Comparative efficiency of solid oxide electrolysis cells in power generation

OCT 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SOEC Technology Background and Objectives

Solid Oxide Electrolysis Cells (SOECs) represent a transformative technology in the energy landscape, evolving from their initial conceptualization in the mid-20th century to becoming a promising solution for efficient power generation and energy storage. The fundamental principle of SOECs involves the electrochemical conversion of water and carbon dioxide into hydrogen, carbon monoxide, and oxygen using solid oxide electrolytes at elevated temperatures (typically 600-900°C). This high-temperature operation enables SOECs to achieve superior thermodynamic efficiency compared to low-temperature electrolysis technologies.

The historical trajectory of SOEC development has been marked by significant advancements in materials science, particularly in the development of more durable and conductive ceramic electrolytes. Early iterations faced substantial challenges related to material degradation and limited operational lifespans. However, recent breakthroughs in perovskite-structured materials and composite electrodes have substantially enhanced both performance and durability metrics.

Current technological objectives for SOEC research center on improving electrical efficiency, extending operational lifetimes, and reducing manufacturing costs to enhance commercial viability. Specifically, researchers aim to achieve electrical efficiencies exceeding 90% (higher heating value basis), operational lifespans of 40,000+ hours, and capital cost reductions below $500/kW to compete effectively with alternative power generation technologies.

The comparative efficiency advantage of SOECs stems from their ability to utilize waste heat from industrial processes or integrate with renewable energy sources, creating highly efficient energy conversion pathways. When operated in reverse mode as fuel cells, they can generate electricity with theoretical efficiencies approaching 70-80%, substantially higher than conventional combustion-based power generation systems limited by Carnot efficiency constraints.

Global research trends indicate accelerating interest in SOEC technology, with annual publication rates increasing by approximately 15% year-over-year since 2015. This growth reflects recognition of SOECs' potential role in future energy systems, particularly in contexts requiring grid-scale energy storage, sector coupling between electricity and gas networks, and decarbonization of industrial processes requiring high-temperature heat.

The technology evolution trajectory suggests SOECs are approaching a critical inflection point, transitioning from laboratory-scale demonstrations to early commercial deployment. This transition is supported by complementary advances in renewable energy generation, creating synergistic opportunities for integrated energy systems that leverage the bidirectional operation capability of solid oxide cells for both power generation and energy storage functions.

The historical trajectory of SOEC development has been marked by significant advancements in materials science, particularly in the development of more durable and conductive ceramic electrolytes. Early iterations faced substantial challenges related to material degradation and limited operational lifespans. However, recent breakthroughs in perovskite-structured materials and composite electrodes have substantially enhanced both performance and durability metrics.

Current technological objectives for SOEC research center on improving electrical efficiency, extending operational lifetimes, and reducing manufacturing costs to enhance commercial viability. Specifically, researchers aim to achieve electrical efficiencies exceeding 90% (higher heating value basis), operational lifespans of 40,000+ hours, and capital cost reductions below $500/kW to compete effectively with alternative power generation technologies.

The comparative efficiency advantage of SOECs stems from their ability to utilize waste heat from industrial processes or integrate with renewable energy sources, creating highly efficient energy conversion pathways. When operated in reverse mode as fuel cells, they can generate electricity with theoretical efficiencies approaching 70-80%, substantially higher than conventional combustion-based power generation systems limited by Carnot efficiency constraints.

Global research trends indicate accelerating interest in SOEC technology, with annual publication rates increasing by approximately 15% year-over-year since 2015. This growth reflects recognition of SOECs' potential role in future energy systems, particularly in contexts requiring grid-scale energy storage, sector coupling between electricity and gas networks, and decarbonization of industrial processes requiring high-temperature heat.

The technology evolution trajectory suggests SOECs are approaching a critical inflection point, transitioning from laboratory-scale demonstrations to early commercial deployment. This transition is supported by complementary advances in renewable energy generation, creating synergistic opportunities for integrated energy systems that leverage the bidirectional operation capability of solid oxide cells for both power generation and energy storage functions.

