Solid oxide electrolysis cells and waste-to-energy conversions

OCT 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SOEC Technology Background and Objectives

Solid Oxide Electrolysis Cells (SOECs) represent a transformative technology in the realm of energy conversion, with roots dating back to the 1980s when researchers began exploring high-temperature electrolysis for hydrogen production. The evolution of SOEC technology has been marked by significant advancements in materials science, particularly in the development of ceramic electrolytes and electrode materials capable of withstanding extreme operating temperatures (700-900°C).

The fundamental principle of SOECs involves the electrochemical conversion of steam and/or carbon dioxide into hydrogen and carbon monoxide using electrical energy. This reverse operation of solid oxide fuel cells enables efficient energy storage and conversion pathways that are increasingly relevant in today's energy landscape. The technology has progressed from laboratory-scale demonstrations to pilot plants, with growing interest in industrial applications.

Recent technological trends indicate a shift toward integrating SOECs with renewable energy sources to utilize excess electricity for producing valuable chemicals and fuels. This integration addresses the intermittency challenges of renewable energy while offering a pathway for decarbonization across multiple sectors. Additionally, there is growing interest in pressurized SOEC operation and the development of reversible solid oxide cells that can function in both electrolysis and fuel cell modes.

The waste-to-energy conversion aspect represents a particularly promising direction, as SOECs can potentially transform carbon-containing waste streams into valuable syngas (H₂ + CO). This approach addresses two critical challenges simultaneously: waste management and clean energy production. By converting waste materials that would otherwise contribute to landfill volumes or greenhouse gas emissions, SOECs offer a circular economy solution with significant environmental benefits.

The primary technical objectives for SOEC development include enhancing durability and stability under various operating conditions, reducing manufacturing costs through materials innovation and process optimization, and improving system integration capabilities. Researchers aim to achieve cell degradation rates below 0.5% per 1000 hours of operation while maintaining high conversion efficiencies (>90% electrical-to-chemical).

Long-term objectives focus on scaling the technology for industrial deployment, particularly in sectors such as steel manufacturing, chemical production, and synthetic fuel generation. The vision is to establish SOECs as a cornerstone technology in a future energy system characterized by sector coupling and flexible energy conversion pathways. This would enable the efficient utilization of renewable electricity for producing chemicals, fuels, and heat, thereby contributing to comprehensive decarbonization strategies across multiple industries.

The fundamental principle of SOECs involves the electrochemical conversion of steam and/or carbon dioxide into hydrogen and carbon monoxide using electrical energy. This reverse operation of solid oxide fuel cells enables efficient energy storage and conversion pathways that are increasingly relevant in today's energy landscape. The technology has progressed from laboratory-scale demonstrations to pilot plants, with growing interest in industrial applications.

Recent technological trends indicate a shift toward integrating SOECs with renewable energy sources to utilize excess electricity for producing valuable chemicals and fuels. This integration addresses the intermittency challenges of renewable energy while offering a pathway for decarbonization across multiple sectors. Additionally, there is growing interest in pressurized SOEC operation and the development of reversible solid oxide cells that can function in both electrolysis and fuel cell modes.

The waste-to-energy conversion aspect represents a particularly promising direction, as SOECs can potentially transform carbon-containing waste streams into valuable syngas (H₂ + CO). This approach addresses two critical challenges simultaneously: waste management and clean energy production. By converting waste materials that would otherwise contribute to landfill volumes or greenhouse gas emissions, SOECs offer a circular economy solution with significant environmental benefits.

The primary technical objectives for SOEC development include enhancing durability and stability under various operating conditions, reducing manufacturing costs through materials innovation and process optimization, and improving system integration capabilities. Researchers aim to achieve cell degradation rates below 0.5% per 1000 hours of operation while maintaining high conversion efficiencies (>90% electrical-to-chemical).

Long-term objectives focus on scaling the technology for industrial deployment, particularly in sectors such as steel manufacturing, chemical production, and synthetic fuel generation. The vision is to establish SOECs as a cornerstone technology in a future energy system characterized by sector coupling and flexible energy conversion pathways. This would enable the efficient utilization of renewable electricity for producing chemicals, fuels, and heat, thereby contributing to comprehensive decarbonization strategies across multiple industries.

