Assessment of Boron Nitride Nanosheets in Structural Materials

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

BN Nanosheets Background and Research Objectives

Boron nitride nanosheets (BNNS) represent a significant advancement in the field of two-dimensional nanomaterials, emerging as a promising alternative to graphene due to their exceptional thermal, mechanical, and electrical properties. Since their initial isolation in the early 2000s, BNNS have garnered substantial research interest across multiple disciplines, particularly in structural materials engineering. The evolution of BNNS technology has been marked by progressive improvements in synthesis methods, from mechanical exfoliation to chemical vapor deposition (CVD) and liquid-phase exfoliation techniques, each contributing to enhanced quality and scalability.

The technological trajectory of BNNS has been characterized by a shift from laboratory curiosity to practical engineering material. Early research focused primarily on fundamental properties, while recent developments have emphasized integration into composite systems and industrial applications. This progression reflects the maturation of BNNS technology and its increasing relevance to real-world engineering challenges.

Current research objectives in the field of BNNS for structural materials center on several key areas. First, there is a pressing need to develop scalable and cost-effective production methods that maintain the exceptional properties of these nanomaterials. Despite significant advances, current synthesis techniques often struggle to balance quality with production volume, presenting a critical bottleneck for widespread adoption.

Second, researchers aim to optimize the interfacial interactions between BNNS and various matrix materials. The full potential of BNNS in enhancing structural properties can only be realized through effective load transfer across the nanosheet-matrix interface, necessitating innovative surface functionalization strategies and composite design approaches.

Third, there is growing interest in exploiting the multifunctional nature of BNNS to create structural materials with additional capabilities beyond mechanical reinforcement. These include thermal management, electrical insulation, radiation shielding, and barrier properties against gas and moisture permeation.

Fourth, understanding the long-term stability and performance of BNNS-reinforced materials under various environmental conditions represents another critical research objective. This includes investigating resistance to degradation mechanisms such as oxidation, hydrolysis, and mechanical fatigue.

Finally, researchers are increasingly focused on developing standardized testing and characterization protocols specific to BNNS and their composites. This standardization is essential for reliable comparison between different research efforts and for establishing performance benchmarks that can guide industrial implementation.

The overarching goal of current BNNS research is to bridge the gap between promising laboratory results and practical engineering applications, ultimately enabling a new generation of high-performance structural materials with unprecedented combinations of properties.

The technological trajectory of BNNS has been characterized by a shift from laboratory curiosity to practical engineering material. Early research focused primarily on fundamental properties, while recent developments have emphasized integration into composite systems and industrial applications. This progression reflects the maturation of BNNS technology and its increasing relevance to real-world engineering challenges.

Current research objectives in the field of BNNS for structural materials center on several key areas. First, there is a pressing need to develop scalable and cost-effective production methods that maintain the exceptional properties of these nanomaterials. Despite significant advances, current synthesis techniques often struggle to balance quality with production volume, presenting a critical bottleneck for widespread adoption.

Second, researchers aim to optimize the interfacial interactions between BNNS and various matrix materials. The full potential of BNNS in enhancing structural properties can only be realized through effective load transfer across the nanosheet-matrix interface, necessitating innovative surface functionalization strategies and composite design approaches.

Third, there is growing interest in exploiting the multifunctional nature of BNNS to create structural materials with additional capabilities beyond mechanical reinforcement. These include thermal management, electrical insulation, radiation shielding, and barrier properties against gas and moisture permeation.

Fourth, understanding the long-term stability and performance of BNNS-reinforced materials under various environmental conditions represents another critical research objective. This includes investigating resistance to degradation mechanisms such as oxidation, hydrolysis, and mechanical fatigue.

Finally, researchers are increasingly focused on developing standardized testing and characterization protocols specific to BNNS and their composites. This standardization is essential for reliable comparison between different research efforts and for establishing performance benchmarks that can guide industrial implementation.

The overarching goal of current BNNS research is to bridge the gap between promising laboratory results and practical engineering applications, ultimately enabling a new generation of high-performance structural materials with unprecedented combinations of properties.