Market Demand Analysis for SOEC Power Generation

The global market for Solid Oxide Electrolysis Cells (SOECs) in power generation is experiencing significant growth driven by increasing demand for clean energy solutions and the urgent need to reduce carbon emissions. Current market projections indicate that the SOEC market is expected to grow at a compound annual growth rate of 15.7% from 2023 to 2030, reaching a market value of approximately 650 million USD by the end of the forecast period.

The primary market demand for SOEC technology stems from its ability to efficiently convert electricity into hydrogen and other fuels, making it a crucial component in the renewable energy transition. With governments worldwide implementing stricter emissions regulations and setting ambitious carbon neutrality targets, industries are increasingly seeking technologies that can facilitate this transition while maintaining economic viability.

Energy storage represents a significant market segment for SOEC applications. The intermittent nature of renewable energy sources like solar and wind creates substantial demand for efficient energy storage solutions. SOECs offer a promising pathway by converting excess renewable electricity into hydrogen or syngas, which can be stored and later reconverted to electricity when needed, addressing the critical challenge of grid stability in renewable-heavy energy systems.

Industrial sectors, particularly those with high heat requirements such as steel, cement, and chemical manufacturing, represent another substantial market for SOEC technology. These industries are under mounting pressure to decarbonize their operations while maintaining productivity. SOECs offer an attractive solution by providing both high-temperature heat and clean hydrogen for various industrial processes.

Regional market analysis reveals varying adoption rates and potential. Europe leads in SOEC market development, driven by aggressive climate policies and substantial investment in hydrogen infrastructure. The European Hydrogen Strategy aims to install at least 40 GW of electrolyzer capacity by 2030, creating significant market opportunities for SOEC technology. North America follows with growing interest, particularly in industrial applications and grid stabilization.

The Asia-Pacific region presents the highest growth potential, with countries like Japan, South Korea, and China making substantial investments in hydrogen technologies. China's latest Five-Year Plan specifically mentions hydrogen as a frontier area for development, indicating strong future market growth in this region.

Customer demand analysis shows increasing interest from utilities, industrial manufacturers, and energy storage providers. These stakeholders are particularly attracted to SOECs' higher efficiency compared to alternative electrolysis technologies, especially when integrated with high-temperature industrial processes or combined heat and power systems.

The primary market demand for SOEC technology stems from its ability to efficiently convert electricity into hydrogen and other fuels, making it a crucial component in the renewable energy transition. With governments worldwide implementing stricter emissions regulations and setting ambitious carbon neutrality targets, industries are increasingly seeking technologies that can facilitate this transition while maintaining economic viability.

Energy storage represents a significant market segment for SOEC applications. The intermittent nature of renewable energy sources like solar and wind creates substantial demand for efficient energy storage solutions. SOECs offer a promising pathway by converting excess renewable electricity into hydrogen or syngas, which can be stored and later reconverted to electricity when needed, addressing the critical challenge of grid stability in renewable-heavy energy systems.

Industrial sectors, particularly those with high heat requirements such as steel, cement, and chemical manufacturing, represent another substantial market for SOEC technology. These industries are under mounting pressure to decarbonize their operations while maintaining productivity. SOECs offer an attractive solution by providing both high-temperature heat and clean hydrogen for various industrial processes.

Regional market analysis reveals varying adoption rates and potential. Europe leads in SOEC market development, driven by aggressive climate policies and substantial investment in hydrogen infrastructure. The European Hydrogen Strategy aims to install at least 40 GW of electrolyzer capacity by 2030, creating significant market opportunities for SOEC technology. North America follows with growing interest, particularly in industrial applications and grid stabilization.

The Asia-Pacific region presents the highest growth potential, with countries like Japan, South Korea, and China making substantial investments in hydrogen technologies. China's latest Five-Year Plan specifically mentions hydrogen as a frontier area for development, indicating strong future market growth in this region.

