The Innovation of Boron Nitride Nanosheets in Coating Technologies

OCT 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

BN Nanosheets Background and Development Goals

Boron nitride nanosheets (BNNSs) represent a significant advancement in two-dimensional nanomaterials, emerging as a critical component in modern coating technologies. Since their initial discovery in the early 2000s, these hexagonal lattice structures have garnered substantial attention due to their remarkable properties, including exceptional thermal conductivity, electrical insulation, mechanical strength, and chemical stability. The evolution of BNNSs has been marked by progressive improvements in synthesis methods, from mechanical exfoliation to chemical vapor deposition (CVD) and wet chemical approaches, each contributing to enhanced quality and scalability.

The technological trajectory of BNNSs has been significantly influenced by the broader development of 2D materials following graphene's isolation in 2004. Unlike graphene, however, BNNSs offer a wide bandgap (5-6 eV) that provides excellent electrical insulation while maintaining thermal conductivity comparable to many metals, creating a unique value proposition for specialized coating applications.

Current research trends indicate a growing focus on developing scalable production methods for high-quality BNNSs with controlled thickness and lateral dimensions. Liquid-phase exfoliation and chemical synthesis routes have shown particular promise for industrial-scale production, though challenges in maintaining structural integrity and purity remain significant hurdles.

The integration of BNNSs into coating technologies aims to address several critical industrial challenges. Thermal management in electronics represents a primary application target, where the exceptional thermal conductivity of BNNSs (up to 2000 W/mK in-plane) could revolutionize heat dissipation in increasingly miniaturized and powerful devices. Additionally, their chemical inertness and oxidation resistance at high temperatures (up to 900°C in air) position them as ideal candidates for protective coatings in harsh environments.

The development goals for BN nanosheet coating technologies are multifaceted. Short-term objectives include optimizing dispersion techniques to achieve uniform distribution within various matrix materials and developing cost-effective, scalable production methods. Medium-term goals focus on enhancing interfacial bonding between BNNSs and substrate materials to maximize thermal transfer efficiency and mechanical durability. Long-term aspirations involve creating multifunctional coatings that simultaneously provide thermal management, corrosion protection, and wear resistance.

Significant technical challenges remain, particularly in controlling nanosheet orientation within coatings to maximize anisotropic property benefits and developing processing techniques compatible with existing industrial coating infrastructure. The field is progressing toward functionalized BNNSs that offer improved matrix compatibility and specialized performance characteristics tailored to specific application requirements.

The technological trajectory of BNNSs has been significantly influenced by the broader development of 2D materials following graphene's isolation in 2004. Unlike graphene, however, BNNSs offer a wide bandgap (5-6 eV) that provides excellent electrical insulation while maintaining thermal conductivity comparable to many metals, creating a unique value proposition for specialized coating applications.

Current research trends indicate a growing focus on developing scalable production methods for high-quality BNNSs with controlled thickness and lateral dimensions. Liquid-phase exfoliation and chemical synthesis routes have shown particular promise for industrial-scale production, though challenges in maintaining structural integrity and purity remain significant hurdles.

The integration of BNNSs into coating technologies aims to address several critical industrial challenges. Thermal management in electronics represents a primary application target, where the exceptional thermal conductivity of BNNSs (up to 2000 W/mK in-plane) could revolutionize heat dissipation in increasingly miniaturized and powerful devices. Additionally, their chemical inertness and oxidation resistance at high temperatures (up to 900°C in air) position them as ideal candidates for protective coatings in harsh environments.

The development goals for BN nanosheet coating technologies are multifaceted. Short-term objectives include optimizing dispersion techniques to achieve uniform distribution within various matrix materials and developing cost-effective, scalable production methods. Medium-term goals focus on enhancing interfacial bonding between BNNSs and substrate materials to maximize thermal transfer efficiency and mechanical durability. Long-term aspirations involve creating multifunctional coatings that simultaneously provide thermal management, corrosion protection, and wear resistance.

