Solid oxide electrolysis cells and energy grid integration research

OCT 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SOEC Technology Evolution and Objectives

Solid oxide electrolysis cells (SOECs) have evolved significantly since their conceptual development in the mid-20th century. Initially derived from solid oxide fuel cell (SOFC) technology, SOECs have transitioned from laboratory curiosities to promising energy conversion devices. The fundamental operating principle—the reverse of SOFCs—involves using electrical energy to split water or carbon dioxide into hydrogen or carbon monoxide, respectively, at high temperatures (700-900°C).

The evolution of SOEC technology has been marked by several key milestones. In the 1980s, researchers demonstrated the first practical SOEC prototypes, though with limited efficiency and durability. The 1990s saw improvements in ceramic materials and manufacturing techniques, leading to enhanced performance. The early 2000s brought significant breakthroughs in electrode materials and cell designs, reducing degradation rates and improving operational stability.

Recent technological advancements have focused on lowering operating temperatures, enhancing durability, and increasing energy conversion efficiency. Modern SOECs can achieve electrical efficiencies exceeding 90% for hydrogen production, substantially higher than alternative electrolysis technologies. This remarkable efficiency is attributed to favorable thermodynamics at elevated temperatures and the ability to utilize waste heat.

The primary objective of current SOEC research is to develop commercially viable systems that can be integrated with renewable energy sources to provide grid-scale energy storage solutions. This involves addressing several technical challenges, including material degradation under thermal cycling, sealing issues at high temperatures, and system complexity. Researchers aim to extend cell lifetimes beyond 40,000 hours while maintaining high performance—a prerequisite for commercial deployment.

Another critical objective is cost reduction through materials innovation and manufacturing optimization. Current SOEC systems remain prohibitively expensive for widespread adoption, with capital costs significantly higher than competing technologies. Research efforts target reducing costs by 50-70% through economies of scale and alternative material formulations.

Integration with energy grids represents perhaps the most ambitious objective. SOECs offer unique capabilities for sector coupling—connecting electricity, gas, and heat networks—potentially enabling more flexible and resilient energy systems. The vision is to develop reversible systems that can operate as both fuel cells and electrolysis cells (rSOCs), providing bidirectional energy conversion capabilities that respond dynamically to grid conditions and energy prices.

Looking forward, SOEC technology aims to become a cornerstone of hydrogen economies and carbon-neutral energy systems, offering pathways for deep decarbonization across multiple sectors including industry, transportation, and power generation.

The evolution of SOEC technology has been marked by several key milestones. In the 1980s, researchers demonstrated the first practical SOEC prototypes, though with limited efficiency and durability. The 1990s saw improvements in ceramic materials and manufacturing techniques, leading to enhanced performance. The early 2000s brought significant breakthroughs in electrode materials and cell designs, reducing degradation rates and improving operational stability.

Recent technological advancements have focused on lowering operating temperatures, enhancing durability, and increasing energy conversion efficiency. Modern SOECs can achieve electrical efficiencies exceeding 90% for hydrogen production, substantially higher than alternative electrolysis technologies. This remarkable efficiency is attributed to favorable thermodynamics at elevated temperatures and the ability to utilize waste heat.

The primary objective of current SOEC research is to develop commercially viable systems that can be integrated with renewable energy sources to provide grid-scale energy storage solutions. This involves addressing several technical challenges, including material degradation under thermal cycling, sealing issues at high temperatures, and system complexity. Researchers aim to extend cell lifetimes beyond 40,000 hours while maintaining high performance—a prerequisite for commercial deployment.

Another critical objective is cost reduction through materials innovation and manufacturing optimization. Current SOEC systems remain prohibitively expensive for widespread adoption, with capital costs significantly higher than competing technologies. Research efforts target reducing costs by 50-70% through economies of scale and alternative material formulations.

Integration with energy grids represents perhaps the most ambitious objective. SOECs offer unique capabilities for sector coupling—connecting electricity, gas, and heat networks—potentially enabling more flexible and resilient energy systems. The vision is to develop reversible systems that can operate as both fuel cells and electrolysis cells (rSOCs), providing bidirectional energy conversion capabilities that respond dynamically to grid conditions and energy prices.

Looking forward, SOEC technology aims to become a cornerstone of hydrogen economies and carbon-neutral energy systems, offering pathways for deep decarbonization across multiple sectors including industry, transportation, and power generation.