Market Analysis for Waste-to-Energy Solutions

The global waste-to-energy (WtE) market is experiencing robust growth, driven by increasing urbanization, rising waste generation, and growing environmental concerns. As of 2023, the market was valued at approximately $35.6 billion, with projections indicating a compound annual growth rate (CAGR) of 6.8% through 2030, potentially reaching $56.8 billion by the end of the forecast period. This growth trajectory is particularly significant in regions with high population density and limited landfill space.

Solid oxide electrolysis cells (SOECs) represent an emerging technological approach within the broader WtE landscape, offering unique value propositions compared to traditional incineration or gasification methods. The integration of SOECs into waste conversion processes enables higher efficiency energy recovery and potentially lower emissions profiles, addressing key market demands for more sustainable waste management solutions.

Regionally, Europe leads the WtE market with approximately 28% market share, driven by stringent waste management regulations and ambitious renewable energy targets. Countries like Denmark, Sweden, and Germany have established sophisticated waste-to-energy infrastructure, with facility utilization rates exceeding 90% in some regions. Asia-Pacific represents the fastest-growing market, with China alone operating over 400 WtE plants and planning significant capacity expansions.

Market segmentation reveals distinct technology preferences across regions. While mass burn incineration dominates with approximately 70% of the global installed capacity, advanced thermal treatment technologies including gasification and pyrolysis are gaining traction, growing at nearly 9% annually. The SOEC-based waste conversion segment, though currently representing less than 5% of the market, is demonstrating the highest growth potential at 12-15% annually due to its superior efficiency and environmental performance.

Key market drivers include tightening landfill regulations, increasing landfill taxes (reaching €94/ton in some European countries), and growing corporate commitments to circular economy principles. Additionally, the potential for carbon credit generation through advanced WtE technologies is creating new revenue streams, with carbon offset prices ranging from $5-15 per ton in voluntary markets to $25-85 in compliance markets.

Consumer demand patterns indicate growing preference for waste management solutions with minimal environmental footprint, creating market pull for technologies like SOECs that can process waste with lower emissions. Municipal governments, which represent approximately 65% of WtE customers, are increasingly incorporating sustainability metrics into procurement decisions, favoring technologies that maximize energy recovery while minimizing environmental impact.

Solid oxide electrolysis cells (SOECs) represent an emerging technological approach within the broader WtE landscape, offering unique value propositions compared to traditional incineration or gasification methods. The integration of SOECs into waste conversion processes enables higher efficiency energy recovery and potentially lower emissions profiles, addressing key market demands for more sustainable waste management solutions.

Regionally, Europe leads the WtE market with approximately 28% market share, driven by stringent waste management regulations and ambitious renewable energy targets. Countries like Denmark, Sweden, and Germany have established sophisticated waste-to-energy infrastructure, with facility utilization rates exceeding 90% in some regions. Asia-Pacific represents the fastest-growing market, with China alone operating over 400 WtE plants and planning significant capacity expansions.

Market segmentation reveals distinct technology preferences across regions. While mass burn incineration dominates with approximately 70% of the global installed capacity, advanced thermal treatment technologies including gasification and pyrolysis are gaining traction, growing at nearly 9% annually. The SOEC-based waste conversion segment, though currently representing less than 5% of the market, is demonstrating the highest growth potential at 12-15% annually due to its superior efficiency and environmental performance.

Key market drivers include tightening landfill regulations, increasing landfill taxes (reaching €94/ton in some European countries), and growing corporate commitments to circular economy principles. Additionally, the potential for carbon credit generation through advanced WtE technologies is creating new revenue streams, with carbon offset prices ranging from $5-15 per ton in voluntary markets to $25-85 in compliance markets.

Consumer demand patterns indicate growing preference for waste management solutions with minimal environmental footprint, creating market pull for technologies like SOECs that can process waste with lower emissions. Municipal governments, which represent approximately 65% of WtE customers, are increasingly incorporating sustainability metrics into procurement decisions, favoring technologies that maximize energy recovery while minimizing environmental impact.

