Solid oxide electrolysis cells at the forefront of energy innovation

OCT 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SOEC Technology Background and Objectives

Solid oxide electrolysis cells (SOECs) represent a transformative technology in the global energy landscape, with roots dating back to the mid-20th century. The fundamental concept of high-temperature electrolysis was first explored in the 1960s, but significant advancements in materials science and engineering over the past two decades have propelled SOECs to the forefront of energy innovation. This technology has evolved from laboratory curiosity to commercial viability, driven by the urgent need for sustainable energy solutions and carbon neutrality commitments worldwide.

The evolution of SOEC technology has been characterized by progressive improvements in cell durability, efficiency, and cost-effectiveness. Early iterations faced substantial challenges related to material degradation at high operating temperatures (800-1000°C), limited operational lifespans, and prohibitive manufacturing costs. Recent breakthroughs in ceramic materials, electrode design, and system integration have addressed many of these limitations, enabling longer operational lifetimes and improved performance metrics.

Current technological trajectories indicate a convergence toward intermediate-temperature SOECs (600-750°C), which balance the kinetic advantages of high-temperature operation with enhanced durability and reduced system complexity. This represents a critical inflection point in the technology's maturation curve, potentially enabling broader commercial adoption across multiple sectors.

The primary objective of contemporary SOEC development is to establish this technology as a cornerstone of sector coupling and energy system integration. Specifically, SOECs aim to provide a highly efficient pathway for converting renewable electricity into chemical energy carriers (hydrogen, syngas) and valuable chemicals, thereby addressing the intermittency challenges inherent to renewable energy sources like wind and solar power.

Technical goals for next-generation SOECs include achieving electrical-to-chemical conversion efficiencies exceeding 90%, operational lifespans of 80,000+ hours with degradation rates below 0.25% per 1000 hours, capital cost reduction to under $500/kW, and scalable manufacturing processes capable of gigawatt-scale production. Additionally, enhancing system flexibility to accommodate dynamic operation under variable input conditions represents a critical frontier for enabling grid-responsive applications.

The strategic importance of SOEC technology extends beyond energy storage to encompass industrial decarbonization, particularly in hard-to-abate sectors such as steel production, ammonia synthesis, and chemical manufacturing. By enabling the efficient conversion of renewable electricity into process heat and chemical feedstocks, SOECs offer a viable pathway toward carbon-neutral industrial operations, aligning with global climate objectives and sustainable development goals.

The evolution of SOEC technology has been characterized by progressive improvements in cell durability, efficiency, and cost-effectiveness. Early iterations faced substantial challenges related to material degradation at high operating temperatures (800-1000°C), limited operational lifespans, and prohibitive manufacturing costs. Recent breakthroughs in ceramic materials, electrode design, and system integration have addressed many of these limitations, enabling longer operational lifetimes and improved performance metrics.

Current technological trajectories indicate a convergence toward intermediate-temperature SOECs (600-750°C), which balance the kinetic advantages of high-temperature operation with enhanced durability and reduced system complexity. This represents a critical inflection point in the technology's maturation curve, potentially enabling broader commercial adoption across multiple sectors.

The primary objective of contemporary SOEC development is to establish this technology as a cornerstone of sector coupling and energy system integration. Specifically, SOECs aim to provide a highly efficient pathway for converting renewable electricity into chemical energy carriers (hydrogen, syngas) and valuable chemicals, thereby addressing the intermittency challenges inherent to renewable energy sources like wind and solar power.

Technical goals for next-generation SOECs include achieving electrical-to-chemical conversion efficiencies exceeding 90%, operational lifespans of 80,000+ hours with degradation rates below 0.25% per 1000 hours, capital cost reduction to under $500/kW, and scalable manufacturing processes capable of gigawatt-scale production. Additionally, enhancing system flexibility to accommodate dynamic operation under variable input conditions represents a critical frontier for enabling grid-responsive applications.