Market Analysis for Grid-Integrated Electrolysis

The global market for grid-integrated electrolysis systems is experiencing significant growth, driven by the increasing focus on decarbonization and renewable energy integration. Current market valuations place the solid oxide electrolysis cell (SOEC) sector at approximately $500 million in 2023, with projections indicating a compound annual growth rate of 25-30% over the next decade. This growth trajectory is supported by substantial investments from both private and public sectors, with government funding for hydrogen technologies exceeding $70 billion globally as of 2023.

Market demand for grid-integrated electrolysis is primarily concentrated in regions with ambitious renewable energy targets and carbon neutrality commitments. The European Union leads this charge, allocating €470 billion toward hydrogen infrastructure development through 2050. Asia-Pacific follows closely, with China, Japan, and South Korea collectively investing over $40 billion in hydrogen technologies, including electrolysis systems. North America represents the third-largest market, with the United States recently allocating $9.5 billion specifically for clean hydrogen initiatives through the Infrastructure Investment and Jobs Act.

Industry analysis reveals distinct market segments within the grid-integrated electrolysis sector. The utility-scale segment currently dominates, accounting for approximately 65% of market share, driven by large-scale green hydrogen production facilities. Industrial applications represent 25% of the market, with the remaining 10% distributed across commercial and research applications. This segmentation reflects the current emphasis on economies of scale in hydrogen production.

The value chain for grid-integrated electrolysis encompasses equipment manufacturers, system integrators, utility companies, and end-users across various industries. Notable is the emergence of specialized service providers offering electrolysis-as-a-service business models, which reduce capital expenditure barriers for potential adopters. This evolution in business models is expected to accelerate market penetration, particularly in regions with less developed hydrogen infrastructure.

Market forecasts indicate that by 2030, grid-integrated electrolysis will become cost-competitive with conventional hydrogen production methods in regions with high renewable energy penetration. This inflection point is anticipated to trigger accelerated adoption across multiple sectors, including chemical manufacturing, steel production, and transportation. The total addressable market is expected to reach $25 billion by 2030, with solid oxide electrolysis cells capturing an increasing share due to their superior efficiency at high temperatures and ability to utilize waste heat from industrial processes.

Customer demand patterns show growing interest in flexible electrolysis systems that can provide grid balancing services while producing hydrogen, creating dual revenue streams for operators. This trend is particularly pronounced in markets with high variable renewable energy penetration, where grid stability services command premium prices.

Market demand for grid-integrated electrolysis is primarily concentrated in regions with ambitious renewable energy targets and carbon neutrality commitments. The European Union leads this charge, allocating €470 billion toward hydrogen infrastructure development through 2050. Asia-Pacific follows closely, with China, Japan, and South Korea collectively investing over $40 billion in hydrogen technologies, including electrolysis systems. North America represents the third-largest market, with the United States recently allocating $9.5 billion specifically for clean hydrogen initiatives through the Infrastructure Investment and Jobs Act.

Industry analysis reveals distinct market segments within the grid-integrated electrolysis sector. The utility-scale segment currently dominates, accounting for approximately 65% of market share, driven by large-scale green hydrogen production facilities. Industrial applications represent 25% of the market, with the remaining 10% distributed across commercial and research applications. This segmentation reflects the current emphasis on economies of scale in hydrogen production.

The value chain for grid-integrated electrolysis encompasses equipment manufacturers, system integrators, utility companies, and end-users across various industries. Notable is the emergence of specialized service providers offering electrolysis-as-a-service business models, which reduce capital expenditure barriers for potential adopters. This evolution in business models is expected to accelerate market penetration, particularly in regions with less developed hydrogen infrastructure.

Market forecasts indicate that by 2030, grid-integrated electrolysis will become cost-competitive with conventional hydrogen production methods in regions with high renewable energy penetration. This inflection point is anticipated to trigger accelerated adoption across multiple sectors, including chemical manufacturing, steel production, and transportation. The total addressable market is expected to reach $25 billion by 2030, with solid oxide electrolysis cells capturing an increasing share due to their superior efficiency at high temperatures and ability to utilize waste heat from industrial processes.

Customer demand patterns show growing interest in flexible electrolysis systems that can provide grid balancing services while producing hydrogen, creating dual revenue streams for operators. This trend is particularly pronounced in markets with high variable renewable energy penetration, where grid stability services command premium prices.