Significant technical challenges remain, particularly in controlling nanosheet orientation within coatings to maximize anisotropic property benefits and developing processing techniques compatible with existing industrial coating infrastructure. The field is progressing toward functionalized BNNSs that offer improved matrix compatibility and specialized performance characteristics tailored to specific application requirements.

Market Analysis for Advanced Coating Technologies

The advanced coating technologies market is experiencing robust growth, driven by increasing demand across multiple industries including automotive, aerospace, electronics, and construction. The global market for advanced coatings was valued at approximately 37.2 billion USD in 2022 and is projected to reach 59.4 billion USD by 2028, growing at a CAGR of 8.1% during the forecast period. This growth trajectory is particularly significant for innovative materials like Boron Nitride Nanosheets (BNNS), which are positioned to capture substantial market share due to their exceptional properties.

Consumer preferences are shifting toward high-performance, multifunctional coatings that offer superior protection and extended durability. Industries are increasingly willing to invest in premium coating solutions that reduce maintenance costs and extend product lifecycles. This trend is especially evident in the electronics sector, where thermal management challenges have intensified with device miniaturization and increased power densities.

Boron Nitride Nanosheets are entering the market at a strategic time when traditional coating materials are reaching their performance limits. The thermal management coatings segment, where BNNS excel, is growing at 9.3% annually, outpacing the broader coatings market. This acceleration is driven by the expanding electronics industry and the rapid adoption of electric vehicles, both requiring advanced thermal management solutions.

Regional analysis reveals that Asia-Pacific dominates the advanced coatings market with 42% share, followed by North America (27%) and Europe (21%). China and South Korea are emerging as key manufacturing hubs for BNNS-based coatings, while North American and European markets are driving innovation through substantial R&D investments. The Middle East and Latin America represent emerging markets with growing potential, particularly in construction and oil & gas applications.

Industry segmentation shows that electronics and semiconductor applications currently represent the largest market opportunity for BNNS coatings (34%), followed by automotive (23%), aerospace (18%), and industrial equipment (15%). The remaining 10% is distributed across various niche applications including medical devices and renewable energy infrastructure.

Market barriers include high production costs of high-quality BNNS, scaling challenges, and competition from established coating technologies. However, these barriers are gradually diminishing as manufacturing processes improve and economies of scale begin to take effect. The price premium for BNNS-based coatings is expected to decrease from the current 40-60% to 15-25% within the next five years, significantly expanding market accessibility.

Customer adoption analysis indicates that early adopters are primarily in high-value applications where performance advantages outweigh cost considerations. As production scales and costs decrease, adoption is expected to accelerate across broader market segments, particularly in consumer electronics and automotive thermal management applications.

Consumer preferences are shifting toward high-performance, multifunctional coatings that offer superior protection and extended durability. Industries are increasingly willing to invest in premium coating solutions that reduce maintenance costs and extend product lifecycles. This trend is especially evident in the electronics sector, where thermal management challenges have intensified with device miniaturization and increased power densities.

Boron Nitride Nanosheets are entering the market at a strategic time when traditional coating materials are reaching their performance limits. The thermal management coatings segment, where BNNS excel, is growing at 9.3% annually, outpacing the broader coatings market. This acceleration is driven by the expanding electronics industry and the rapid adoption of electric vehicles, both requiring advanced thermal management solutions.

Regional analysis reveals that Asia-Pacific dominates the advanced coatings market with 42% share, followed by North America (27%) and Europe (21%). China and South Korea are emerging as key manufacturing hubs for BNNS-based coatings, while North American and European markets are driving innovation through substantial R&D investments. The Middle East and Latin America represent emerging markets with growing potential, particularly in construction and oil & gas applications.

Industry segmentation shows that electronics and semiconductor applications currently represent the largest market opportunity for BNNS coatings (34%), followed by automotive (23%), aerospace (18%), and industrial equipment (15%). The remaining 10% is distributed across various niche applications including medical devices and renewable energy infrastructure.

