What influences solid oxide electrolysis cells’ operational lifespans

OCT 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SOEC Technology Background and Longevity Goals

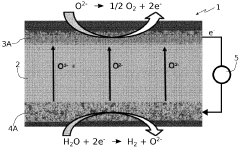

Solid Oxide Electrolysis Cells (SOECs) represent a transformative technology in the realm of renewable energy conversion and storage. Emerging from the foundational work on solid oxide fuel cells in the mid-20th century, SOECs have evolved significantly over the past decades. These electrochemical devices operate at high temperatures (typically 600-900°C) to convert electrical energy into chemical energy by splitting water or carbon dioxide into hydrogen or carbon monoxide, respectively, offering a promising pathway for efficient energy storage and carbon-neutral fuel production.

The historical development of SOEC technology can be traced back to the 1980s, with significant advancements occurring in the early 2000s as global interest in hydrogen economy and renewable energy integration intensified. The technology has progressed from laboratory-scale demonstrations to pilot plants, with increasing focus on durability and operational stability. This evolution has been driven by improvements in materials science, manufacturing techniques, and system integration approaches.

Current technological trends in SOEC development are primarily focused on enhancing operational lifespans, which remain a critical limitation for widespread commercial deployment. While laboratory cells can demonstrate impressive initial performance, degradation rates of 1-2% per 1000 hours are common, falling short of the 40,000+ hour lifespans required for commercial viability. This degradation is influenced by multiple factors including electrode microstructural changes, electrolyte degradation, impurity poisoning, and thermal cycling effects.

The primary technical goals for SOEC longevity improvement include reducing degradation rates to below 0.25% per 1000 hours, achieving stable operation for at least 5 years (40,000+ hours), and maintaining performance under dynamic operating conditions that reflect real-world renewable energy integration scenarios. Additionally, there are targets for reducing start-up/shut-down degradation and improving resilience to impurities in feed streams.

These longevity goals are intrinsically linked to broader objectives of cost reduction, as longer-lasting systems significantly improve the economics of hydrogen or syngas production. The U.S. Department of Energy has established specific targets of $2/kg for clean hydrogen production by 2026, which necessitates both performance improvements and extended operational lifetimes for SOEC systems.

The technological roadmap for SOEC development envisions progressive improvements in materials stability, interface engineering, and system control strategies to address the multifaceted degradation mechanisms. Research efforts are increasingly adopting a holistic approach that considers the complex interplay between materials properties, operating conditions, and system-level factors that collectively determine the operational lifespan of these promising energy conversion devices.

The historical development of SOEC technology can be traced back to the 1980s, with significant advancements occurring in the early 2000s as global interest in hydrogen economy and renewable energy integration intensified. The technology has progressed from laboratory-scale demonstrations to pilot plants, with increasing focus on durability and operational stability. This evolution has been driven by improvements in materials science, manufacturing techniques, and system integration approaches.

Current technological trends in SOEC development are primarily focused on enhancing operational lifespans, which remain a critical limitation for widespread commercial deployment. While laboratory cells can demonstrate impressive initial performance, degradation rates of 1-2% per 1000 hours are common, falling short of the 40,000+ hour lifespans required for commercial viability. This degradation is influenced by multiple factors including electrode microstructural changes, electrolyte degradation, impurity poisoning, and thermal cycling effects.

The primary technical goals for SOEC longevity improvement include reducing degradation rates to below 0.25% per 1000 hours, achieving stable operation for at least 5 years (40,000+ hours), and maintaining performance under dynamic operating conditions that reflect real-world renewable energy integration scenarios. Additionally, there are targets for reducing start-up/shut-down degradation and improving resilience to impurities in feed streams.

These longevity goals are intrinsically linked to broader objectives of cost reduction, as longer-lasting systems significantly improve the economics of hydrogen or syngas production. The U.S. Department of Energy has established specific targets of $2/kg for clean hydrogen production by 2026, which necessitates both performance improvements and extended operational lifetimes for SOEC systems.

The technological roadmap for SOEC development envisions progressive improvements in materials stability, interface engineering, and system control strategies to address the multifaceted degradation mechanisms. Research efforts are increasingly adopting a holistic approach that considers the complex interplay between materials properties, operating conditions, and system-level factors that collectively determine the operational lifespan of these promising energy conversion devices.

