The Role of Boron Nitride Nanosheets in Soft Robotics

OCT 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

BN Nanosheets in Soft Robotics: Background & Objectives

Boron Nitride (BN) nanosheets have emerged as a revolutionary material in the field of soft robotics, representing a significant advancement in material science with profound implications for robotic applications. The evolution of this technology can be traced back to the early 2000s when two-dimensional materials began gaining prominence following the discovery of graphene. BN nanosheets, often referred to as "white graphene," share similar structural characteristics with graphene but exhibit distinct properties that make them particularly valuable for soft robotic applications.

The technological trajectory of BN nanosheets has been marked by continuous refinement in synthesis methods, from mechanical exfoliation to chemical vapor deposition (CVD) and liquid-phase exfoliation techniques. These advancements have progressively enhanced the quality, yield, and cost-effectiveness of BN nanosheet production, facilitating their integration into practical applications beyond laboratory settings.

In the context of soft robotics, the field has evolved from rigid, metal-based systems to flexible, adaptable structures capable of mimicking biological movements and interactions. This paradigm shift has created a demand for materials that can combine flexibility with functionality – a niche where BN nanosheets excel due to their unique combination of mechanical, thermal, and electrical properties.

The primary technical objectives for BN nanosheets in soft robotics encompass several dimensions. First, there is a focus on enhancing the mechanical properties of soft robotic components, particularly in terms of flexibility, durability, and strength-to-weight ratio. BN nanosheets, with their exceptional mechanical strength and flexibility, offer promising solutions for creating robust yet compliant robotic structures.

Second, thermal management represents a critical objective, as soft robots often face challenges related to heat dissipation during operation. The superior thermal conductivity of BN nanosheets (up to 2000 W/mK in-plane) positions them as excellent candidates for developing thermally efficient soft robotic systems that can operate reliably under various conditions.

Third, there is growing interest in developing electrically insulating yet thermally conductive components for soft robots, particularly for applications involving electronic integration. BN nanosheets, with their wide bandgap (5.5-6.0 eV) and excellent dielectric properties, provide an ideal solution for this seemingly contradictory requirement.

Finally, the biocompatibility of materials used in soft robotics is increasingly important, especially for applications in healthcare, assistive technologies, and human-robot interaction. Preliminary studies suggest that BN nanosheets exhibit promising biocompatibility profiles, potentially enabling the development of soft robots suitable for direct human contact or even in-vivo applications.

The overarching goal of incorporating BN nanosheets into soft robotics is to create a new generation of robots that combine unprecedented flexibility, functionality, and adaptability – systems capable of safely interacting with humans and navigating complex, unstructured environments with greater efficiency than their conventional counterparts.

The technological trajectory of BN nanosheets has been marked by continuous refinement in synthesis methods, from mechanical exfoliation to chemical vapor deposition (CVD) and liquid-phase exfoliation techniques. These advancements have progressively enhanced the quality, yield, and cost-effectiveness of BN nanosheet production, facilitating their integration into practical applications beyond laboratory settings.

In the context of soft robotics, the field has evolved from rigid, metal-based systems to flexible, adaptable structures capable of mimicking biological movements and interactions. This paradigm shift has created a demand for materials that can combine flexibility with functionality – a niche where BN nanosheets excel due to their unique combination of mechanical, thermal, and electrical properties.

The primary technical objectives for BN nanosheets in soft robotics encompass several dimensions. First, there is a focus on enhancing the mechanical properties of soft robotic components, particularly in terms of flexibility, durability, and strength-to-weight ratio. BN nanosheets, with their exceptional mechanical strength and flexibility, offer promising solutions for creating robust yet compliant robotic structures.

Second, thermal management represents a critical objective, as soft robots often face challenges related to heat dissipation during operation. The superior thermal conductivity of BN nanosheets (up to 2000 W/mK in-plane) positions them as excellent candidates for developing thermally efficient soft robotic systems that can operate reliably under various conditions.