Customer demand analysis shows increasing interest from utilities, industrial manufacturers, and energy storage providers. These stakeholders are particularly attracted to SOECs' higher efficiency compared to alternative electrolysis technologies, especially when integrated with high-temperature industrial processes or combined heat and power systems.

Current Status and Technical Challenges of SOECs

Solid Oxide Electrolysis Cells (SOECs) have emerged as a promising technology for efficient power generation and energy storage, particularly in the context of renewable energy integration. Currently, SOECs operate at commercial efficiency levels of 70-80% for hydrogen production, significantly higher than alternative electrolysis technologies such as Polymer Electrolyte Membrane (PEM) and alkaline electrolysis which typically achieve 60-70% efficiency.

The global SOEC market is experiencing rapid growth, with major deployments in Europe, North America, and increasingly in Asia. Recent technological advancements have extended SOEC operational lifetimes to 20,000-30,000 hours in laboratory settings, though commercial systems still struggle to consistently achieve these durations under real-world conditions. Material degradation rates have improved to 0.5-2% per 1000 hours, representing significant progress but still falling short of the targeted <0.1% degradation rate necessary for widespread commercial viability.

Despite these advances, SOECs face several critical technical challenges. High-temperature operation (700-850°C) remains a fundamental limitation, creating thermal stress that accelerates degradation of cell components and increases system complexity. The development of intermediate-temperature SOECs (500-700°C) has shown promise but introduces new materials challenges that have yet to be fully resolved.

Material durability presents another significant obstacle. Current state-of-the-art electrolyte materials like yttria-stabilized zirconia (YSZ) and electrode materials such as lanthanum strontium manganite (LSM) and nickel-YSZ cermets suffer from chemical and mechanical degradation during long-term operation. Chromium poisoning from metallic interconnects and silicon contamination from sealing materials further compromise performance over time.

Scale-up and manufacturing challenges persist in the SOEC industry. While laboratory cells demonstrate excellent performance, translating these results to industrial-scale stacks introduces issues of uniformity, reproducibility, and cost-effectiveness. Current manufacturing techniques struggle to produce large-area cells with consistent properties, limiting commercial scalability.

System integration represents another frontier of development. Thermal management systems, power electronics for electrical input, and balance-of-plant components must be optimized to maximize overall system efficiency. The integration of SOECs with renewable energy sources introduces additional complexities related to load variability and system response dynamics.

Cost remains a significant barrier to widespread adoption. Current SOEC systems have capital costs of approximately $800-1,200/kW, substantially higher than the $300-500/kW target needed to compete with conventional hydrogen production methods. Material costs, complex manufacturing processes, and the need for specialized high-temperature components all contribute to this economic challenge.

The global SOEC market is experiencing rapid growth, with major deployments in Europe, North America, and increasingly in Asia. Recent technological advancements have extended SOEC operational lifetimes to 20,000-30,000 hours in laboratory settings, though commercial systems still struggle to consistently achieve these durations under real-world conditions. Material degradation rates have improved to 0.5-2% per 1000 hours, representing significant progress but still falling short of the targeted <0.1% degradation rate necessary for widespread commercial viability.

Despite these advances, SOECs face several critical technical challenges. High-temperature operation (700-850°C) remains a fundamental limitation, creating thermal stress that accelerates degradation of cell components and increases system complexity. The development of intermediate-temperature SOECs (500-700°C) has shown promise but introduces new materials challenges that have yet to be fully resolved.

Material durability presents another significant obstacle. Current state-of-the-art electrolyte materials like yttria-stabilized zirconia (YSZ) and electrode materials such as lanthanum strontium manganite (LSM) and nickel-YSZ cermets suffer from chemical and mechanical degradation during long-term operation. Chromium poisoning from metallic interconnects and silicon contamination from sealing materials further compromise performance over time.