The strategic importance of SOEC technology extends beyond energy storage to encompass industrial decarbonization, particularly in hard-to-abate sectors such as steel production, ammonia synthesis, and chemical manufacturing. By enabling the efficient conversion of renewable electricity into process heat and chemical feedstocks, SOECs offer a viable pathway toward carbon-neutral industrial operations, aligning with global climate objectives and sustainable development goals.

Market Analysis for Hydrogen Production via Electrolysis

The global hydrogen market is experiencing unprecedented growth, driven by the increasing focus on decarbonization and clean energy transitions. Current estimates value the hydrogen production market at approximately $130 billion, with projections suggesting expansion to $200 billion by 2030. Within this broader market, electrolysis-based hydrogen production represents a rapidly growing segment, currently accounting for less than 5% of total hydrogen production but expected to reach 20-30% by 2040.

Solid oxide electrolysis cells (SOECs) are positioned as a premium segment within the electrolysis market, competing with alkaline and proton exchange membrane (PEM) technologies. While alkaline electrolysis currently dominates with about 60% market share due to its maturity and lower capital costs, SOECs are gaining traction in specialized applications where high-temperature operation provides efficiency advantages.

The demand for green hydrogen produced via electrolysis is being driven by multiple sectors. Industrial applications, particularly in refining, ammonia production, and metallurgy, represent the largest current market, consuming approximately 70% of hydrogen produced. Transportation applications, including fuel cell vehicles and synthetic fuel production, are emerging as high-growth segments with annual growth rates exceeding 25% in some regions.

Geographically, Europe leads in electrolysis deployment with over 40% of installed capacity, followed by Asia-Pacific at 30% and North America at 20%. Countries with ambitious hydrogen strategies such as Germany, Japan, South Korea, and Australia are creating favorable market conditions through substantial subsidies and regulatory frameworks that incentivize green hydrogen production.

The economics of hydrogen production via electrolysis remain challenging but are improving rapidly. Current production costs range from $4-6/kg for green hydrogen compared to $1-2/kg for conventional methods. However, declining renewable electricity costs and improving electrolyzer technologies are narrowing this gap. SOEC technology specifically offers potential production cost advantages of 15-25% over other electrolysis methods when integrated with industrial processes that can utilize waste heat.

Market barriers include high capital expenditure requirements, limited infrastructure for hydrogen transport and storage, and regulatory uncertainties. Despite these challenges, investment in hydrogen electrolysis technologies has surged, with over $300 billion in announced projects through 2030, indicating strong market confidence in the long-term viability of this technology pathway.

Customer segments for SOEC technology are diversifying beyond traditional industrial users to include energy utilities, transportation companies, and even residential energy systems in some advanced markets, creating multiple pathways for market penetration and growth.

Solid oxide electrolysis cells (SOECs) are positioned as a premium segment within the electrolysis market, competing with alkaline and proton exchange membrane (PEM) technologies. While alkaline electrolysis currently dominates with about 60% market share due to its maturity and lower capital costs, SOECs are gaining traction in specialized applications where high-temperature operation provides efficiency advantages.

The demand for green hydrogen produced via electrolysis is being driven by multiple sectors. Industrial applications, particularly in refining, ammonia production, and metallurgy, represent the largest current market, consuming approximately 70% of hydrogen produced. Transportation applications, including fuel cell vehicles and synthetic fuel production, are emerging as high-growth segments with annual growth rates exceeding 25% in some regions.

Geographically, Europe leads in electrolysis deployment with over 40% of installed capacity, followed by Asia-Pacific at 30% and North America at 20%. Countries with ambitious hydrogen strategies such as Germany, Japan, South Korea, and Australia are creating favorable market conditions through substantial subsidies and regulatory frameworks that incentivize green hydrogen production.

