Impact of Boron Nitride Nanosheets on Environmental Sustainability

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Boron Nitride Nanosheets Background and Research Objectives

Boron Nitride Nanosheets (BNNSs) have emerged as a significant two-dimensional nanomaterial in the field of materials science over the past two decades. First theoretically predicted in the early 1990s and successfully synthesized in the mid-2000s, these hexagonal lattice structures composed of alternating boron and nitrogen atoms represent a critical advancement in nanomaterial development. The evolution of BNNSs has paralleled that of graphene, yet with distinct properties that make them uniquely valuable for environmental applications.

The development trajectory of BNNSs has seen remarkable acceleration since 2010, with significant breakthroughs in synthesis methods including chemical vapor deposition, liquid exfoliation, and chemical blowing techniques. These advancements have progressively reduced production costs while improving the quality and scalability of BNNS production, marking important milestones in their technological maturation.

BNNSs possess several distinctive properties that position them advantageously for environmental sustainability applications. Their exceptional thermal stability (up to 900°C in air), outstanding thermal conductivity (approximately 2000 W/mK), excellent mechanical strength, and wide bandgap (5.5-6.0 eV) collectively create a material profile uniquely suited for environmental remediation and protection technologies. Additionally, their chemical inertness and resistance to oxidation provide durability advantages in harsh environmental conditions.

Current research trends indicate growing interest in leveraging BNNSs for environmental sustainability, with publication rates in this specific domain increasing by approximately 35% annually since 2018. This surge reflects the scientific community's recognition of BNNSs' potential to address pressing environmental challenges through applications in water purification, catalysis for environmental remediation, and development of sustainable energy technologies.

The primary objective of this technical research is to comprehensively evaluate the impact of BNNSs on environmental sustainability across multiple dimensions. Specifically, we aim to assess their effectiveness in water purification applications, particularly for removing heavy metals, organic pollutants, and emerging contaminants from water sources. Additionally, we seek to analyze their potential in air purification technologies, focusing on adsorption capabilities for various atmospheric pollutants.

Further research goals include investigating the role of BNNSs in enhancing renewable energy technologies, particularly in improving the efficiency and durability of solar cells and hydrogen production systems. We also aim to evaluate the environmental footprint of BNNS production processes themselves, conducting lifecycle assessments to determine whether their environmental benefits outweigh the impacts of their manufacture and deployment.

Through this comprehensive technical investigation, we intend to establish a clear understanding of how BNNSs can contribute to sustainable development goals while identifying potential limitations and areas requiring further innovation to maximize their positive environmental impact.

The development trajectory of BNNSs has seen remarkable acceleration since 2010, with significant breakthroughs in synthesis methods including chemical vapor deposition, liquid exfoliation, and chemical blowing techniques. These advancements have progressively reduced production costs while improving the quality and scalability of BNNS production, marking important milestones in their technological maturation.

BNNSs possess several distinctive properties that position them advantageously for environmental sustainability applications. Their exceptional thermal stability (up to 900°C in air), outstanding thermal conductivity (approximately 2000 W/mK), excellent mechanical strength, and wide bandgap (5.5-6.0 eV) collectively create a material profile uniquely suited for environmental remediation and protection technologies. Additionally, their chemical inertness and resistance to oxidation provide durability advantages in harsh environmental conditions.

Current research trends indicate growing interest in leveraging BNNSs for environmental sustainability, with publication rates in this specific domain increasing by approximately 35% annually since 2018. This surge reflects the scientific community's recognition of BNNSs' potential to address pressing environmental challenges through applications in water purification, catalysis for environmental remediation, and development of sustainable energy technologies.

The primary objective of this technical research is to comprehensively evaluate the impact of BNNSs on environmental sustainability across multiple dimensions. Specifically, we aim to assess their effectiveness in water purification applications, particularly for removing heavy metals, organic pollutants, and emerging contaminants from water sources. Additionally, we seek to analyze their potential in air purification technologies, focusing on adsorption capabilities for various atmospheric pollutants.

Further research goals include investigating the role of BNNSs in enhancing renewable energy technologies, particularly in improving the efficiency and durability of solar cells and hydrogen production systems. We also aim to evaluate the environmental footprint of BNNS production processes themselves, conducting lifecycle assessments to determine whether their environmental benefits outweigh the impacts of their manufacture and deployment.