Current SOEC Development Status and Barriers

Solid Oxide Electrolysis Cells (SOECs) have emerged as a promising technology for efficient energy conversion and storage, particularly in waste-to-energy applications. Currently, SOECs have achieved electrical efficiencies of 70-90% in laboratory settings, significantly outperforming conventional electrolysis technologies. Commercial systems typically operate at temperatures between 700-900°C, with power densities ranging from 0.3 to 0.7 W/cm².

Despite these advancements, widespread SOEC deployment faces substantial barriers. Material degradation remains a critical challenge, with current state-of-the-art cells experiencing performance losses of 1-2% per 1000 hours of operation. This degradation is primarily attributed to chromium poisoning from interconnect materials, delamination at electrode-electrolyte interfaces, and nickel agglomeration in hydrogen electrodes during high-temperature operation.

Cost factors present another significant obstacle. Current SOEC stack manufacturing costs range from $2000-5000/kW, substantially higher than the $300-500/kW target needed for commercial viability. The expensive ceramic materials, complex manufacturing processes, and specialized sealing technologies contribute significantly to these elevated costs.

Thermal management represents a persistent technical challenge. The high operating temperatures necessary for optimal ionic conductivity create substantial thermal stress during startup and shutdown cycles. Current systems typically require 6-12 hours for safe heating and cooling, limiting operational flexibility and responsiveness to fluctuating energy inputs from renewable sources or waste streams.

Durability under real-world conditions remains problematic. Laboratory demonstrations have achieved lifespans of 5,000-10,000 hours, whereas commercial viability requires 40,000+ hours of stable operation. When processing waste-derived feedstocks, contaminants such as sulfur compounds, siloxanes, and particulates can rapidly deactivate catalytic surfaces, reducing cell performance by up to 50% within the first 1,000 hours of operation.

Integration challenges with waste conversion systems further complicate implementation. Current waste gasification technologies produce syngas with variable composition and impurity profiles, requiring extensive gas cleaning systems that add complexity and cost. The mismatch between waste processing rates and optimal SOEC operating conditions necessitates sophisticated control systems and thermal storage solutions that are still under development.

Globally, research efforts are concentrated in Europe (particularly Denmark, Germany, and France), Japan, South Korea, and the United States. European initiatives lead in system integration and demonstration projects, while Asian research focuses more on novel materials development. Recent collaborative international projects have begun addressing these barriers through interdisciplinary approaches combining materials science, electrochemistry, and systems engineering.

Despite these advancements, widespread SOEC deployment faces substantial barriers. Material degradation remains a critical challenge, with current state-of-the-art cells experiencing performance losses of 1-2% per 1000 hours of operation. This degradation is primarily attributed to chromium poisoning from interconnect materials, delamination at electrode-electrolyte interfaces, and nickel agglomeration in hydrogen electrodes during high-temperature operation.

Cost factors present another significant obstacle. Current SOEC stack manufacturing costs range from $2000-5000/kW, substantially higher than the $300-500/kW target needed for commercial viability. The expensive ceramic materials, complex manufacturing processes, and specialized sealing technologies contribute significantly to these elevated costs.

Thermal management represents a persistent technical challenge. The high operating temperatures necessary for optimal ionic conductivity create substantial thermal stress during startup and shutdown cycles. Current systems typically require 6-12 hours for safe heating and cooling, limiting operational flexibility and responsiveness to fluctuating energy inputs from renewable sources or waste streams.

Durability under real-world conditions remains problematic. Laboratory demonstrations have achieved lifespans of 5,000-10,000 hours, whereas commercial viability requires 40,000+ hours of stable operation. When processing waste-derived feedstocks, contaminants such as sulfur compounds, siloxanes, and particulates can rapidly deactivate catalytic surfaces, reducing cell performance by up to 50% within the first 1,000 hours of operation.

Integration challenges with waste conversion systems further complicate implementation. Current waste gasification technologies produce syngas with variable composition and impurity profiles, requiring extensive gas cleaning systems that add complexity and cost. The mismatch between waste processing rates and optimal SOEC operating conditions necessitates sophisticated control systems and thermal storage solutions that are still under development.

Globally, research efforts are concentrated in Europe (particularly Denmark, Germany, and France), Japan, South Korea, and the United States. European initiatives lead in system integration and demonstration projects, while Asian research focuses more on novel materials development. Recent collaborative international projects have begun addressing these barriers through interdisciplinary approaches combining materials science, electrochemistry, and systems engineering.