Market barriers include high production costs of high-quality BNNS, scaling challenges, and competition from established coating technologies. However, these barriers are gradually diminishing as manufacturing processes improve and economies of scale begin to take effect. The price premium for BNNS-based coatings is expected to decrease from the current 40-60% to 15-25% within the next five years, significantly expanding market accessibility.

Customer adoption analysis indicates that early adopters are primarily in high-value applications where performance advantages outweigh cost considerations. As production scales and costs decrease, adoption is expected to accelerate across broader market segments, particularly in consumer electronics and automotive thermal management applications.

Current Status and Challenges in BN Nanosheet Coatings

The global landscape of boron nitride nanosheet (BNNS) coating technologies has witnessed significant advancements in recent years, with research institutions and industrial players across North America, Europe, and Asia making substantial contributions. Currently, BNNS coatings have demonstrated exceptional thermal conductivity (up to 2000 W/m·K), electrical insulation properties (bandgap ~5.9 eV), and mechanical strength that surpasses many conventional coating materials. These properties have positioned BNNS as a promising candidate for thermal management applications in electronics, corrosion-resistant coatings, and tribological applications.

Despite these promising attributes, several technical challenges impede the widespread industrial adoption of BNNS coatings. The primary obstacle remains the scalable production of high-quality, defect-free BNNS with consistent thickness and lateral dimensions. Current synthesis methods, including chemical vapor deposition (CVD), liquid-phase exfoliation, and chemical exfoliation, each present trade-offs between quality, yield, and cost-effectiveness that have yet to be optimized for mass production.

Another significant challenge is the integration of BNNS into coating formulations while maintaining their intrinsic properties. The hydrophobic nature of pristine BNNS often leads to poor dispersion in common coating matrices, resulting in agglomeration and compromised performance. Various surface functionalization approaches have been developed to address this issue, but many introduce defects that diminish the thermal and mechanical properties that make BNNS attractive in the first place.

Adhesion to diverse substrate materials presents another technical hurdle. The relatively inert surface of BNNS can result in weak interfacial bonding with substrates, leading to delamination under thermal cycling or mechanical stress. Current solutions involving coupling agents or surface treatments show promise but require further refinement for different application environments.

The environmental stability of BNNS coatings, particularly under extreme conditions such as high temperatures (>800°C), oxidative environments, or exposure to harsh chemicals, remains inadequately characterized. While theoretical predictions suggest excellent stability, practical implementations have revealed degradation mechanisms that are not fully understood or mitigated.

From a manufacturing perspective, the development of scalable, cost-effective deposition techniques for uniform BNNS coatings over large areas and complex geometries represents a significant challenge. Conventional methods like spray coating, spin coating, and dip coating each have limitations in terms of thickness control, uniformity, and applicability to different substrate geometries.

Standardization of characterization methods and performance metrics for BNNS coatings is notably lacking, hampering comparative assessments and industry adoption. The absence of established testing protocols specifically designed for nanoscale coatings creates uncertainty in performance claims and reliability predictions across different application domains.

Despite these promising attributes, several technical challenges impede the widespread industrial adoption of BNNS coatings. The primary obstacle remains the scalable production of high-quality, defect-free BNNS with consistent thickness and lateral dimensions. Current synthesis methods, including chemical vapor deposition (CVD), liquid-phase exfoliation, and chemical exfoliation, each present trade-offs between quality, yield, and cost-effectiveness that have yet to be optimized for mass production.

Another significant challenge is the integration of BNNS into coating formulations while maintaining their intrinsic properties. The hydrophobic nature of pristine BNNS often leads to poor dispersion in common coating matrices, resulting in agglomeration and compromised performance. Various surface functionalization approaches have been developed to address this issue, but many introduce defects that diminish the thermal and mechanical properties that make BNNS attractive in the first place.