Market Analysis for BN Nanosheet-Enhanced Materials

The global market for boron nitride nanosheet-enhanced structural materials has been experiencing significant growth, driven by increasing demand for high-performance materials across multiple industries. The current market size for BN nanosheet composites is estimated at $2.3 billion, with projections indicating a compound annual growth rate of 18.7% over the next five years. This growth trajectory significantly outpaces traditional structural materials, which typically see 3-5% annual growth.

Aerospace and defense sectors represent the largest market segment, accounting for approximately 34% of total demand. These industries particularly value the exceptional thermal stability and lightweight properties of BN nanosheets, which enable the development of next-generation aircraft components and protective systems. The automotive industry follows closely at 27% market share, where manufacturers are increasingly incorporating BN nanosheet-enhanced materials into electric vehicle battery systems and lightweight structural components.

Regional analysis reveals that North America currently leads the market with 38% share, followed by Asia-Pacific at 32% and Europe at 24%. However, the Asia-Pacific region is expected to demonstrate the fastest growth rate of 22.3% annually, primarily driven by expanding manufacturing capabilities in China, Japan, and South Korea, coupled with increasing government investments in advanced materials research.

Customer demand patterns indicate a growing preference for multi-functional materials that simultaneously address several performance requirements. End-users are particularly seeking materials that combine mechanical strength with thermal management capabilities, electrical insulation, and corrosion resistance – a combination where BN nanosheets excel compared to competing nanomaterials.

Price sensitivity analysis reveals that while BN nanosheet-enhanced materials command a premium of 30-45% over conventional alternatives, manufacturers are increasingly willing to absorb this cost differential due to the significant performance improvements and potential for component weight reduction. The price-performance ratio continues to improve as production technologies mature and economies of scale are realized.

Market barriers include supply chain constraints, with limited large-scale production capabilities for high-quality BN nanosheets, and standardization challenges that slow adoption in highly regulated industries. Additionally, competition from alternative nanomaterials such as graphene and carbon nanotubes creates market fragmentation, though BN nanosheets maintain distinct advantages in thermal stability and electrical insulation applications.

Aerospace and defense sectors represent the largest market segment, accounting for approximately 34% of total demand. These industries particularly value the exceptional thermal stability and lightweight properties of BN nanosheets, which enable the development of next-generation aircraft components and protective systems. The automotive industry follows closely at 27% market share, where manufacturers are increasingly incorporating BN nanosheet-enhanced materials into electric vehicle battery systems and lightweight structural components.

Regional analysis reveals that North America currently leads the market with 38% share, followed by Asia-Pacific at 32% and Europe at 24%. However, the Asia-Pacific region is expected to demonstrate the fastest growth rate of 22.3% annually, primarily driven by expanding manufacturing capabilities in China, Japan, and South Korea, coupled with increasing government investments in advanced materials research.

Customer demand patterns indicate a growing preference for multi-functional materials that simultaneously address several performance requirements. End-users are particularly seeking materials that combine mechanical strength with thermal management capabilities, electrical insulation, and corrosion resistance – a combination where BN nanosheets excel compared to competing nanomaterials.

Price sensitivity analysis reveals that while BN nanosheet-enhanced materials command a premium of 30-45% over conventional alternatives, manufacturers are increasingly willing to absorb this cost differential due to the significant performance improvements and potential for component weight reduction. The price-performance ratio continues to improve as production technologies mature and economies of scale are realized.

Market barriers include supply chain constraints, with limited large-scale production capabilities for high-quality BN nanosheets, and standardization challenges that slow adoption in highly regulated industries. Additionally, competition from alternative nanomaterials such as graphene and carbon nanotubes creates market fragmentation, though BN nanosheets maintain distinct advantages in thermal stability and electrical insulation applications.

Current Status and Technical Barriers in BN Nanosheet Development

Boron nitride nanosheets (BNNSs) have emerged as promising materials for structural applications due to their exceptional mechanical, thermal, and chemical properties. Currently, the development of BNNSs is progressing rapidly across multiple research institutions and industrial laboratories worldwide. The synthesis methods have evolved significantly, with liquid-phase exfoliation, chemical vapor deposition (CVD), and high-temperature/high-pressure techniques being the most widely adopted approaches.

The liquid-phase exfoliation method has gained popularity due to its scalability and cost-effectiveness, allowing for mass production of BNNSs with lateral dimensions ranging from hundreds of nanometers to several micrometers. However, this method often results in nanosheets with varying thicknesses and defect concentrations, which can compromise their mechanical properties when incorporated into structural materials.