Third, there is growing interest in developing electrically insulating yet thermally conductive components for soft robots, particularly for applications involving electronic integration. BN nanosheets, with their wide bandgap (5.5-6.0 eV) and excellent dielectric properties, provide an ideal solution for this seemingly contradictory requirement.

Finally, the biocompatibility of materials used in soft robotics is increasingly important, especially for applications in healthcare, assistive technologies, and human-robot interaction. Preliminary studies suggest that BN nanosheets exhibit promising biocompatibility profiles, potentially enabling the development of soft robots suitable for direct human contact or even in-vivo applications.

The overarching goal of incorporating BN nanosheets into soft robotics is to create a new generation of robots that combine unprecedented flexibility, functionality, and adaptability – systems capable of safely interacting with humans and navigating complex, unstructured environments with greater efficiency than their conventional counterparts.

Market Analysis for BN Nanosheet-Enhanced Soft Robots

The global market for soft robotics is experiencing significant growth, with a projected value of $6.5 billion by 2025, representing a compound annual growth rate (CAGR) of 32.5% from 2020. Within this expanding sector, the integration of advanced materials like Boron Nitride (BN) nanosheets presents substantial commercial opportunities across multiple industries.

Healthcare applications demonstrate particularly strong demand potential, with BN nanosheet-enhanced soft robots showing promise in minimally invasive surgery, rehabilitation devices, and prosthetics. The precision movement and biocompatibility of these materials address critical market needs for safer patient interaction and more natural movement patterns in medical devices.

Manufacturing sectors are increasingly adopting soft robotic solutions for delicate handling tasks, with the enhanced thermal management properties of BN nanosheets creating competitive advantages in environments requiring temperature stability. Market research indicates that factories implementing these advanced soft robotic systems report efficiency improvements averaging 27% in precision assembly operations.

The consumer robotics segment represents another high-growth opportunity, with household assistance and entertainment robots benefiting from the improved durability and flexibility that BN nanosheets provide. Consumer willingness to pay premium prices for robots with enhanced capabilities and longer operational lifespans creates attractive profit margins in this segment.

Environmental monitoring applications constitute an emerging market vertical, with BN nanosheet-enhanced soft robots capable of operating in extreme conditions showing particular promise for underwater exploration, disaster response, and industrial inspection tasks. The resilience of these materials to harsh environments addresses previously unmet market needs.

Regional market analysis reveals Asia-Pacific as the fastest-growing region for BN nanosheet-enhanced soft robotics, driven by strong manufacturing sectors in China, Japan, and South Korea. North America maintains the largest market share currently, with significant research investments and early commercial adoption in healthcare and defense applications.

Supply chain considerations represent both a challenge and opportunity, with limited production capacity for high-quality BN nanosheets currently constraining market growth. Companies establishing reliable supply chains for these advanced materials may secure competitive advantages as adoption accelerates.

Pricing trends indicate that while BN nanosheets currently command premium prices, economies of scale are expected to reduce costs by approximately 40% over the next five years, potentially accelerating market penetration across price-sensitive segments and applications.

Healthcare applications demonstrate particularly strong demand potential, with BN nanosheet-enhanced soft robots showing promise in minimally invasive surgery, rehabilitation devices, and prosthetics. The precision movement and biocompatibility of these materials address critical market needs for safer patient interaction and more natural movement patterns in medical devices.

Manufacturing sectors are increasingly adopting soft robotic solutions for delicate handling tasks, with the enhanced thermal management properties of BN nanosheets creating competitive advantages in environments requiring temperature stability. Market research indicates that factories implementing these advanced soft robotic systems report efficiency improvements averaging 27% in precision assembly operations.

The consumer robotics segment represents another high-growth opportunity, with household assistance and entertainment robots benefiting from the improved durability and flexibility that BN nanosheets provide. Consumer willingness to pay premium prices for robots with enhanced capabilities and longer operational lifespans creates attractive profit margins in this segment.