Adhesion to diverse substrate materials presents another technical hurdle. The relatively inert surface of BNNS can result in weak interfacial bonding with substrates, leading to delamination under thermal cycling or mechanical stress. Current solutions involving coupling agents or surface treatments show promise but require further refinement for different application environments.

The environmental stability of BNNS coatings, particularly under extreme conditions such as high temperatures (>800°C), oxidative environments, or exposure to harsh chemicals, remains inadequately characterized. While theoretical predictions suggest excellent stability, practical implementations have revealed degradation mechanisms that are not fully understood or mitigated.

From a manufacturing perspective, the development of scalable, cost-effective deposition techniques for uniform BNNS coatings over large areas and complex geometries represents a significant challenge. Conventional methods like spray coating, spin coating, and dip coating each have limitations in terms of thickness control, uniformity, and applicability to different substrate geometries.

Standardization of characterization methods and performance metrics for BNNS coatings is notably lacking, hampering comparative assessments and industry adoption. The absence of established testing protocols specifically designed for nanoscale coatings creates uncertainty in performance claims and reliability predictions across different application domains.

Current Technical Solutions for BN Nanosheet Synthesis and Application

01 Synthesis methods for boron nitride nanosheets

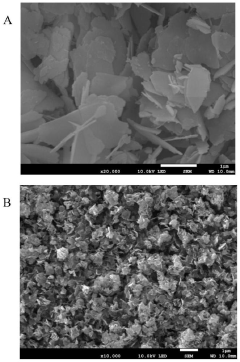

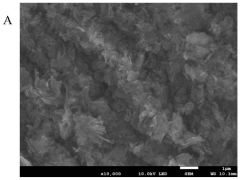

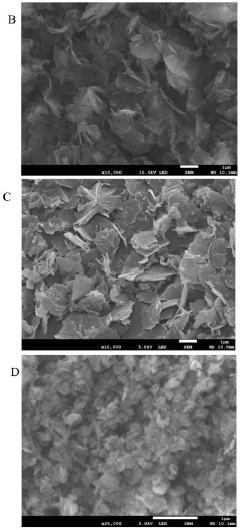

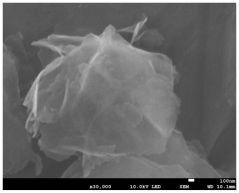

Various methods can be employed to synthesize boron nitride nanosheets, including chemical vapor deposition, exfoliation techniques, and thermal treatments. These processes involve the conversion of precursor materials under controlled conditions to form hexagonal boron nitride structures with nanoscale thickness. The synthesis parameters significantly influence the quality, size, and properties of the resulting nanosheets, which can be tailored for specific applications.- Synthesis methods for boron nitride nanosheets: Various methods can be employed to synthesize boron nitride nanosheets, including chemical vapor deposition, exfoliation techniques, and chemical synthesis routes. These methods control the thickness, size, and quality of the nanosheets. The synthesis parameters such as temperature, pressure, and precursor materials significantly influence the properties of the resulting nanosheets. Optimization of these parameters can lead to high-quality boron nitride nanosheets with desired characteristics for specific applications.

- Functionalization and modification of boron nitride nanosheets: Boron nitride nanosheets can be functionalized or modified to enhance their properties or compatibility with various matrices. Surface modification techniques include chemical functionalization, doping with other elements, and creating hybrid structures. These modifications can improve dispersion in solvents or polymer matrices, enhance thermal conductivity, or introduce new electronic properties. Functionalized boron nitride nanosheets find applications in areas requiring specific surface interactions or enhanced performance characteristics.

- Thermal and mechanical properties of boron nitride nanosheets: Boron nitride nanosheets exhibit exceptional thermal conductivity and mechanical strength. They can efficiently dissipate heat in electronic devices and serve as reinforcement in composite materials. The thermal stability of these nanosheets at high temperatures makes them suitable for applications in harsh environments. Their mechanical properties, including high tensile strength and flexibility, contribute to their use in structural applications and as reinforcing agents in various matrices.