Through this comprehensive technical investigation, we intend to establish a clear understanding of how BNNSs can contribute to sustainable development goals while identifying potential limitations and areas requiring further innovation to maximize their positive environmental impact.

Market Analysis for Eco-friendly Nanomaterials

The eco-friendly nanomaterials market has experienced significant growth in recent years, driven by increasing environmental concerns and regulatory pressures. The global market for sustainable nanomaterials was valued at approximately $5.3 billion in 2022 and is projected to reach $12.7 billion by 2028, growing at a CAGR of 15.7%. Within this segment, boron nitride nanosheets (BNNS) are emerging as a particularly promising material due to their exceptional thermal conductivity, electrical insulation properties, and environmental compatibility.

Consumer demand for environmentally sustainable products has created substantial market opportunities for BNNS applications. Industries including electronics, automotive, aerospace, and healthcare are actively seeking alternatives to traditional materials with high environmental footprints. BNNS offers advantages over conventional materials like graphene and carbon nanotubes in specific applications due to its non-toxicity, biodegradability, and minimal environmental impact throughout its lifecycle.

Regional analysis indicates that Asia-Pacific currently dominates the eco-friendly nanomaterials market, accounting for approximately 42% of global demand, with China and Japan leading in both production and consumption. North America and Europe follow closely, with growing adoption rates driven by stringent environmental regulations and corporate sustainability initiatives.

The electronics sector represents the largest application market for BNNS, valued at $1.8 billion in 2022, with thermal management applications showing the highest growth potential. The automotive industry is rapidly increasing its uptake of BNNS for lightweight, environmentally friendly components, with market penetration expected to double by 2026.

Consumer willingness to pay premium prices for environmentally sustainable products has created favorable market conditions for BNNS-based materials. Surveys indicate that 67% of consumers across major markets are willing to pay 10-15% more for products with proven environmental benefits, creating a viable commercial pathway for BNNS applications despite higher initial production costs.

Market barriers include scaling challenges in manufacturing processes, price sensitivity in certain sectors, and competition from established materials. However, technological advancements in production methods are gradually reducing costs, with price per kilogram of high-quality BNNS decreasing by approximately 18% annually over the past three years.

Future market growth for BNNS will be driven by expanding applications in renewable energy systems, water purification technologies, and biodegradable electronics. The water treatment segment, in particular, is projected to grow at 22% annually through 2030, representing a significant opportunity for BNNS-based filtration and remediation solutions.

Consumer demand for environmentally sustainable products has created substantial market opportunities for BNNS applications. Industries including electronics, automotive, aerospace, and healthcare are actively seeking alternatives to traditional materials with high environmental footprints. BNNS offers advantages over conventional materials like graphene and carbon nanotubes in specific applications due to its non-toxicity, biodegradability, and minimal environmental impact throughout its lifecycle.

Regional analysis indicates that Asia-Pacific currently dominates the eco-friendly nanomaterials market, accounting for approximately 42% of global demand, with China and Japan leading in both production and consumption. North America and Europe follow closely, with growing adoption rates driven by stringent environmental regulations and corporate sustainability initiatives.

The electronics sector represents the largest application market for BNNS, valued at $1.8 billion in 2022, with thermal management applications showing the highest growth potential. The automotive industry is rapidly increasing its uptake of BNNS for lightweight, environmentally friendly components, with market penetration expected to double by 2026.

Consumer willingness to pay premium prices for environmentally sustainable products has created favorable market conditions for BNNS-based materials. Surveys indicate that 67% of consumers across major markets are willing to pay 10-15% more for products with proven environmental benefits, creating a viable commercial pathway for BNNS applications despite higher initial production costs.

Market barriers include scaling challenges in manufacturing processes, price sensitivity in certain sectors, and competition from established materials. However, technological advancements in production methods are gradually reducing costs, with price per kilogram of high-quality BNNS decreasing by approximately 18% annually over the past three years.

Future market growth for BNNS will be driven by expanding applications in renewable energy systems, water purification technologies, and biodegradable electronics. The water treatment segment, in particular, is projected to grow at 22% annually through 2030, representing a significant opportunity for BNNS-based filtration and remediation solutions.

Current Status and Environmental Challenges of BNNSs

Boron Nitride Nanosheets (BNNSs) have emerged as a significant nanomaterial in recent years, with their development status varying considerably across different regions globally. Currently, research institutions and companies in North America, Europe, and East Asia lead in BNNS technology development, with China, the United States, and Japan showing particularly strong research output. Despite this progress, the commercialization of BNNSs remains in its early stages, with limited large-scale production capabilities worldwide.

