Solid oxide electrolysis cells integration in smart grid technology

OCT 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SOEC Technology Evolution and Integration Goals

Solid oxide electrolysis cells (SOECs) have evolved significantly since their conceptual development in the mid-20th century. Initially designed as reverse solid oxide fuel cells, SOECs have progressed from laboratory curiosities to commercially viable technologies for energy conversion and storage. The evolution trajectory has been marked by breakthroughs in materials science, particularly in electrolyte and electrode development, enabling higher efficiency and durability at lower operating temperatures.

Early SOEC systems operated at extremely high temperatures (900-1000°C), limiting their practical applications and component longevity. Recent advancements have reduced operating temperatures to 600-800°C, significantly expanding integration possibilities while maintaining high conversion efficiencies. This temperature reduction represents a critical milestone in SOEC development, making grid integration increasingly feasible.

The primary integration goal for SOECs in smart grid technology is to establish flexible, bidirectional energy conversion systems that can effectively balance supply and demand fluctuations inherent in renewable energy sources. When renewable generation exceeds demand, SOECs can convert surplus electricity into storable hydrogen or syngas, functioning as energy storage mechanisms. During peak demand periods, these stored energy carriers can be reconverted to electricity, providing grid stabilization services.

Another crucial integration objective involves developing scalable SOEC systems that can be deployed at various capacities, from distributed residential applications to centralized industrial installations. This scalability is essential for creating a decentralized energy infrastructure that enhances grid resilience and reduces transmission losses.

Achieving cost-competitiveness represents perhaps the most significant integration challenge. Current SOEC systems remain expensive compared to alternative technologies, with capital costs exceeding $2,000/kW. Integration goals include reducing this to below $800/kW through manufacturing optimization, materials innovation, and economies of scale.

System durability and operational flexibility constitute additional integration priorities. SOECs must withstand thousands of thermal and redox cycles while maintaining performance integrity. Current degradation rates of 1-2% per 1000 hours must be reduced to less than 0.5% to ensure long-term viability in grid applications.

The ultimate integration vision encompasses fully automated SOEC systems that respond dynamically to grid signals, seamlessly transitioning between electricity consumption and production modes based on real-time grid conditions. This requires sophisticated control systems, predictive analytics, and integration with broader energy management platforms to optimize operation across multiple timescales, from second-by-second frequency regulation to seasonal energy storage.

Early SOEC systems operated at extremely high temperatures (900-1000°C), limiting their practical applications and component longevity. Recent advancements have reduced operating temperatures to 600-800°C, significantly expanding integration possibilities while maintaining high conversion efficiencies. This temperature reduction represents a critical milestone in SOEC development, making grid integration increasingly feasible.

The primary integration goal for SOECs in smart grid technology is to establish flexible, bidirectional energy conversion systems that can effectively balance supply and demand fluctuations inherent in renewable energy sources. When renewable generation exceeds demand, SOECs can convert surplus electricity into storable hydrogen or syngas, functioning as energy storage mechanisms. During peak demand periods, these stored energy carriers can be reconverted to electricity, providing grid stabilization services.

Another crucial integration objective involves developing scalable SOEC systems that can be deployed at various capacities, from distributed residential applications to centralized industrial installations. This scalability is essential for creating a decentralized energy infrastructure that enhances grid resilience and reduces transmission losses.

Achieving cost-competitiveness represents perhaps the most significant integration challenge. Current SOEC systems remain expensive compared to alternative technologies, with capital costs exceeding $2,000/kW. Integration goals include reducing this to below $800/kW through manufacturing optimization, materials innovation, and economies of scale.

System durability and operational flexibility constitute additional integration priorities. SOECs must withstand thousands of thermal and redox cycles while maintaining performance integrity. Current degradation rates of 1-2% per 1000 hours must be reduced to less than 0.5% to ensure long-term viability in grid applications.

The ultimate integration vision encompasses fully automated SOEC systems that respond dynamically to grid signals, seamlessly transitioning between electricity consumption and production modes based on real-time grid conditions. This requires sophisticated control systems, predictive analytics, and integration with broader energy management platforms to optimize operation across multiple timescales, from second-by-second frequency regulation to seasonal energy storage.