The economics of hydrogen production via electrolysis remain challenging but are improving rapidly. Current production costs range from $4-6/kg for green hydrogen compared to $1-2/kg for conventional methods. However, declining renewable electricity costs and improving electrolyzer technologies are narrowing this gap. SOEC technology specifically offers potential production cost advantages of 15-25% over other electrolysis methods when integrated with industrial processes that can utilize waste heat.

Market barriers include high capital expenditure requirements, limited infrastructure for hydrogen transport and storage, and regulatory uncertainties. Despite these challenges, investment in hydrogen electrolysis technologies has surged, with over $300 billion in announced projects through 2030, indicating strong market confidence in the long-term viability of this technology pathway.

Customer segments for SOEC technology are diversifying beyond traditional industrial users to include energy utilities, transportation companies, and even residential energy systems in some advanced markets, creating multiple pathways for market penetration and growth.

SOEC Development Status and Technical Barriers

Solid Oxide Electrolysis Cells (SOECs) have emerged as a promising technology for clean energy conversion, particularly for hydrogen production and carbon dioxide utilization. Currently, SOECs are transitioning from laboratory-scale research to early commercial deployment, with several demonstration projects operational worldwide. Leading research institutions in Europe, North America, and Asia have achieved significant breakthroughs in cell performance and durability over the past decade.

Despite these advancements, SOECs face substantial technical barriers that hinder widespread commercial adoption. The most critical challenge remains the high operating temperature (typically 700-900°C), which necessitates expensive materials and creates thermal management complexities. This temperature requirement significantly impacts system costs and operational flexibility, limiting rapid start-up capabilities essential for integration with intermittent renewable energy sources.

Material degradation presents another formidable obstacle. Current state-of-the-art electrodes and electrolytes suffer from performance deterioration during long-term operation, with degradation rates typically ranging from 0.5% to 2% per 1000 hours—still considerably higher than the commercial target of less than 0.25%. This degradation stems from multiple mechanisms including chromium poisoning, nickel agglomeration in hydrogen electrodes, and delamination at electrode-electrolyte interfaces.

Scalability challenges persist in manufacturing processes. While laboratory cells demonstrate impressive performance metrics, translating these results to industrial-scale production while maintaining quality and performance consistency remains problematic. Current manufacturing techniques struggle with reproducibility issues and high rejection rates when scaling to larger cell areas and stack configurations.

System integration represents another significant barrier. The complex balance-of-plant components required for thermal management, gas handling, and electrical conversion add substantial costs and complexity to SOEC systems. Additionally, the integration of SOECs with downstream processes for hydrogen storage or synthetic fuel production introduces further technical complications that require optimization.

From a geographical perspective, SOEC technology development shows distinct regional characteristics. European efforts, particularly in Denmark, Germany, and France, focus heavily on integration with renewable energy systems. Asian research, led by Japan and increasingly China, emphasizes materials innovation and manufacturing scalability. North American programs concentrate on high-temperature co-electrolysis processes for syngas production.

Economic viability remains a critical challenge, with current SOEC system costs exceeding $1,000/kW, significantly higher than the $500/kW threshold generally considered necessary for commercial competitiveness. The high capital expenditure, coupled with limited operational experience and uncertain lifetime performance, creates substantial barriers to investment and deployment.

Despite these advancements, SOECs face substantial technical barriers that hinder widespread commercial adoption. The most critical challenge remains the high operating temperature (typically 700-900°C), which necessitates expensive materials and creates thermal management complexities. This temperature requirement significantly impacts system costs and operational flexibility, limiting rapid start-up capabilities essential for integration with intermittent renewable energy sources.

Material degradation presents another formidable obstacle. Current state-of-the-art electrodes and electrolytes suffer from performance deterioration during long-term operation, with degradation rates typically ranging from 0.5% to 2% per 1000 hours—still considerably higher than the commercial target of less than 0.25%. This degradation stems from multiple mechanisms including chromium poisoning, nickel agglomeration in hydrogen electrodes, and delamination at electrode-electrolyte interfaces.