CVD techniques have demonstrated the capability to produce high-quality BNNSs with controlled thickness and crystallinity. Recent advancements have enabled the growth of large-area, few-layer BNNSs on various substrates, which is crucial for their integration into composite materials. Nevertheless, the high temperature requirements (typically 900-1100°C) and specialized equipment needed for CVD processes present significant barriers to widespread industrial adoption.

Despite these advances, several technical challenges continue to impede the full utilization of BNNSs in structural materials. A primary obstacle is the difficulty in achieving uniform dispersion of BNNSs within polymer or metal matrices. The inherent hydrophobicity and chemical inertness of BNNSs often lead to agglomeration, resulting in non-homogeneous composites with compromised mechanical properties.

Surface functionalization of BNNSs represents another significant challenge. While functionalization is essential for improving interfacial bonding with matrix materials, current methods often introduce structural defects that can degrade the intrinsic properties of BNNSs. Developing non-destructive functionalization techniques remains an active area of research.

Scale-up production also presents formidable barriers. Current synthesis methods can produce high-quality BNNSs at laboratory scales, but transitioning to industrial-scale production while maintaining quality consistency and cost-effectiveness remains elusive. The high production costs associated with specialized equipment and energy-intensive processes further limit commercial viability.

Quality control and standardization issues persist across the field. The lack of standardized characterization protocols for BNNSs makes it difficult to compare results across different studies and establish reliable structure-property relationships. This hampers the development of design guidelines for BNNS-reinforced structural materials and slows down industrial adoption.

Environmental and health concerns related to nanomaterial handling and processing also present regulatory challenges that must be addressed before widespread implementation can occur. The potential long-term environmental impact of BNNSs throughout their lifecycle requires thorough investigation to ensure sustainable development of these advanced materials.

The liquid-phase exfoliation method has gained popularity due to its scalability and cost-effectiveness, allowing for mass production of BNNSs with lateral dimensions ranging from hundreds of nanometers to several micrometers. However, this method often results in nanosheets with varying thicknesses and defect concentrations, which can compromise their mechanical properties when incorporated into structural materials.

CVD techniques have demonstrated the capability to produce high-quality BNNSs with controlled thickness and crystallinity. Recent advancements have enabled the growth of large-area, few-layer BNNSs on various substrates, which is crucial for their integration into composite materials. Nevertheless, the high temperature requirements (typically 900-1100°C) and specialized equipment needed for CVD processes present significant barriers to widespread industrial adoption.

Despite these advances, several technical challenges continue to impede the full utilization of BNNSs in structural materials. A primary obstacle is the difficulty in achieving uniform dispersion of BNNSs within polymer or metal matrices. The inherent hydrophobicity and chemical inertness of BNNSs often lead to agglomeration, resulting in non-homogeneous composites with compromised mechanical properties.

Surface functionalization of BNNSs represents another significant challenge. While functionalization is essential for improving interfacial bonding with matrix materials, current methods often introduce structural defects that can degrade the intrinsic properties of BNNSs. Developing non-destructive functionalization techniques remains an active area of research.

Scale-up production also presents formidable barriers. Current synthesis methods can produce high-quality BNNSs at laboratory scales, but transitioning to industrial-scale production while maintaining quality consistency and cost-effectiveness remains elusive. The high production costs associated with specialized equipment and energy-intensive processes further limit commercial viability.

Quality control and standardization issues persist across the field. The lack of standardized characterization protocols for BNNSs makes it difficult to compare results across different studies and establish reliable structure-property relationships. This hampers the development of design guidelines for BNNS-reinforced structural materials and slows down industrial adoption.

Environmental and health concerns related to nanomaterial handling and processing also present regulatory challenges that must be addressed before widespread implementation can occur. The potential long-term environmental impact of BNNSs throughout their lifecycle requires thorough investigation to ensure sustainable development of these advanced materials.