- Applications in composite materials and coatings: Boron nitride nanosheets are widely used in composite materials and coatings to enhance thermal, mechanical, and barrier properties. When incorporated into polymers, ceramics, or metals, they can significantly improve thermal conductivity while maintaining electrical insulation. These nanosheets also enhance the mechanical strength and wear resistance of the host material. In coatings, they provide thermal management, corrosion protection, and improved tribological properties, making them valuable in aerospace, automotive, and electronic industries.

- Electronic and optical applications of boron nitride nanosheets: Boron nitride nanosheets have unique electronic and optical properties that make them suitable for various advanced applications. Their wide bandgap nature makes them excellent insulators and substrates for electronic devices. They can be used in optoelectronic devices, ultraviolet light emitters, and detectors. When combined with other 2D materials, they form heterostructures with novel properties for next-generation electronic devices. Their transparency and thermal stability also make them valuable in optical applications requiring heat resistance.

02 Functionalization and modification of boron nitride nanosheets

Boron nitride nanosheets can be functionalized or modified with various chemical groups or compounds to enhance their properties or compatibility with different matrices. Surface modification techniques include covalent functionalization, non-covalent functionalization, and doping with other elements. These modifications can improve dispersion in solvents or polymer matrices, enhance thermal conductivity, or introduce new properties such as electrical conductivity or catalytic activity.Expand Specific Solutions03 Thermal management applications of boron nitride nanosheets

Boron nitride nanosheets exhibit excellent thermal conductivity and electrical insulation properties, making them ideal for thermal management applications. They can be incorporated into thermal interface materials, heat dissipation coatings, and thermally conductive composites. When added to polymers or other matrices, they create pathways for heat transfer while maintaining electrical insulation, addressing thermal challenges in electronics, aerospace, and other high-performance applications.Expand Specific Solutions04 Composite materials incorporating boron nitride nanosheets

Boron nitride nanosheets can be incorporated into various matrices to form composite materials with enhanced properties. These composites may include polymer-based, ceramic-based, or metal-based materials with improved mechanical strength, thermal stability, and barrier properties. The nanosheets can be dispersed within the matrix or arranged in specific orientations to achieve directional properties. Applications include aerospace components, electronic packaging, and protective coatings.Expand Specific Solutions05 Environmental and energy applications of boron nitride nanosheets

Boron nitride nanosheets demonstrate potential in environmental remediation and energy-related applications. They can be used as adsorbents for pollutant removal, membranes for water purification, or supports for catalysts in environmental processes. In energy applications, they serve as components in batteries, supercapacitors, and fuel cells, where their thermal stability, chemical inertness, and unique surface properties contribute to improved performance and durability of energy storage and conversion devices.Expand Specific Solutions

Leading Companies and Research Institutions in BN Nanomaterials

The innovation of Boron Nitride Nanosheets (BNNS) in coating technologies is currently in a growth phase, with the market expanding rapidly due to increasing applications in thermal management, corrosion protection, and electronics. The global market size for BNNS coatings is projected to reach significant value by 2030, driven by demand in aerospace, automotive, and electronics sectors. Technologically, BNNS applications are transitioning from research to commercialization, with key players demonstrating varying levels of maturity. Academic institutions like Deakin University, KAIST, and Northwestern University are pioneering fundamental research, while companies such as BNNT Materials LLC, Momentive Performance Materials, and Li-S Energy are commercializing applications. NASA and Toyota Central R&D Labs are investing in advanced development, indicating strong industry confidence in this emerging technology's potential.

Momentive Performance Materials, Inc.