Scale-up and manufacturing challenges persist in the SOEC industry. While laboratory cells demonstrate excellent performance, translating these results to industrial-scale stacks introduces issues of uniformity, reproducibility, and cost-effectiveness. Current manufacturing techniques struggle to produce large-area cells with consistent properties, limiting commercial scalability.

System integration represents another frontier of development. Thermal management systems, power electronics for electrical input, and balance-of-plant components must be optimized to maximize overall system efficiency. The integration of SOECs with renewable energy sources introduces additional complexities related to load variability and system response dynamics.

Cost remains a significant barrier to widespread adoption. Current SOEC systems have capital costs of approximately $800-1,200/kW, substantially higher than the $300-500/kW target needed to compete with conventional hydrogen production methods. Material costs, complex manufacturing processes, and the need for specialized high-temperature components all contribute to this economic challenge.

Current SOEC Efficiency Solutions

01 Electrode materials for improved efficiency

The efficiency of solid oxide electrolysis cells can be significantly improved by optimizing electrode materials. Advanced materials such as perovskites, mixed ionic-electronic conductors, and nanostructured electrodes can reduce polarization resistance and enhance electrochemical performance. These materials facilitate faster ion transport and electron transfer at the electrode-electrolyte interfaces, resulting in lower operating temperatures and higher conversion efficiencies.- Electrode materials for improved efficiency: The choice of electrode materials significantly impacts the efficiency of solid oxide electrolysis cells (SOECs). Advanced materials such as perovskite-structured oxides and composite electrodes can reduce polarization resistance and enhance electrochemical performance. These materials offer improved catalytic activity, stability at high operating temperatures, and better ionic/electronic conductivity, leading to higher conversion efficiencies and longer operational lifetimes.

- Electrolyte optimization techniques: Optimizing the electrolyte layer is crucial for enhancing SOEC efficiency. Thin-film electrolytes with high ionic conductivity reduce ohmic losses and operating temperatures. Advanced manufacturing techniques can create dense, defect-free electrolytes that minimize gas leakage and electronic current leakage. Doped zirconia and ceria-based electrolytes show promising performance characteristics, contributing to overall system efficiency improvements.

- Thermal management and system integration: Effective thermal management strategies are essential for maximizing SOEC efficiency. This includes heat recovery systems, optimized cell stack designs, and integrated thermal insulation. Advanced system architectures that balance heat distribution and minimize thermal gradients can significantly improve overall efficiency. Integration with renewable energy sources and smart control systems allows for dynamic operation that adapts to varying input conditions.

- Nanostructured components and interfaces: Incorporating nanostructured materials and engineered interfaces can substantially enhance SOEC efficiency. Nano-engineered electrodes provide increased active surface area for electrochemical reactions, while carefully designed interfaces reduce resistance to ion transport. These approaches lead to improved reaction kinetics, lower polarization losses, and enhanced durability under operating conditions, ultimately resulting in higher system efficiency.

- Pressurized operation and advanced cell configurations: Operating SOECs under pressurized conditions can significantly improve thermodynamic efficiency. Advanced cell configurations, such as tubular designs or segmented-in-series arrangements, offer benefits in terms of mechanical stability and thermal management. These approaches, combined with innovative sealing technologies and optimized flow field designs, can lead to substantial improvements in overall system efficiency and hydrogen production rates.

02 Electrolyte optimization techniques

The electrolyte plays a crucial role in determining the efficiency of solid oxide electrolysis cells. Thin-film electrolytes with high ionic conductivity can significantly reduce ohmic losses. Composite electrolytes and doped materials such as yttria-stabilized zirconia (YSZ) or gadolinium-doped ceria (GDC) offer enhanced performance. Optimizing the microstructure and thickness of the electrolyte layer helps achieve higher current densities and improved overall system efficiency.Expand Specific Solutions03 Thermal management and operating conditions