SOEC Technical Barriers and Global Development Status

Despite significant advancements in SOEC technology, several critical technical barriers continue to impede widespread commercial deployment. The most pressing challenge remains cell durability and degradation rates, with current systems experiencing performance losses of 1-2% per 1000 hours of operation—significantly higher than the 0.1-0.2% target required for commercial viability. This degradation primarily stems from chromium poisoning at the oxygen electrode, delamination at electrode-electrolyte interfaces, and microstructural changes during thermal cycling.

Material constraints present another substantial barrier, particularly the reliance on rare earth elements and precious metals for catalysts and electrodes. The high operating temperatures (700-850°C) necessitate specialized materials that can withstand thermal stress while maintaining electrochemical performance, significantly increasing system costs and limiting scalability.

System integration challenges are equally problematic, especially regarding thermal management and balance-of-plant components. The thermal cycling between startup and shutdown creates mechanical stresses that reduce stack lifetime, while the need for high-temperature steam generation adds complexity and energy penalties to the overall system.

Globally, SOEC development exhibits distinct regional characteristics. Europe leads in research intensity, with Denmark's Technical University and Germany's Forschungszentrum Jülich pioneering advanced cell architectures. The European Union has established multiple large-scale demonstration projects under the Horizon Europe framework, focusing on green hydrogen production integrated with renewable energy sources.

The United States demonstrates strength in fundamental materials research through Department of Energy initiatives at national laboratories, particularly Idaho National Laboratory and Pacific Northwest National Laboratory. Their focus has shifted toward modular designs suitable for nuclear energy integration.

In Asia, China has rapidly expanded its research capacity, emphasizing manufacturing scalability and cost reduction. Japan maintains leadership in materials science innovation through companies like Kyocera and Mitsubishi Heavy Industries, while South Korea focuses on system integration through public-private partnerships.

Recent technological breakthroughs include the development of proton-conducting SOECs operating at intermediate temperatures (500-650°C), which show promise for reducing degradation rates. Additionally, novel manufacturing techniques such as tape casting and 3D printing are beginning to address cost barriers by enabling more precise microstructural control and reducing material waste.

Material constraints present another substantial barrier, particularly the reliance on rare earth elements and precious metals for catalysts and electrodes. The high operating temperatures (700-850°C) necessitate specialized materials that can withstand thermal stress while maintaining electrochemical performance, significantly increasing system costs and limiting scalability.

System integration challenges are equally problematic, especially regarding thermal management and balance-of-plant components. The thermal cycling between startup and shutdown creates mechanical stresses that reduce stack lifetime, while the need for high-temperature steam generation adds complexity and energy penalties to the overall system.

Globally, SOEC development exhibits distinct regional characteristics. Europe leads in research intensity, with Denmark's Technical University and Germany's Forschungszentrum Jülich pioneering advanced cell architectures. The European Union has established multiple large-scale demonstration projects under the Horizon Europe framework, focusing on green hydrogen production integrated with renewable energy sources.

The United States demonstrates strength in fundamental materials research through Department of Energy initiatives at national laboratories, particularly Idaho National Laboratory and Pacific Northwest National Laboratory. Their focus has shifted toward modular designs suitable for nuclear energy integration.

In Asia, China has rapidly expanded its research capacity, emphasizing manufacturing scalability and cost reduction. Japan maintains leadership in materials science innovation through companies like Kyocera and Mitsubishi Heavy Industries, while South Korea focuses on system integration through public-private partnerships.

Recent technological breakthroughs include the development of proton-conducting SOECs operating at intermediate temperatures (500-650°C), which show promise for reducing degradation rates. Additionally, novel manufacturing techniques such as tape casting and 3D printing are beginning to address cost barriers by enabling more precise microstructural control and reducing material waste.

Current Grid Integration Architectures for SOEC Systems

01 Electrode materials and structures for SOECs

Various electrode materials and structures are used in solid oxide electrolysis cells to improve performance and durability. These include specialized cathode and anode materials that enhance electrochemical reactions, reduce degradation, and improve conductivity. Advanced electrode structures such as porous electrodes with optimized microstructures facilitate gas diffusion and increase active reaction sites, leading to higher efficiency in hydrogen or syngas production.- Electrode materials and structures for solid oxide electrolysis cells: Various electrode materials and structures can be used in solid oxide electrolysis cells to improve performance and durability. These include specialized cathode and anode materials that enhance electrochemical reactions, reduce degradation, and improve conductivity. Advanced electrode structures such as porous designs facilitate gas diffusion and increase active reaction sites, while composite electrodes combining multiple materials can provide synergistic benefits for electrolysis efficiency.