Technical Solution: Momentive Performance Materials has developed an innovative approach to boron nitride nanosheet (BNNS) coatings through their SilTech™ BNNS platform. This technology combines their expertise in silicone chemistry with exfoliated hexagonal boron nitride to create hybrid coating systems with enhanced performance characteristics. Their proprietary process involves liquid-phase exfoliation of h-BN in specialized silicone-based solvents, resulting in stable dispersions of few-layer BNNSs (3-5 layers) with lateral dimensions of 0.5-2 μm. These dispersions are then incorporated into silicone matrices to form coatings with exceptional thermal stability (operating temperature range -50°C to 400°C), hydrophobicity (water contact angles >150°), and dielectric properties (breakdown strength >40 kV/mm). Momentive's BNNS-enhanced silicone coatings demonstrate a 45% improvement in thermal conductivity while maintaining electrical insulation properties. The company has also developed UV-curable formulations containing functionalized BNNSs, enabling rapid processing and application to heat-sensitive substrates. Recent innovations include self-stratifying BNNS coatings that form protective surface layers during curing, providing enhanced barrier properties against moisture, chemicals, and thermal degradation.

Strengths: Excellent compatibility with existing silicone coating systems; superior adhesion to various substrates including metals, ceramics, and polymers; enhanced thermal stability and conductivity; established global manufacturing and distribution network. Weaknesses: Higher cost compared to conventional silicone coatings; potential challenges in achieving uniform BNNS dispersion at higher loadings; limited transparency in thicker applications.

Toyota Central R&D Labs, Inc.

Technical Solution: Toyota Central R&D Labs has developed advanced boron nitride nanosheet (BNNS) coating technologies specifically targeted at automotive applications. Their proprietary "BN-Shield" technology utilizes liquid-phase exfoliated h-BN nanosheets with controlled thickness (2-5 layers) and lateral dimensions (1-3 μm) to create multifunctional protective coatings. The lab has pioneered a scalable chemical vapor deposition (CVD) process for direct growth of BNNS films on metal substrates, achieving uniform coverage with thicknesses ranging from 10-100 nm. These coatings demonstrate exceptional thermal stability (up to 800°C in air), tribological properties (friction coefficient <0.1), and corrosion resistance. Toyota's researchers have developed BNNS-polymer composite coatings that reduce thermal conductivity by 35-40% while maintaining mechanical durability, making them ideal for thermal management in electric vehicle components. Their latest innovation involves self-healing BNNS-ceramic hybrid coatings that can repair microcracks through a thermally-activated mechanism, significantly extending component lifespan under thermal cycling conditions. The lab has also created transparent BNNS coatings for automotive glass that provide UV protection while enhancing scratch resistance.

Strengths: Exceptional thermal stability and barrier properties; superior tribological performance reducing wear in moving components; compatibility with existing automotive manufacturing processes; demonstrated durability in real-world automotive environments. Weaknesses: Higher production costs compared to conventional coatings; challenges in achieving uniform dispersion at industrial scales; potential adhesion issues on certain polymer substrates requiring surface pretreatment.

Key Patents and Breakthroughs in BN Nanosheet Coatings

An efficient method for preparing boron nitride nanosheets

PatentActiveCN114751387B

Innovation

- Zinc borate nanosheets are used as boron source and substrate template, and boron nitride nanosheets are prepared through high-temperature nitridation reaction in an ammonia atmosphere. Boron nitride is deposited using the surface diffusion reaction of zinc borate nanosheets and eluted ultrasonically with concentrated hydrochloric acid. Zinc oxide to obtain pure boron nitride nanosheets.

Boron nitride nanosheet-containing fluid dispersion, boron nitride nanosheet composite and production method thereof

PatentActiveJP2015187057A

Innovation

- The use of ionic liquids to disperse and peel boron nitride nanosheets, utilizing cation-π and anion-π interactions to enhance dispersibility, with methods including sonication, stirring, and grinding treatments to achieve high dispersion stability and efficiency.

