Solid oxide electrolysis cells strategies for industrial scalability

OCT 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SOEC Technology Background and Objectives

Solid oxide electrolysis cells (SOECs) represent a transformative technology in the realm of renewable energy conversion and storage systems. Emerging from solid oxide fuel cell (SOFC) research in the mid-20th century, SOECs have evolved significantly over the past decades, transitioning from laboratory curiosities to promising industrial solutions. The fundamental principle of SOECs involves the electrochemical conversion of steam and/or carbon dioxide into hydrogen and/or carbon monoxide using electrical energy, effectively storing renewable electricity in chemical form.

The technology has witnessed accelerated development since the early 2000s, driven by the global push toward decarbonization and renewable energy integration. Initially focused on hydrogen production through steam electrolysis, SOEC technology has expanded to include co-electrolysis of H2O and CO2, enabling synthetic fuel production pathways that align with circular carbon economy principles.

Current technological trajectories indicate a convergence toward more durable materials, higher operating efficiencies, and scalable manufacturing processes. The evolution from button cells to increasingly larger active areas demonstrates the field's progression toward industrial relevance. Recent breakthroughs in electrode materials and cell architectures have substantially improved performance metrics, with current density capabilities increasing tenfold over the past decade.

The primary technical objectives for SOEC industrial scalability center on four critical dimensions: durability, efficiency, cost reduction, and manufacturing scalability. Achieving operational lifetimes exceeding 40,000 hours under dynamic loading conditions remains a paramount challenge. Simultaneously, electrical efficiency targets of over 85% (lower heating value basis) are essential for economic viability in competitive energy markets.

Cost reduction pathways focus on materials innovation, with particular emphasis on reducing or eliminating critical raw materials while maintaining performance. Manufacturing scalability objectives include transitioning from batch processing to continuous production methods capable of gigawatt-scale annual output, with standardized quality control protocols.

Beyond technical parameters, the broader objective encompasses integration with renewable energy sources and existing industrial infrastructure. This includes developing load-following capabilities to accommodate the intermittent nature of renewable electricity generation and ensuring compatibility with downstream processes in chemical production, refining, and energy storage applications.

The ultimate goal for SOEC technology development is establishing a commercially viable, environmentally sustainable platform for large-scale energy conversion that can significantly contribute to industrial decarbonization efforts while creating new value chains in the hydrogen and synthetic fuels economy.

The technology has witnessed accelerated development since the early 2000s, driven by the global push toward decarbonization and renewable energy integration. Initially focused on hydrogen production through steam electrolysis, SOEC technology has expanded to include co-electrolysis of H2O and CO2, enabling synthetic fuel production pathways that align with circular carbon economy principles.

Current technological trajectories indicate a convergence toward more durable materials, higher operating efficiencies, and scalable manufacturing processes. The evolution from button cells to increasingly larger active areas demonstrates the field's progression toward industrial relevance. Recent breakthroughs in electrode materials and cell architectures have substantially improved performance metrics, with current density capabilities increasing tenfold over the past decade.

The primary technical objectives for SOEC industrial scalability center on four critical dimensions: durability, efficiency, cost reduction, and manufacturing scalability. Achieving operational lifetimes exceeding 40,000 hours under dynamic loading conditions remains a paramount challenge. Simultaneously, electrical efficiency targets of over 85% (lower heating value basis) are essential for economic viability in competitive energy markets.

Cost reduction pathways focus on materials innovation, with particular emphasis on reducing or eliminating critical raw materials while maintaining performance. Manufacturing scalability objectives include transitioning from batch processing to continuous production methods capable of gigawatt-scale annual output, with standardized quality control protocols.

Beyond technical parameters, the broader objective encompasses integration with renewable energy sources and existing industrial infrastructure. This includes developing load-following capabilities to accommodate the intermittent nature of renewable electricity generation and ensuring compatibility with downstream processes in chemical production, refining, and energy storage applications.

The ultimate goal for SOEC technology development is establishing a commercially viable, environmentally sustainable platform for large-scale energy conversion that can significantly contribute to industrial decarbonization efforts while creating new value chains in the hydrogen and synthetic fuels economy.

Market Demand Analysis for Green Hydrogen Production

The global market for green hydrogen production is experiencing unprecedented growth, driven by the urgent need to decarbonize energy-intensive industries and meet ambitious climate targets. Current projections indicate the green hydrogen market could reach $300 billion by 2050, with an annual growth rate exceeding 50% in the coming decade. Solid oxide electrolysis cells (SOECs) represent a critical enabling technology within this expanding market, offering higher efficiency compared to conventional alkaline and PEM electrolyzers.