- Electrolyte compositions for high-temperature operation: Specialized electrolyte compositions are developed for solid oxide electrolysis cells operating at high temperatures. These electrolytes typically feature oxide-ion conducting materials with high ionic conductivity and stability at elevated temperatures. Innovations include doped zirconia and ceria-based materials that maintain performance while reducing operating temperatures, as well as thin-film electrolytes that decrease ohmic resistance and improve overall cell efficiency.

- System integration and stack design for solid oxide electrolysis: System integration and stack design are critical for efficient solid oxide electrolysis operation. This includes optimized cell stacking configurations that maximize active area while minimizing electrical resistance, thermal management systems that maintain uniform temperature distribution, and sealing technologies that prevent gas leakage at high temperatures. Advanced manifold designs ensure even gas distribution across cells, while interconnect materials provide electrical contact while withstanding harsh operating conditions.

- Hydrogen and syngas production methods using solid oxide electrolysis: Solid oxide electrolysis cells can be used for efficient hydrogen and syngas production through various methods. These include steam electrolysis for pure hydrogen generation, co-electrolysis of steam and carbon dioxide to produce syngas, and integration with renewable energy sources for green hydrogen production. Advanced operational strategies such as thermal cycling protocols and pressure management techniques help optimize production rates while maintaining cell integrity over extended operation periods.

- Degradation mechanisms and durability enhancement: Understanding and mitigating degradation mechanisms is essential for improving the durability of solid oxide electrolysis cells. Key degradation issues include electrode poisoning, electrolyte cracking, and interface delamination. Strategies to enhance durability include protective coatings that prevent chromium poisoning, dopants that stabilize material structures at high temperatures, and engineered microstructures that accommodate thermal expansion mismatches. Advanced manufacturing techniques and materials selection can significantly extend cell lifetime under operational conditions.

02 Electrolyte compositions for high-temperature operation

Specialized electrolyte materials enable solid oxide electrolysis cells to operate efficiently at high temperatures. These electrolytes, typically ceramic-based, offer excellent ionic conductivity while maintaining stability under extreme conditions. Advanced compositions include doped zirconia, ceria-based materials, and composite electrolytes that minimize ohmic resistance and enhance overall cell performance while extending operational lifetime at temperatures ranging from 600-900°C.Expand Specific Solutions03 System integration and stack design

Innovative stack designs and system integration approaches enhance the performance and scalability of solid oxide electrolysis cells. These include optimized cell stacking configurations, improved sealing technologies, and efficient thermal management systems. Advanced interconnect designs minimize electrical resistance while facilitating gas distribution. Complete systems incorporate balance-of-plant components such as heat exchangers, gas handling subsystems, and control electronics to maximize efficiency and operational flexibility.Expand Specific Solutions04 Reversible operation for energy storage applications

Reversible solid oxide cells can function in both electrolysis and fuel cell modes, enabling energy storage applications. These systems convert electricity to hydrogen or syngas during periods of excess renewable energy and then generate electricity when needed. This bidirectional capability requires specialized materials and designs that maintain stability and performance during mode switching. Advanced control strategies optimize operation based on energy demand and supply conditions, making these systems valuable for grid stabilization and renewable energy integration.Expand Specific Solutions05 Co-electrolysis for syngas production

Co-electrolysis processes using solid oxide electrolysis cells enable simultaneous reduction of steam and carbon dioxide to produce syngas (H₂ and CO mixture). This approach offers an efficient pathway for converting captured CO₂ into valuable chemical feedstocks or synthetic fuels. Specialized catalysts and electrode materials enhance selectivity and conversion efficiency while minimizing carbon deposition. Operating parameters such as temperature, pressure, and feed composition can be optimized to control the H₂/CO ratio in the syngas output for specific downstream applications.Expand Specific Solutions

Leading SOEC Manufacturers and Research Institutions

Solid oxide electrolysis cells (SOECs) technology is currently in the early commercialization phase, with a growing market projected to reach significant scale as green hydrogen demand increases. The competitive landscape features established industrial players like Toshiba, Kyocera, and Samsung Electro-Mechanics developing core components, while specialized firms such as DynElectro and Topsoe focus on system optimization and grid integration. Academic institutions including Tsinghua University and Georgia Tech are advancing fundamental research. Technical maturity varies across applications, with stationary systems more developed than dynamic load-following capabilities. Key challenges include durability under fluctuating renewable inputs, with companies like DynElectro specifically addressing cell degradation to extend operational lifetimes from two to ten years, critical for economic viability in energy grid applications.

