the technology matures and scales. Industry projections suggest green hydrogen could reach cost parity with fossil-based hydrogen in favorable regions by 2030, substantially expanding addressable markets.

Global SOEC Development Status and Challenges

Solid oxide electrolysis cells (SOECs) have gained significant traction globally as a promising technology for clean hydrogen production and carbon utilization. Currently, the global SOEC landscape shows varying degrees of development across different regions, with Europe, North America, and Asia leading research and commercialization efforts.

In Europe, countries like Germany, Denmark, and France have established robust SOEC research programs with substantial government funding. The European Union's Horizon Europe program has allocated over €100 million specifically for SOEC development between 2021-2027. Companies like Sunfire (Germany) and Haldor Topsoe (Denmark) have demonstrated multi-megawatt SOEC systems with electrical efficiencies exceeding 80%.

North America, particularly the United States, has focused on SOEC development through Department of Energy initiatives, with significant progress in materials durability and system integration. The U.S. Hydrogen Shot program aims to reduce clean hydrogen costs to $1/kg by 2030, with SOECs playing a crucial role in this strategy.

In Asia, Japan and South Korea have made notable advancements in SOEC technology, with companies like Kyocera and POSCO developing proprietary cell designs. China has recently accelerated its SOEC research efforts, primarily through academic institutions and state-owned enterprises, focusing on cost reduction and mass manufacturing capabilities.

Despite these advancements, several critical challenges persist in global SOEC development. Material degradation remains a significant hurdle, with current state-of-the-art cells showing performance losses of 1-2% per 1000 hours of operation, far from the commercial target of <0.25% per 1000 hours. High-temperature sealing materials continue to present reliability issues, particularly in thermal cycling conditions.

Cost competitiveness represents another major challenge. Current SOEC stack costs range from $2000-5000/kW, significantly higher than the $500/kW target needed for widespread commercial adoption. Manufacturing scalability presents additional difficulties, as current production methods remain largely semi-automated and laboratory-scale.

System integration challenges include thermal management during operation, particularly for reversible systems that must function in both electrolysis and fuel cell modes. Grid integration and dynamic operation capabilities need further development to enable SOECs to effectively utilize variable renewable energy sources.

Regulatory frameworks for hydrogen production and carbon utilization vary significantly across regions, creating market uncertainties for SOEC deployment. Additionally, the lack of standardized testing protocols and performance metrics hampers meaningful comparison between different SOEC technologies and slows industry-wide progress.

In Europe, countries like Germany, Denmark, and France have established robust SOEC research programs with substantial government funding. The European Union's Horizon Europe program has allocated over €100 million specifically for SOEC development between 2021-2027. Companies like Sunfire (Germany) and Haldor Topsoe (Denmark) have demonstrated multi-megawatt SOEC systems with electrical efficiencies exceeding 80%.

North America, particularly the United States, has focused on SOEC development through Department of Energy initiatives, with significant progress in materials durability and system integration. The U.S. Hydrogen Shot program aims to reduce clean hydrogen costs to $1/kg by 2030, with SOECs playing a crucial role in this strategy.

In Asia, Japan and South Korea have made notable advancements in SOEC technology, with companies like Kyocera and POSCO developing proprietary cell designs. China has recently accelerated its SOEC research efforts, primarily through academic institutions and state-owned enterprises, focusing on cost reduction and mass manufacturing capabilities.

Despite these advancements, several critical challenges persist in global SOEC development. Material degradation remains a significant hurdle, with current state-of-the-art cells showing performance losses of 1-2% per 1000 hours of operation, far from the commercial target of <0.25% per 1000 hours. High-temperature sealing materials continue to present reliability issues, particularly in thermal cycling conditions.

Cost competitiveness represents another major challenge. Current SOEC stack costs range from $2000-5000/kW, significantly higher than the $500/kW target needed for widespread commercial adoption. Manufacturing scalability presents additional difficulties, as current production methods remain largely semi-automated and laboratory-scale.

System integration challenges include thermal management during operation, particularly for reversible systems that must function in both electrolysis and fuel cell modes. Grid integration and dynamic operation capabilities need further development to enable SOECs to effectively utilize variable renewable energy sources.