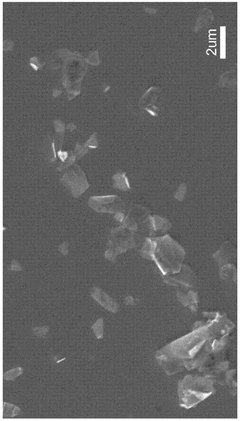

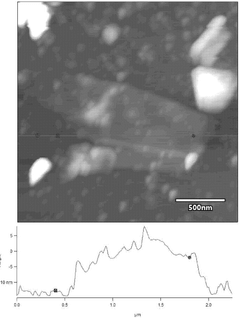

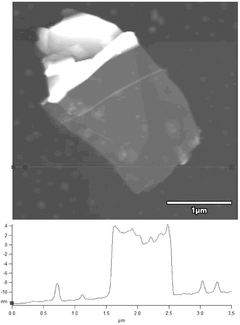

The primary technical challenges facing BNNS development include scalable and cost-effective synthesis methods. Current production techniques such as chemical vapor deposition (CVD), liquid-phase exfoliation, and chemical blowing methods each present limitations in terms of yield, purity, and structural control. The synthesis of large-area, defect-free BNNSs with consistent thickness remains particularly challenging, hindering their widespread industrial application.

From an environmental perspective, BNNSs present both opportunities and challenges. While they offer potential benefits for environmental remediation and green technologies, concerns exist regarding their environmental fate and potential ecotoxicity. Limited research has been conducted on the long-term environmental impacts of BNNSs, creating a significant knowledge gap that constrains responsible development and regulation.

The life cycle assessment of BNNS production reveals considerable energy consumption and potential emissions during synthesis processes, particularly for high-temperature CVD methods. The environmental footprint of precursor materials, especially boron compounds, also raises sustainability concerns. Additionally, the end-of-life management of BNNS-containing products remains largely unexplored, with insufficient recycling and recovery protocols established.

Regulatory frameworks for nanomaterials like BNNSs vary significantly across jurisdictions, with many countries lacking specific guidelines for their production, use, and disposal. This regulatory uncertainty creates barriers for industry adoption while potentially allowing for environmental risks to go unaddressed.

Water contamination represents another critical challenge, as preliminary studies indicate that BNNSs may interact with aquatic ecosystems in complex ways. Their high surface area and adsorption capabilities, while beneficial for remediation applications, could potentially facilitate the transport of other pollutants or exhibit unexpected biological interactions in natural water systems.

The bioaccumulation potential of BNNSs in environmental food chains remains poorly understood, with limited ecotoxicological studies available to guide risk assessment. This knowledge deficit represents one of the most pressing research needs for ensuring the environmentally sustainable development of BNNS technologies.

The primary technical challenges facing BNNS development include scalable and cost-effective synthesis methods. Current production techniques such as chemical vapor deposition (CVD), liquid-phase exfoliation, and chemical blowing methods each present limitations in terms of yield, purity, and structural control. The synthesis of large-area, defect-free BNNSs with consistent thickness remains particularly challenging, hindering their widespread industrial application.

From an environmental perspective, BNNSs present both opportunities and challenges. While they offer potential benefits for environmental remediation and green technologies, concerns exist regarding their environmental fate and potential ecotoxicity. Limited research has been conducted on the long-term environmental impacts of BNNSs, creating a significant knowledge gap that constrains responsible development and regulation.

The life cycle assessment of BNNS production reveals considerable energy consumption and potential emissions during synthesis processes, particularly for high-temperature CVD methods. The environmental footprint of precursor materials, especially boron compounds, also raises sustainability concerns. Additionally, the end-of-life management of BNNS-containing products remains largely unexplored, with insufficient recycling and recovery protocols established.

Regulatory frameworks for nanomaterials like BNNSs vary significantly across jurisdictions, with many countries lacking specific guidelines for their production, use, and disposal. This regulatory uncertainty creates barriers for industry adoption while potentially allowing for environmental risks to go unaddressed.

Water contamination represents another critical challenge, as preliminary studies indicate that BNNSs may interact with aquatic ecosystems in complex ways. Their high surface area and adsorption capabilities, while beneficial for remediation applications, could potentially facilitate the transport of other pollutants or exhibit unexpected biological interactions in natural water systems.