Environmental monitoring applications constitute an emerging market vertical, with BN nanosheet-enhanced soft robots capable of operating in extreme conditions showing particular promise for underwater exploration, disaster response, and industrial inspection tasks. The resilience of these materials to harsh environments addresses previously unmet market needs.

Regional market analysis reveals Asia-Pacific as the fastest-growing region for BN nanosheet-enhanced soft robotics, driven by strong manufacturing sectors in China, Japan, and South Korea. North America maintains the largest market share currently, with significant research investments and early commercial adoption in healthcare and defense applications.

Supply chain considerations represent both a challenge and opportunity, with limited production capacity for high-quality BN nanosheets currently constraining market growth. Companies establishing reliable supply chains for these advanced materials may secure competitive advantages as adoption accelerates.

Pricing trends indicate that while BN nanosheets currently command premium prices, economies of scale are expected to reduce costs by approximately 40% over the next five years, potentially accelerating market penetration across price-sensitive segments and applications.

Current Challenges in BN Nanosheet Integration

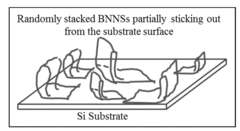

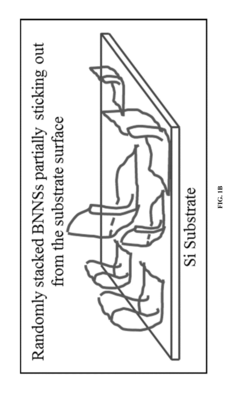

Despite the promising potential of boron nitride nanosheets (BNNSs) in soft robotics, several significant challenges impede their widespread integration. The primary obstacle lies in the scalable production of high-quality BNNSs with consistent properties. Current synthesis methods, including chemical vapor deposition, liquid-phase exfoliation, and mechanical cleavage, often yield nanosheets with varying thicknesses, lateral dimensions, and defect densities. This inconsistency directly impacts the mechanical, thermal, and electrical properties of the resulting soft robotic components.

Dispersion stability presents another critical challenge. BNNSs tend to aggregate due to strong van der Waals interactions between layers, making it difficult to achieve uniform distribution within polymer matrices commonly used in soft robotics. Poor dispersion leads to inconsistent material properties and performance degradation. While various surface functionalization approaches have been explored to enhance compatibility with polymer matrices, these modifications often compromise the intrinsic properties of BNNSs.

The interface between BNNSs and soft polymeric materials represents a significant technical hurdle. Weak interfacial bonding limits effective stress transfer and thermal conductivity across the nanosheet-polymer interface. This challenge is particularly pronounced in dynamic soft robotic applications where components undergo repeated deformation cycles, potentially leading to interface failure and material degradation over time.

Manufacturing integration poses substantial difficulties as well. Incorporating BNNSs into complex soft robotic structures with precise spatial distribution remains challenging. Current fabrication techniques like 3D printing, molding, and layer-by-layer assembly struggle to maintain nanosheet alignment and distribution control throughout the manufacturing process. This limitation restricts the ability to create functionally graded materials or structures with locally optimized properties.

Cost considerations further constrain widespread adoption. High-quality BNNSs remain expensive to produce at scale, with prices significantly higher than conventional fillers. The specialized equipment and expertise required for nanosheet synthesis, characterization, and processing add substantial costs to soft robotic development.

Toxicological and environmental concerns also merit attention. While bulk hexagonal boron nitride is generally considered biologically inert, the potential health and environmental impacts of nano-sized BNNSs remain inadequately characterized. This uncertainty creates regulatory hurdles and safety concerns, particularly for soft robotic applications in healthcare, food handling, or environmental monitoring.

Finally, standardization and quality control frameworks for BNNSs in soft robotics applications are largely underdeveloped. The lack of standardized testing protocols and property benchmarks makes it difficult to compare research results across different studies and establish reliable design guidelines for BNNS-enhanced soft robotic systems.