Existing SOEC and Waste-to-Energy Methodologies

01 SOEC materials and composition

Solid oxide electrolysis cells require specific materials for optimal performance. These include specialized electrolytes, electrodes, and catalysts that can withstand high operating temperatures while maintaining ionic conductivity. Advanced ceramic materials, composite structures, and doped compounds are used to enhance stability and efficiency. Material selection focuses on minimizing degradation during operation and improving overall cell durability.- SOEC electrode materials and structures: Solid oxide electrolysis cells require specialized electrode materials and structures to function efficiently. These materials must withstand high operating temperatures while maintaining conductivity and catalytic activity. Advanced electrode designs incorporate composite structures with mixed ionic-electronic conductors to enhance electrochemical performance. Optimization of electrode microstructure, including porosity and thickness, is crucial for improving gas diffusion and reaction kinetics at the electrode-electrolyte interfaces.

- Electrolyte development for high-temperature operation: The electrolyte in solid oxide electrolysis cells plays a critical role in ion transport while maintaining gas separation. Research focuses on developing thin, dense electrolyte materials with high ionic conductivity at operating temperatures. Yttria-stabilized zirconia (YSZ) remains common, but newer materials like gadolinium-doped ceria (GDC) and scandium-stabilized zirconia offer improved performance. Advanced manufacturing techniques are being employed to create thinner electrolytes that reduce ohmic resistance while maintaining mechanical integrity during thermal cycling.

- System integration and stack design: Effective integration of solid oxide electrolysis cells into complete systems requires careful stack design and balance-of-plant considerations. Stack configurations must address thermal management, gas distribution, and electrical connections while minimizing degradation mechanisms. Innovations include improved sealing technologies to prevent gas leakage at high temperatures and interconnect designs that reduce contact resistance. System-level approaches focus on heat recovery, pressurization strategies, and integration with renewable energy sources to improve overall efficiency.

- Durability and degradation mechanisms: Long-term stability remains a key challenge for solid oxide electrolysis cells. Research addresses various degradation mechanisms including chromium poisoning, nickel agglomeration, and delamination at interfaces. Protective coatings and modified compositions are being developed to mitigate these issues. Studies focus on understanding degradation under dynamic operating conditions, particularly during thermal cycling and load variations. Advanced characterization techniques help identify failure modes and inform the development of more robust materials and cell designs.

- Co-electrolysis and syngas production: Solid oxide electrolysis cells can simultaneously electrolyze water and carbon dioxide to produce syngas (H₂ and CO mixture), which serves as a precursor for synthetic fuels. This co-electrolysis process offers a pathway for carbon utilization and renewable fuel production. Research focuses on optimizing catalyst compositions for selective CO₂ reduction and developing operating strategies that balance the kinetics of different reactions. Advanced cell designs incorporate specialized materials that promote co-electrolysis while minimizing carbon deposition and other side reactions.

02 SOEC system design and integration

System design for solid oxide electrolysis cells involves the integration of multiple components including stacks, thermal management systems, and control mechanisms. These systems are engineered to optimize energy efficiency, manage heat distribution, and ensure stable operation under varying conditions. Design considerations include stack configuration, sealing methods, and interconnection techniques that minimize electrical resistance while maintaining structural integrity during thermal cycling.Expand Specific Solutions03 Hydrogen production optimization in SOECs

Techniques for optimizing hydrogen production in solid oxide electrolysis cells focus on improving conversion efficiency and production rates. This includes operating parameter optimization such as temperature control, pressure management, and electrical input modulation. Advanced methods incorporate steam composition adjustments, feed gas purification, and innovative cell geometries that enhance mass transfer and reaction kinetics, resulting in higher hydrogen yields with lower energy consumption.Expand Specific Solutions04 Degradation mechanisms and durability enhancement

Understanding and mitigating degradation mechanisms is crucial for extending SOEC operational lifetime. Research focuses on addressing issues such as electrode delamination, electrolyte cracking, chromium poisoning, and carbon deposition. Protective coatings, microstructural engineering, and compositional modifications are employed to enhance durability. Operating strategies that minimize thermal stress and chemical reactions that lead to performance deterioration are developed to ensure long-term stability.Expand Specific Solutions05 Co-electrolysis and syngas production