Smart Grid Market Demand Analysis

The global smart grid market is experiencing significant growth driven by increasing energy demands, aging infrastructure, and the transition towards renewable energy sources. According to recent market analyses, the smart grid market is projected to reach $92.1 billion by 2026, growing at a CAGR of 17.4% from 2021. This substantial growth reflects the urgent need for more efficient, reliable, and sustainable energy management systems worldwide.

The integration of Solid Oxide Electrolysis Cells (SOEC) into smart grid technology addresses several critical market demands. Primarily, there is a growing need for energy storage solutions that can effectively manage the intermittent nature of renewable energy sources. SOECs offer a promising approach by converting excess electricity into hydrogen or syngas, which can be stored and later reconverted to electricity when demand increases.

Utility companies are increasingly seeking technologies that enhance grid flexibility and resilience. Market research indicates that approximately 67% of utility executives consider grid modernization a top priority, with energy storage solutions being a key component. SOECs provide this flexibility by enabling bidirectional energy flow and supporting demand response mechanisms.

The commercial and industrial sectors represent another significant market segment, with businesses looking to reduce energy costs and carbon footprints. These sectors account for nearly 60% of global electricity consumption and are increasingly adopting distributed energy resources. SOECs integrated with smart grid technology offer these customers enhanced energy independence and cost optimization opportunities.

Geographically, North America and Europe currently lead the smart grid market, with Asia-Pacific showing the fastest growth rate. Government initiatives and regulatory frameworks supporting clean energy transition are key drivers in these regions. For instance, the European Union's Green Deal and the United States' infrastructure plans allocate substantial funding for smart grid development and renewable energy integration.

Consumer behavior is also evolving, with growing awareness and demand for sustainable energy solutions. Market surveys indicate that 73% of consumers are willing to pay premium prices for products and services that demonstrate environmental responsibility. This shift in consumer preferences creates additional market pull for innovative technologies like SOEC integration in smart grids.

The COVID-19 pandemic has accelerated digitalization across industries, including the energy sector. This has increased the demand for automated, remotely managed energy systems, further boosting the market potential for advanced smart grid technologies incorporating SOECs.

The integration of Solid Oxide Electrolysis Cells (SOEC) into smart grid technology addresses several critical market demands. Primarily, there is a growing need for energy storage solutions that can effectively manage the intermittent nature of renewable energy sources. SOECs offer a promising approach by converting excess electricity into hydrogen or syngas, which can be stored and later reconverted to electricity when demand increases.

Utility companies are increasingly seeking technologies that enhance grid flexibility and resilience. Market research indicates that approximately 67% of utility executives consider grid modernization a top priority, with energy storage solutions being a key component. SOECs provide this flexibility by enabling bidirectional energy flow and supporting demand response mechanisms.

The commercial and industrial sectors represent another significant market segment, with businesses looking to reduce energy costs and carbon footprints. These sectors account for nearly 60% of global electricity consumption and are increasingly adopting distributed energy resources. SOECs integrated with smart grid technology offer these customers enhanced energy independence and cost optimization opportunities.

Geographically, North America and Europe currently lead the smart grid market, with Asia-Pacific showing the fastest growth rate. Government initiatives and regulatory frameworks supporting clean energy transition are key drivers in these regions. For instance, the European Union's Green Deal and the United States' infrastructure plans allocate substantial funding for smart grid development and renewable energy integration.

Consumer behavior is also evolving, with growing awareness and demand for sustainable energy solutions. Market surveys indicate that 73% of consumers are willing to pay premium prices for products and services that demonstrate environmental responsibility. This shift in consumer preferences creates additional market pull for innovative technologies like SOEC integration in smart grids.

The COVID-19 pandemic has accelerated digitalization across industries, including the energy sector. This has increased the demand for automated, remotely managed energy systems, further boosting the market potential for advanced smart grid technologies incorporating SOECs.

SOEC Integration Challenges and Global Status

The integration of Solid Oxide Electrolysis Cells (SOECs) into smart grid technology presents significant challenges despite its promising potential. One primary obstacle is the high operating temperature requirement (700-900°C), necessitating specialized materials and thermal management systems that can withstand such extreme conditions while maintaining grid compatibility. This thermal constraint impacts system responsiveness, making rapid load following—essential for smart grid applications—technically difficult to achieve.