DynElectro ApS

Technical Solution: DynElectro has developed a proprietary SOEC technology platform focused on dynamic operation capabilities essential for renewable energy grid integration. Their cells utilize a novel composite electrode structure that maintains performance stability during rapid power fluctuations, addressing a critical challenge for grid-responsive electrolysis. The company's "DynStack" architecture incorporates advanced thermal management systems that maintain optimal temperature distribution even during variable load operation, with thermal gradients kept below 30°C across the stack. Their grid integration approach includes predictive control algorithms that anticipate renewable energy fluctuations based on weather forecasting data, optimizing hydrogen production schedules to maximize efficiency and minimize degradation. DynElectro's systems have demonstrated remarkable durability under dynamic operating conditions, maintaining over 80% of initial performance after 500 rapid load cycles between 20% and 100% capacity. Their modular design philosophy enables scalable deployment from distributed energy storage applications to industrial-scale hydrogen production facilities.

Strengths: Superior dynamic operation capabilities, advanced predictive control systems, and proven durability under variable load conditions. Weaknesses: As a smaller specialized company, DynElectro may face challenges in manufacturing scale-up and global market penetration compared to larger industrial players.

Chinese Academy of Sciences Institute of Physics

Technical Solution: The Chinese Academy of Sciences Institute of Physics has developed cutting-edge SOEC technology focusing on novel materials and interface engineering. Their research has yielded proprietary double perovskite electrode materials that demonstrate exceptional electrochemical performance and stability under high-temperature electrolysis conditions. The institute's SOEC design incorporates nanoscale catalyst infiltration techniques that significantly reduce electrode polarization resistance, enabling operation at lower temperatures (650-750°C) while maintaining high current densities of 1.0-1.3 A/cm². Their grid integration approach emphasizes system flexibility through innovative thermal management strategies that allow rapid startup and shutdown cycles, critical for integration with intermittent renewable energy sources. The institute has demonstrated advanced control systems that enable their SOEC stacks to respond to grid signals within minutes, providing valuable grid balancing capabilities. Their research includes comprehensive degradation studies under dynamic operating conditions, identifying key failure mechanisms and developing mitigation strategies that have extended operational lifetimes by over 40% compared to conventional designs. Recent demonstration projects have successfully integrated their SOEC technology with renewable hydrogen production and industrial carbon utilization pathways.

Strengths: World-class materials science capabilities, innovative interface engineering approaches, and comprehensive degradation mechanism understanding. Weaknesses: Technology commercialization pathway less developed than Western competitors, with fewer large-scale demonstration projects completed to date.

Critical Patents in SOEC Materials and System Design

Solid oxide electrolysis unit

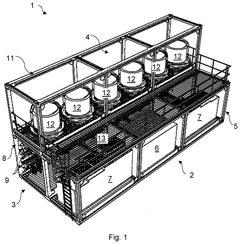

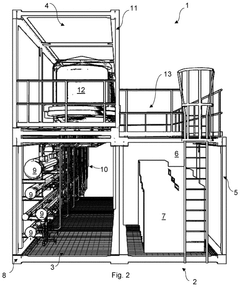

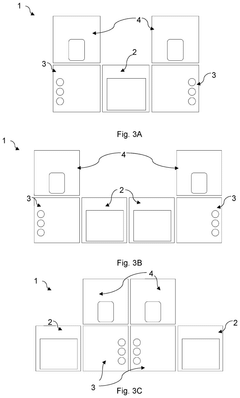

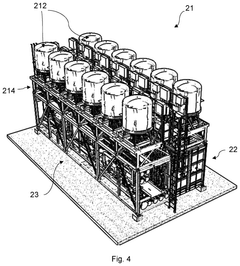

PatentPendingUS20250297377A1

Innovation

- The arrangement of Solid Oxide Electrolysis cores above power supply and piping modules, with compact design of power supply and fluidic transfer components, reduces the footprint and simplifies maintenance by keeping connections short and accessible.