Scalability challenges persist in manufacturing processes. While laboratory cells demonstrate impressive performance metrics, translating these results to industrial-scale production while maintaining quality and performance consistency remains problematic. Current manufacturing techniques struggle with reproducibility issues and high rejection rates when scaling to larger cell areas and stack configurations.

System integration represents another significant barrier. The complex balance-of-plant components required for thermal management, gas handling, and electrical conversion add substantial costs and complexity to SOEC systems. Additionally, the integration of SOECs with downstream processes for hydrogen storage or synthetic fuel production introduces further technical complications that require optimization.

From a geographical perspective, SOEC technology development shows distinct regional characteristics. European efforts, particularly in Denmark, Germany, and France, focus heavily on integration with renewable energy systems. Asian research, led by Japan and increasingly China, emphasizes materials innovation and manufacturing scalability. North American programs concentrate on high-temperature co-electrolysis processes for syngas production.

Economic viability remains a critical challenge, with current SOEC system costs exceeding $1,000/kW, significantly higher than the $500/kW threshold generally considered necessary for commercial competitiveness. The high capital expenditure, coupled with limited operational experience and uncertain lifetime performance, creates substantial barriers to investment and deployment.

Current SOEC System Architectures and Materials

01 Electrode materials and structures for SOECs

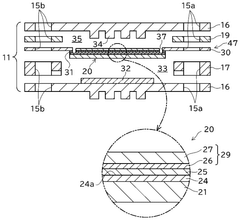

Various electrode materials and structures are used in solid oxide electrolysis cells to improve performance and durability. These include specialized cathode and anode materials that enhance electrochemical reactions, reduce degradation, and improve conductivity. Advanced electrode structures such as porous designs facilitate gas diffusion and increase active reaction sites, while composite electrodes combining multiple materials can provide synergistic benefits for electrolysis efficiency.- Electrode materials and structures for solid oxide electrolysis cells: Various electrode materials and structures are used in solid oxide electrolysis cells to enhance performance and durability. These include specialized cathode and anode materials that can withstand high operating temperatures while maintaining conductivity. Advanced electrode designs incorporate porous structures to facilitate gas diffusion and reaction sites, while composite electrodes combine multiple materials to optimize electrochemical performance. These innovations help improve the efficiency of hydrogen or syngas production through electrolysis.

- Electrolyte compositions for high-temperature operation: Specialized electrolyte materials are developed for solid oxide electrolysis cells that can operate efficiently at high temperatures. These electrolytes typically consist of ceramic materials with high ionic conductivity, such as yttria-stabilized zirconia (YSZ) or gadolinium-doped ceria (GDC). The composition and microstructure of these electrolytes are engineered to minimize resistance while maintaining mechanical stability at operating temperatures of 600-900°C, which is crucial for efficient electrolysis operation.

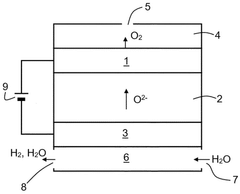

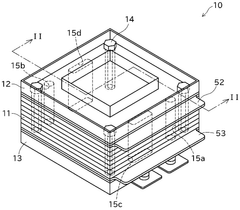

- System integration and stack design for solid oxide electrolysis: The integration of solid oxide electrolysis cells into complete systems involves specialized stack designs that optimize electrical connections, gas flow paths, and thermal management. These systems include components for gas handling, heat exchangers, and power electronics to control the electrolysis process. Advanced stack designs focus on minimizing internal resistance, ensuring uniform temperature distribution, and facilitating easy maintenance. These integrated systems are crucial for scaling up hydrogen or syngas production through high-temperature electrolysis.