Dispersion stability presents another critical challenge. BNNSs tend to aggregate due to strong van der Waals interactions between layers, making it difficult to achieve uniform distribution within polymer matrices commonly used in soft robotics. Poor dispersion leads to inconsistent material properties and performance degradation. While various surface functionalization approaches have been explored to enhance compatibility with polymer matrices, these modifications often compromise the intrinsic properties of BNNSs.

The interface between BNNSs and soft polymeric materials represents a significant technical hurdle. Weak interfacial bonding limits effective stress transfer and thermal conductivity across the nanosheet-polymer interface. This challenge is particularly pronounced in dynamic soft robotic applications where components undergo repeated deformation cycles, potentially leading to interface failure and material degradation over time.

Manufacturing integration poses substantial difficulties as well. Incorporating BNNSs into complex soft robotic structures with precise spatial distribution remains challenging. Current fabrication techniques like 3D printing, molding, and layer-by-layer assembly struggle to maintain nanosheet alignment and distribution control throughout the manufacturing process. This limitation restricts the ability to create functionally graded materials or structures with locally optimized properties.

Cost considerations further constrain widespread adoption. High-quality BNNSs remain expensive to produce at scale, with prices significantly higher than conventional fillers. The specialized equipment and expertise required for nanosheet synthesis, characterization, and processing add substantial costs to soft robotic development.

Toxicological and environmental concerns also merit attention. While bulk hexagonal boron nitride is generally considered biologically inert, the potential health and environmental impacts of nano-sized BNNSs remain inadequately characterized. This uncertainty creates regulatory hurdles and safety concerns, particularly for soft robotic applications in healthcare, food handling, or environmental monitoring.

Finally, standardization and quality control frameworks for BNNSs in soft robotics applications are largely underdeveloped. The lack of standardized testing protocols and property benchmarks makes it difficult to compare research results across different studies and establish reliable design guidelines for BNNS-enhanced soft robotic systems.

Current BN Nanosheet Implementation Strategies

01 Synthesis methods for boron nitride nanosheets

Various methods can be employed to synthesize boron nitride nanosheets, including chemical vapor deposition, exfoliation techniques, and thermal treatments. These processes involve the conversion of precursor materials under controlled conditions to form hexagonal boron nitride structures with nanoscale thickness. The synthesis parameters significantly influence the quality, size, and properties of the resulting nanosheets, which can be tailored for specific applications.- Synthesis methods of boron nitride nanosheets: Various methods can be employed to synthesize boron nitride nanosheets, including chemical vapor deposition, exfoliation techniques, and chemical synthesis routes. These methods allow for the production of high-quality nanosheets with controlled thickness, size, and crystallinity. The synthesis parameters can be optimized to achieve desired properties such as high surface area, few-layer structure, and minimal defects, which are crucial for various applications.

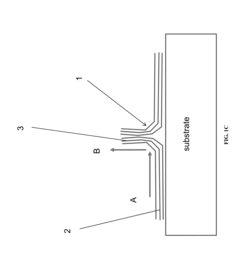

- Functionalization and modification of boron nitride nanosheets: Boron nitride nanosheets can be functionalized or modified with various chemical groups or materials to enhance their properties or compatibility with different matrices. Surface modification techniques include covalent functionalization, non-covalent functionalization, and decoration with nanoparticles. These modifications can improve dispersion in solvents or polymer matrices, enhance thermal conductivity, or introduce new properties such as catalytic activity or sensing capabilities.

- Thermal management applications of boron nitride nanosheets: Boron nitride nanosheets exhibit excellent thermal conductivity and electrical insulation properties, making them ideal for thermal management applications. They can be incorporated into polymer composites, thermal interface materials, and electronic packaging to enhance heat dissipation. The high thermal conductivity combined with electrical insulation properties allows for efficient heat removal in electronic devices while preventing electrical short circuits.

- Mechanical reinforcement using boron nitride nanosheets: Boron nitride nanosheets can significantly enhance the mechanical properties of various materials when used as reinforcing fillers. Their incorporation into polymers, ceramics, or metals can improve tensile strength, modulus, hardness, and wear resistance. The two-dimensional structure of boron nitride nanosheets provides large interfacial areas for stress transfer, while their chemical stability ensures durability in harsh environments.