Energy Storage Solutions for SOEC-Grid Systems

Energy storage systems are critical components for the successful integration of Solid Oxide Electrolysis Cells (SOECs) with modern power grids. These storage solutions address the inherent intermittency of renewable energy sources that often power SOEC operations, ensuring continuous hydrogen production despite fluctuating electricity supply. Several storage technologies have emerged as particularly promising for SOEC-grid integration scenarios.

Hydrogen storage represents the most direct approach, where excess hydrogen produced during periods of abundant renewable energy can be stored for later use. This includes compressed gas storage (350-700 bar), liquid hydrogen storage (-253°C), and chemical carriers like ammonia or metal hydrides. Each method offers different energy densities and operational requirements, with compressed storage being the most commercially mature despite its relatively low volumetric efficiency.

Battery systems, particularly lithium-ion and flow batteries, provide short to medium-term electricity storage capabilities that can stabilize power delivery to SOECs. Advanced battery management systems enable rapid response to grid fluctuations, maintaining optimal SOEC operating conditions even during transient power events. The declining cost trajectory of battery technologies (approximately 85% reduction since 2010) has significantly improved the economic viability of these hybrid systems.

Thermal energy storage solutions leverage the high-temperature operation of SOECs (700-850°C) by capturing waste heat or storing excess energy as heat. Molten salt systems, phase change materials, and thermochemical storage can maintain temperature stability in SOEC stacks, reducing thermal cycling stress and extending cell lifetimes while improving overall system efficiency by 15-20%.

Power-to-X-to-Power pathways offer versatile energy storage options where hydrogen or synthetic fuels produced by SOECs can be reconverted to electricity through fuel cells or turbines when needed. This approach enables seasonal storage capabilities with minimal self-discharge losses compared to batteries, though with lower round-trip efficiencies (typically 30-45%).

Grid-scale solutions including pumped hydro storage and compressed air energy storage complement SOEC operations by providing bulk energy management capabilities. These technologies can absorb or release large quantities of electricity to balance supply and demand across the grid, creating favorable conditions for SOEC operation during periods of excess renewable generation.

The optimal storage solution for SOEC-grid integration depends on specific application requirements, including response time needs, storage duration, geographical constraints, and economic considerations. Most commercial implementations utilize hybrid approaches combining multiple storage technologies to address different temporal scales of energy management.

Hydrogen storage represents the most direct approach, where excess hydrogen produced during periods of abundant renewable energy can be stored for later use. This includes compressed gas storage (350-700 bar), liquid hydrogen storage (-253°C), and chemical carriers like ammonia or metal hydrides. Each method offers different energy densities and operational requirements, with compressed storage being the most commercially mature despite its relatively low volumetric efficiency.

Battery systems, particularly lithium-ion and flow batteries, provide short to medium-term electricity storage capabilities that can stabilize power delivery to SOECs. Advanced battery management systems enable rapid response to grid fluctuations, maintaining optimal SOEC operating conditions even during transient power events. The declining cost trajectory of battery technologies (approximately 85% reduction since 2010) has significantly improved the economic viability of these hybrid systems.

Thermal energy storage solutions leverage the high-temperature operation of SOECs (700-850°C) by capturing waste heat or storing excess energy as heat. Molten salt systems, phase change materials, and thermochemical storage can maintain temperature stability in SOEC stacks, reducing thermal cycling stress and extending cell lifetimes while improving overall system efficiency by 15-20%.

Power-to-X-to-Power pathways offer versatile energy storage options where hydrogen or synthetic fuels produced by SOECs can be reconverted to electricity through fuel cells or turbines when needed. This approach enables seasonal storage capabilities with minimal self-discharge losses compared to batteries, though with lower round-trip efficiencies (typically 30-45%).

Grid-scale solutions including pumped hydro storage and compressed air energy storage complement SOEC operations by providing bulk energy management capabilities. These technologies can absorb or release large quantities of electricity to balance supply and demand across the grid, creating favorable conditions for SOEC operation during periods of excess renewable generation.

The optimal storage solution for SOEC-grid integration depends on specific application requirements, including response time needs, storage duration, geographical constraints, and economic considerations. Most commercial implementations utilize hybrid approaches combining multiple storage technologies to address different temporal scales of energy management.