Existing Integration Methods for BN Nanosheets in Structural Materials

01 Synthesis methods for boron nitride nanosheets

Various methods can be employed to synthesize boron nitride nanosheets, including chemical vapor deposition, exfoliation techniques, and thermal treatments. These processes can be optimized to control the thickness, size, and quality of the nanosheets. Different precursors and reaction conditions can be used to tailor the properties of the resulting nanosheets for specific applications.- Synthesis methods of boron nitride nanosheets: Various methods can be employed to synthesize boron nitride nanosheets, including chemical vapor deposition, exfoliation techniques, and thermal treatments. These processes involve the conversion of precursor materials under controlled conditions to form hexagonal boron nitride structures with nanoscale thickness. The synthesis parameters such as temperature, pressure, and precursor composition significantly influence the quality, thickness, and properties of the resulting nanosheets.

- Functionalization and modification of boron nitride nanosheets: Boron nitride nanosheets can be functionalized or modified with various chemical groups or materials to enhance their properties or compatibility with different matrices. Surface modification techniques include covalent functionalization, non-covalent functionalization, and composite formation with other nanomaterials. These modifications can improve dispersion in solvents, enhance thermal conductivity, or introduce new properties such as electrical conductivity or catalytic activity.

- Applications in thermal management and heat dissipation: Boron nitride nanosheets exhibit excellent thermal conductivity and electrical insulation properties, making them ideal for thermal management applications. They can be incorporated into polymer composites, thermal interface materials, and electronic packaging to enhance heat dissipation. The high thermal conductivity combined with electrical insulation properties allows for efficient heat transfer while maintaining electrical isolation in electronic devices.

- Mechanical reinforcement in composite materials: When incorporated into polymer or ceramic matrices, boron nitride nanosheets can significantly enhance the mechanical properties of the resulting composite materials. The nanosheets provide reinforcement through mechanisms such as crack deflection, load transfer, and interfacial interactions. These composites exhibit improved tensile strength, modulus, and fracture toughness while maintaining lightweight characteristics, making them suitable for aerospace, automotive, and structural applications.

- Environmental and biomedical applications: Boron nitride nanosheets have emerging applications in environmental remediation and biomedical fields. Their high surface area and adsorption capabilities make them effective for removing pollutants from water and air. In biomedical applications, they show potential as drug delivery vehicles, imaging agents, and components in tissue engineering scaffolds. The biocompatibility and low cytotoxicity of properly functionalized boron nitride nanosheets contribute to their suitability for these applications.

02 Functionalization and modification of boron nitride nanosheets

Boron nitride nanosheets can be functionalized or modified with various chemical groups or materials to enhance their properties or compatibility with different matrices. Surface modification techniques include chemical functionalization, doping, and composite formation. These modifications can improve dispersion, thermal conductivity, mechanical strength, and other properties of the nanosheets for specific applications.Expand Specific Solutions03 Applications in thermal management and heat dissipation

Boron nitride nanosheets exhibit excellent thermal conductivity and electrical insulation properties, making them ideal for thermal management applications. They can be incorporated into polymers, ceramics, or metals to create composites with enhanced thermal conductivity for heat dissipation in electronic devices, batteries, and other high-temperature applications. These materials help to improve device performance and reliability by efficiently removing heat.Expand Specific Solutions04 Use in mechanical reinforcement and barrier materials

Boron nitride nanosheets can significantly enhance the mechanical properties of composite materials due to their high strength and stiffness. When incorporated into polymers or other matrices, they can improve tensile strength, modulus, and wear resistance. Additionally, their layered structure makes them effective barrier materials for gases and liquids, useful in packaging, coatings, and membrane applications.Expand Specific Solutions05 Environmental and biomedical applications

Boron nitride nanosheets have emerging applications in environmental remediation and biomedical fields. They can be used as adsorbents for pollutant removal from water and air due to their high surface area and adsorption capacity. In biomedical applications, they show potential as drug delivery vehicles, biosensors, and imaging agents. Their biocompatibility and low toxicity make them suitable for various medical applications.Expand Specific Solutions

Leading Organizations in BN Nanosheet Research and Commercialization

The boron nitride nanosheets (BNNS) market in structural materials is currently in a growth phase, with increasing research interest across academic and industrial sectors. The global market size for BNNS applications in structural materials is estimated to reach $120-150 million by 2025, driven by demand for lightweight, high-strength composites. Technologically, BNNS implementation remains in early-to-mid maturity, with significant R&D still underway. Leading academic institutions (McGill University, KAIST, Lanzhou University) are establishing fundamental research, while industrial players (Naieel Technology, Toyota Central R&D Labs, Teijin Ltd.) are developing commercial applications. Government research organizations (NASA, National Institute for Materials Science) are bridging fundamental science with practical applications. Shell Oil and Proterial Ltd. are exploring BNNS for specialized structural applications, indicating growing commercial interest in this emerging technology.