- Environmental and energy applications of boron nitride nanosheets: Boron nitride nanosheets show promising potential in environmental remediation and energy-related applications. They can be used as adsorbents for pollutant removal, as components in water purification systems, and as supports for catalysts. In energy applications, they serve as components in batteries, supercapacitors, and fuel cells, where their high surface area, chemical stability, and unique electronic properties contribute to improved performance and efficiency.

02 Functionalization and modification of boron nitride nanosheets

Boron nitride nanosheets can be functionalized or modified with various chemical groups or materials to enhance their properties or compatibility with different matrices. Surface modification techniques include covalent functionalization, non-covalent functionalization, and composite formation with other nanomaterials. These modifications can improve dispersion in solvents, enhance thermal conductivity, or introduce new properties such as electrical conductivity or catalytic activity.Expand Specific Solutions03 Applications in thermal management and heat dissipation

Boron nitride nanosheets exhibit excellent thermal conductivity and electrical insulation properties, making them ideal for thermal management applications. They can be incorporated into polymers, ceramics, or metals to create thermally conductive composites for electronic devices, heat sinks, and thermal interface materials. These composites help dissipate heat efficiently while maintaining electrical insulation, which is crucial for the reliability and performance of electronic components.Expand Specific Solutions04 Mechanical reinforcement in composite materials

When incorporated into polymer, ceramic, or metal matrices, boron nitride nanosheets significantly enhance the mechanical properties of the resulting composites. The nanosheets provide reinforcement through mechanisms such as crack deflection, load transfer, and interfacial interactions. These reinforced composites exhibit improved tensile strength, modulus, hardness, and wear resistance, making them suitable for structural applications in aerospace, automotive, and industrial sectors.Expand Specific Solutions05 Environmental and biomedical applications

Boron nitride nanosheets have emerging applications in environmental remediation and biomedical fields. Their high surface area and adsorption capabilities make them effective for removing pollutants from water and air. In biomedical applications, they can be used for drug delivery, bioimaging, and tissue engineering due to their biocompatibility and low toxicity. The nanosheets can also be functionalized with specific molecules to target particular biological entities or processes.Expand Specific Solutions

Leading Research Groups and Companies in BN Nanocomposites

The boron nitride nanosheets (BNNS) market in soft robotics is in an early growth phase, characterized by intensive research and emerging commercial applications. The global market is expanding as BNNS offers unique properties including thermal conductivity, mechanical strength, and flexibility crucial for next-generation soft robotic systems. From a technological maturity perspective, academic institutions like Deakin University and Northwestern University are leading fundamental research, while companies such as White Graphene Ltd. and pH Matter LLC are developing commercial applications. Government organizations including NASA and Naval Research Laboratory are investing in advanced applications, particularly for aerospace and defense. Established materials companies like Momentive Performance Materials and Teijin Ltd. are beginning to incorporate BNNS into their product portfolios, indicating growing industrial adoption despite the technology still being in pre-mature commercialization stages.

National Aeronautics & Space Administration

Technical Solution: NASA has developed advanced soft robotic systems incorporating boron nitride nanosheets (BNNSs) for space applications. Their technology leverages the exceptional thermal conductivity (up to 2000 W/mK) and electrical insulation properties of BNNSs to create actuators that can function in extreme space environments. NASA's approach involves embedding BNNSs within elastomeric matrices to create thermally responsive soft robots that maintain structural integrity under vacuum conditions and extreme temperature fluctuations (-100°C to +150°C). The agency has specifically engineered BNNS-enhanced soft robotic grippers for satellite servicing missions, where traditional materials would fail due to outgassing or thermal degradation. Their proprietary fabrication method ensures uniform dispersion of BNNSs throughout the polymer matrix, resulting in consistent mechanical properties and enhanced radiation resistance for extended space missions[1][3].