Economic Viability and Policy Frameworks

The economic viability of Solid Oxide Electrolysis Cells (SOECs) remains a critical factor determining their widespread adoption in energy systems. Current capital costs for SOEC systems range between $800-1,500/kW, significantly higher than competing hydrogen production technologies. However, cost projections indicate potential reductions to $500-700/kW by 2030 through manufacturing scale-up and materials optimization, particularly in electrode fabrication and stack assembly processes.

Operating expenses present another economic challenge, with electricity costs comprising 60-70% of hydrogen production expenses via electrolysis. Grid integration strategies that leverage variable renewable energy sources during low-demand periods can substantially improve the economic case. Analysis shows that SOEC systems operating with electricity prices below $40/MWh can achieve hydrogen production costs competitive with steam methane reforming when carbon pricing mechanisms are in place.

Policy frameworks across major economies are increasingly supportive of SOEC technology deployment. The European Union's Hydrogen Strategy targets 40GW of electrolyzer capacity by 2030, backed by the Innovation Fund and Horizon Europe programs providing dedicated funding streams for SOEC research and demonstration projects. Similarly, the United States has established the Hydrogen Shot initiative aiming to reduce clean hydrogen costs to $1/kg within a decade, with the Infrastructure Investment and Jobs Act allocating $9.5 billion toward hydrogen hubs and manufacturing improvements.

Carbon pricing mechanisms represent a crucial policy lever affecting SOEC economic viability. Jurisdictions with carbon prices exceeding €50/tonne CO₂ create favorable conditions for SOEC adoption compared to fossil-based alternatives. Additionally, regulatory frameworks addressing grid connection fees and electricity taxation significantly impact operational economics, with several countries now implementing exemptions for electrolytic hydrogen production to improve competitiveness.

Investment incentives through accelerated depreciation allowances, production tax credits, and capital grants are emerging as effective policy tools. The U.S. Inflation Reduction Act's clean hydrogen production tax credit of up to $3/kg represents a transformative policy intervention that substantially improves SOEC project economics. Meanwhile, Japan's Green Innovation Fund and South Korea's Hydrogen Economy Roadmap provide similar financial support mechanisms tailored to their industrial contexts.

Long-term policy stability remains essential for attracting the substantial capital investments required for SOEC manufacturing scale-up and deployment. Countries establishing clear hydrogen strategies with consistent regulatory frameworks and funding mechanisms are witnessing accelerated private sector engagement and technology adoption rates, highlighting the critical interplay between policy design and economic viability in this emerging technology space.

Operating expenses present another economic challenge, with electricity costs comprising 60-70% of hydrogen production expenses via electrolysis. Grid integration strategies that leverage variable renewable energy sources during low-demand periods can substantially improve the economic case. Analysis shows that SOEC systems operating with electricity prices below $40/MWh can achieve hydrogen production costs competitive with steam methane reforming when carbon pricing mechanisms are in place.

Policy frameworks across major economies are increasingly supportive of SOEC technology deployment. The European Union's Hydrogen Strategy targets 40GW of electrolyzer capacity by 2030, backed by the Innovation Fund and Horizon Europe programs providing dedicated funding streams for SOEC research and demonstration projects. Similarly, the United States has established the Hydrogen Shot initiative aiming to reduce clean hydrogen costs to $1/kg within a decade, with the Infrastructure Investment and Jobs Act allocating $9.5 billion toward hydrogen hubs and manufacturing improvements.

Carbon pricing mechanisms represent a crucial policy lever affecting SOEC economic viability. Jurisdictions with carbon prices exceeding €50/tonne CO₂ create favorable conditions for SOEC adoption compared to fossil-based alternatives. Additionally, regulatory frameworks addressing grid connection fees and electricity taxation significantly impact operational economics, with several countries now implementing exemptions for electrolytic hydrogen production to improve competitiveness.

Investment incentives through accelerated depreciation allowances, production tax credits, and capital grants are emerging as effective policy tools. The U.S. Inflation Reduction Act's clean hydrogen production tax credit of up to $3/kg represents a transformative policy intervention that substantially improves SOEC project economics. Meanwhile, Japan's Green Innovation Fund and South Korea's Hydrogen Economy Roadmap provide similar financial support mechanisms tailored to their industrial contexts.

Long-term policy stability remains essential for attracting the substantial capital investments required for SOEC manufacturing scale-up and deployment. Countries establishing clear hydrogen strategies with consistent regulatory frameworks and funding mechanisms are witnessing accelerated private sector engagement and technology adoption rates, highlighting the critical interplay between policy design and economic viability in this emerging technology space.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!