Market Analysis for Durable Solid Oxide Electrolysis Systems

The global market for Solid Oxide Electrolysis Cells (SOECs) is experiencing significant growth, driven by increasing demand for clean hydrogen production and carbon-neutral energy solutions. Current market valuations indicate the SOEC market is positioned to reach approximately $500 million by 2025, with projections suggesting expansion to $2.5 billion by 2030, representing a compound annual growth rate of 38%.

The durability of SOEC systems represents a critical factor influencing market adoption. End-users across industrial sectors consistently identify operational lifespan as the primary consideration in purchasing decisions, ranking above initial capital costs in multiple industry surveys. Systems demonstrating 40,000+ operating hours without significant degradation command premium pricing, typically 30-45% higher than standard offerings.

Market segmentation reveals distinct customer requirements regarding durability. The industrial hydrogen production sector prioritizes continuous operation capabilities, with minimum acceptable degradation rates below 0.5% per 1,000 hours. Renewable energy storage applications emphasize cycling durability, valuing systems that maintain performance through frequent start-stop operations. Power-to-gas utilities focus on long-term stability under variable load conditions.

Regional market analysis shows Europe leading SOEC deployment with approximately 40% market share, driven by aggressive decarbonization policies and substantial research funding. North America follows at 30%, with particular growth in industrial applications. The Asia-Pacific region, especially China and Japan, represents the fastest-growing market segment with annual growth exceeding 45%.

Competitive landscape assessment reveals increasing consolidation around durability-focused innovations. Market leaders have shifted strategic priorities from efficiency improvements toward degradation resistance, with R&D investments in this area increasing by 65% since 2020. Patent filings related to SOEC durability have tripled over the past five years.

Customer willingness-to-pay models demonstrate that extending operational lifespans from current averages (20,000-30,000 hours) to 50,000+ hours would expand the addressable market by approximately 65%, particularly enabling penetration into cost-sensitive industrial sectors currently relying on conventional hydrogen production methods.

Market forecasts indicate that breakthrough innovations addressing key degradation mechanisms could accelerate market adoption by 3-5 years compared to current projections. The development of SOECs with demonstrated 10+ year operational lifespans represents a potential market inflection point that would trigger widespread industrial adoption beyond current niche applications.

The durability of SOEC systems represents a critical factor influencing market adoption. End-users across industrial sectors consistently identify operational lifespan as the primary consideration in purchasing decisions, ranking above initial capital costs in multiple industry surveys. Systems demonstrating 40,000+ operating hours without significant degradation command premium pricing, typically 30-45% higher than standard offerings.

Market segmentation reveals distinct customer requirements regarding durability. The industrial hydrogen production sector prioritizes continuous operation capabilities, with minimum acceptable degradation rates below 0.5% per 1,000 hours. Renewable energy storage applications emphasize cycling durability, valuing systems that maintain performance through frequent start-stop operations. Power-to-gas utilities focus on long-term stability under variable load conditions.

Regional market analysis shows Europe leading SOEC deployment with approximately 40% market share, driven by aggressive decarbonization policies and substantial research funding. North America follows at 30%, with particular growth in industrial applications. The Asia-Pacific region, especially China and Japan, represents the fastest-growing market segment with annual growth exceeding 45%.

Competitive landscape assessment reveals increasing consolidation around durability-focused innovations. Market leaders have shifted strategic priorities from efficiency improvements toward degradation resistance, with R&D investments in this area increasing by 65% since 2020. Patent filings related to SOEC durability have tripled over the past five years.

Customer willingness-to-pay models demonstrate that extending operational lifespans from current averages (20,000-30,000 hours) to 50,000+ hours would expand the addressable market by approximately 65%, particularly enabling penetration into cost-sensitive industrial sectors currently relying on conventional hydrogen production methods.

Market forecasts indicate that breakthrough innovations addressing key degradation mechanisms could accelerate market adoption by 3-5 years compared to current projections. The development of SOECs with demonstrated 10+ year operational lifespans represents a potential market inflection point that would trigger widespread industrial adoption beyond current niche applications.