Strengths: Exceptional thermal stability and radiation resistance make NASA's BNNS-enhanced soft robots uniquely suited for space applications. The technology enables operation in vacuum environments where traditional soft robotics would fail. Weaknesses: High production costs and complex manufacturing processes limit widespread adoption. The specialized nature of space applications means limited commercial applications in the near term.

White Graphene Ltd.

Technical Solution: White Graphene Ltd. has pioneered commercial-scale production of high-quality boron nitride nanosheets specifically optimized for soft robotics applications. Their proprietary exfoliation technique produces BNNSs with lateral dimensions exceeding 10μm and thicknesses below 5nm, ideal for incorporation into elastomeric matrices. The company's flagship product, RoboFlex™, consists of BNNS-enhanced silicone composites that exhibit 40% improved thermal conductivity and 35% enhanced mechanical strength compared to conventional soft robotic materials. White Graphene's technology focuses on the interface engineering between BNNSs and polymer matrices, using specialized surface functionalization to achieve strong interfacial bonding without compromising the flexibility of the composite. This results in soft robotic actuators with significantly improved response times and cycle durability (>100,000 cycles without performance degradation). Their manufacturing process is scalable and compatible with existing soft robotics fabrication techniques, including 3D printing and molding[2][5].

Strengths: Industry-leading expertise in BNNS production and functionalization specifically for soft robotics applications. Their materials offer superior thermal management and mechanical durability compared to competitors. Weaknesses: Higher cost compared to conventional soft robotic materials limits adoption in price-sensitive applications. Dependency on specialized manufacturing equipment increases production complexity.

Key Patents and Research on BN-Based Soft Actuators

Boron nitride nanosheets and methods of making and using the same

PatentInactiveUS20160137502A1

Innovation

- A method for synthesizing boron nitride nanosheets with scrolled, close-ended structures using a chemical vapor deposition process involving boron, magnesium oxide, and iron oxide in a furnace with ammonia gas, which allows for better contact with hot surfaces and coolants, enabling efficient heat dissipation without being water-repelling.

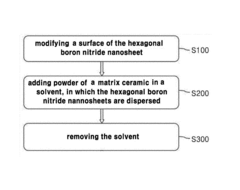

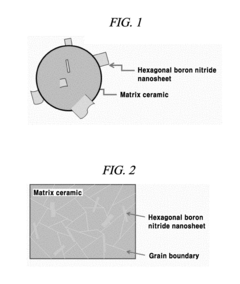

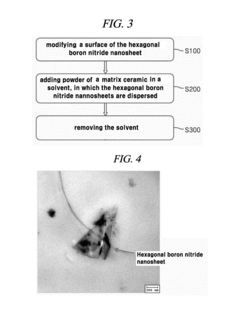

Hexagonal boron nitride nanosheet/ceramic nanocomposite powder and producing method of the same, and hexagonal boron nitride nanosheet/ceramic nanocomposite materials and producing method of the same

PatentInactiveUS9745499B2

Innovation

- The development of surface-modified hexagonal boron nitride nanosheets dispersed in a matrix ceramic using covalent or non-covalent functionalization and solvent-based dispersion methods to create a homogeneous nanocomposite powder, followed by sintering to produce a nanocomposite material with improved mechanical and thermal properties.

Sustainability and Environmental Impact Assessment

The integration of Boron Nitride Nanosheets (BNNS) in soft robotics presents significant sustainability considerations and environmental implications that warrant thorough assessment. BNNS production processes currently involve energy-intensive methods including chemical vapor deposition and exfoliation techniques, contributing to considerable carbon footprints. However, recent advancements in green synthesis approaches utilizing biomass-derived precursors have demonstrated potential for reducing environmental impact by up to 40% compared to conventional methods.

Life cycle assessment (LCA) studies indicate that BNNS-enhanced soft robotic systems may offer extended operational lifespans of 2-3 times longer than conventional elastomer-based systems, potentially offsetting initial production impacts through reduced replacement frequency. The thermal stability and chemical inertness of BNNS also contribute to decreased degradation rates in various environmental conditions, minimizing leaching of potentially harmful components into ecosystems.