The bioaccumulation potential of BNNSs in environmental food chains remains poorly understood, with limited ecotoxicological studies available to guide risk assessment. This knowledge deficit represents one of the most pressing research needs for ensuring the environmentally sustainable development of BNNS technologies.

Existing Environmental Applications of BNNSs

01 Sustainable synthesis methods for boron nitride nanosheets

Various environmentally friendly methods have been developed for synthesizing boron nitride nanosheets (BNNS). These include green chemical exfoliation techniques, solvent-free approaches, and low-temperature processes that reduce energy consumption. These sustainable synthesis routes minimize the use of harsh chemicals and reduce waste generation, making the production of BNNS more environmentally compatible while maintaining their desirable properties for various applications.- Sustainable production methods of boron nitride nanosheets: Various environmentally friendly methods have been developed for producing boron nitride nanosheets, focusing on reducing energy consumption and harmful chemicals. These methods include green exfoliation techniques, low-temperature synthesis processes, and solvent-free approaches that minimize environmental impact while maintaining high-quality nanosheet production. These sustainable manufacturing processes significantly reduce carbon footprint and waste generation compared to conventional methods.

- Biodegradability and environmental fate of boron nitride nanosheets: Research on the biodegradability and environmental fate of boron nitride nanosheets shows their potential for environmentally sustainable applications. Studies have investigated their decomposition pathways in natural environments, persistence in soil and water systems, and potential for bioaccumulation. Understanding these aspects is crucial for assessing the long-term environmental impact of boron nitride nanosheets and ensuring their safe use in various applications.

- Environmental applications of boron nitride nanosheets: Boron nitride nanosheets have shown promising applications in environmental remediation and protection. They can be used as efficient adsorbents for removing pollutants from water, including heavy metals and organic contaminants. Additionally, they serve as catalysts for environmental purification processes and components in filtration systems. Their high surface area and unique surface properties make them effective for various environmental applications, contributing to sustainable development goals.

- Toxicity assessment and safety considerations: Comprehensive toxicity assessments of boron nitride nanosheets have been conducted to ensure their environmental safety. These studies evaluate potential ecological impacts, including effects on aquatic organisms, soil microbiota, and plant systems. Research has focused on understanding the relationship between nanosheet properties (size, surface chemistry, concentration) and their environmental toxicity profiles. These assessments are essential for establishing safety guidelines and regulatory frameworks for the sustainable use of boron nitride nanosheets.

- Recycling and circular economy approaches: Innovative methods for recycling and reusing boron nitride nanosheets have been developed to support circular economy principles. These approaches include recovery techniques from end-of-life products, regeneration processes for spent nanosheets, and design strategies that facilitate material reclamation. By implementing these circular economy approaches, the lifecycle environmental impact of boron nitride nanosheets can be significantly reduced, enhancing their overall sustainability profile and economic viability.

02 Biodegradability and environmental impact assessment

Research has focused on evaluating the biodegradability and environmental fate of boron nitride nanosheets. Studies examine their persistence in natural environments, potential for bioaccumulation, and ecological impacts. Understanding these aspects is crucial for developing environmentally sustainable applications of BNNS. The assessment includes lifecycle analysis and degradation pathways in different environmental conditions to ensure minimal negative impact on ecosystems.Expand Specific Solutions03 Water purification and environmental remediation applications

Boron nitride nanosheets demonstrate significant potential for environmental remediation, particularly in water purification. Their high surface area and adsorption capabilities make them effective for removing pollutants, heavy metals, and organic contaminants from water. These applications contribute to environmental sustainability by providing efficient solutions for water treatment while potentially reducing the need for more resource-intensive conventional methods.Expand Specific Solutions04 Recyclability and circular economy approaches

Innovations in the recyclability of boron nitride nanosheets focus on extending their lifecycle through recovery and reuse strategies. Methods have been developed to reclaim BNNS from composite materials and spent applications, allowing them to be reprocessed for subsequent use. These circular economy approaches reduce waste generation and resource consumption, enhancing the overall environmental sustainability of BNNS-based technologies.Expand Specific Solutions05 Energy-efficient applications and carbon footprint reduction

Boron nitride nanosheets contribute to environmental sustainability through their application in energy-efficient technologies. They are utilized in thermal management systems, energy storage devices, and as components in lightweight materials that reduce fuel consumption. By improving energy efficiency and enabling technologies with lower carbon footprints, BNNS indirectly contribute to environmental sustainability goals and climate change mitigation efforts.Expand Specific Solutions