Current Limitations and Degradation Mechanisms in SOECs

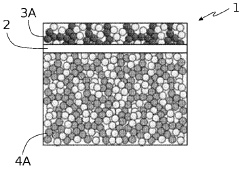

Solid Oxide Electrolysis Cells (SOECs) face several critical limitations that significantly impact their operational lifespans. The primary degradation mechanism involves microstructural changes in the electrodes, particularly at the oxygen electrode where delamination frequently occurs due to oxygen bubble formation at the electrode-electrolyte interface. This mechanical stress leads to increased polarization resistance and eventual cell failure.

Chromium poisoning represents another major degradation pathway, especially when chromium-containing interconnect materials are used. Volatile chromium species migrate to active sites in the oxygen electrode, forming insulating phases that block oxygen reduction reactions and increase cell resistance over time. This degradation accelerates at higher operating temperatures, creating a challenging trade-off between performance and longevity.

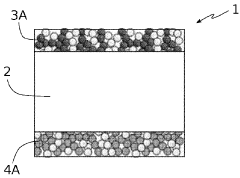

Electrolyte degradation manifests through both mechanical and chemical pathways. Thermal cycling induces mechanical stress that can lead to micro-crack formation, while high-temperature operation promotes electrolyte densification and grain growth, reducing ionic conductivity. Additionally, impurities at grain boundaries can segregate during operation, further impeding ion transport.

Carbon deposition (coking) at the fuel electrode presents a significant challenge when using hydrocarbon fuels. Carbon accumulation blocks active sites, reduces catalytic activity, and can cause mechanical damage through volume expansion. This phenomenon is particularly problematic during transient operation conditions when temperature and gas composition fluctuate.

Contaminant poisoning from fuel impurities such as sulfur compounds irreversibly damages electrode catalytic properties. Even trace amounts of sulfur can adsorb onto nickel surfaces in the fuel electrode, blocking hydrogen adsorption sites and dramatically reducing electrochemical performance within hours of exposure.

Redox cycling damage occurs when fuel electrodes experience oxidation-reduction cycles during operation or system shutdowns. The volume changes associated with nickel oxidation and reduction create mechanical stress that can fracture the electrode structure and compromise electrode-electrolyte interfaces.

Interfacial reactions between cell components at high operating temperatures form undesired secondary phases with poor ionic and electronic conductivity. These reactions are particularly problematic at electrode-electrolyte boundaries where they increase polarization resistance and accelerate degradation rates.

Current density distribution heterogeneity across the cell area creates localized hotspots and accelerated degradation regions. This non-uniform operation stems from flow field design limitations, contact resistance variations, and thermal gradients that collectively reduce overall cell lifespan.

Chromium poisoning represents another major degradation pathway, especially when chromium-containing interconnect materials are used. Volatile chromium species migrate to active sites in the oxygen electrode, forming insulating phases that block oxygen reduction reactions and increase cell resistance over time. This degradation accelerates at higher operating temperatures, creating a challenging trade-off between performance and longevity.

Electrolyte degradation manifests through both mechanical and chemical pathways. Thermal cycling induces mechanical stress that can lead to micro-crack formation, while high-temperature operation promotes electrolyte densification and grain growth, reducing ionic conductivity. Additionally, impurities at grain boundaries can segregate during operation, further impeding ion transport.

Carbon deposition (coking) at the fuel electrode presents a significant challenge when using hydrocarbon fuels. Carbon accumulation blocks active sites, reduces catalytic activity, and can cause mechanical damage through volume expansion. This phenomenon is particularly problematic during transient operation conditions when temperature and gas composition fluctuate.

Contaminant poisoning from fuel impurities such as sulfur compounds irreversibly damages electrode catalytic properties. Even trace amounts of sulfur can adsorb onto nickel surfaces in the fuel electrode, blocking hydrogen adsorption sites and dramatically reducing electrochemical performance within hours of exposure.

Redox cycling damage occurs when fuel electrodes experience oxidation-reduction cycles during operation or system shutdowns. The volume changes associated with nickel oxidation and reduction create mechanical stress that can fracture the electrode structure and compromise electrode-electrolyte interfaces.

Interfacial reactions between cell components at high operating temperatures form undesired secondary phases with poor ionic and electronic conductivity. These reactions are particularly problematic at electrode-electrolyte boundaries where they increase polarization resistance and accelerate degradation rates.