Grid integration challenges extend to power electronics and control systems. SOECs require DC power while grids operate on AC, demanding sophisticated power conversion equipment with high efficiency to prevent energy losses. Additionally, the control systems must manage complex electrochemical processes while responding to grid signals, requiring advanced algorithms and robust communication protocols that can operate reliably in harsh environments.

Durability remains a critical concern, with degradation rates still exceeding commercial viability thresholds. Current SOEC systems typically show 1-2% performance degradation per 1000 hours, whereas smart grid applications require stability over tens of thousands of hours. This degradation is exacerbated by the dynamic operation patterns inherent to renewable energy integration.

Globally, research efforts addressing these challenges show regional specialization. Europe leads in system integration research, with significant projects in Denmark (DTU), Germany (Sunfire), and France (CEA). The European Union's Horizon Europe program has allocated substantial funding specifically for SOEC grid integration projects, focusing on renewable energy coupling.

The United States focuses on materials innovation through the Department of Energy's SOFC Program and National Laboratories, with particular emphasis on durability improvements and advanced manufacturing techniques. ARPA-E's REFUEL program specifically targets SOEC integration with renewable electricity sources.

In Asia, Japan (through NEDO) and South Korea (through KIER) are advancing high-efficiency SOEC systems with improved thermal cycling capabilities. China has rapidly expanded its research capacity, particularly at institutions like Tsinghua University and the Dalian Institute of Chemical Physics, focusing on cost reduction and mass production technologies.

Recent technological breakthroughs include the development of proton-conducting SOECs operating at lower temperatures (500-600°C), potentially addressing thermal management challenges. Additionally, novel electrode materials with enhanced durability under fluctuating loads have shown promising results in laboratory settings, though commercial-scale validation remains pending.

Grid integration challenges extend to power electronics and control systems. SOECs require DC power while grids operate on AC, demanding sophisticated power conversion equipment with high efficiency to prevent energy losses. Additionally, the control systems must manage complex electrochemical processes while responding to grid signals, requiring advanced algorithms and robust communication protocols that can operate reliably in harsh environments.

Durability remains a critical concern, with degradation rates still exceeding commercial viability thresholds. Current SOEC systems typically show 1-2% performance degradation per 1000 hours, whereas smart grid applications require stability over tens of thousands of hours. This degradation is exacerbated by the dynamic operation patterns inherent to renewable energy integration.

Globally, research efforts addressing these challenges show regional specialization. Europe leads in system integration research, with significant projects in Denmark (DTU), Germany (Sunfire), and France (CEA). The European Union's Horizon Europe program has allocated substantial funding specifically for SOEC grid integration projects, focusing on renewable energy coupling.

The United States focuses on materials innovation through the Department of Energy's SOFC Program and National Laboratories, with particular emphasis on durability improvements and advanced manufacturing techniques. ARPA-E's REFUEL program specifically targets SOEC integration with renewable electricity sources.

In Asia, Japan (through NEDO) and South Korea (through KIER) are advancing high-efficiency SOEC systems with improved thermal cycling capabilities. China has rapidly expanded its research capacity, particularly at institutions like Tsinghua University and the Dalian Institute of Chemical Physics, focusing on cost reduction and mass production technologies.

Recent technological breakthroughs include the development of proton-conducting SOECs operating at lower temperatures (500-600°C), potentially addressing thermal management challenges. Additionally, novel electrode materials with enhanced durability under fluctuating loads have shown promising results in laboratory settings, though commercial-scale validation remains pending.

Current SOEC-Smart Grid Integration Solutions

01 Electrode materials and structures for solid oxide electrolysis cells

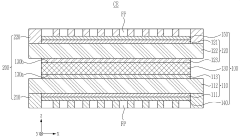

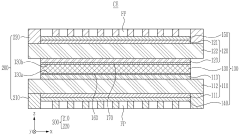

Various electrode materials and structures are used in solid oxide electrolysis cells to improve performance and durability. These include specialized cathode and anode materials that enhance electrochemical reactions, reduce degradation, and improve conductivity. Advanced electrode structures may incorporate composite materials, nanostructures, or gradient compositions to optimize the triple-phase boundary where electrolyte, electrode, and gas phases meet, thereby enhancing overall cell efficiency and longevity.- Electrode materials and structures for SOECs: The choice of electrode materials and their structural design significantly impacts the performance of solid oxide electrolysis cells. Advanced materials such as perovskites, cermets, and composite electrodes can enhance electrochemical activity and durability. Optimized electrode structures with controlled porosity and thickness facilitate efficient gas diffusion and electrochemical reactions at the triple-phase boundaries, leading to improved cell efficiency and longevity.