Environmental Impact and Sustainability of BN Nanosheet Coatings

The environmental implications of Boron Nitride (BN) nanosheet coatings represent a critical dimension in evaluating their long-term viability and alignment with global sustainability goals. Current research indicates that BN nanosheets offer several environmentally favorable characteristics compared to traditional coating materials, particularly in terms of their non-toxic nature and chemical stability. Unlike many conventional coatings that release volatile organic compounds (VOCs) during application and curing, BN nanosheet-based formulations typically demonstrate significantly lower emissions, contributing to improved air quality in both manufacturing environments and end-use settings.

The production processes for BN nanosheets have evolved considerably, with recent advancements focusing on green synthesis methods that reduce energy consumption and hazardous waste generation. Liquid-phase exfoliation techniques using environmentally benign solvents have emerged as promising alternatives to more resource-intensive chemical vapor deposition approaches, potentially lowering the overall carbon footprint associated with manufacturing these advanced materials.

Life cycle assessment (LCA) studies, though still limited in number, suggest that the extended service life of BN nanosheet coatings may offset their initial production impacts. The exceptional thermal stability and wear resistance of these coatings translate to reduced replacement frequency and associated resource consumption, particularly in high-temperature industrial applications where conventional coatings fail prematurely.

Waste management considerations for BN nanosheet coatings present both challenges and opportunities. While the strong chemical bonds in hexagonal boron nitride structures render these materials highly durable, this same characteristic raises questions about their biodegradability and end-of-life management. Current research is exploring potential recovery and recycling pathways, including chemical and thermal treatments that could enable material reclamation from spent coatings.

Water conservation represents another significant environmental benefit of BN nanosheet technologies. The hydrophobic properties of these coatings can reduce water consumption in maintenance operations, while their application in water treatment systems shows promise for improving filtration efficiency and reducing energy requirements in desalination processes.

Regulatory frameworks governing nanomaterials in various jurisdictions are evolving to address potential environmental risks. While current evidence suggests minimal ecotoxicity for BN nanosheets, ongoing studies are essential to fully characterize their environmental fate and behavior, particularly regarding potential bioaccumulation in aquatic ecosystems and long-term soil interactions.

The integration of BN nanosheet coatings into circular economy models represents perhaps the most promising sustainability pathway. Research initiatives focused on designing these materials for eventual recovery and reuse are gaining momentum, potentially transforming what might otherwise be a linear consumption model into a more sustainable closed-loop system.

The production processes for BN nanosheets have evolved considerably, with recent advancements focusing on green synthesis methods that reduce energy consumption and hazardous waste generation. Liquid-phase exfoliation techniques using environmentally benign solvents have emerged as promising alternatives to more resource-intensive chemical vapor deposition approaches, potentially lowering the overall carbon footprint associated with manufacturing these advanced materials.

Life cycle assessment (LCA) studies, though still limited in number, suggest that the extended service life of BN nanosheet coatings may offset their initial production impacts. The exceptional thermal stability and wear resistance of these coatings translate to reduced replacement frequency and associated resource consumption, particularly in high-temperature industrial applications where conventional coatings fail prematurely.

Waste management considerations for BN nanosheet coatings present both challenges and opportunities. While the strong chemical bonds in hexagonal boron nitride structures render these materials highly durable, this same characteristic raises questions about their biodegradability and end-of-life management. Current research is exploring potential recovery and recycling pathways, including chemical and thermal treatments that could enable material reclamation from spent coatings.

Water conservation represents another significant environmental benefit of BN nanosheet technologies. The hydrophobic properties of these coatings can reduce water consumption in maintenance operations, while their application in water treatment systems shows promise for improving filtration efficiency and reducing energy requirements in desalination processes.

Regulatory frameworks governing nanomaterials in various jurisdictions are evolving to address potential environmental risks. While current evidence suggests minimal ecotoxicity for BN nanosheets, ongoing studies are essential to fully characterize their environmental fate and behavior, particularly regarding potential bioaccumulation in aquatic ecosystems and long-term soil interactions.