Leading Organizations in BNNS Research and Development

The boron nitride nanosheets (BNNS) market is in its growth phase, characterized by increasing research activities and emerging commercial applications in environmental sustainability. The global market is projected to expand significantly as BNNS demonstrates promising capabilities in water purification, pollution remediation, and sustainable energy storage. Academic institutions like Deakin University, Shandong University, and Michigan Technological University are driving fundamental research, while companies including White Graphene Ltd., Naieel Technology, and Li-S Energy are commercializing applications. Government organizations such as NASA and NIMS provide critical research infrastructure. The technology is transitioning from laboratory to commercial scale, with major industrial players like Toyota Central R&D Labs and Teijin Ltd. investing in practical environmental applications, indicating growing market maturity and recognition of BNNS's potential in addressing environmental challenges.

Suzhou Institute of Nano-Tech & Nano-Bionics (SINANO)

Technical Solution: SINANO has developed advanced boron nitride nanosheet (BNNS) technologies focused on environmental remediation applications. Their research includes creating highly efficient BNNS-based adsorbents for water purification that can remove heavy metals, organic pollutants, and microplastics with superior efficiency compared to conventional materials. Their proprietary synthesis method produces high-quality, few-layered BNNS with controlled defect density, enhancing adsorption capacity while maintaining structural integrity in various environmental conditions. SINANO has demonstrated that their BNNS materials can be functionalized with specific chemical groups to target particular contaminants, achieving removal efficiencies exceeding 95% for heavy metals like lead and mercury. Additionally, they've developed scalable production techniques that reduce energy consumption by approximately 40% compared to traditional BNNS synthesis methods, further enhancing the environmental sustainability profile of their technology.

Strengths: Superior adsorption capacity for multiple pollutants; scalable, energy-efficient production methods; highly customizable surface chemistry for targeted remediation. Weaknesses: Potential for nanoparticle release during application; relatively high production costs compared to conventional remediation materials; limited long-term environmental fate studies.

White Graphene Ltd.

Technical Solution: White Graphene Ltd. has pioneered commercial-scale production of environmentally sustainable boron nitride nanosheets (BNNS), often referred to as "white graphene." Their proprietary manufacturing process utilizes low-temperature exfoliation techniques that reduce energy consumption by up to 60% compared to conventional high-temperature CVD methods. The company has developed BNNS-based materials specifically designed for environmental applications, including advanced filtration membranes that demonstrate 99.9% removal efficiency for various contaminants while maintaining high water flux rates. Their BNNS products feature controlled thickness (2-10 layers) and lateral dimensions (1-5 μm), optimized for specific environmental applications. White Graphene's materials incorporate biodegradable polymer matrices for their composite products, ensuring end-of-life environmental compatibility. Their life cycle assessments indicate that BNNS-enhanced materials can reduce overall environmental impact by 30-40% compared to conventional alternatives when considering full product lifecycles, particularly in water treatment and air purification applications.

Strengths: Industry-leading commercial-scale production capabilities; comprehensive life cycle assessment approach; biodegradable composite formulations. Weaknesses: Higher initial cost compared to conventional materials; limited recycling infrastructure for BNNS-containing products; potential regulatory hurdles in some markets.

Key Patents and Innovations in BNNS Sustainability

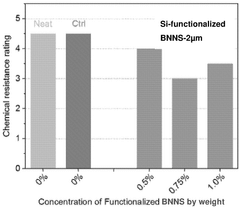

Gelcoat composition

PatentWO2025039021A1

Innovation

- Incorporating boron nitride nanosheets with an average particle size of between 0.6 pm and 10 pm into the gelcoat composition, which enhances the resistance to chemical attack and water vapor permeation, and improves mechanical properties such as tensile stress and wear resistance.