Effective thermal management is essential for maximizing the efficiency of solid oxide electrolysis cells. Operating temperature significantly impacts ionic conductivity, reaction kinetics, and degradation rates. Advanced thermal control systems, heat recovery mechanisms, and optimized cell designs can reduce energy losses and improve system efficiency. Controlling temperature gradients across the cell and implementing efficient heat exchange systems contribute to sustained high-performance operation.Expand Specific Solutions04 Cell design and structural innovations

Innovative cell designs can substantially enhance the efficiency of solid oxide electrolysis cells. Planar, tubular, and micro-tubular configurations offer different advantages in terms of power density, thermal cycling resistance, and manufacturing complexity. Advanced structural features such as supported thin electrolytes, optimized flow channels, and integrated sealing systems reduce internal resistance and improve gas distribution. These design innovations lead to higher current densities and improved overall system efficiency.Expand Specific Solutions05 System integration and process optimization

The overall efficiency of solid oxide electrolysis systems depends on effective integration with other components and process optimization. Combining electrolysis with heat recovery systems, renewable energy sources, and intelligent control strategies can significantly improve energy utilization. Advanced power electronics for efficient electrical input, optimized gas handling systems, and pressure management contribute to higher system efficiencies. Integrated approaches that consider the entire energy conversion chain maximize the practical efficiency of solid oxide electrolysis technology.Expand Specific Solutions

Major Industry Players in SOEC Development

The solid oxide electrolysis cell (SOEC) power generation market is in its early growth phase, characterized by significant R&D investment but limited commercial deployment. The global market is projected to expand rapidly as hydrogen economy initiatives gain momentum, with estimates suggesting multi-billion dollar growth potential by 2030. Technical maturity varies considerably among key players. Industry leaders like Samsung Electro Mechanics, TDK, and Murata Manufacturing are leveraging their materials expertise to enhance cell durability and efficiency. Academic institutions (Tsinghua University, Northwestern University) are driving fundamental research, while specialized companies like DynElectro ApS have developed proprietary technologies extending SOEC lifespan from two to ten years. Energy corporations including Hyundai, Kia, and Osaka Gas are increasingly investing in SOEC technology for green hydrogen production and energy storage applications.

The Kansai Electric Power Co., Inc.

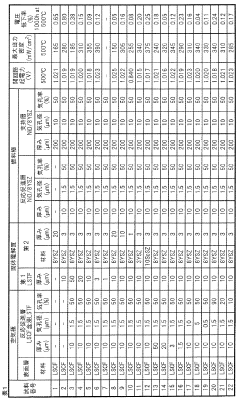

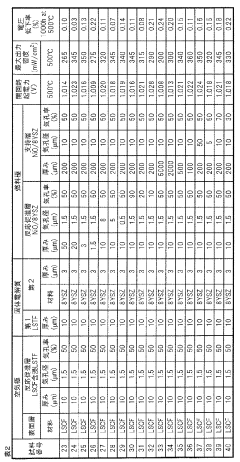

Technical Solution: Kansai Electric has developed an advanced SOEC system optimized for grid-scale energy storage and power generation. Their technology utilizes a proprietary zirconia-based electrolyte with cobalt-doped perovskite electrodes that demonstrate exceptional durability under fluctuating load conditions. The system achieves hydrogen production efficiency of 3.7 kWh/Nm³ H₂ at 750°C, representing a significant improvement over conventional electrolysis. Their integrated thermal management system recovers waste heat, boosting overall system efficiency to over 85% when operated in reversible mode. Kansai's SOECs incorporate a novel interconnect design that reduces chromium poisoning and maintains performance over 20,000+ operating hours with degradation rates below 0.7% per 1000 hours. The company has demonstrated MW-scale installations that can rapidly switch between electrolysis and power generation modes in under 15 minutes, providing valuable grid balancing services.

Strengths: Exceptional thermal cycling capability suitable for intermittent renewable integration; advanced materials science reduces degradation; proven at commercial scale with multiple demonstration projects. Weaknesses: Higher capital costs compared to polymer electrolyte systems; requires specialized balance-of-plant components to manage high-temperature operation; optimal performance requires steady-state operation.