Industrial sectors including steel manufacturing, ammonia production, refining, and heavy transportation are actively seeking viable pathways to reduce carbon emissions, with hydrogen increasingly viewed as the preferred solution. The steel industry alone, responsible for approximately 7-9% of global CO2 emissions, represents a substantial potential market for SOEC-produced hydrogen, with major producers like ArcelorMittal and ThyssenKrupp announcing hydrogen-based steel production initiatives.

Geographically, Europe leads demand for green hydrogen technologies, supported by the European Hydrogen Strategy targeting 40GW of electrolyzer capacity by 2030. Asia-Pacific follows closely, with China, Japan, and South Korea making significant investments in hydrogen infrastructure. North America is rapidly accelerating adoption through initiatives like the U.S. Hydrogen Earthshot program.

Market analysis reveals that cost remains the primary barrier to widespread adoption. Current green hydrogen production costs range between $3-8/kg, significantly higher than gray hydrogen at $1-2/kg. However, SOEC technology offers a promising cost reduction pathway through higher electrical efficiency and potential for heat integration, potentially reducing production costs by 20-30% compared to other electrolysis technologies.

Policy support is increasingly robust across major economies. The EU's Innovation Fund, Japan's Green Growth Strategy, and the U.S. Inflation Reduction Act all provide substantial financial incentives for green hydrogen production. These policy frameworks are expected to accelerate market growth by reducing investment risks and improving project economics.

Customer requirements are evolving rapidly, with end-users demanding scalable solutions that can be deployed at industrial levels (100+ MW). This presents both challenges and opportunities for SOEC technology, which must transition from laboratory and pilot scales to full industrial implementation. Market research indicates that customers prioritize reliability, durability (20,000+ operating hours), and integration capabilities with existing industrial processes.

The transportation sector represents an emerging market segment, with hydrogen fuel cell vehicles gaining traction in heavy-duty applications. Major automotive and logistics companies are investing in hydrogen infrastructure, creating additional demand for cost-effective green hydrogen production technologies like advanced SOECs.

Industrial sectors including steel manufacturing, ammonia production, refining, and heavy transportation are actively seeking viable pathways to reduce carbon emissions, with hydrogen increasingly viewed as the preferred solution. The steel industry alone, responsible for approximately 7-9% of global CO2 emissions, represents a substantial potential market for SOEC-produced hydrogen, with major producers like ArcelorMittal and ThyssenKrupp announcing hydrogen-based steel production initiatives.

Geographically, Europe leads demand for green hydrogen technologies, supported by the European Hydrogen Strategy targeting 40GW of electrolyzer capacity by 2030. Asia-Pacific follows closely, with China, Japan, and South Korea making significant investments in hydrogen infrastructure. North America is rapidly accelerating adoption through initiatives like the U.S. Hydrogen Earthshot program.

Market analysis reveals that cost remains the primary barrier to widespread adoption. Current green hydrogen production costs range between $3-8/kg, significantly higher than gray hydrogen at $1-2/kg. However, SOEC technology offers a promising cost reduction pathway through higher electrical efficiency and potential for heat integration, potentially reducing production costs by 20-30% compared to other electrolysis technologies.

Policy support is increasingly robust across major economies. The EU's Innovation Fund, Japan's Green Growth Strategy, and the U.S. Inflation Reduction Act all provide substantial financial incentives for green hydrogen production. These policy frameworks are expected to accelerate market growth by reducing investment risks and improving project economics.

Customer requirements are evolving rapidly, with end-users demanding scalable solutions that can be deployed at industrial levels (100+ MW). This presents both challenges and opportunities for SOEC technology, which must transition from laboratory and pilot scales to full industrial implementation. Market research indicates that customers prioritize reliability, durability (20,000+ operating hours), and integration capabilities with existing industrial processes.

The transportation sector represents an emerging market segment, with hydrogen fuel cell vehicles gaining traction in heavy-duty applications. Major automotive and logistics companies are investing in hydrogen infrastructure, creating additional demand for cost-effective green hydrogen production technologies like advanced SOECs.