Current density distribution heterogeneity across the cell area creates localized hotspots and accelerated degradation regions. This non-uniform operation stems from flow field design limitations, contact resistance variations, and thermal gradients that collectively reduce overall cell lifespan.

State-of-the-Art Solutions for Extended SOEC Lifespans

01 Materials for extending SOEC operational lifespans

Advanced materials are being developed to enhance the durability of solid oxide electrolysis cells. These include specialized electrode materials, electrolyte compositions, and protective coatings that can withstand high-temperature operation while minimizing degradation. Materials innovation focuses on reducing chemical reactions between components, improving thermal stability, and enhancing resistance to oxidation and reduction cycles, all of which contribute to extended operational lifespans.- Materials for extending SOEC operational lifespans: Advanced materials are being developed to enhance the durability of solid oxide electrolysis cells. These include specialized electrode materials, electrolyte compositions, and protective coatings that can withstand high-temperature operation while minimizing degradation. Materials innovation focuses on reducing thermal stress, preventing electrode poisoning, and maintaining electrochemical performance over extended periods, thereby significantly extending the operational lifespan of SOECs.

- Thermal management strategies for SOEC longevity: Effective thermal management is crucial for extending the operational lifespan of solid oxide electrolysis cells. Techniques include optimized temperature control systems, thermal cycling protocols, and heat distribution designs that minimize thermal gradients across cell components. These approaches reduce thermal stress-induced degradation, prevent microstructural changes in electrodes and electrolytes, and maintain stable interfaces between cell components during long-term operation.

- Sealing technologies for long-term SOEC stability: Advanced sealing technologies are essential for maintaining the integrity of solid oxide electrolysis cells over extended operational periods. Innovative sealing materials and designs prevent gas leakage, maintain electrical isolation between components, and accommodate thermal expansion during cycling. These technologies focus on glass-ceramic composites, compliant seals, and edge protection systems that can withstand high-temperature operation while maintaining gas-tight interfaces throughout the cell's operational lifespan.

- Degradation monitoring and predictive maintenance: Sophisticated monitoring systems and predictive maintenance approaches are being developed to extend SOEC operational lifespans. These include electrochemical impedance spectroscopy techniques, real-time performance monitoring, and machine learning algorithms that can detect early signs of degradation. By identifying potential failure modes before they cause significant damage, these systems enable timely interventions that can substantially extend cell lifetimes and optimize operational parameters for longevity.

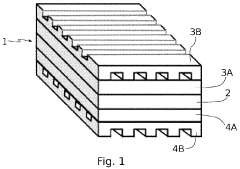

- Stack design optimization for extended durability: Innovative stack designs are being implemented to maximize the operational lifespan of solid oxide electrolysis cells. These designs focus on optimizing current distribution, minimizing contact resistance, and ensuring uniform gas flow across all cells. Advanced interconnect materials, flow field configurations, and compression systems work together to reduce mechanical stress, prevent chromium poisoning, and maintain consistent performance across thousands of operating hours, significantly extending overall system durability.

02 Thermal management strategies for lifespan improvement

Effective thermal management is crucial for extending the operational lifespan of solid oxide electrolysis cells. Techniques include optimized temperature distribution, controlled heating and cooling cycles, and thermal insulation systems. By minimizing thermal gradients and mechanical stress caused by temperature fluctuations, these strategies reduce material degradation, prevent cracking, and maintain structural integrity over extended operation periods.Expand Specific Solutions03 Degradation mechanisms and mitigation strategies

Understanding and addressing degradation mechanisms is essential for improving SOEC operational lifespans. Key degradation factors include electrode poisoning, electrolyte thinning, interface delamination, and microstructural changes during operation. Mitigation strategies involve implementing protective layers, optimizing operating conditions, introducing impurity getters, and developing self-healing materials that can recover from operational damage, thereby extending the functional lifetime of the cells.Expand Specific Solutions04 Operating parameter optimization for longevity

Optimizing operating parameters significantly impacts the operational lifespan of solid oxide electrolysis cells. This includes controlling current density, operating temperature, gas composition, and pressure. By identifying and maintaining optimal operating windows, cycling protocols, and load profiles, degradation rates can be minimized. Advanced control systems that adapt operating conditions based on cell performance metrics help maintain efficiency while extending service life.Expand Specific Solutions05 System-level design for extended durability