Co-electrolysis processes in solid oxide cells enable simultaneous reduction of steam and carbon dioxide to produce syngas (H₂ and CO mixture). This approach offers pathways for carbon utilization and production of synthetic fuels. The technology requires specialized electrode materials that promote both hydrogen and carbon monoxide formation while preventing carbon deposition. Process parameters are optimized to control the H₂/CO ratio in the syngas output, making it suitable for downstream applications such as Fischer-Tropsch synthesis.Expand Specific Solutions

Leading Organizations in SOEC and Waste Conversion

The solid oxide electrolysis cell (SOEC) and waste-to-energy conversion market is currently in a growth phase, with an estimated global market size of $2-3 billion and projected annual growth of 15-20%. The technology is approaching commercial maturity, with key players demonstrating different levels of advancement. Companies like DynElectro ApS have made significant breakthroughs in extending SOEC life expectancy from two to ten years, while established corporations such as Samsung Electro Mechanics, Sinopec, and Saudi Aramco are investing heavily in R&D. Academic institutions including Northwestern University, Tsinghua University, and Technical University of Denmark are driving fundamental research. The competitive landscape features both specialized startups and diversified energy conglomerates, with increasing collaboration between industry and academia to overcome remaining technical challenges in durability, efficiency, and cost reduction.

DynElectro ApS

Technical Solution: DynElectro has developed advanced solid oxide electrolysis cell (SOEC) technology focused on dynamic operation capabilities. Their proprietary ceramic cells operate at high temperatures (700-850°C) enabling efficient conversion of electricity to hydrogen through water electrolysis with efficiency rates exceeding 80%. The company's innovation lies in their specialized electrode materials and cell architecture that allows for rapid start-up and shutdown cycles without degradation - a significant advancement over traditional SOECs that suffer from thermal cycling issues. Their technology incorporates waste heat utilization systems that can be integrated with industrial processes, effectively converting waste thermal energy into valuable hydrogen production capacity. DynElectro's cells also demonstrate capability for reversible operation (SOFC/SOEC mode), providing flexibility for energy storage applications[1][2].

Strengths: Superior dynamic operation allowing for integration with intermittent renewable energy sources; high electrical efficiency; ability to utilize waste heat to further improve overall system efficiency. Weaknesses: Still requires high operating temperatures which presents materials challenges; limited commercial-scale deployment experience compared to low-temperature electrolysis technologies.

FCET Inc

Technical Solution: FCET (Fuel Cell Energy Technology) has developed proprietary tubular solid oxide electrolysis cells that offer distinct advantages for waste-to-energy applications. Their innovative design eliminates the need for high-temperature seals between cells, addressing a key failure point in traditional planar SOEC designs. FCET's technology incorporates specialized catalysts that enable direct internal reforming of waste-derived hydrocarbons, simplifying system integration with waste gasification processes. Their cells operate efficiently at 750-850°C and can achieve steam electrolysis efficiencies exceeding 90% when waste heat is effectively utilized. The company has demonstrated long-term stability with their cells operating continuously for over 15,000 hours with minimal performance degradation. FCET has also pioneered a modular system architecture that allows for easy scaling from kilowatt to megawatt installations, making their technology adaptable to various waste processing facilities from municipal to industrial scales[7][8].

Strengths: Tubular design eliminates critical sealing challenges; excellent thermal cycling capability; simplified system integration with waste processing facilities. Weaknesses: Lower volumetric power density compared to planar designs; more complex manufacturing process; higher materials cost per active cell area.

Critical Materials and Cell Design Innovations

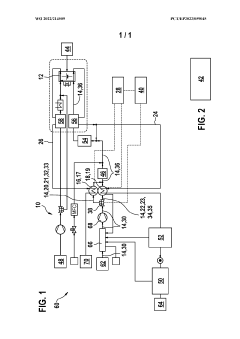

Solid oxide electrolysis cell device, method for operating a solid oxide electrolysis cell device, and solid oxide electrolysis cell system

PatentWO2022214509A1

Innovation

- The device incorporates two heat exchanger units arranged in parallel on the water supply line, one for hydrogen and one for oxygen, to efficiently transfer waste heat from the electrolytic cell units to the water, along with a valve unit to adjust water flow ratios based on heat capacity flow ratios, ensuring optimal heat utilization and preheating.