- Electrolyte development for high-temperature operation: High-performance electrolytes are crucial for solid oxide electrolysis cells operating at elevated temperatures. Materials with high ionic conductivity, such as yttria-stabilized zirconia (YSZ) and gadolinium-doped ceria (GDC), enable efficient oxygen ion transport while maintaining mechanical and chemical stability. Thin-film electrolytes can reduce ohmic resistance and operating temperatures, improving overall system efficiency and extending operational lifetime.

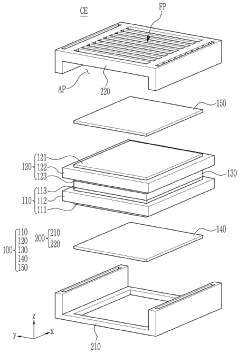

- System integration and stack design: Effective integration of solid oxide electrolysis cells into complete systems requires optimized stack designs that address thermal management, gas distribution, and electrical connections. Advanced sealing technologies prevent gas leakage while accommodating thermal expansion. Modular stack configurations enable scalability for various applications, from distributed hydrogen production to large-scale industrial processes, while improving maintenance accessibility and operational flexibility.

- Degradation mechanisms and durability enhancement: Understanding and mitigating degradation mechanisms is essential for extending the operational lifetime of solid oxide electrolysis cells. Key degradation factors include chromium poisoning, nickel agglomeration, and interfacial reactions between cell components. Protective coatings, dopants, and compositional modifications can enhance chemical stability and reduce degradation rates. Advanced operating strategies, such as controlled current density and temperature cycling, further improve long-term durability.

- Co-electrolysis and multi-functional applications: Solid oxide electrolysis cells can be utilized for co-electrolysis of steam and carbon dioxide to produce syngas (H₂ and CO mixture), offering pathways for carbon utilization and synthetic fuel production. These multi-functional capabilities enable integration with renewable energy sources for energy storage and conversion applications. Reversible operation as both fuel cells and electrolysis cells provides additional flexibility for grid balancing and seasonal energy storage solutions.

02 Electrolyte compositions for high-temperature operation

Specialized electrolyte compositions are developed for solid oxide electrolysis cells that operate at high temperatures. These electrolytes typically consist of ceramic materials with high ionic conductivity, such as yttria-stabilized zirconia (YSZ), gadolinium-doped ceria (GDC), or lanthanum gallate-based materials. The composition and structure of these electrolytes are engineered to maintain stability at elevated temperatures while facilitating efficient oxygen ion transport, which is crucial for the electrolysis process.Expand Specific Solutions03 System integration and stack design for solid oxide electrolysis cells

System integration and stack design are critical aspects of solid oxide electrolysis cell technology. This includes the development of efficient cell stacking methods, sealing technologies, and interconnect materials that can withstand high-temperature operation. Advanced stack designs focus on optimizing gas flow distribution, minimizing ohmic losses, and ensuring uniform temperature distribution across the stack. These improvements lead to enhanced system efficiency, increased hydrogen production rates, and extended operational lifetimes.Expand Specific Solutions04 Reversible operation as fuel cells and electrolysis cells

Some solid oxide cells are designed for reversible operation, functioning as both fuel cells (generating electricity) and electrolysis cells (producing hydrogen). These reversible solid oxide cells (RSOCs) incorporate specialized materials and designs that maintain stability and performance in both operating modes. This dual functionality allows for energy storage through hydrogen production during periods of excess electricity and electricity generation when needed, making them valuable components in renewable energy systems and grid stabilization applications.Expand Specific Solutions05 Manufacturing methods and process optimization