Regulatory frameworks for hydrogen production and carbon utilization vary significantly across regions, creating market uncertainties for SOEC deployment. Additionally, the lack of standardized testing protocols and performance metrics hampers meaningful comparison between different SOEC technologies and slows industry-wide progress.

Current SOEC System Designs and Solutions

01 Electrode materials and structures for SOECs

Advanced electrode materials and structures are crucial for improving the performance of solid oxide electrolysis cells. These include novel cathode and anode compositions that enhance electrochemical reactions, reduce polarization resistance, and improve durability under operating conditions. Specialized structures such as porous electrodes with optimized microstructures facilitate gas diffusion and increase active reaction sites, leading to higher efficiency in hydrogen or syngas production.- Materials and compositions for solid oxide electrolysis cells: Various materials and compositions are used in solid oxide electrolysis cells to enhance performance and durability. These include specialized electrolytes, electrodes, and catalysts that can withstand high operating temperatures while maintaining ionic conductivity. Advanced ceramic materials, composite structures, and doped compounds are developed to improve efficiency and reduce degradation during operation. The selection of appropriate materials is crucial for optimizing the electrochemical reactions and overall cell performance.

- Cell design and structural configurations: Innovative designs and structural configurations of solid oxide electrolysis cells focus on optimizing performance and durability. These designs include planar, tubular, or monolithic cell architectures with various flow field patterns and sealing mechanisms. Advanced configurations incorporate thermal management systems, stress-relieving structures, and optimized electrode-electrolyte interfaces. The cell design significantly impacts gas distribution, current collection, and overall system integration, affecting efficiency and operational stability.

- Operating conditions and control systems: Effective operation of solid oxide electrolysis cells requires precise control of temperature, pressure, gas flow rates, and electrical parameters. Advanced control systems monitor and adjust operating conditions to maintain optimal performance while preventing degradation. Thermal cycling strategies, load management techniques, and gas composition control are implemented to extend cell lifetime and improve efficiency. Operating parameters significantly influence reaction kinetics, current density distribution, and overall system performance.

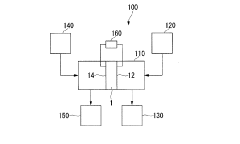

- Integration with renewable energy systems: Solid oxide electrolysis cells can be integrated with renewable energy sources to enable efficient energy storage and conversion. These integrated systems utilize intermittent renewable power to produce hydrogen or syngas through high-temperature electrolysis. Smart grid integration, power conditioning systems, and hybrid energy configurations enhance the flexibility and responsiveness of electrolysis operations. Such integration supports grid balancing, seasonal energy storage, and carbon-neutral fuel production pathways.

- Production methods and manufacturing techniques: Advanced manufacturing techniques for solid oxide electrolysis cells include tape casting, screen printing, physical vapor deposition, and additive manufacturing. These methods enable precise control of microstructure, composition, and interfacial properties. Scalable production processes, quality control systems, and automated assembly techniques are developed to reduce costs and improve consistency. Manufacturing innovations focus on reducing defects, enhancing reproducibility, and enabling mass production of high-performance cells.

02 Electrolyte development for high-temperature operation

Electrolyte materials for solid oxide electrolysis cells are designed to withstand high operating temperatures while maintaining excellent ionic conductivity. These materials typically include yttria-stabilized zirconia (YSZ), gadolinium-doped ceria (GDC), or lanthanum gallate-based compounds. Advanced electrolyte formulations focus on reducing ohmic resistance, enhancing mechanical stability, and preventing degradation during thermal cycling, which collectively improve the overall efficiency and lifespan of the cells.Expand Specific Solutions03 System integration and stack design

Effective integration of solid oxide electrolysis cells into complete systems requires specialized stack designs that optimize electrical connections, gas flow distribution, and thermal management. These designs incorporate sealing technologies to prevent gas leakage, interconnect materials that resist corrosion at high temperatures, and structural components that maintain mechanical integrity during thermal cycling. Advanced stack configurations also focus on minimizing internal resistance and maximizing active cell area to improve overall system efficiency.Expand Specific Solutions04 Co-electrolysis for syngas production

Co-electrolysis processes in solid oxide cells enable simultaneous reduction of steam and carbon dioxide to produce syngas (a mixture of hydrogen and carbon monoxide). This approach offers an efficient pathway for converting renewable electricity into valuable chemical feedstocks for synthetic fuel production. The technology requires specialized catalysts and operating conditions to control the ratio of hydrogen to carbon monoxide in the output gas, while minimizing carbon deposition that can degrade cell performance over time.Expand Specific Solutions05 Degradation mechanisms and durability enhancement