DynElectro ApS

Technical Solution: DynElectro has pioneered a dynamic electrolysis cell technology that specifically addresses the intermittent nature of renewable energy sources. Their SOEC design features a scandium-doped zirconia electrolyte with nano-engineered electrodes that demonstrate exceptional resistance to thermal cycling. Operating at intermediate temperatures (650-750°C), their cells achieve hydrogen production rates of 1.2 Nl/cm²/h at 1.3V with current densities exceeding 1.5 A/cm². A key innovation is their proprietary "DynStack" architecture that enables rapid load-following capabilities, responding to power fluctuations in seconds rather than minutes. The company has demonstrated over 5,000 thermal cycles with minimal performance degradation (<3% total), addressing a critical challenge for renewable energy integration. Their systems achieve electrical efficiency of 82% (LHV) in electrolysis mode and can operate in reversible mode with round-trip efficiencies approaching 60%, significantly outperforming alternative energy storage technologies.

Strengths: Exceptional thermal cycling capability ideal for renewable energy integration; rapid response time enables grid balancing services; intermediate temperature operation balances efficiency and durability. Weaknesses: Technology is relatively new with limited long-term field data; requires specialized manufacturing techniques for nano-engineered electrodes; higher complexity in system control algorithms.

Key Technical Innovations in SOEC Design

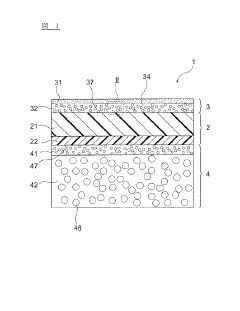

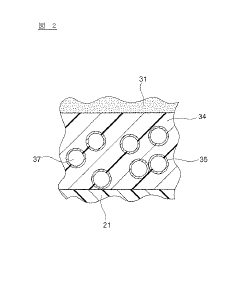

Power Generation Cell for Solid Electrolyte Fuel Cell and Structure of Fuel Electrode Thereof

PatentInactiveUS20090274941A1

Innovation

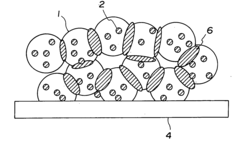

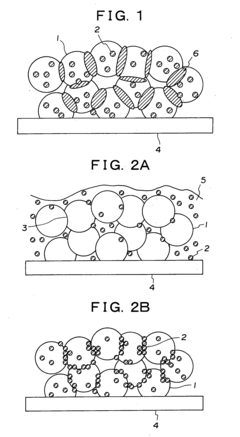

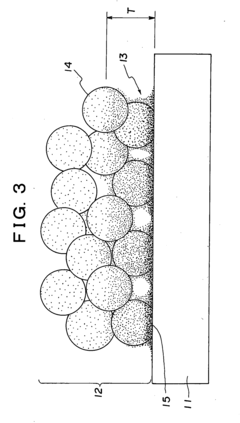

- The fuel electrode design features B-doped ceria particles with average sizes of 100 nm or less, densely distributed around the framework structure neck portions of porous nickel, and the use of ruthenium-supported B-doped ceria to enhance fuel gas permeability and stability, thereby preventing nickel particle coarsening and maintaining high surface area.

Power generation cell for solid oxide fuel cell

PatentInactiveJP2012074307A

Innovation

- A power generation cell for a solid oxide fuel cell using a composite electrolyte structure with (La, Sr)(Ti, Fe)O3 as the first solid electrolyte and dense Zr oxide as the second solid electrolyte, combined with a porous air and fuel electrode structure to enhance oxide ion conductivity and prevent electron short circuits, ensuring high reliability and performance at low temperatures.

Environmental Impact Assessment of SOEC Technology

The environmental impact assessment of Solid Oxide Electrolysis Cell (SOEC) technology reveals significant advantages compared to conventional power generation methods. SOECs operate with minimal direct emissions during operation, as they primarily convert electricity into hydrogen or syngas without combustion processes. This represents a substantial reduction in greenhouse gas emissions when compared to traditional fossil fuel-based power generation systems.