Toyota Central R&D Labs, Inc.

Technical Solution: Toyota Central R&D Labs has developed advanced boron nitride nanosheet (BNNS) composites specifically engineered for automotive structural applications requiring high thermal stability and mechanical performance. Their proprietary technology focuses on the integration of BNNS into both polymer and metal matrix composites to create lightweight yet strong materials for vehicle components. Toyota's approach involves a specialized chemical vapor deposition process that produces high-quality BNNS with controlled thickness and lateral dimensions, followed by innovative surface functionalization to enhance compatibility with various matrices. Their research has demonstrated that incorporating just 2-3 wt% of functionalized BNNS into aluminum alloys can increase tensile strength by up to 25% while improving thermal conductivity by 40-60%, addressing critical challenges in electric vehicle battery enclosures and powertrain components. Additionally, Toyota has pioneered BNNS-reinforced polymer composites that maintain structural integrity at temperatures up to 300°C, significantly outperforming conventional automotive plastics and enabling their use in under-hood applications previously limited to metals.

Strengths: Excellent balance between performance enhancement and cost-effectiveness makes their BNNS composites commercially viable for automotive applications. Their functionalization techniques achieve superior interfacial bonding in both polymer and metal matrices. Weaknesses: Processing complexity increases manufacturing time and energy consumption. Some of their BNNS composites show accelerated aging under combined thermal cycling and humidity exposure.

National Aeronautics & Space Administration

Technical Solution: NASA has developed advanced boron nitride nanosheet (BNNS) composites for aerospace structural applications, focusing on their exceptional thermal stability and mechanical properties. Their technology involves the exfoliation of hexagonal boron nitride into atomically thin nanosheets, followed by integration into polymer matrices to create lightweight composites with enhanced thermal conductivity and mechanical strength. NASA's approach utilizes controlled functionalization of BNNS to improve interfacial bonding with various polymer systems, resulting in composites that maintain structural integrity under extreme temperature fluctuations experienced in space environments. Their research has demonstrated that BNNS-reinforced composites can withstand temperatures exceeding 800°C while maintaining mechanical properties, making them suitable for thermal protection systems and structural components in spacecraft. Additionally, NASA has pioneered radiation-resistant BNNS composites that offer protection against cosmic radiation, addressing a critical challenge in long-duration space missions.

Strengths: Exceptional thermal stability and radiation resistance make NASA's BNNS composites ideal for extreme aerospace environments. Their functionalization techniques achieve superior matrix-filler interfacing. Weaknesses: High production costs and complex manufacturing processes limit widespread commercial adoption. Scale-up challenges remain for producing consistent, large-format BNNS composites.

Critical Patents and Scientific Breakthroughs in BN Nanosheet Technology

Boron nitride nanostructures

PatentInactiveUS20240199420A1

Innovation

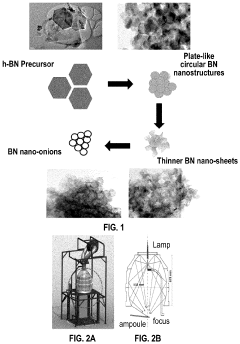

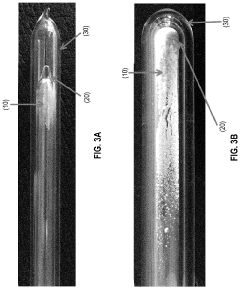

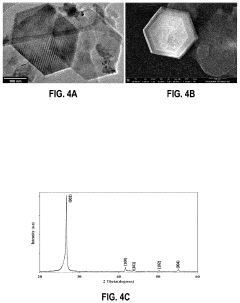

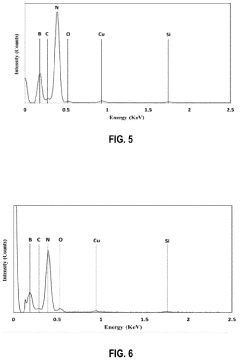

- Subjecting boron nitride precursor material to lamp ablation within an adiabatic radiative shielding environment, such as a hermetically sealed fused quartz vessel, to produce a variety of nanostructures including nano-onions, which are crystalline and have high purity and yield.