Understanding and mitigating degradation mechanisms is essential for improving the long-term durability of solid oxide electrolysis cells. Key degradation factors include chromium poisoning from interconnects, nickel agglomeration in hydrogen electrodes, delamination at interfaces, and impurity segregation at grain boundaries. Advanced protective coatings, dopants, and microstructural engineering approaches are employed to enhance stability under high-temperature electrolysis conditions, extending cell lifetime and maintaining performance over thousands of operating hours.Expand Specific Solutions

Leading SOEC Manufacturers and Research Institutions

The solid oxide electrolysis cells (SOEC) market is currently in a growth phase, with increasing regulatory focus on clean energy technologies driving development. The global market size is projected to expand significantly as hydrogen economy initiatives gain momentum worldwide. From a technological maturity perspective, academic institutions like Tsinghua University and Technical University of Denmark are leading fundamental research, while established industrial players such as Toshiba, Air Liquide, and Bloom Energy are advancing commercial applications. Asian companies, particularly from Japan and China (including Sinopec and IHI Corp.), are increasingly active in patent filings, suggesting a geographical shift in innovation leadership. The competitive landscape shows a mix of energy conglomerates diversifying into SOEC technology and specialized firms focusing on technological refinement, with regulatory milestones in carbon reduction accelerating commercialization efforts.

Technical University of Denmark

Technical Solution: The Technical University of Denmark (DTU) has developed state-of-the-art SOEC technology through their Department of Energy Conversion and Storage. Their approach focuses on metal-supported cells that offer improved robustness and reduced material costs compared to conventional ceramic-supported designs. DTU's SOEC systems operate at temperatures between 650-800°C and utilize scandia-stabilized zirconia electrolytes with enhanced ionic conductivity. Their electrode designs incorporate infiltrated nano-catalysts that significantly improve electrochemical performance while reducing degradation mechanisms. DTU has pioneered advanced manufacturing techniques including tape casting and co-sintering processes that enable cost-effective production with high reproducibility. Their SOEC stacks demonstrate exceptional durability with degradation rates below 0.3% per 1000 hours under steady-state operation. DTU has also developed innovative approaches to pressurized SOEC operation (up to 10 bar), which improves thermodynamic efficiency and enables direct integration with downstream processes. Their systems have demonstrated hydrogen production at electrical efficiencies exceeding 90% when operating in thermoneutral mode with proper thermal integration.

Strengths: Advanced metal-supported cell architecture improving mechanical durability while reducing costs; sophisticated manufacturing processes enabling scalability; exceptional performance under pressurized operation. Weaknesses: Complex system integration requirements; challenges in sealing and manifolding for pressurized operation; thermal management complexities during dynamic operation.

Bloom Energy Corp.

Technical Solution: Bloom Energy has developed a proprietary solid oxide technology platform for clean, reliable electricity and hydrogen generation. Their SOEC technology operates at high temperatures (around 800-1000°C) and utilizes a ceramic electrolyte that conducts oxygen ions. The company's reversible systems can operate in both fuel cell mode (SOFC) and electrolysis mode (SOEC), providing flexibility for energy storage and generation. Bloom's SOEC technology achieves high electrical efficiency (over 70%) by leveraging waste heat recovery and system integration. Their modular "Energy Server" platform incorporates these cells into scalable systems that can be deployed for various applications including green hydrogen production, carbon capture, and grid balancing. Bloom has also made significant advancements in electrode materials to improve durability and reduce degradation rates to less than 1% per year, addressing one of the key challenges in SOEC commercialization.

Strengths: High electrical efficiency exceeding 70% through waste heat utilization; modular and scalable system architecture; reversible operation capability allowing for flexible energy management. Weaknesses: High operating temperatures require specialized materials and thermal management; higher capital costs compared to low-temperature electrolysis technologies; longer startup times limiting rapid response capabilities.

Key Patents and Technical Innovations in SOEC

Solid oxide electrolysis cell, electrolysis system, and method of producing carbon monoxide and hydrogen

PatentActiveJP2019218578A

Innovation

- A solid oxide electrolysis cell with a cathode electrode composed of a spinel structure solid oxide, such as CuFe2O4, is used, along with an anode electrode and an electrolyte layer, to enhance stability and maintain catalytic activity.