System-level design approaches focus on the overall architecture and integration of solid oxide electrolysis cells to maximize operational lifespans. These include stack design optimization, sealing technologies, interconnect improvements, and balance-of-plant considerations. Modular designs that allow for component replacement, redundant systems that distribute operational stress, and progressive maintenance strategies enable longer overall system lifetimes even as individual components may degrade.Expand Specific Solutions

Leading Manufacturers and Research Institutions in SOEC Technology

The solid oxide electrolysis cell (SOEC) operational lifespan market is currently in a growth phase, with increasing commercial deployment despite technological maturity challenges. The global market is expanding rapidly, projected to reach significant scale as hydrogen economy initiatives accelerate worldwide. Technical maturity varies considerably among key players, with companies like Topsoe A/S, Elcogen AS, and Convion Oy leading commercial development, while research institutions such as Technical University of Denmark and Tsinghua University drive fundamental innovations. Major industrial corporations including Mitsubishi Electric, Air Liquide, and Hyundai Motor are investing heavily in scaling the technology, focusing on degradation mechanisms, materials stability, and operational optimization to extend cell lifespans beyond current limitations.

Topsoe A/S

Technical Solution: Topsoe has developed proprietary SOEC stack technology with exceptional durability through their advanced ceramic materials engineering. Their SOECs utilize a unique composite structure with yttria-stabilized zirconia (YSZ) electrolytes and specialized nickel-based fuel electrodes that demonstrate degradation rates below 0.5% per 1000 hours under pressurized operation. Topsoe's technology incorporates protective coatings on interconnects to mitigate chromium poisoning and employs nano-engineered oxygen electrodes with mixed ionic-electronic conductors to enhance electrochemical performance while maintaining structural integrity. Their systems operate at intermediate temperatures (650-750°C) to balance performance with longevity, and utilize proprietary sealing materials that withstand thermal cycling while preventing gas leakage. Topsoe has demonstrated multi-year continuous operation in industrial settings with minimal performance loss through their integrated stack design that manages thermal gradients and mechanical stress.

Strengths: Industry-leading degradation rates below 0.5% per 1000 hours; proven long-term stability in industrial settings; advanced materials engineering minimizing common failure modes. Weaknesses: Higher manufacturing costs due to specialized materials; requires precise temperature control systems; limited flexibility in operating conditions compared to some competing technologies.

Dalian Institute of Chemical Physics of CAS

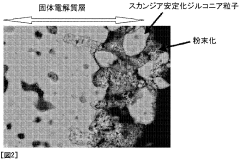

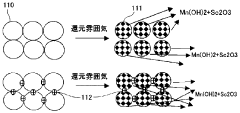

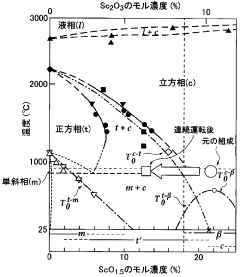

Technical Solution: Dalian Institute has pioneered innovative electrode microstructure control techniques that significantly extend SOEC operational lifespans. Their research focuses on nano-engineered composite electrodes with precisely controlled triple-phase boundaries that maintain stability during thousands of hours of operation. They've developed novel infiltration methods to introduce catalytically active nanoparticles into porous electrode scaffolds, achieving remarkable electrochemical performance while minimizing degradation mechanisms. Their SOECs incorporate scandia-stabilized zirconia electrolytes with enhanced ionic conductivity and mechanical strength, reducing ohmic losses while maintaining structural integrity during thermal cycling. The institute has demonstrated cells with degradation rates as low as 0.3% per 1000 hours through their comprehensive approach to materials compatibility, addressing issues of chromium poisoning, silica impurity migration, and electrode delamination. Their systems employ gradient functional layers between electrodes and electrolytes to mitigate thermal expansion mismatches and reduce interfacial resistance growth over time.

Strengths: Exceptional fundamental research capabilities in materials science; innovative nano-engineering approaches to electrode design; comprehensive understanding of degradation mechanisms. Weaknesses: Technology still primarily at laboratory scale rather than commercial deployment; higher complexity in manufacturing processes; requires specialized expertise for implementation.