- Reversible operation for energy storage applications: Solid oxide cells can be designed for reversible operation, functioning as both electrolysis cells (SOEC) and fuel cells (SOFC). This reversibility allows the systems to produce hydrogen or syngas when excess electricity is available and generate electricity when needed. The materials and structures must be optimized to withstand cycling between electrolysis and fuel cell modes while maintaining performance and durability. This capability makes solid oxide cells particularly valuable for grid-scale energy storage applications and integration with renewable energy sources.

- Co-electrolysis for syngas production: Solid oxide electrolysis cells can be used for co-electrolysis of steam and carbon dioxide to produce syngas (a mixture of hydrogen and carbon monoxide). This process requires specialized catalysts and operating conditions to facilitate the simultaneous reduction of both H2O and CO2. The syngas produced can serve as a feedstock for various synthetic fuel production processes. Co-electrolysis technology offers a pathway for carbon utilization and production of valuable chemical precursors using renewable electricity as the primary energy input.

02 Electrolyte compositions for high-temperature operation

Specialized electrolyte materials are developed for solid oxide electrolysis cells that can withstand high operating temperatures while maintaining ionic conductivity. These electrolytes typically include yttria-stabilized zirconia (YSZ), gadolinium-doped ceria (GDC), or other ceramic materials that facilitate oxygen ion transport. Innovations in electrolyte composition focus on reducing resistance, enhancing stability, and enabling operation at intermediate temperatures to improve overall system efficiency.Expand Specific Solutions03 System integration and stack design

Advanced stack designs and system integration approaches are crucial for solid oxide electrolysis cell performance. These include innovative cell stacking methods, sealing technologies, and interconnect designs that minimize electrical resistance and thermal stress. Integrated systems may incorporate heat recovery mechanisms, gas handling subsystems, and control electronics to optimize efficiency. Modular designs allow for scalability while maintaining thermal management and uniform gas distribution across the stack.Expand Specific Solutions04 High-efficiency hydrogen and syngas production

Solid oxide electrolysis cells are optimized for efficient production of hydrogen and synthesis gas through water splitting and co-electrolysis of water and carbon dioxide. Advanced catalysts and electrode materials enhance reaction kinetics while reducing energy requirements. Operating parameters such as temperature, pressure, and feed gas composition are carefully controlled to maximize conversion efficiency. These systems can achieve higher electrical efficiency compared to low-temperature electrolysis technologies, especially when integrated with renewable energy sources.Expand Specific Solutions05 Degradation mitigation and durability enhancement

Various approaches are employed to mitigate degradation and enhance the durability of solid oxide electrolysis cells during long-term operation. These include protective coatings for electrodes and interconnects that prevent chromium poisoning and other contamination mechanisms. Material modifications reduce thermal expansion mismatches and chemical reactivity between components. Advanced operating strategies, such as controlled current density and thermal cycling protocols, minimize stress and extend cell lifetime while maintaining performance.Expand Specific Solutions

Leading Organizations in SOEC Research and Commercialization

Solid oxide electrolysis cells (SOECs) are currently in the early commercialization phase of development, with the global market expected to reach $500 million by 2025 and grow at a CAGR of 15-20%. The technology has reached moderate maturity with several key players advancing innovations. Academic institutions like Tsinghua University, Ulsan National Institute of Science & Technology, and University of South Carolina are driving fundamental research, while commercial entities including DynElectro ApS, Storagenergy Technologies, and Precision Combustion are developing practical applications. Major corporations such as Toshiba, Nissan, and Hyundai are investing in SOEC technology for energy storage and hydrogen production. Chinese players like Sinopec and Wuhan Huake Fusai are rapidly expanding capabilities, positioning SOECs as a critical component in the global transition to renewable energy systems.