When powered by renewable energy sources such as solar or wind, SOEC systems can achieve near-zero lifecycle emissions. Life cycle assessment (LCA) studies indicate that SOEC-based power generation can reduce carbon dioxide emissions by 60-90% compared to natural gas combined cycle plants, depending on the electricity source used for electrolysis operations.

Material sustainability presents both challenges and opportunities for SOEC technology. The cells require rare earth elements and specialized ceramics, raising concerns about resource depletion and mining impacts. However, recent advancements in materials science have reduced the reliance on scarce materials, with newer generations of SOECs utilizing more abundant elements and demonstrating longer operational lifespans of 40,000+ hours, thereby improving their overall environmental footprint.

Water consumption metrics for SOEC systems are favorable compared to conventional thermal power generation. While water is consumed during the electrolysis process, the total water footprint is significantly lower than coal or natural gas plants that require substantial cooling water. Quantitative assessments show SOECs consume approximately 1.5-2.5 liters of water per kilogram of hydrogen produced, compared to 10-15 liters per equivalent energy output in conventional thermal plants.

Land use efficiency of SOEC installations also demonstrates environmental advantages. The modular nature of SOEC systems allows for flexible deployment with minimal land disturbance. A 1 MW SOEC installation typically requires less than 200 square meters, approximately 70-80% less land area than equivalent solar photovoltaic installations for the same energy output.

Waste heat recovery represents another environmental benefit of SOEC technology. Operating at high temperatures (700-900°C), SOECs generate substantial waste heat that can be captured for district heating, industrial processes, or to improve overall system efficiency through thermal integration. This co-generation capability can increase total system efficiency to over 85%, significantly reducing primary energy consumption compared to separate heat and power generation systems.

When powered by renewable energy sources such as solar or wind, SOEC systems can achieve near-zero lifecycle emissions. Life cycle assessment (LCA) studies indicate that SOEC-based power generation can reduce carbon dioxide emissions by 60-90% compared to natural gas combined cycle plants, depending on the electricity source used for electrolysis operations.

Material sustainability presents both challenges and opportunities for SOEC technology. The cells require rare earth elements and specialized ceramics, raising concerns about resource depletion and mining impacts. However, recent advancements in materials science have reduced the reliance on scarce materials, with newer generations of SOECs utilizing more abundant elements and demonstrating longer operational lifespans of 40,000+ hours, thereby improving their overall environmental footprint.

Water consumption metrics for SOEC systems are favorable compared to conventional thermal power generation. While water is consumed during the electrolysis process, the total water footprint is significantly lower than coal or natural gas plants that require substantial cooling water. Quantitative assessments show SOECs consume approximately 1.5-2.5 liters of water per kilogram of hydrogen produced, compared to 10-15 liters per equivalent energy output in conventional thermal plants.

Land use efficiency of SOEC installations also demonstrates environmental advantages. The modular nature of SOEC systems allows for flexible deployment with minimal land disturbance. A 1 MW SOEC installation typically requires less than 200 square meters, approximately 70-80% less land area than equivalent solar photovoltaic installations for the same energy output.

Waste heat recovery represents another environmental benefit of SOEC technology. Operating at high temperatures (700-900°C), SOECs generate substantial waste heat that can be captured for district heating, industrial processes, or to improve overall system efficiency through thermal integration. This co-generation capability can increase total system efficiency to over 85%, significantly reducing primary energy consumption compared to separate heat and power generation systems.

Economic Viability and Cost Analysis of SOEC Systems

The economic viability of Solid Oxide Electrolysis Cell (SOEC) systems remains a critical factor determining their widespread adoption in power generation applications. Current capital expenditure (CAPEX) for SOEC systems ranges between $2,000-5,000/kW, significantly higher than competing technologies such as alkaline electrolyzers ($1,000-1,500/kW) and PEM electrolyzers ($1,500-2,500/kW). This cost differential presents a substantial barrier to market penetration despite the superior efficiency advantages of SOEC technology.