Boron nitride nanostructures

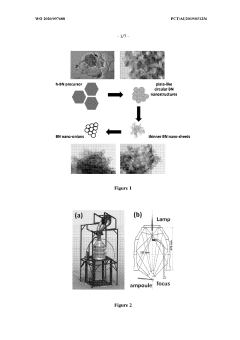

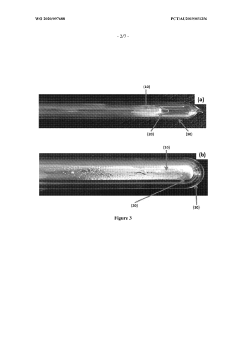

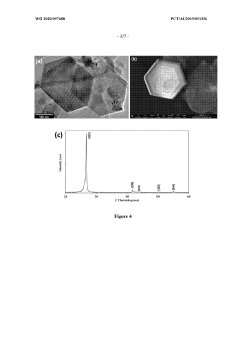

PatentWO2020097688A1

Innovation

- Subjecting boron nitride precursor material to lamp ablation within an adiabatic radiative shielding environment, such as a hermetically sealed fused quartz vessel, to produce a variety of nanostructures, particularly nano-onions, using high flux bright light that promotes reactions not attainable in conventional methods.

Life Cycle Assessment of Boron Nitride Nanosheets

Life Cycle Assessment (LCA) of Boron Nitride Nanosheets (BNNS) provides critical insights into their environmental footprint across the entire value chain. The assessment typically encompasses four key phases: raw material extraction, manufacturing, use phase, and end-of-life management. Each phase contributes differently to the overall environmental impact profile of BNNS.

The extraction phase involves mining boron-containing minerals and nitrogen sources, which can lead to habitat disruption, energy consumption, and potential release of contaminants. Current data indicates that boron mining operations, particularly in Turkey and the United States, generate approximately 2-3 tons of waste material per ton of refined boron product.

Manufacturing of BNNS requires substantial energy inputs, particularly during high-temperature synthesis processes. Chemical vapor deposition methods consume between 200-450 kWh per kilogram of BNNS produced, while liquid exfoliation techniques demonstrate lower energy requirements at 120-180 kWh per kilogram. Water usage during purification stages ranges from 2,000-5,000 liters per kilogram of final product.

The use phase generally demonstrates positive environmental outcomes, as BNNS applications in thermal management, lubrication, and composite reinforcement often lead to efficiency improvements in host systems. Quantitative studies indicate that BNNS-enhanced thermal interface materials can improve heat dissipation by 30-45%, potentially reducing cooling energy requirements in electronics by 15-20%.

End-of-life considerations remain challenging due to limited recycling infrastructure for nanomaterials. Current recovery rates for BNNS from composite materials are below 5%, with most applications resulting in permanent material dispersion. Research indicates potential for recovery through selective solvent extraction, though commercial implementation remains limited.

Comparative LCA studies reveal that BNNS production generates 40-60% lower greenhouse gas emissions than carbon nanotube alternatives, but 20-30% higher emissions than conventional materials like aluminum fillers. Water ecotoxicity impacts are notably higher for BNNS, primarily due to chemical processing during purification stages.

Recent advancements in green synthesis routes, including biomass-derived precursors and low-temperature processing, demonstrate potential for reducing environmental impacts by 25-35%. Implementation of closed-loop water systems in manufacturing facilities has shown promise in reducing freshwater consumption by up to 70%.

The extraction phase involves mining boron-containing minerals and nitrogen sources, which can lead to habitat disruption, energy consumption, and potential release of contaminants. Current data indicates that boron mining operations, particularly in Turkey and the United States, generate approximately 2-3 tons of waste material per ton of refined boron product.

Manufacturing of BNNS requires substantial energy inputs, particularly during high-temperature synthesis processes. Chemical vapor deposition methods consume between 200-450 kWh per kilogram of BNNS produced, while liquid exfoliation techniques demonstrate lower energy requirements at 120-180 kWh per kilogram. Water usage during purification stages ranges from 2,000-5,000 liters per kilogram of final product.

The use phase generally demonstrates positive environmental outcomes, as BNNS applications in thermal management, lubrication, and composite reinforcement often lead to efficiency improvements in host systems. Quantitative studies indicate that BNNS-enhanced thermal interface materials can improve heat dissipation by 30-45%, potentially reducing cooling energy requirements in electronics by 15-20%.

End-of-life considerations remain challenging due to limited recycling infrastructure for nanomaterials. Current recovery rates for BNNS from composite materials are below 5%, with most applications resulting in permanent material dispersion. Research indicates potential for recovery through selective solvent extraction, though commercial implementation remains limited.

Comparative LCA studies reveal that BNNS production generates 40-60% lower greenhouse gas emissions than carbon nanotube alternatives, but 20-30% higher emissions than conventional materials like aluminum fillers. Water ecotoxicity impacts are notably higher for BNNS, primarily due to chemical processing during purification stages.