Various manufacturing methods and process optimization techniques are employed to produce high-performance solid oxide electrolysis cells. These include advanced ceramic processing techniques, thin-film deposition methods, and sintering protocols that ensure proper microstructure development. Innovations in manufacturing focus on reducing production costs, improving reproducibility, and scaling up production while maintaining cell quality and performance. Process optimization also addresses challenges related to thermal cycling, mechanical integrity, and long-term stability of the cells.Expand Specific Solutions

Leading Companies and Research Institutions

The integration of Solid Oxide Electrolysis Cells (SOECs) in smart grid technology is in an early growth phase, with the market expanding as renewable energy integration accelerates. Current market size remains modest but shows significant growth potential due to increasing focus on green hydrogen production and energy storage solutions. Technologically, the field is advancing rapidly with varying maturity levels among key players. Academic institutions like Tsinghua University and Northwestern University are driving fundamental research, while companies demonstrate different specialization levels: DynElectro has developed proprietary technology extending SOEC lifespan, Topsoe focuses on industrial-scale implementation, and established corporations like Samsung, Hyundai, and Toshiba are leveraging their manufacturing expertise to scale solutions for commercial deployment.

Battelle Energy Alliance LLC

Technical Solution: Battelle Energy Alliance has developed an integrated SOEC-smart grid platform through their management of Idaho National Laboratory. Their technology focuses on nuclear-renewable hybrid energy systems that incorporate SOECs as flexible load components. The system utilizes high-temperature steam electrolysis cells operating at 800-850°C with zirconia-based electrolytes that achieve hydrogen production efficiencies exceeding 85%. Their proprietary grid integration architecture includes advanced power electronics capable of handling multiple input sources (nuclear baseload, solar, wind) while maintaining optimal SOEC operating parameters. The system features real-time monitoring with predictive degradation algorithms that can forecast maintenance needs based on operational patterns. Battelle has demonstrated grid-scale implementations exceeding 250kW that respond to grid signals within regulatory timeframes for ancillary services. Their hybrid approach enables continuous SOEC operation even during renewable intermittency by utilizing nuclear baseload power, achieving capacity factors above 90% compared to standalone renewable-powered systems (typically 30-60%).

Strengths: Unique nuclear-renewable hybrid approach providing high capacity factors; extensive research infrastructure and testing capabilities; advanced predictive maintenance systems reducing operational costs. Weaknesses: Heavy reliance on nuclear power infrastructure limiting deployment flexibility; higher system complexity requiring specialized operational expertise; technology primarily demonstrated at research scale rather than full commercial deployment.

Topsoe A/S

Technical Solution: Topsoe has developed advanced solid oxide electrolysis cell (SOEC) technology that integrates seamlessly with smart grid systems. Their eCOs™ technology converts electricity and CO2 into synthesis gas at high efficiency (>90%) using proprietary ceramic cells operating at 700-850°C. The system features dynamic operation capabilities allowing it to respond to fluctuating renewable energy inputs from smart grids, with ramp-up times as low as 15 minutes from standby mode. Topsoe's SOECs can operate in reversible mode (rSOC), functioning as both fuel cells and electrolysis cells depending on grid demands, providing grid balancing services during peak and off-peak periods. Their modular stack design enables scalable implementation from kilowatt to megawatt installations, with integrated heat recovery systems that utilize waste heat to improve overall system efficiency by up to 15%. Topsoe has demonstrated successful grid integration projects with response times compatible with grid frequency regulation requirements (sub-minute response).

Strengths: Industry-leading electrical efficiency (>90%) compared to competitors' 70-80%; proven reversible operation capability providing grid flexibility; advanced thermal management systems. Weaknesses: High operating temperatures (700-850°C) require specialized materials and thermal management; higher capital costs compared to alternative technologies; limited operational experience in full-scale commercial smart grid applications.

Key Patents and Innovations in SOEC Grid Technology

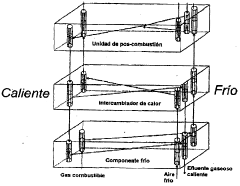

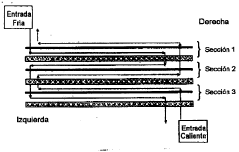

SOLID OXIDE STACK SYSTEM WITH THERMALLY EQUALIZED HEAT EXCHANGER INTEGRATED IN THE STACK

PatentInactiveAR096120A1

Innovation

- Integration of thermally matched heat exchangers within the stack system, aligning thermal gradients with adjacent components, reducing hot surface areas and eliminating heat loss from collectors, pipes, and compression systems, while using integrated heat exchangers with the same assembly processes as the stack.