Material costs constitute approximately 60-70% of total SOEC system expenses, with rare earth elements and specialized ceramics being primary contributors. The stack components, particularly electrolytes and electrodes requiring high-purity materials, represent nearly 40% of material costs. Balance of plant components, including heat exchangers, power electronics, and control systems, account for the remaining system costs.

Operational expenditure (OPEX) analysis reveals that electricity consumption remains the dominant cost factor, representing 65-80% of lifetime operational costs. At current electricity prices, SOEC systems require approximately 40-45 kWh per kilogram of hydrogen produced, translating to $2.00-2.25/kg H₂ at industrial electricity rates of $0.05/kWh. Maintenance costs add an additional $0.30-0.50/kg H₂ over the system lifetime.

Levelized cost of hydrogen (LCOH) calculations indicate that SOEC systems currently deliver hydrogen at $3.50-5.00/kg, compared to $1.50-2.50/kg for steam methane reforming (SMR). However, when carbon pricing mechanisms are incorporated at $50-100/ton CO₂, the economic gap narrows significantly, with SOEC hydrogen becoming competitive at approximately $3.00-4.00/kg.

Economies of scale present promising pathways for cost reduction. Manufacturing scale-up models project potential cost decreases of 45-60% when production volumes increase from current pilot scales (MW range) to industrial scales (GW range). Learning curve effects suggest an 18-22% cost reduction with each doubling of cumulative production capacity, following patterns observed in other renewable technologies.

Return on investment (ROI) calculations indicate that SOEC systems currently achieve payback periods of 8-12 years under standard operating conditions. This timeframe can be reduced to 5-7 years with policy support mechanisms such as production tax credits, carbon pricing, or renewable energy subsidies. Sensitivity analysis demonstrates that electricity prices and capacity factors are the most influential variables affecting economic viability, with a 10% decrease in electricity costs improving ROI by approximately 15-20%.

Material costs constitute approximately 60-70% of total SOEC system expenses, with rare earth elements and specialized ceramics being primary contributors. The stack components, particularly electrolytes and electrodes requiring high-purity materials, represent nearly 40% of material costs. Balance of plant components, including heat exchangers, power electronics, and control systems, account for the remaining system costs.

Operational expenditure (OPEX) analysis reveals that electricity consumption remains the dominant cost factor, representing 65-80% of lifetime operational costs. At current electricity prices, SOEC systems require approximately 40-45 kWh per kilogram of hydrogen produced, translating to $2.00-2.25/kg H₂ at industrial electricity rates of $0.05/kWh. Maintenance costs add an additional $0.30-0.50/kg H₂ over the system lifetime.

Levelized cost of hydrogen (LCOH) calculations indicate that SOEC systems currently deliver hydrogen at $3.50-5.00/kg, compared to $1.50-2.50/kg for steam methane reforming (SMR). However, when carbon pricing mechanisms are incorporated at $50-100/ton CO₂, the economic gap narrows significantly, with SOEC hydrogen becoming competitive at approximately $3.00-4.00/kg.

Economies of scale present promising pathways for cost reduction. Manufacturing scale-up models project potential cost decreases of 45-60% when production volumes increase from current pilot scales (MW range) to industrial scales (GW range). Learning curve effects suggest an 18-22% cost reduction with each doubling of cumulative production capacity, following patterns observed in other renewable technologies.

Return on investment (ROI) calculations indicate that SOEC systems currently achieve payback periods of 8-12 years under standard operating conditions. This timeframe can be reduced to 5-7 years with policy support mechanisms such as production tax credits, carbon pricing, or renewable energy subsidies. Sensitivity analysis demonstrates that electricity prices and capacity factors are the most influential variables affecting economic viability, with a 10% decrease in electricity costs improving ROI by approximately 15-20%.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!