Battelle Energy Alliance LLC

Technical Solution: Battelle Energy Alliance has developed advanced solid oxide electrolysis cell (SOEC) technology through their management of Idaho National Laboratory. Their approach focuses on high-temperature electrolysis operating at 700-850°C, which significantly reduces electricity requirements for hydrogen production. Their innovative cell design incorporates specialized ceramic materials like yttria-stabilized zirconia (YSZ) electrolytes and nickel-based electrodes that demonstrate exceptional durability under extreme operating conditions. Battelle has pioneered reversible solid oxide cell systems that can function in both electrolysis and fuel cell modes, providing flexible energy storage solutions. Their integrated system architecture includes thermal management subsystems that utilize waste heat recovery to improve overall efficiency, achieving system efficiencies exceeding 90% when coupled with nuclear or renewable energy sources.

Strengths: Superior energy efficiency compared to low-temperature electrolysis; excellent integration capabilities with nuclear and renewable energy sources; demonstrated long-term durability in testing environments. Weaknesses: High capital costs; complex thermal management requirements; materials degradation challenges at sustained high temperatures.

DynElectro ApS

Technical Solution: DynElectro has developed a proprietary SOEC technology platform called "DynCell" that operates at intermediate temperatures (600-700°C), striking a balance between efficiency and material stability. Their cells utilize advanced composite electrodes with nanostructured catalysts that significantly reduce polarization resistance and enhance electrochemical performance. DynElectro's innovation includes a patented cell architecture that minimizes chromium poisoning and sulfur contamination, two common degradation mechanisms in SOECs. Their modular stack design enables scalable deployment from kilowatt to megawatt applications, with demonstrated degradation rates below 0.5% per 1000 hours of operation. DynElectro has successfully integrated their SOEC technology with dynamic load capabilities, allowing for responsive operation with fluctuating renewable energy inputs, making it particularly suitable for green hydrogen production and Power-to-X applications.

Strengths: Excellent dynamic operation capabilities with renewable energy sources; innovative materials that reduce degradation; modular design enabling flexible scaling. Weaknesses: Limited commercial-scale deployment history; higher manufacturing complexity due to specialized materials; requires precise thermal cycling protocols to prevent mechanical failure.

Critical Patents and Breakthroughs in SOEC Technology

Solid oxide electrolysis cell with cathode, and method

PatentWO2025056199A1

Innovation

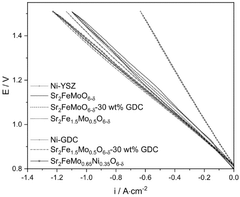

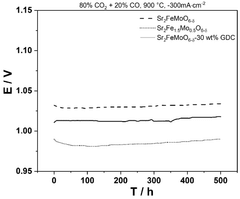

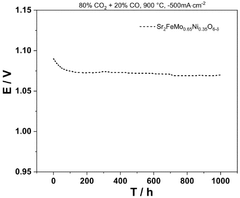

- A fixed oxide electrolysis cell design featuring a fuel electrode made from materials such as SR2FE2-xMo_xO6, which includes components like nickel, cobalt, and gadolinium ceroxide, and an electrolyte that allows for efficient gas permeability and ion conductivity.

Solid oxide electrolyzer cell and use of same

PatentWO2025105416A1

Innovation

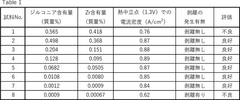

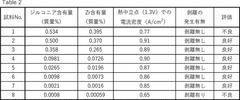

- The use of a solid oxide electrolysis cell with a cathode represented by the general formula ABO3, where A is La and Sr, and B is Co and Fe, and the air electrode containing ZrO2, with a Zr content of 7.4 × 10^−4 Mass% or more, helps to suppress peeling and current density decrease.

Integration Challenges with Renewable Energy Sources

The integration of Solid Oxide Electrolysis Cells (SOECs) with renewable energy sources presents significant technical challenges despite their promising potential for energy conversion and storage. The intermittent nature of renewable energy sources such as solar and wind creates operational difficulties for SOECs, which traditionally perform optimally under steady-state conditions. These fluctuations in power supply can lead to thermal cycling and mechanical stress on the ceramic components, potentially reducing cell lifespan and efficiency.