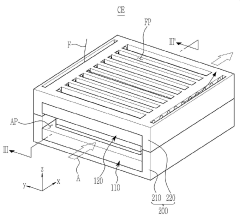

Solid oxide electrolysis cell and cell assembly including the same

PatentPendingKR1020240085112A

Innovation

- A solid oxide electrolysis cell design that combines two unit cells with mirror-symmetrical stacking and reduced separator plates, along with parallel electrical connections and circuit breakers, to prevent local high voltage and minimize thickness.

Energy Policy and Regulatory Framework

The integration of Solid Oxide Electrolysis Cells (SOECs) into smart grid technology necessitates a comprehensive energy policy and regulatory framework. Currently, most jurisdictions lack specific regulations addressing SOEC integration, creating uncertainty for investors and developers. The European Union has taken a leading role through its Renewable Energy Directive (RED II) and the European Green Deal, which provide incentives for green hydrogen production using renewable electricity. These frameworks establish targets for renewable energy penetration and carbon reduction, indirectly supporting SOEC deployment.

In the United States, policies vary significantly by state, with California's Low Carbon Fuel Standard and Self-Generation Incentive Program offering financial incentives that can benefit SOEC integration projects. At the federal level, the Investment Tax Credit and Production Tax Credit have been extended to include certain hydrogen production technologies, though specific provisions for SOECs remain limited. The Infrastructure Investment and Jobs Act of 2021 allocates substantial funding for hydrogen hubs, potentially accelerating SOEC deployment.

Regulatory challenges include the classification of SOECs within existing energy market structures. Questions persist regarding whether SOECs should be regulated as generation assets, storage facilities, or grid services providers. This classification significantly impacts permitting requirements, interconnection standards, and market participation rules. Grid codes and interconnection standards need updating to accommodate the bidirectional energy flow capabilities of SOECs in smart grid environments.

Carbon pricing mechanisms represent another critical policy lever. Regions with established carbon markets or taxes, such as the EU Emissions Trading System, provide indirect support for SOEC technologies by increasing the cost competitiveness of low-carbon alternatives. However, carbon pricing remains fragmented globally, creating uneven market conditions for technology deployment.

Standardization efforts are emerging but remain insufficient. The International Electrotechnical Commission (IEC) and IEEE have begun developing standards for hydrogen technologies and grid integration, but SOEC-specific standards are still evolving. This standardization gap creates technical barriers to widespread adoption and complicates cross-border deployment.

Future policy development should focus on creating technology-specific incentives for SOEC deployment, establishing clear regulatory classifications, developing comprehensive grid integration standards, and implementing consistent carbon valuation mechanisms. Regulatory sandboxes and demonstration projects with temporary regulatory exemptions could accelerate real-world testing while informing permanent regulatory frameworks.

In the United States, policies vary significantly by state, with California's Low Carbon Fuel Standard and Self-Generation Incentive Program offering financial incentives that can benefit SOEC integration projects. At the federal level, the Investment Tax Credit and Production Tax Credit have been extended to include certain hydrogen production technologies, though specific provisions for SOECs remain limited. The Infrastructure Investment and Jobs Act of 2021 allocates substantial funding for hydrogen hubs, potentially accelerating SOEC deployment.

Regulatory challenges include the classification of SOECs within existing energy market structures. Questions persist regarding whether SOECs should be regulated as generation assets, storage facilities, or grid services providers. This classification significantly impacts permitting requirements, interconnection standards, and market participation rules. Grid codes and interconnection standards need updating to accommodate the bidirectional energy flow capabilities of SOECs in smart grid environments.

Carbon pricing mechanisms represent another critical policy lever. Regions with established carbon markets or taxes, such as the EU Emissions Trading System, provide indirect support for SOEC technologies by increasing the cost competitiveness of low-carbon alternatives. However, carbon pricing remains fragmented globally, creating uneven market conditions for technology deployment.