SOEC Development Status and Technical Barriers

Solid oxide electrolysis cells (SOECs) have demonstrated significant potential for efficient hydrogen production and carbon dioxide conversion at laboratory scale. However, the transition to industrial-scale implementation faces substantial technical barriers. Current SOEC systems typically operate at capacities of 1-10 kW in research environments, while industrial applications require multi-MW systems with integrated heat management and robust operation.

Material degradation remains a critical challenge for SOEC scalability. The high operating temperatures (700-850°C) accelerate degradation mechanisms including chromium poisoning at air electrodes, nickel agglomeration at fuel electrodes, and interdiffusion at electrode-electrolyte interfaces. State-of-the-art SOECs exhibit degradation rates of 1-2% per 1000 hours, significantly higher than the 0.1-0.2% target needed for commercial viability over 5+ year lifespans.

Stack sealing technology presents another major barrier. Current glass-ceramic and compressive seals struggle to maintain integrity during thermal cycling at industrial scale. Thermal expansion mismatches between components lead to mechanical stress and eventual failure points. Recent developments in compliant seals show promise but require further optimization for large-format stacks exceeding 100 cells.

Manufacturing scalability faces limitations in both materials processing and assembly techniques. Conventional ceramic processing methods like tape casting and screen printing exhibit inconsistencies when scaled beyond laboratory dimensions. The precision required for thin electrolyte layers (10-20 μm) becomes increasingly difficult to maintain across larger surface areas, resulting in performance variability and yield issues.

System integration complexity increases exponentially with scale. Thermal management becomes particularly challenging as stack size increases, with temperature gradients across large-format stacks causing thermal stresses and performance heterogeneity. Current thermal models accurately predict behavior in small stacks but lose fidelity at industrial scales where flow distribution and heat transfer mechanisms become more complex.

Economic barriers compound technical challenges. Current SOEC stack manufacturing costs exceed $2000/kW, significantly higher than the $500/kW threshold considered viable for green hydrogen production. Material costs constitute approximately 60% of stack expenses, with rare earth elements in electrodes and specialized interconnect materials representing major cost drivers.

Standardization remains underdeveloped across the SOEC industry. Unlike PEM electrolyzers, which benefit from established testing protocols and performance metrics, SOEC technology lacks unified standards for durability assessment, performance reporting, and safety requirements. This hampers comparative analysis between different technological approaches and slows industry-wide progress toward commercialization.

Material degradation remains a critical challenge for SOEC scalability. The high operating temperatures (700-850°C) accelerate degradation mechanisms including chromium poisoning at air electrodes, nickel agglomeration at fuel electrodes, and interdiffusion at electrode-electrolyte interfaces. State-of-the-art SOECs exhibit degradation rates of 1-2% per 1000 hours, significantly higher than the 0.1-0.2% target needed for commercial viability over 5+ year lifespans.

Stack sealing technology presents another major barrier. Current glass-ceramic and compressive seals struggle to maintain integrity during thermal cycling at industrial scale. Thermal expansion mismatches between components lead to mechanical stress and eventual failure points. Recent developments in compliant seals show promise but require further optimization for large-format stacks exceeding 100 cells.

Manufacturing scalability faces limitations in both materials processing and assembly techniques. Conventional ceramic processing methods like tape casting and screen printing exhibit inconsistencies when scaled beyond laboratory dimensions. The precision required for thin electrolyte layers (10-20 μm) becomes increasingly difficult to maintain across larger surface areas, resulting in performance variability and yield issues.

System integration complexity increases exponentially with scale. Thermal management becomes particularly challenging as stack size increases, with temperature gradients across large-format stacks causing thermal stresses and performance heterogeneity. Current thermal models accurately predict behavior in small stacks but lose fidelity at industrial scales where flow distribution and heat transfer mechanisms become more complex.

Economic barriers compound technical challenges. Current SOEC stack manufacturing costs exceed $2000/kW, significantly higher than the $500/kW threshold considered viable for green hydrogen production. Material costs constitute approximately 60% of stack expenses, with rare earth elements in electrodes and specialized interconnect materials representing major cost drivers.

Standardization remains underdeveloped across the SOEC industry. Unlike PEM electrolyzers, which benefit from established testing protocols and performance metrics, SOEC technology lacks unified standards for durability assessment, performance reporting, and safety requirements. This hampers comparative analysis between different technological approaches and slows industry-wide progress toward commercialization.