Environmental Impact Assessment

The environmental impact of solid oxide electrolysis cells (SOECs) and waste-to-energy (WtE) conversion technologies represents a critical consideration in their development and implementation. These technologies offer significant potential for reducing greenhouse gas emissions compared to conventional energy generation methods. SOECs, when powered by renewable electricity sources, can produce hydrogen and syngas with near-zero carbon emissions, providing a clean alternative to fossil fuel-based hydrogen production which currently accounts for substantial CO2 emissions globally.

Waste-to-energy conversion processes demonstrate notable environmental benefits through diversion of waste from landfills, thereby reducing methane emissions which have 25 times the global warming potential of CO2. Modern WtE facilities incorporate advanced emission control systems that significantly reduce pollutants compared to earlier generation incinerators, with filtration efficiencies exceeding 99% for particulate matter and substantial reductions in dioxins and furans.

Life cycle assessment (LCA) studies indicate that integrated SOEC and WtE systems can achieve carbon neutrality or even negative emissions when biogenic carbon in waste is considered. The carbon intensity of hydrogen produced via SOEC technology ranges from 0.5-3 kg CO2eq/kg H2 when powered by renewable electricity, compared to 9-12 kg CO2eq/kg H2 for conventional steam methane reforming processes.

Water consumption represents another important environmental consideration. SOECs require high-purity water inputs, though at significantly lower volumes than competing hydrogen production technologies. Advanced WtE systems incorporating water recovery can operate with minimal external water requirements, creating potential synergies when these technologies are integrated.

Land use impacts vary considerably based on implementation scale and technology configuration. Distributed SOEC systems coupled with localized waste processing facilities can minimize transportation-related emissions and reduce the environmental footprint associated with centralized infrastructure development. This distributed approach also enhances resilience against climate-related disruptions.

Air quality improvements represent a significant co-benefit of these technologies. By replacing conventional waste management practices and fossil fuel combustion, integrated SOEC-WtE systems can reduce emissions of nitrogen oxides, sulfur dioxide, and particulate matter. Quantitative studies indicate potential reductions of 60-85% in these criteria pollutants compared to conventional waste management and energy generation approaches.

Resource conservation effects extend beyond emissions reduction. The recovery of valuable materials from waste streams prior to energy conversion, coupled with the production of hydrogen and other chemical feedstocks, creates a circular economy framework that significantly reduces primary resource extraction requirements and associated environmental impacts.

Waste-to-energy conversion processes demonstrate notable environmental benefits through diversion of waste from landfills, thereby reducing methane emissions which have 25 times the global warming potential of CO2. Modern WtE facilities incorporate advanced emission control systems that significantly reduce pollutants compared to earlier generation incinerators, with filtration efficiencies exceeding 99% for particulate matter and substantial reductions in dioxins and furans.

Life cycle assessment (LCA) studies indicate that integrated SOEC and WtE systems can achieve carbon neutrality or even negative emissions when biogenic carbon in waste is considered. The carbon intensity of hydrogen produced via SOEC technology ranges from 0.5-3 kg CO2eq/kg H2 when powered by renewable electricity, compared to 9-12 kg CO2eq/kg H2 for conventional steam methane reforming processes.

Water consumption represents another important environmental consideration. SOECs require high-purity water inputs, though at significantly lower volumes than competing hydrogen production technologies. Advanced WtE systems incorporating water recovery can operate with minimal external water requirements, creating potential synergies when these technologies are integrated.

Land use impacts vary considerably based on implementation scale and technology configuration. Distributed SOEC systems coupled with localized waste processing facilities can minimize transportation-related emissions and reduce the environmental footprint associated with centralized infrastructure development. This distributed approach also enhances resilience against climate-related disruptions.

Air quality improvements represent a significant co-benefit of these technologies. By replacing conventional waste management practices and fossil fuel combustion, integrated SOEC-WtE systems can reduce emissions of nitrogen oxides, sulfur dioxide, and particulate matter. Quantitative studies indicate potential reductions of 60-85% in these criteria pollutants compared to conventional waste management and energy generation approaches.