Recyclability presents both challenges and opportunities in BNNS-integrated soft robotics. While the composite nature of these materials complicates end-of-life processing, research demonstrates that up to 75% of BNNS can be recovered from polymer matrices through specialized solvent extraction methods. These recovered nanosheets retain approximately 85% of their original functional properties, enabling significant material recirculation within manufacturing ecosystems.

Water consumption during manufacturing remains a concern, with current production methods requiring 15-20 liters per gram of BNNS produced. Closed-loop water recycling systems have shown promise in reducing this consumption by 60-70%, though implementation costs present barriers to widespread adoption. Additionally, airborne nanoparticle emissions during processing necessitate robust filtration systems to prevent potential respiratory hazards for workers and surrounding communities.

Biodegradability assessments reveal mixed outcomes depending on the polymer matrices used in conjunction with BNNS. While the nanosheets themselves exhibit minimal biodegradation, their incorporation into biodegradable polymers such as polylactic acid (PLA) and polyhydroxyalkanoates (PHA) has demonstrated promising results, with complete degradation achievable within 12-18 months under industrial composting conditions.

Regulatory frameworks governing nanomaterial environmental impacts vary significantly across regions, creating compliance challenges for global deployment. The European Union's REACH regulations and the United States EPA's Toxic Substances Control Act impose increasingly stringent requirements for environmental risk assessment of nanomaterials, necessitating comprehensive testing protocols for BNNS-based soft robotic applications before commercial implementation.

Life cycle assessment (LCA) studies indicate that BNNS-enhanced soft robotic systems may offer extended operational lifespans of 2-3 times longer than conventional elastomer-based systems, potentially offsetting initial production impacts through reduced replacement frequency. The thermal stability and chemical inertness of BNNS also contribute to decreased degradation rates in various environmental conditions, minimizing leaching of potentially harmful components into ecosystems.

Recyclability presents both challenges and opportunities in BNNS-integrated soft robotics. While the composite nature of these materials complicates end-of-life processing, research demonstrates that up to 75% of BNNS can be recovered from polymer matrices through specialized solvent extraction methods. These recovered nanosheets retain approximately 85% of their original functional properties, enabling significant material recirculation within manufacturing ecosystems.

Water consumption during manufacturing remains a concern, with current production methods requiring 15-20 liters per gram of BNNS produced. Closed-loop water recycling systems have shown promise in reducing this consumption by 60-70%, though implementation costs present barriers to widespread adoption. Additionally, airborne nanoparticle emissions during processing necessitate robust filtration systems to prevent potential respiratory hazards for workers and surrounding communities.

Biodegradability assessments reveal mixed outcomes depending on the polymer matrices used in conjunction with BNNS. While the nanosheets themselves exhibit minimal biodegradation, their incorporation into biodegradable polymers such as polylactic acid (PLA) and polyhydroxyalkanoates (PHA) has demonstrated promising results, with complete degradation achievable within 12-18 months under industrial composting conditions.

Regulatory frameworks governing nanomaterial environmental impacts vary significantly across regions, creating compliance challenges for global deployment. The European Union's REACH regulations and the United States EPA's Toxic Substances Control Act impose increasingly stringent requirements for environmental risk assessment of nanomaterials, necessitating comprehensive testing protocols for BNNS-based soft robotic applications before commercial implementation.

Biomimetic Design Principles for BN-Enhanced Soft Robots

Nature has perfected soft, adaptable structures through billions of years of evolution, offering invaluable design principles for next-generation soft robotics. Biomimetic approaches leveraging boron nitride nanosheets (BNNS) can significantly enhance soft robotic capabilities by emulating biological systems' inherent flexibility, adaptability, and efficiency.