Current Industrial Scaling Solutions for SOECs

01 Cell design and materials for industrial scale SOECs

Industrial scalability of solid oxide electrolysis cells (SOECs) depends significantly on cell design and material selection. Advanced materials such as specialized ceramics and composite electrodes can enhance durability and performance at industrial scales. Optimized cell geometries and configurations help manage thermal stresses and improve efficiency when scaling up. These design considerations are crucial for maintaining performance while transitioning from laboratory to industrial applications.- Cell stack design and manufacturing for industrial scale: Industrial scalability of solid oxide electrolysis cells (SOECs) requires optimized stack designs that can be manufactured efficiently. This includes developing modular stack configurations, improving sealing technologies, and enhancing interconnect materials to ensure reliable operation at high temperatures. Advanced manufacturing techniques such as tape casting, screen printing, and co-firing processes enable mass production of cell components with consistent quality, which is essential for industrial deployment.

- Materials development for durability and performance: The industrial scalability of SOECs depends significantly on the development of advanced materials that can withstand harsh operating conditions while maintaining high performance. This includes research on robust electrolyte materials, high-performance electrodes with enhanced catalytic activity, and degradation-resistant components. Novel composite materials and protective coatings are being developed to extend cell lifetime and maintain efficiency during long-term operation, which is crucial for commercial viability.

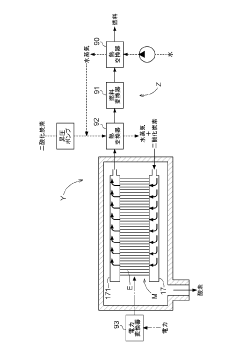

- System integration and process optimization: For industrial implementation, SOECs must be effectively integrated into larger energy systems. This involves optimizing thermal management strategies, developing efficient balance-of-plant components, and creating control systems that can handle variable inputs. Process integration considerations include heat recovery systems, gas handling equipment, and product purification technologies. These system-level optimizations are essential for achieving economically viable operation at industrial scale.

- Scale-up methodologies and production techniques: Transitioning from laboratory-scale to industrial-scale SOEC production requires specialized scale-up methodologies. This includes developing automated manufacturing lines, quality control protocols, and standardized testing procedures. Innovations in cell fabrication techniques, such as additive manufacturing and roll-to-roll processing, are being explored to increase production capacity while maintaining cell performance. Cost-effective production methods are critical for commercial deployment of SOEC technology.

- Economic and operational considerations for commercialization: The commercial viability of industrial-scale SOEC systems depends on economic factors such as capital costs, operational expenses, and market conditions. Research focuses on reducing material costs, improving energy efficiency, and extending operational lifetimes to enhance economic competitiveness. Additionally, operational considerations such as maintenance requirements, system flexibility, and integration with renewable energy sources are being addressed to facilitate widespread industrial adoption of SOEC technology.

02 Stack and system integration for large-scale deployment

Effective stack design and system integration are essential for industrial SOEC deployment. This includes developing robust sealing technologies, interconnect systems, and thermal management solutions that can withstand high-temperature operation at scale. Integration challenges involve balancing electrical connections, gas distribution, and mechanical stability across multiple cells while maintaining uniform performance. Advanced stack architectures enable higher throughput and more efficient operation in industrial settings.Expand Specific Solutions03 Manufacturing processes for mass production

Scalable manufacturing processes are critical for industrial SOEC deployment. Techniques such as tape casting, screen printing, and co-sintering must be adapted for high-volume production while maintaining quality and consistency. Automated assembly methods and quality control systems help reduce defects and variability in mass-produced cells. Cost-effective manufacturing approaches that minimize expensive materials and complex processing steps are essential for commercial viability.Expand Specific Solutions04 Durability and degradation management at industrial scale

Long-term durability is a key challenge for industrial SOEC implementation. Managing degradation mechanisms such as electrode delamination, chromium poisoning, and microstructural changes becomes more critical at scale. Advanced monitoring systems and operational strategies can help extend cell lifetime under industrial conditions. Developing accelerated testing protocols that accurately predict long-term performance in real-world industrial environments is essential for commercial deployment.Expand Specific Solutions05 Economic and operational considerations for commercialization

Commercial viability of industrial SOEC systems depends on economic and operational factors beyond technical performance. This includes optimizing energy efficiency, reducing capital costs, and developing flexible operation strategies that can respond to variable energy inputs. Integration with renewable energy sources and existing industrial processes requires careful system design and control strategies. Regulatory frameworks, market incentives, and supply chain considerations also significantly impact the industrial scalability of SOEC technology.Expand Specific Solutions