Regulatory Framework and Policy Incentives

The regulatory landscape for solid oxide electrolysis cells (SOECs) has evolved significantly over the past decade, shaped by growing concerns about climate change and the transition to clean energy systems. At the international level, the Paris Agreement of 2015 marked a pivotal moment, establishing decarbonization targets that indirectly stimulated interest in hydrogen production technologies, including SOECs.

The European Union has emerged as a regulatory frontrunner, implementing the European Green Deal in 2019 and subsequently launching the EU Hydrogen Strategy in 2020. These frameworks specifically recognize electrolysis as a key technology for green hydrogen production, with SOECs benefiting from dedicated funding mechanisms through programs like Horizon Europe and the Innovation Fund. The EU's Renewable Energy Directive II (RED II) further supports SOECs by establishing targets for renewable hydrogen in industrial applications.

In the United States, regulatory support has been more fragmented but gained momentum with the Inflation Reduction Act of 2022, which provides substantial tax credits for clean hydrogen production. The Department of Energy's Hydrogen Shot initiative aims to reduce clean hydrogen costs to $1 per kilogram within a decade, creating favorable conditions for SOEC deployment and commercialization.

Japan and South Korea have established hydrogen roadmaps with specific provisions for high-temperature electrolysis technologies. Japan's Green Growth Strategy includes SOECs as part of its hydrogen supply chain development, while South Korea's Hydrogen Economy Roadmap emphasizes the role of efficient electrolysis in achieving its hydrogen economy goals.

Financial incentives across jurisdictions have evolved from research grants to production-based support mechanisms. Capital expenditure subsidies covering 20-40% of installation costs are common in early markets, while operational support through feed-in premiums for hydrogen production is emerging in mature regulatory environments. Carbon pricing mechanisms, particularly in the EU Emissions Trading System, indirectly benefit SOECs by increasing the cost competitiveness of green hydrogen against fossil-based alternatives.

Standardization efforts led by organizations such as the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC) are addressing critical aspects of SOEC deployment, including safety protocols, performance metrics, and grid integration requirements. These standards are essential for market development and cross-border technology transfer.

Regulatory gaps remain in areas such as grid connection rules for large-scale electrolyzers and certification schemes for green hydrogen. Addressing these gaps will be crucial for the widespread commercial adoption of SOEC technology and its integration into existing energy infrastructure.

The European Union has emerged as a regulatory frontrunner, implementing the European Green Deal in 2019 and subsequently launching the EU Hydrogen Strategy in 2020. These frameworks specifically recognize electrolysis as a key technology for green hydrogen production, with SOECs benefiting from dedicated funding mechanisms through programs like Horizon Europe and the Innovation Fund. The EU's Renewable Energy Directive II (RED II) further supports SOECs by establishing targets for renewable hydrogen in industrial applications.

In the United States, regulatory support has been more fragmented but gained momentum with the Inflation Reduction Act of 2022, which provides substantial tax credits for clean hydrogen production. The Department of Energy's Hydrogen Shot initiative aims to reduce clean hydrogen costs to $1 per kilogram within a decade, creating favorable conditions for SOEC deployment and commercialization.

Japan and South Korea have established hydrogen roadmaps with specific provisions for high-temperature electrolysis technologies. Japan's Green Growth Strategy includes SOECs as part of its hydrogen supply chain development, while South Korea's Hydrogen Economy Roadmap emphasizes the role of efficient electrolysis in achieving its hydrogen economy goals.

Financial incentives across jurisdictions have evolved from research grants to production-based support mechanisms. Capital expenditure subsidies covering 20-40% of installation costs are common in early markets, while operational support through feed-in premiums for hydrogen production is emerging in mature regulatory environments. Carbon pricing mechanisms, particularly in the EU Emissions Trading System, indirectly benefit SOECs by increasing the cost competitiveness of green hydrogen against fossil-based alternatives.

Standardization efforts led by organizations such as the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC) are addressing critical aspects of SOEC deployment, including safety protocols, performance metrics, and grid integration requirements. These standards are essential for market development and cross-border technology transfer.