Thermal management represents a critical integration challenge. SOECs operate at high temperatures (700-900°C), requiring substantial energy for startup and shutdown procedures. When coupled with variable renewable energy inputs, maintaining optimal temperature ranges becomes technically complex and energy-intensive, reducing overall system efficiency. The development of rapid thermal response materials and advanced thermal management systems remains an ongoing research priority.

Grid-level integration poses additional challenges, particularly regarding response time and load-following capabilities. While renewable energy production can change rapidly based on environmental conditions, SOECs typically require gradual power adjustments to maintain structural integrity. This mismatch necessitates intermediate energy storage solutions or hybrid systems that can buffer the variability, adding complexity and cost to integrated systems.

Scale compatibility issues further complicate integration efforts. Renewable installations often operate at megawatt scales, while current SOEC technologies have been predominantly demonstrated at laboratory or small pilot scales. Scaling up SOEC systems to match renewable generation capacity involves addressing manufacturing challenges, system control complexities, and substantial capital investments.

The economic viability of integrated systems faces challenges from both technological and market perspectives. The high capital costs of SOECs, combined with additional expenses for integration components such as power electronics, thermal management systems, and control infrastructure, create significant barriers to commercial deployment. These costs must decrease substantially through technological advancement and manufacturing scale to compete with alternative energy storage and conversion technologies.

Regulatory frameworks and infrastructure limitations also present non-technical barriers to integration. Many existing energy systems lack the necessary infrastructure for hydrogen or syngas distribution, storage, and utilization. Additionally, current energy market structures often do not adequately value the flexibility and multi-vector energy services that integrated SOEC-renewable systems could provide, limiting economic incentives for deployment.

Thermal management represents a critical integration challenge. SOECs operate at high temperatures (700-900°C), requiring substantial energy for startup and shutdown procedures. When coupled with variable renewable energy inputs, maintaining optimal temperature ranges becomes technically complex and energy-intensive, reducing overall system efficiency. The development of rapid thermal response materials and advanced thermal management systems remains an ongoing research priority.

Grid-level integration poses additional challenges, particularly regarding response time and load-following capabilities. While renewable energy production can change rapidly based on environmental conditions, SOECs typically require gradual power adjustments to maintain structural integrity. This mismatch necessitates intermediate energy storage solutions or hybrid systems that can buffer the variability, adding complexity and cost to integrated systems.

Scale compatibility issues further complicate integration efforts. Renewable installations often operate at megawatt scales, while current SOEC technologies have been predominantly demonstrated at laboratory or small pilot scales. Scaling up SOEC systems to match renewable generation capacity involves addressing manufacturing challenges, system control complexities, and substantial capital investments.

The economic viability of integrated systems faces challenges from both technological and market perspectives. The high capital costs of SOECs, combined with additional expenses for integration components such as power electronics, thermal management systems, and control infrastructure, create significant barriers to commercial deployment. These costs must decrease substantially through technological advancement and manufacturing scale to compete with alternative energy storage and conversion technologies.

Regulatory frameworks and infrastructure limitations also present non-technical barriers to integration. Many existing energy systems lack the necessary infrastructure for hydrogen or syngas distribution, storage, and utilization. Additionally, current energy market structures often do not adequately value the flexibility and multi-vector energy services that integrated SOEC-renewable systems could provide, limiting economic incentives for deployment.

Economic Viability and Cost Reduction Strategies

The economic viability of Solid Oxide Electrolysis Cells (SOECs) remains a critical challenge despite their promising technological advantages. Current SOEC systems face high capital expenditure (CAPEX) costs, ranging from $800-1,500/kW, significantly higher than competing hydrogen production technologies. This cost barrier primarily stems from expensive ceramic materials, complex manufacturing processes, and the need for high-temperature operation systems.