Major Industry Players and Competitive Landscape

The solid oxide electrolysis cells (SOEC) market is in an early growth phase, with increasing industrial interest driven by decarbonization goals. The global market size is projected to expand significantly as hydrogen economy develops, though currently remains relatively modest. Technical maturity varies across players, with academic institutions like Technical University of Denmark, Tsinghua University, and Northwestern University leading fundamental research, while industrial entities including Toshiba, Hyundai, Samsung, and Kyocera focus on scalable applications. Companies like Commissariat à l'énergie atomique and KIST are bridging research-to-commercialization gaps. The competitive landscape shows regional clusters in Asia (particularly Japan, China, South Korea), Europe, and North America, with increasing collaboration between academic and industrial players to overcome manufacturing scale-up challenges and cost barriers.

Technical University of Denmark

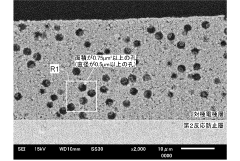

Technical Solution: Technical University of Denmark (DTU) has developed advanced solid oxide electrolysis cell technologies focusing on industrial scalability through their comprehensive cell and stack design approach. Their research centers on improving electrode microstructures and developing novel materials to enhance durability and efficiency. DTU has pioneered the use of infiltration techniques to create nano-structured electrodes that significantly improve electrochemical performance while maintaining long-term stability. Their scalable manufacturing processes include tape casting and screen printing methods optimized for mass production. DTU has also developed innovative sealing solutions using glass-ceramic composites that maintain integrity during thermal cycling, addressing one of the key challenges in SOEC stack manufacturing. Their systems integration approach incorporates thermal management strategies that enable efficient heat recovery and utilization, critical for industrial implementation.

Strengths: Strong academic research foundation with extensive experimental facilities; collaborative approach with industry partners enables practical implementation; advanced materials expertise. Weaknesses: As an academic institution, faces challenges in direct commercialization; requires industrial partnerships to achieve full-scale manufacturing implementation.

Toshiba Energy Systems & Solutions Corp.

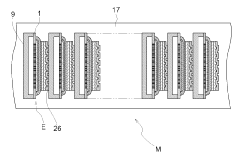

Technical Solution: Toshiba Energy Systems & Solutions has developed a comprehensive industrial scalability strategy for solid oxide electrolysis cells centered on their proprietary cell architecture and manufacturing processes. Their approach focuses on high-temperature co-electrolysis of steam and CO2 to produce syngas, with demonstrated system efficiency exceeding 80%. Toshiba has implemented advanced ceramic processing techniques including tape casting and screen printing that enable consistent large-scale production with tight quality control parameters. Their stack design incorporates innovative interconnect materials with protective coatings that significantly reduce chromium poisoning and extend operational lifetimes beyond 20,000 hours. Toshiba's industrial implementation strategy includes modular system architecture that allows for incremental capacity expansion and integration with existing industrial infrastructure. Their manufacturing process incorporates automated quality control systems using machine vision and AI-based defect detection to maintain consistent cell performance across production batches.

Strengths: Extensive industrial manufacturing expertise; established supply chain relationships; strong system integration capabilities with existing energy infrastructure. Weaknesses: Higher capital costs compared to some competitors; technology primarily optimized for specific applications rather than universal deployment.

Critical Patents and Technical Literature in SOEC Scaling

Solid oxide electrolysis cell, and method and system for operating same

PatentWO2020196236A1

Innovation

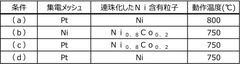

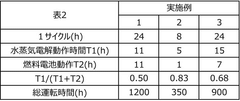

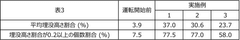

- A method for operating a solid oxide electrolytic cell with a hydrogen electrode composed of a mixed electron-ion conductive oxide, featuring a catalyst layer with Ni-containing particles dispersed on a porous body, and an alternating operation mode between steam electrolysis and fuel cell operation to suppress electrode deterioration.

Solid oxide type electrolysis cell, manufacturing method for solid oxide type electrolysis cell, solid oxide type electrolytic module, electrochemical device and energy system

PatentPendingJP2023144948A

Innovation

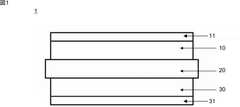

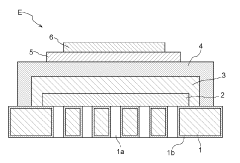

- A solid oxide electrolytic cell design with specific pore configurations in the electrode layers, including micron- and nano-order pores, and a reaction prevention layer to manage oxygen release and prevent peeling, supported by a metal substrate to maintain structural integrity.