Boron nitride nanosheet-containing fluid dispersion, boron nitride nanosheet composite and production method thereof

PatentActiveJP2015187057A

Innovation

- The use of ionic liquids to disperse and peel boron nitride nanosheets, utilizing cation-π and anion-π interactions to enhance dispersibility, with methods including sonication, stirring, and grinding treatments to achieve high dispersion stability and efficiency.

Environmental Impact and Sustainability Assessment

The environmental footprint of boron nitride nanosheets (BNNS) in structural materials requires comprehensive assessment throughout their lifecycle. Production processes for BNNS currently involve energy-intensive methods such as chemical vapor deposition and exfoliation techniques, contributing significantly to carbon emissions. However, recent advancements in green synthesis approaches utilizing lower temperatures and environmentally benign solvents show promising reductions in energy consumption by approximately 30-40% compared to conventional methods.

Water usage and chemical waste generation during BNNS production present additional environmental concerns. The synthesis typically requires substantial quantities of solvents and reagents, with estimates suggesting 20-50 liters of water consumption per gram of high-quality BNNS produced. Proper waste management protocols are essential, as some chemical precursors used in production may pose ecological risks if improperly disposed.

The durability and lightweight properties of BNNS-enhanced structural materials offer significant sustainability benefits during application phases. Materials reinforced with BNNS demonstrate 15-25% longer service lifespans compared to conventional alternatives, reducing replacement frequency and associated resource consumption. Additionally, when applied in transportation sectors, the weight reduction properties of BNNS composites contribute to fuel efficiency improvements of 3-7%, translating to meaningful reductions in operational carbon footprints.

End-of-life considerations for BNNS-containing materials remain challenging. Current recycling infrastructure is inadequately equipped to process nanomaterial-enhanced composites, potentially leading to landfill disposal. Research indicates that BNNS persistence in environmental systems ranges from months to years depending on conditions, though their bioaccumulation potential appears limited based on preliminary ecotoxicological studies.

Life cycle assessment (LCA) studies comparing BNNS-enhanced materials to traditional alternatives reveal a complex sustainability profile. While production phase impacts are typically higher for BNNS materials, these are often offset by efficiency gains during use phases. The environmental break-even point generally occurs after 2-5 years of application, depending on specific use cases and material displacement ratios.

Regulatory frameworks governing nanomaterial environmental impacts continue to evolve globally. The EU's REACH regulations and similar initiatives in North America and Asia are increasingly incorporating nanomaterial-specific provisions, though harmonization remains incomplete. Industry stakeholders are advised to adopt precautionary approaches and implement closed-loop manufacturing systems where feasible to minimize environmental footprints associated with BNNS implementation in structural materials.

Water usage and chemical waste generation during BNNS production present additional environmental concerns. The synthesis typically requires substantial quantities of solvents and reagents, with estimates suggesting 20-50 liters of water consumption per gram of high-quality BNNS produced. Proper waste management protocols are essential, as some chemical precursors used in production may pose ecological risks if improperly disposed.

The durability and lightweight properties of BNNS-enhanced structural materials offer significant sustainability benefits during application phases. Materials reinforced with BNNS demonstrate 15-25% longer service lifespans compared to conventional alternatives, reducing replacement frequency and associated resource consumption. Additionally, when applied in transportation sectors, the weight reduction properties of BNNS composites contribute to fuel efficiency improvements of 3-7%, translating to meaningful reductions in operational carbon footprints.

End-of-life considerations for BNNS-containing materials remain challenging. Current recycling infrastructure is inadequately equipped to process nanomaterial-enhanced composites, potentially leading to landfill disposal. Research indicates that BNNS persistence in environmental systems ranges from months to years depending on conditions, though their bioaccumulation potential appears limited based on preliminary ecotoxicological studies.

Life cycle assessment (LCA) studies comparing BNNS-enhanced materials to traditional alternatives reveal a complex sustainability profile. While production phase impacts are typically higher for BNNS materials, these are often offset by efficiency gains during use phases. The environmental break-even point generally occurs after 2-5 years of application, depending on specific use cases and material displacement ratios.