The integration of BN nanosheet coatings into circular economy models represents perhaps the most promising sustainability pathway. Research initiatives focused on designing these materials for eventual recovery and reuse are gaining momentum, potentially transforming what might otherwise be a linear consumption model into a more sustainable closed-loop system.

Scalability and Industrial Implementation Challenges

Despite the promising properties of Boron Nitride Nanosheets (BNNS) in coating technologies, significant challenges remain in scaling production from laboratory to industrial levels. Current synthesis methods such as chemical vapor deposition (CVD), liquid exfoliation, and chemical blowing techniques face limitations in producing consistent, high-quality BNNS at commercial scales. The batch-to-batch variation in nanosheet thickness, lateral dimensions, and defect density presents a major hurdle for quality control in industrial settings.

Cost factors represent another substantial barrier to widespread implementation. Raw material expenses, particularly for high-purity boron precursors, remain prohibitively high for mass production. Additionally, energy-intensive processing conditions, including high-temperature CVD methods that often require temperatures exceeding 900°C, contribute significantly to production costs and carbon footprint concerns.

Integration of BNNS into existing coating manufacturing lines presents technical complexities that must be addressed. Conventional coating equipment and processes are not optimized for nanomaterial handling, requiring modifications to prevent agglomeration and ensure uniform dispersion. The development of specialized mixing, application, and curing protocols tailored to BNNS-enhanced formulations is essential for consistent performance.

Regulatory and safety considerations further complicate industrial adoption. The nanoscale dimensions of BNNS raise occupational exposure concerns during manufacturing, necessitating robust containment systems and handling protocols. Environmental impact assessments and compliance with evolving nanomaterial regulations across different jurisdictions add layers of complexity to commercialization efforts.

Supply chain stability represents an ongoing challenge, with limited suppliers of high-quality BNNS materials and precursors. This constraint creates potential bottlenecks for manufacturers seeking reliable material sources for large-scale production. Strategic partnerships between material suppliers and coating manufacturers may help address these supply limitations.

Recent advances in continuous flow synthesis methods and roll-to-roll processing show promise for overcoming some scalability issues. These approaches enable higher throughput production while potentially improving consistency in nanosheet properties. Additionally, emerging hybrid manufacturing techniques that combine aspects of different synthesis methods are demonstrating improved yield-to-cost ratios that may accelerate industrial feasibility.

Cost factors represent another substantial barrier to widespread implementation. Raw material expenses, particularly for high-purity boron precursors, remain prohibitively high for mass production. Additionally, energy-intensive processing conditions, including high-temperature CVD methods that often require temperatures exceeding 900°C, contribute significantly to production costs and carbon footprint concerns.

Integration of BNNS into existing coating manufacturing lines presents technical complexities that must be addressed. Conventional coating equipment and processes are not optimized for nanomaterial handling, requiring modifications to prevent agglomeration and ensure uniform dispersion. The development of specialized mixing, application, and curing protocols tailored to BNNS-enhanced formulations is essential for consistent performance.

Regulatory and safety considerations further complicate industrial adoption. The nanoscale dimensions of BNNS raise occupational exposure concerns during manufacturing, necessitating robust containment systems and handling protocols. Environmental impact assessments and compliance with evolving nanomaterial regulations across different jurisdictions add layers of complexity to commercialization efforts.

Supply chain stability represents an ongoing challenge, with limited suppliers of high-quality BNNS materials and precursors. This constraint creates potential bottlenecks for manufacturers seeking reliable material sources for large-scale production. Strategic partnerships between material suppliers and coating manufacturers may help address these supply limitations.

Recent advances in continuous flow synthesis methods and roll-to-roll processing show promise for overcoming some scalability issues. These approaches enable higher throughput production while potentially improving consistency in nanosheet properties. Additionally, emerging hybrid manufacturing techniques that combine aspects of different synthesis methods are demonstrating improved yield-to-cost ratios that may accelerate industrial feasibility.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!