Cost-Performance Analysis of SOEC Manufacturing Methods

The manufacturing cost structure of Solid Oxide Electrolysis Cells (SOECs) represents a critical factor in determining their industrial scalability. Current manufacturing methods exhibit significant variations in cost-performance ratios, with cell production costs ranging from $500-2,000/kW depending on production volume and technological maturity. Material selection constitutes approximately 40-60% of total manufacturing costs, with ceramic electrolytes like yttria-stabilized zirconia (YSZ) and electrodes made from nickel-based cermets representing major cost components.

Traditional manufacturing techniques such as tape casting and screen printing offer lower capital investment requirements but result in higher per-unit costs at scale. These methods typically achieve production rates of 10-100 cells per day with moderate yield rates of 80-90%. Labor costs remain significant, accounting for 15-25% of total manufacturing expenses in these conventional approaches.

Advanced manufacturing methods including plasma spraying and additive manufacturing demonstrate promising cost reduction potential at industrial scales. These technologies can reduce material waste by 30-50% compared to conventional methods and decrease processing time by up to 70%. However, they require substantial initial capital investment, with equipment costs ranging from $1-5 million for industrial-scale implementation.

Energy consumption during manufacturing represents another significant cost factor, particularly during high-temperature sintering processes (1200-1400°C) required for cell fabrication. Modern energy-efficient kilns and optimized thermal cycles can reduce energy costs by 20-30%, significantly impacting overall production economics when scaled to industrial volumes.

Quality control processes contribute 5-15% to manufacturing costs but directly influence cell performance and longevity. Advanced in-line inspection systems utilizing machine vision and impedance spectroscopy can reduce defect rates from typical 5-10% to below 3%, improving overall cost-performance metrics despite their implementation costs.

Economic analysis indicates that achieving cost parity with competing hydrogen production technologies requires manufacturing scale of at least 100 MW annual production capacity. At this scale, SOEC manufacturing costs could potentially decrease to $300-400/kW, approaching commercial viability thresholds. The learning curve effect suggests a 15-20% cost reduction with each doubling of production capacity, highlighting the importance of scaled manufacturing.

Automation represents a critical pathway to cost reduction, with fully automated production lines potentially reducing labor costs by 60-80% while improving consistency. The capital expenditure for such automation ranges from $5-20 million depending on production capacity but offers payback periods of 2-4 years at industrial production volumes.

Traditional manufacturing techniques such as tape casting and screen printing offer lower capital investment requirements but result in higher per-unit costs at scale. These methods typically achieve production rates of 10-100 cells per day with moderate yield rates of 80-90%. Labor costs remain significant, accounting for 15-25% of total manufacturing expenses in these conventional approaches.

Advanced manufacturing methods including plasma spraying and additive manufacturing demonstrate promising cost reduction potential at industrial scales. These technologies can reduce material waste by 30-50% compared to conventional methods and decrease processing time by up to 70%. However, they require substantial initial capital investment, with equipment costs ranging from $1-5 million for industrial-scale implementation.

Energy consumption during manufacturing represents another significant cost factor, particularly during high-temperature sintering processes (1200-1400°C) required for cell fabrication. Modern energy-efficient kilns and optimized thermal cycles can reduce energy costs by 20-30%, significantly impacting overall production economics when scaled to industrial volumes.

Quality control processes contribute 5-15% to manufacturing costs but directly influence cell performance and longevity. Advanced in-line inspection systems utilizing machine vision and impedance spectroscopy can reduce defect rates from typical 5-10% to below 3%, improving overall cost-performance metrics despite their implementation costs.

Economic analysis indicates that achieving cost parity with competing hydrogen production technologies requires manufacturing scale of at least 100 MW annual production capacity. At this scale, SOEC manufacturing costs could potentially decrease to $300-400/kW, approaching commercial viability thresholds. The learning curve effect suggests a 15-20% cost reduction with each doubling of production capacity, highlighting the importance of scaled manufacturing.

Automation represents a critical pathway to cost reduction, with fully automated production lines potentially reducing labor costs by 60-80% while improving consistency. The capital expenditure for such automation ranges from $5-20 million depending on production capacity but offers payback periods of 2-4 years at industrial production volumes.