Standardization efforts are emerging but remain insufficient. The International Electrotechnical Commission (IEC) and IEEE have begun developing standards for hydrogen technologies and grid integration, but SOEC-specific standards are still evolving. This standardization gap creates technical barriers to widespread adoption and complicates cross-border deployment.

Future policy development should focus on creating technology-specific incentives for SOEC deployment, establishing clear regulatory classifications, developing comprehensive grid integration standards, and implementing consistent carbon valuation mechanisms. Regulatory sandboxes and demonstration projects with temporary regulatory exemptions could accelerate real-world testing while informing permanent regulatory frameworks.

Economic Viability and Scaling Considerations

The economic viability of integrating Solid Oxide Electrolysis Cells (SOECs) into smart grid technology depends significantly on capital expenditure, operational costs, and system efficiency. Current SOEC systems require substantial initial investment, with costs ranging from $800 to $2,000 per kilowatt of capacity. These high capital costs present a significant barrier to widespread adoption, particularly for utility-scale implementations. However, cost projections indicate a potential 40-60% reduction over the next decade as manufacturing processes mature and economies of scale are realized.

Operational economics show promising trends, with SOECs demonstrating superior efficiency compared to alternative hydrogen production methods. When integrated with renewable energy sources, SOECs can achieve electrical-to-chemical conversion efficiencies exceeding 80%, substantially higher than the 60-70% typical of PEM electrolyzers. This efficiency advantage translates to lower operational costs over the system lifetime, partially offsetting the higher initial investment.

Scaling considerations reveal both challenges and opportunities. The modular nature of SOEC technology allows for incremental capacity expansion, reducing financial risk compared to large, monolithic infrastructure projects. However, the high-temperature operation (700-850°C) necessitates specialized materials and thermal management systems that become increasingly complex at larger scales. Grid integration at utility scale would require substantial balance-of-plant components, including heat exchangers, power electronics, and control systems.

Return on investment calculations indicate break-even periods of 7-12 years for current SOEC implementations, depending on electricity pricing, utilization rates, and regulatory frameworks. This timeline may be shortened through policy mechanisms such as carbon pricing, renewable energy credits, or direct subsidies for clean hydrogen production. Markets with high renewable penetration and frequent curtailment offer particularly favorable economics, as SOECs can utilize otherwise wasted electricity during overgeneration periods.

The pathway to commercial viability will likely require a phased approach, beginning with niche applications where high-value products (such as synthetic fuels or industrial chemicals) can justify premium costs. As technology matures and costs decline, broader applications in grid balancing and seasonal energy storage become economically feasible. Strategic co-location with industrial facilities that can utilize both hydrogen and waste heat further improves the economic proposition by creating additional value streams beyond pure electricity arbitrage.

Operational economics show promising trends, with SOECs demonstrating superior efficiency compared to alternative hydrogen production methods. When integrated with renewable energy sources, SOECs can achieve electrical-to-chemical conversion efficiencies exceeding 80%, substantially higher than the 60-70% typical of PEM electrolyzers. This efficiency advantage translates to lower operational costs over the system lifetime, partially offsetting the higher initial investment.

Scaling considerations reveal both challenges and opportunities. The modular nature of SOEC technology allows for incremental capacity expansion, reducing financial risk compared to large, monolithic infrastructure projects. However, the high-temperature operation (700-850°C) necessitates specialized materials and thermal management systems that become increasingly complex at larger scales. Grid integration at utility scale would require substantial balance-of-plant components, including heat exchangers, power electronics, and control systems.

Return on investment calculations indicate break-even periods of 7-12 years for current SOEC implementations, depending on electricity pricing, utilization rates, and regulatory frameworks. This timeline may be shortened through policy mechanisms such as carbon pricing, renewable energy credits, or direct subsidies for clean hydrogen production. Markets with high renewable penetration and frequent curtailment offer particularly favorable economics, as SOECs can utilize otherwise wasted electricity during overgeneration periods.

The pathway to commercial viability will likely require a phased approach, beginning with niche applications where high-value products (such as synthetic fuels or industrial chemicals) can justify premium costs. As technology matures and costs decline, broader applications in grid balancing and seasonal energy storage become economically feasible. Strategic co-location with industrial facilities that can utilize both hydrogen and waste heat further improves the economic proposition by creating additional value streams beyond pure electricity arbitrage.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!