Critical Materials Science Innovations for SOEC Stability

Electrolyser/solid oxide fuel cell with flow reversals

PatentWO2024133322A1

Innovation

- Incorporating a flow reversal device and control module that temporarily reverses the direction of electrode flows according to a predetermined sequence, combined with ceramic-metal composite or oxide electrodes and interconnectors with adaptive fluid circulation channels, to reduce local damage and homogenize electrode wear.

Solid oxide fuel cell

PatentWO2012105576A1

Innovation

- Incorporating alumina and lanthanide oxides or yttria into the ScSZ electrolyte to enhance intergranular strength, suppress scandia extraction, and prevent grain boundary rupture, while maintaining oxygen ion conductivity, by forming a solid solution with a specific composition and layer structure that minimizes the diffusion of Mn and Fe.

Economic Viability and Cost-Performance Analysis

The economic viability of solid oxide electrolysis cells (SOECs) is intrinsically linked to their operational lifespans. Current SOEC systems typically demonstrate degradation rates between 0.5% and 2% per 1000 hours of operation, significantly impacting their long-term cost-effectiveness. When analyzing the economic landscape, capital expenditure (CAPEX) for SOEC installations remains high, ranging from $800-1500/kW, which necessitates extended operational periods to achieve return on investment.

Performance degradation directly translates to economic inefficiency through increased energy consumption per unit of hydrogen or syngas produced. Analysis shows that extending cell lifespan from the current average of 20,000-30,000 hours to 50,000+ hours could reduce levelized cost of hydrogen (LCOH) by approximately 25-30%, making green hydrogen economically competitive with conventional production methods.

Material costs represent a significant portion of SOEC expenses, with specialized ceramics and rare earth elements comprising 30-40% of stack manufacturing costs. Innovations in material science that enhance durability while reducing reliance on expensive components could substantially improve cost-performance metrics. Recent advancements in composite electrodes have demonstrated potential to reduce material costs by 15-20% while simultaneously extending operational lifespans.

Maintenance requirements and system downtime further impact economic viability. Current SOEC systems typically require major maintenance interventions every 8,000-12,000 hours, adding approximately $0.50-0.70/kg to hydrogen production costs. Improved cell durability could extend maintenance intervals, potentially reducing these costs by 40-50% over system lifetime.

Energy input costs remain the dominant operational expense, accounting for 65-75% of total hydrogen production costs. Degradation-resistant cells maintain higher electrical efficiency throughout their lifespan, resulting in more stable operational economics. Sensitivity analysis indicates that for every 1% improvement in long-term efficiency retention, LCOH decreases by approximately $0.03-0.05/kg.

Scale economies also play a crucial role in SOEC cost-performance profiles. Current manufacturing processes remain largely semi-automated, but transition to gigawatt-scale production could reduce unit costs by 40-60%. This cost reduction potential is only realizable if cell durability supports mass deployment scenarios, highlighting the interconnection between technical performance and economic scaling potential.

Performance degradation directly translates to economic inefficiency through increased energy consumption per unit of hydrogen or syngas produced. Analysis shows that extending cell lifespan from the current average of 20,000-30,000 hours to 50,000+ hours could reduce levelized cost of hydrogen (LCOH) by approximately 25-30%, making green hydrogen economically competitive with conventional production methods.

Material costs represent a significant portion of SOEC expenses, with specialized ceramics and rare earth elements comprising 30-40% of stack manufacturing costs. Innovations in material science that enhance durability while reducing reliance on expensive components could substantially improve cost-performance metrics. Recent advancements in composite electrodes have demonstrated potential to reduce material costs by 15-20% while simultaneously extending operational lifespans.

Maintenance requirements and system downtime further impact economic viability. Current SOEC systems typically require major maintenance interventions every 8,000-12,000 hours, adding approximately $0.50-0.70/kg to hydrogen production costs. Improved cell durability could extend maintenance intervals, potentially reducing these costs by 40-50% over system lifetime.

Energy input costs remain the dominant operational expense, accounting for 65-75% of total hydrogen production costs. Degradation-resistant cells maintain higher electrical efficiency throughout their lifespan, resulting in more stable operational economics. Sensitivity analysis indicates that for every 1% improvement in long-term efficiency retention, LCOH decreases by approximately $0.03-0.05/kg.