Energy Policy Impacts on SOEC Commercialization

Energy policies across the globe significantly influence the commercialization trajectory of Solid Oxide Electrolysis Cell (SOEC) technology. Government incentives for renewable energy integration and carbon reduction have created favorable conditions for SOEC development. The European Union's Green Deal and Hydrogen Strategy explicitly support hydrogen production technologies, allocating substantial funding for SOEC research and demonstration projects. Similarly, the United States' Inflation Reduction Act provides tax credits for clean hydrogen production, effectively reducing the economic barriers to SOEC deployment.

Carbon pricing mechanisms, implemented in various forms worldwide, enhance the economic competitiveness of SOEC technology by internalizing the environmental costs of conventional hydrogen production methods. The EU Emissions Trading System (ETS) and carbon taxes in countries like Canada and Sweden create financial incentives for industries to adopt low-carbon technologies like SOECs. These policy instruments effectively narrow the cost gap between green hydrogen from electrolysis and gray hydrogen from fossil fuels.

Regulatory frameworks for grid integration also play a crucial role in SOEC commercialization. Policies allowing electrolyzers to participate in grid balancing services create additional revenue streams for SOEC operators. Countries like Germany and Denmark have implemented regulatory sandboxes that permit experimental business models for electrolysis, facilitating market entry for innovative SOEC applications.

Public procurement policies represent another powerful lever for SOEC market development. Government commitments to purchase green hydrogen for public transportation, heating of public buildings, or industrial processes create guaranteed demand that reduces investment risks. The H2Global initiative in Germany exemplifies this approach by establishing a double auction mechanism to bridge the cost gap between green hydrogen production and market prices.

International cooperation frameworks further accelerate SOEC commercialization through knowledge sharing and harmonized standards. The International Partnership for Hydrogen and Fuel Cells in the Economy (IPHE) and Mission Innovation's Clean Hydrogen Mission coordinate research efforts and develop common certification schemes that reduce market fragmentation and enable global SOEC deployment.

However, policy inconsistencies and regulatory uncertainties remain significant barriers. The lack of standardized definitions for green hydrogen across jurisdictions creates market confusion. Additionally, permitting processes for large-scale electrolysis facilities often involve multiple authorities with overlapping responsibilities, resulting in delays that impede industrial scalability. Addressing these policy challenges requires coordinated efforts across government departments and international cooperation to create a coherent regulatory environment conducive to SOEC commercialization at industrial scale.

Carbon pricing mechanisms, implemented in various forms worldwide, enhance the economic competitiveness of SOEC technology by internalizing the environmental costs of conventional hydrogen production methods. The EU Emissions Trading System (ETS) and carbon taxes in countries like Canada and Sweden create financial incentives for industries to adopt low-carbon technologies like SOECs. These policy instruments effectively narrow the cost gap between green hydrogen from electrolysis and gray hydrogen from fossil fuels.

Regulatory frameworks for grid integration also play a crucial role in SOEC commercialization. Policies allowing electrolyzers to participate in grid balancing services create additional revenue streams for SOEC operators. Countries like Germany and Denmark have implemented regulatory sandboxes that permit experimental business models for electrolysis, facilitating market entry for innovative SOEC applications.

Public procurement policies represent another powerful lever for SOEC market development. Government commitments to purchase green hydrogen for public transportation, heating of public buildings, or industrial processes create guaranteed demand that reduces investment risks. The H2Global initiative in Germany exemplifies this approach by establishing a double auction mechanism to bridge the cost gap between green hydrogen production and market prices.

International cooperation frameworks further accelerate SOEC commercialization through knowledge sharing and harmonized standards. The International Partnership for Hydrogen and Fuel Cells in the Economy (IPHE) and Mission Innovation's Clean Hydrogen Mission coordinate research efforts and develop common certification schemes that reduce market fragmentation and enable global SOEC deployment.

However, policy inconsistencies and regulatory uncertainties remain significant barriers. The lack of standardized definitions for green hydrogen across jurisdictions creates market confusion. Additionally, permitting processes for large-scale electrolysis facilities often involve multiple authorities with overlapping responsibilities, resulting in delays that impede industrial scalability. Addressing these policy challenges requires coordinated efforts across government departments and international cooperation to create a coherent regulatory environment conducive to SOEC commercialization at industrial scale.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!