Resource conservation effects extend beyond emissions reduction. The recovery of valuable materials from waste streams prior to energy conversion, coupled with the production of hydrogen and other chemical feedstocks, creates a circular economy framework that significantly reduces primary resource extraction requirements and associated environmental impacts.

Economic Viability and Scalability Analysis

The economic viability of solid oxide electrolysis cells (SOECs) and waste-to-energy (WTE) conversion technologies remains a critical factor determining their widespread adoption. Current cost analyses indicate that SOEC systems require significant capital investment, with estimates ranging from $2,000-5,000 per kW of installed capacity. This high initial cost presents a substantial barrier to commercialization despite the technology's promising efficiency metrics.

Operating expenses for SOEC systems are primarily driven by electricity costs, which typically account for 60-70% of total operational expenditures. The economic equation becomes more favorable when integrated with renewable energy sources that can provide low-cost electricity during peak production periods. Financial modeling suggests that hydrogen production via SOECs could become cost-competitive with conventional methods when electricity prices fall below $0.04/kWh, assuming current technology performance levels.

Scalability considerations reveal both challenges and opportunities. Laboratory-scale SOEC systems have demonstrated impressive performance, but industrial-scale implementations face issues related to thermal management, mechanical stability, and uniform gas distribution across larger cell areas. Current commercial SOEC stacks typically range from 1-10 kW, while meaningful industrial applications would require systems in the MW range.

For waste-to-energy conversion pathways utilizing SOECs, economic assessments indicate potential viability when processing high-calorific waste streams. The integration of waste gasification with SOEC systems creates value-added synergies, as the synthesis gas produced can be further upgraded to higher-value products. Preliminary economic models suggest payback periods of 5-8 years for integrated WTE-SOEC systems, depending on waste tipping fees, product values, and regional energy prices.

Economies of scale represent a crucial factor for future viability. Manufacturing costs for SOEC components are projected to decrease by 40-60% with mass production techniques. Learning curve analyses suggest that doubling production volumes could reduce unit costs by approximately 15-20%. However, these projections depend on continued technological improvements, particularly in extending cell lifetimes beyond the current 10,000-20,000 operating hours to the 40,000+ hours required for most industrial applications.

Regional economic factors significantly impact viability assessments. Markets with high renewable energy penetration, substantial waste management challenges, and supportive policy frameworks offer the most promising deployment opportunities. Carbon pricing mechanisms, when implemented effectively, can further enhance the economic case for these technologies by monetizing their environmental benefits.

Operating expenses for SOEC systems are primarily driven by electricity costs, which typically account for 60-70% of total operational expenditures. The economic equation becomes more favorable when integrated with renewable energy sources that can provide low-cost electricity during peak production periods. Financial modeling suggests that hydrogen production via SOECs could become cost-competitive with conventional methods when electricity prices fall below $0.04/kWh, assuming current technology performance levels.

Scalability considerations reveal both challenges and opportunities. Laboratory-scale SOEC systems have demonstrated impressive performance, but industrial-scale implementations face issues related to thermal management, mechanical stability, and uniform gas distribution across larger cell areas. Current commercial SOEC stacks typically range from 1-10 kW, while meaningful industrial applications would require systems in the MW range.

For waste-to-energy conversion pathways utilizing SOECs, economic assessments indicate potential viability when processing high-calorific waste streams. The integration of waste gasification with SOEC systems creates value-added synergies, as the synthesis gas produced can be further upgraded to higher-value products. Preliminary economic models suggest payback periods of 5-8 years for integrated WTE-SOEC systems, depending on waste tipping fees, product values, and regional energy prices.

Economies of scale represent a crucial factor for future viability. Manufacturing costs for SOEC components are projected to decrease by 40-60% with mass production techniques. Learning curve analyses suggest that doubling production volumes could reduce unit costs by approximately 15-20%. However, these projections depend on continued technological improvements, particularly in extending cell lifetimes beyond the current 10,000-20,000 operating hours to the 40,000+ hours required for most industrial applications.

Regional economic factors significantly impact viability assessments. Markets with high renewable energy penetration, substantial waste management challenges, and supportive policy frameworks offer the most promising deployment opportunities. Carbon pricing mechanisms, when implemented effectively, can further enhance the economic case for these technologies by monetizing their environmental benefits.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!