Scale economies also play a crucial role in SOEC cost-performance profiles. Current manufacturing processes remain largely semi-automated, but transition to gigawatt-scale production could reduce unit costs by 40-60%. This cost reduction potential is only realizable if cell durability supports mass deployment scenarios, highlighting the interconnection between technical performance and economic scaling potential.

Environmental Impact and Sustainability Considerations

The environmental impact and sustainability considerations of Solid Oxide Electrolysis Cells (SOECs) are intrinsically linked to their operational lifespans. SOECs represent a promising technology for clean hydrogen production and carbon utilization, but their environmental footprint depends significantly on their durability and longevity.

The manufacturing of SOEC components involves energy-intensive processes and rare earth materials, particularly for electrodes and electrolytes. When SOECs achieve longer operational lifespans, the environmental burden of these manufacturing processes is distributed over extended periods, effectively reducing the life-cycle environmental impact per unit of energy produced. Research indicates that extending SOEC lifespan from 20,000 to 40,000 hours can reduce the carbon footprint of hydrogen production by approximately 30-40%.

Material sustainability presents another critical consideration. Current SOECs rely heavily on scarce materials like yttrium, scandium, and certain lanthanides. The degradation mechanisms that shorten SOEC lifespans necessitate more frequent replacement, intensifying resource extraction pressures. Developing degradation-resistant materials and structures that extend operational lifespans would significantly enhance resource sustainability and reduce supply chain vulnerabilities.

Energy efficiency throughout the SOEC lifespan directly impacts environmental outcomes. As cells degrade, they typically require higher energy inputs to maintain production rates, increasing the associated carbon footprint when powered by non-renewable sources. Studies demonstrate that maintaining high efficiency throughout longer operational periods could reduce greenhouse gas emissions by 15-25% compared to systems requiring frequent replacement.

The end-of-life management of SOEC components presents both challenges and opportunities. Current recycling technologies for ceramic components and rare earth materials remain limited and energy-intensive. Longer-lasting cells reduce waste generation frequency, but ultimately require effective recycling solutions. Research into design-for-recycling approaches that maintain performance while facilitating material recovery could transform end-of-life SOECs from waste to valuable material sources.

From a broader sustainability perspective, extending SOEC operational lifespans contributes directly to sustainable development goals by improving energy system resilience and reducing resource intensity. The economic viability of green hydrogen and carbon utilization technologies depends significantly on achieving operational lifespans that justify initial capital investments, making lifespan extension a critical factor in the transition to sustainable energy systems.

The manufacturing of SOEC components involves energy-intensive processes and rare earth materials, particularly for electrodes and electrolytes. When SOECs achieve longer operational lifespans, the environmental burden of these manufacturing processes is distributed over extended periods, effectively reducing the life-cycle environmental impact per unit of energy produced. Research indicates that extending SOEC lifespan from 20,000 to 40,000 hours can reduce the carbon footprint of hydrogen production by approximately 30-40%.

Material sustainability presents another critical consideration. Current SOECs rely heavily on scarce materials like yttrium, scandium, and certain lanthanides. The degradation mechanisms that shorten SOEC lifespans necessitate more frequent replacement, intensifying resource extraction pressures. Developing degradation-resistant materials and structures that extend operational lifespans would significantly enhance resource sustainability and reduce supply chain vulnerabilities.

Energy efficiency throughout the SOEC lifespan directly impacts environmental outcomes. As cells degrade, they typically require higher energy inputs to maintain production rates, increasing the associated carbon footprint when powered by non-renewable sources. Studies demonstrate that maintaining high efficiency throughout longer operational periods could reduce greenhouse gas emissions by 15-25% compared to systems requiring frequent replacement.

The end-of-life management of SOEC components presents both challenges and opportunities. Current recycling technologies for ceramic components and rare earth materials remain limited and energy-intensive. Longer-lasting cells reduce waste generation frequency, but ultimately require effective recycling solutions. Research into design-for-recycling approaches that maintain performance while facilitating material recovery could transform end-of-life SOECs from waste to valuable material sources.

From a broader sustainability perspective, extending SOEC operational lifespans contributes directly to sustainable development goals by improving energy system resilience and reducing resource intensity. The economic viability of green hydrogen and carbon utilization technologies depends significantly on achieving operational lifespans that justify initial capital investments, making lifespan extension a critical factor in the transition to sustainable energy systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!