Material innovation represents a primary cost reduction pathway. Research indicates that replacing traditional ceramic materials with lower-cost alternatives while maintaining performance could reduce material costs by 30-40%. Specifically, developing composite electrodes with reduced rare earth element content and exploring alternative manufacturing techniques for electrolyte production show particular promise.

Manufacturing scale-up presents another significant opportunity for cost reduction. Current SOEC production remains largely semi-automated and batch-oriented. Industry analyses suggest that transitioning to fully automated production lines and achieving economies of scale could potentially reduce manufacturing costs by 45-60% over the next decade. Companies pioneering mass production techniques have already demonstrated 25% cost reductions in pilot programs.

Operational efficiency improvements offer additional economic benefits. Extending cell lifetime from current averages of 20,000-30,000 hours to 50,000+ hours would substantially improve lifetime economics. Furthermore, reducing degradation rates from current 1-2% per 1,000 hours to below 0.5% would significantly enhance long-term operational viability. These improvements would directly impact levelized cost of hydrogen (LCOH) metrics.

Integration with renewable energy sources creates compelling economic synergies. When coupled with low-cost renewable electricity (below $30/MWh), SOECs can achieve hydrogen production costs approaching $3-4/kg, becoming competitive with conventional production methods. Additionally, utilizing waste heat from industrial processes could reduce operational energy requirements by 15-25%, further improving economics.

Policy support mechanisms remain crucial for near-term deployment. Carbon pricing, production tax credits, and direct subsidies significantly impact economic calculations. Modeling suggests that carbon prices above $50/ton or production incentives of $1-2/kg hydrogen could accelerate SOEC adoption by 5-7 years compared to purely market-driven scenarios.

The projected learning curve for SOECs indicates potential for 65-75% cost reduction by 2035 with sustained deployment and research investment. This trajectory would position SOECs as economically viable solutions for large-scale energy storage and industrial decarbonization applications, particularly in regions with abundant renewable energy resources and supportive policy frameworks.

Material innovation represents a primary cost reduction pathway. Research indicates that replacing traditional ceramic materials with lower-cost alternatives while maintaining performance could reduce material costs by 30-40%. Specifically, developing composite electrodes with reduced rare earth element content and exploring alternative manufacturing techniques for electrolyte production show particular promise.

Manufacturing scale-up presents another significant opportunity for cost reduction. Current SOEC production remains largely semi-automated and batch-oriented. Industry analyses suggest that transitioning to fully automated production lines and achieving economies of scale could potentially reduce manufacturing costs by 45-60% over the next decade. Companies pioneering mass production techniques have already demonstrated 25% cost reductions in pilot programs.

Operational efficiency improvements offer additional economic benefits. Extending cell lifetime from current averages of 20,000-30,000 hours to 50,000+ hours would substantially improve lifetime economics. Furthermore, reducing degradation rates from current 1-2% per 1,000 hours to below 0.5% would significantly enhance long-term operational viability. These improvements would directly impact levelized cost of hydrogen (LCOH) metrics.

Integration with renewable energy sources creates compelling economic synergies. When coupled with low-cost renewable electricity (below $30/MWh), SOECs can achieve hydrogen production costs approaching $3-4/kg, becoming competitive with conventional production methods. Additionally, utilizing waste heat from industrial processes could reduce operational energy requirements by 15-25%, further improving economics.

Policy support mechanisms remain crucial for near-term deployment. Carbon pricing, production tax credits, and direct subsidies significantly impact economic calculations. Modeling suggests that carbon prices above $50/ton or production incentives of $1-2/kg hydrogen could accelerate SOEC adoption by 5-7 years compared to purely market-driven scenarios.

The projected learning curve for SOECs indicates potential for 65-75% cost reduction by 2035 with sustained deployment and research investment. This trajectory would position SOECs as economically viable solutions for large-scale energy storage and industrial decarbonization applications, particularly in regions with abundant renewable energy resources and supportive policy frameworks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!