Regulatory gaps remain in areas such as grid connection rules for large-scale electrolyzers and certification schemes for green hydrogen. Addressing these gaps will be crucial for the widespread commercial adoption of SOEC technology and its integration into existing energy infrastructure.

Environmental Impact and Sustainability Assessment

Solid oxide electrolysis cells (SOECs) represent a promising technology for clean hydrogen production, yet their environmental footprint and sustainability credentials require thorough assessment. The life cycle analysis of SOECs reveals significant advantages over conventional hydrogen production methods, with potential greenhouse gas emission reductions of 60-90% when powered by renewable energy sources compared to steam methane reforming processes.

Material selection for SOECs presents both environmental challenges and opportunities. The rare earth elements and precious metals used in cell components raise concerns regarding resource depletion and mining impacts. However, recent advancements in reducing critical material content and improving recycling processes have shown potential to mitigate these concerns. Research indicates that extending SOEC operational lifetimes from current 20,000 hours to targeted 80,000+ hours could reduce lifetime environmental impact by approximately 75%.

Water consumption represents another critical environmental consideration. While electrolysis requires high-purity water inputs, SOECs demonstrate 15-30% higher efficiency than low-temperature electrolysis technologies, translating to proportionally lower water requirements per kilogram of hydrogen produced. Furthermore, waste heat recovery systems can significantly improve overall system efficiency, reducing both energy consumption and associated environmental impacts.

The integration of SOECs with renewable energy systems creates particularly compelling sustainability benefits. These systems can utilize excess renewable electricity during low-demand periods, effectively storing energy as hydrogen while preventing curtailment of renewable generation. Studies suggest that such integrated systems could achieve carbon payback periods of 1-3 years, depending on deployment location and energy mix.

Regulatory frameworks increasingly recognize these environmental attributes. The EU Taxonomy for Sustainable Activities has established a threshold of 3 kgCO2e/kgH2 for hydrogen production to qualify as sustainable, a benchmark achievable by SOEC systems when powered predominantly by low-carbon electricity. Similarly, the US Department of Energy's Hydrogen Shot initiative targets clean hydrogen production at $1/kg within one decade, with environmental performance metrics embedded in funding criteria.

End-of-life management presents both challenges and opportunities. Current SOEC recycling processes recover approximately 60-85% of valuable materials, though technological improvements could increase this rate. Circular economy principles are increasingly being incorporated into SOEC design, with manufacturers developing modular components that facilitate repair, reuse, and eventual recycling.

Material selection for SOECs presents both environmental challenges and opportunities. The rare earth elements and precious metals used in cell components raise concerns regarding resource depletion and mining impacts. However, recent advancements in reducing critical material content and improving recycling processes have shown potential to mitigate these concerns. Research indicates that extending SOEC operational lifetimes from current 20,000 hours to targeted 80,000+ hours could reduce lifetime environmental impact by approximately 75%.

Water consumption represents another critical environmental consideration. While electrolysis requires high-purity water inputs, SOECs demonstrate 15-30% higher efficiency than low-temperature electrolysis technologies, translating to proportionally lower water requirements per kilogram of hydrogen produced. Furthermore, waste heat recovery systems can significantly improve overall system efficiency, reducing both energy consumption and associated environmental impacts.

The integration of SOECs with renewable energy systems creates particularly compelling sustainability benefits. These systems can utilize excess renewable electricity during low-demand periods, effectively storing energy as hydrogen while preventing curtailment of renewable generation. Studies suggest that such integrated systems could achieve carbon payback periods of 1-3 years, depending on deployment location and energy mix.

Regulatory frameworks increasingly recognize these environmental attributes. The EU Taxonomy for Sustainable Activities has established a threshold of 3 kgCO2e/kgH2 for hydrogen production to qualify as sustainable, a benchmark achievable by SOEC systems when powered predominantly by low-carbon electricity. Similarly, the US Department of Energy's Hydrogen Shot initiative targets clean hydrogen production at $1/kg within one decade, with environmental performance metrics embedded in funding criteria.

End-of-life management presents both challenges and opportunities. Current SOEC recycling processes recover approximately 60-85% of valuable materials, though technological improvements could increase this rate. Circular economy principles are increasingly being incorporated into SOEC design, with manufacturers developing modular components that facilitate repair, reuse, and eventual recycling.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!