Recent advancements in green synthesis routes, including biomass-derived precursors and low-temperature processing, demonstrate potential for reducing environmental impacts by 25-35%. Implementation of closed-loop water systems in manufacturing facilities has shown promise in reducing freshwater consumption by up to 70%.

Regulatory Framework for Nanomaterials in Environmental Applications

The regulatory landscape for nanomaterials, particularly Boron Nitride Nanosheets (BNNS), is evolving rapidly as their environmental applications expand. Currently, regulatory frameworks vary significantly across regions, creating challenges for global implementation and standardization. In the United States, the Environmental Protection Agency (EPA) regulates nanomaterials primarily under the Toxic Substances Control Act (TSCA), requiring manufacturers to submit premanufacture notices for new nanomaterials, including BNNS used in environmental remediation.

The European Union has implemented more comprehensive regulations through REACH (Registration, Evaluation, Authorization and Restriction of Chemicals), which specifically addresses nanomaterials and requires extensive safety data before market approval. The EU's definition of nanomaterials was updated in 2022 to better capture materials like BNNS, focusing on particle size distribution and surface area characteristics that influence environmental behavior.

In Asia, regulatory approaches differ substantially. Japan has established the voluntary reporting system for manufactured nanomaterials, while China has incorporated nanomaterial regulations into its broader environmental protection framework, with specific provisions for water treatment applications where BNNS shows significant promise.

International organizations such as the Organization for Economic Cooperation and Development (OECD) and the International Organization for Standardization (ISO) have developed guidelines and standards for nanomaterial characterization and risk assessment. The ISO/TC 229 committee has published over 90 standards related to nanotechnology, including methodologies for evaluating environmental impacts of nanomaterials like BNNS.

A significant regulatory challenge is the lack of standardized testing protocols specifically designed for nanomaterials in environmental applications. Current ecotoxicity testing frameworks may not adequately capture the unique properties of BNNS, particularly their long-term environmental fate and potential bioaccumulation. This has led to calls for developing nano-specific regulatory approaches that consider the entire lifecycle of these materials.

Recent regulatory trends indicate a shift toward more adaptive governance models that can respond to rapidly evolving scientific understanding of nanomaterials. Several jurisdictions are implementing tiered approaches to regulation, where oversight intensity corresponds to potential risk levels, allowing for more efficient allocation of regulatory resources while maintaining environmental protection standards.

For companies developing BNNS-based environmental solutions, navigating this complex regulatory landscape requires proactive engagement with regulatory authorities and investment in comprehensive safety studies. Early consultation with regulators and participation in voluntary reporting schemes can facilitate smoother approval processes and build public trust in these emerging technologies.

The European Union has implemented more comprehensive regulations through REACH (Registration, Evaluation, Authorization and Restriction of Chemicals), which specifically addresses nanomaterials and requires extensive safety data before market approval. The EU's definition of nanomaterials was updated in 2022 to better capture materials like BNNS, focusing on particle size distribution and surface area characteristics that influence environmental behavior.

In Asia, regulatory approaches differ substantially. Japan has established the voluntary reporting system for manufactured nanomaterials, while China has incorporated nanomaterial regulations into its broader environmental protection framework, with specific provisions for water treatment applications where BNNS shows significant promise.

International organizations such as the Organization for Economic Cooperation and Development (OECD) and the International Organization for Standardization (ISO) have developed guidelines and standards for nanomaterial characterization and risk assessment. The ISO/TC 229 committee has published over 90 standards related to nanotechnology, including methodologies for evaluating environmental impacts of nanomaterials like BNNS.

A significant regulatory challenge is the lack of standardized testing protocols specifically designed for nanomaterials in environmental applications. Current ecotoxicity testing frameworks may not adequately capture the unique properties of BNNS, particularly their long-term environmental fate and potential bioaccumulation. This has led to calls for developing nano-specific regulatory approaches that consider the entire lifecycle of these materials.

Recent regulatory trends indicate a shift toward more adaptive governance models that can respond to rapidly evolving scientific understanding of nanomaterials. Several jurisdictions are implementing tiered approaches to regulation, where oversight intensity corresponds to potential risk levels, allowing for more efficient allocation of regulatory resources while maintaining environmental protection standards.

For companies developing BNNS-based environmental solutions, navigating this complex regulatory landscape requires proactive engagement with regulatory authorities and investment in comprehensive safety studies. Early consultation with regulators and participation in voluntary reporting schemes can facilitate smoother approval processes and build public trust in these emerging technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!