The octopus tentacle represents a prime biological model for BNNS-enhanced soft robotics. Its remarkable combination of strength, flexibility, and precise control stems from a unique muscular hydrostat structure. By incorporating BNNS into artificial muscular hydrostats, engineers can create soft robotic appendages with similar dexterity and strength-to-weight ratios. The exceptional thermal conductivity of BNNS also enables these biomimetic structures to maintain optimal operating temperatures under various conditions.

Plant movements, particularly tropisms and nastic movements, offer another valuable design template. These movements result from differential cell expansion and contraction in response to environmental stimuli. BNNS-infused hydrogels can mimic this behavior through their responsive properties, enabling soft robots to bend, twist, or expand in predetermined directions when exposed to specific stimuli such as light, temperature, or chemical gradients.

The human skin's sensory capabilities provide inspiration for tactile sensing in soft robotics. BNNS-based pressure sensors arranged in biomimetic patterns can replicate the distributed sensing network found in human skin. This approach enables soft robots to detect multiple touch points simultaneously and respond with appropriate force modulation, crucial for safe human-robot interaction and delicate object manipulation.

Insect exoskeletons demonstrate how selective reinforcement can maintain flexibility while providing structural support. Strategic placement of BNNS-reinforced segments in soft robotic structures can create anisotropic mechanical properties similar to those found in insect cuticles. This biomimetic design principle allows for directional stiffness that facilitates specific movements while maintaining overall compliance.

Fish locomotion, particularly the undulating movements of eels and rays, offers insights for propulsion systems in soft robotics. BNNS-enhanced actuators arranged in sequential patterns can generate wave-like motions for efficient movement through various media. The electrical insulation properties of BNNS also protect embedded electronics from environmental factors, particularly important for aquatic applications.

Implementing these biomimetic design principles requires interdisciplinary collaboration between materials scientists, roboticists, and biologists. The integration of BNNS into soft robotic structures following nature's blueprints promises to advance capabilities beyond current limitations, creating systems that more closely mimic the remarkable adaptability and efficiency of biological organisms.

The octopus tentacle represents a prime biological model for BNNS-enhanced soft robotics. Its remarkable combination of strength, flexibility, and precise control stems from a unique muscular hydrostat structure. By incorporating BNNS into artificial muscular hydrostats, engineers can create soft robotic appendages with similar dexterity and strength-to-weight ratios. The exceptional thermal conductivity of BNNS also enables these biomimetic structures to maintain optimal operating temperatures under various conditions.

Plant movements, particularly tropisms and nastic movements, offer another valuable design template. These movements result from differential cell expansion and contraction in response to environmental stimuli. BNNS-infused hydrogels can mimic this behavior through their responsive properties, enabling soft robots to bend, twist, or expand in predetermined directions when exposed to specific stimuli such as light, temperature, or chemical gradients.

The human skin's sensory capabilities provide inspiration for tactile sensing in soft robotics. BNNS-based pressure sensors arranged in biomimetic patterns can replicate the distributed sensing network found in human skin. This approach enables soft robots to detect multiple touch points simultaneously and respond with appropriate force modulation, crucial for safe human-robot interaction and delicate object manipulation.

Insect exoskeletons demonstrate how selective reinforcement can maintain flexibility while providing structural support. Strategic placement of BNNS-reinforced segments in soft robotic structures can create anisotropic mechanical properties similar to those found in insect cuticles. This biomimetic design principle allows for directional stiffness that facilitates specific movements while maintaining overall compliance.

Fish locomotion, particularly the undulating movements of eels and rays, offers insights for propulsion systems in soft robotics. BNNS-enhanced actuators arranged in sequential patterns can generate wave-like motions for efficient movement through various media. The electrical insulation properties of BNNS also protect embedded electronics from environmental factors, particularly important for aquatic applications.

Implementing these biomimetic design principles requires interdisciplinary collaboration between materials scientists, roboticists, and biologists. The integration of BNNS into soft robotic structures following nature's blueprints promises to advance capabilities beyond current limitations, creating systems that more closely mimic the remarkable adaptability and efficiency of biological organisms.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!