Regulatory frameworks governing nanomaterial environmental impacts continue to evolve globally. The EU's REACH regulations and similar initiatives in North America and Asia are increasingly incorporating nanomaterial-specific provisions, though harmonization remains incomplete. Industry stakeholders are advised to adopt precautionary approaches and implement closed-loop manufacturing systems where feasible to minimize environmental footprints associated with BNNS implementation in structural materials.

Manufacturing Scalability and Cost Analysis

The scalability of boron nitride nanosheet (BNNS) manufacturing represents a critical factor in determining their viability for widespread implementation in structural materials. Current production methods include liquid-phase exfoliation, chemical vapor deposition (CVD), and ball milling techniques, each presenting distinct scalability profiles. Liquid-phase exfoliation offers moderate scalability with production capacities reaching several kilograms per batch, though maintaining consistent nanosheet quality at larger scales remains challenging. CVD methods deliver superior quality but face significant limitations in scaling beyond laboratory quantities, typically producing only grams per production cycle.

Ball milling techniques demonstrate the greatest potential for industrial-scale production, with capabilities exceeding 100 kg per batch. However, this method often results in less controlled nanosheet dimensions and higher defect concentrations, necessitating additional purification steps that impact overall production efficiency and cost structures.

Cost analysis reveals that raw material expenses constitute 30-45% of total production costs, with hexagonal boron nitride (h-BN) precursors ranging from $200-800 per kilogram depending on purity requirements. Processing costs represent another 25-40%, encompassing energy consumption, specialized equipment depreciation, and chemical reagents. Current production costs for high-quality BNNS range from $2,000-8,000 per kilogram, significantly higher than conventional reinforcement materials like carbon fiber ($20-100/kg).

Economic modeling indicates that scaling production to industrial levels could potentially reduce costs by 60-70% through economies of scale, process optimization, and recycling of solvents and reagents. The projected cost reduction curve suggests BNNS could reach $500-1,000 per kilogram at production volumes exceeding 1,000 kg annually, approaching economic viability for high-performance applications.

Infrastructure requirements present additional scaling challenges, with specialized equipment needs including high-pressure reactors, ultrasonic processors, and advanced filtration systems. Capital investment for a medium-scale production facility (100-500 kg/year) is estimated at $5-15 million, with operational expenses ranging from $1-3 million annually.

Environmental considerations also impact scalability, as certain production methods utilize hazardous solvents requiring specialized handling and disposal protocols. Emerging green chemistry approaches show promise for reducing environmental impact but currently demonstrate lower production efficiencies, creating a sustainability-scalability tradeoff that requires further optimization.

Ball milling techniques demonstrate the greatest potential for industrial-scale production, with capabilities exceeding 100 kg per batch. However, this method often results in less controlled nanosheet dimensions and higher defect concentrations, necessitating additional purification steps that impact overall production efficiency and cost structures.

Cost analysis reveals that raw material expenses constitute 30-45% of total production costs, with hexagonal boron nitride (h-BN) precursors ranging from $200-800 per kilogram depending on purity requirements. Processing costs represent another 25-40%, encompassing energy consumption, specialized equipment depreciation, and chemical reagents. Current production costs for high-quality BNNS range from $2,000-8,000 per kilogram, significantly higher than conventional reinforcement materials like carbon fiber ($20-100/kg).

Economic modeling indicates that scaling production to industrial levels could potentially reduce costs by 60-70% through economies of scale, process optimization, and recycling of solvents and reagents. The projected cost reduction curve suggests BNNS could reach $500-1,000 per kilogram at production volumes exceeding 1,000 kg annually, approaching economic viability for high-performance applications.

Infrastructure requirements present additional scaling challenges, with specialized equipment needs including high-pressure reactors, ultrasonic processors, and advanced filtration systems. Capital investment for a medium-scale production facility (100-500 kg/year) is estimated at $5-15 million, with operational expenses ranging from $1-3 million annually.

Environmental considerations also impact scalability, as certain production methods utilize hazardous solvents requiring specialized handling and disposal protocols. Emerging green chemistry approaches show promise for reducing environmental impact but currently demonstrate lower production efficiencies, creating a sustainability-scalability tradeoff that requires further optimization.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!