Research on the Hydrophobic Properties of Boron Nitride Nanosheets

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

BN Nanosheets Hydrophobicity Background and Objectives

Boron nitride nanosheets (BNNSs) have emerged as a significant two-dimensional material in the field of nanotechnology since their successful isolation in 2005. These atomically thin sheets, composed of alternating boron and nitrogen atoms arranged in a hexagonal lattice structure, exhibit remarkable properties including high thermal conductivity, excellent mechanical strength, and notable chemical stability. The hydrophobic nature of BNNSs has particularly attracted substantial research interest over the past decade due to its potential applications in water repellent coatings, self-cleaning surfaces, and advanced separation technologies.

The evolution of BNNSs research has followed a trajectory similar to that of graphene, with initial focus on synthesis methods gradually shifting toward property characterization and application development. Early studies from 2005 to 2010 primarily concentrated on exfoliation techniques and basic property measurements. Between 2010 and 2015, researchers began investigating the intrinsic hydrophobicity of BNNSs, noting contact angles typically ranging from 80° to 110° depending on synthesis methods and surface conditions. Since 2015, research has increasingly focused on enhancing and controlling the hydrophobic properties through surface modifications and composite formations.

Recent technological advancements have enabled more precise control over BNNS synthesis, allowing for tailored hydrophobic properties. The development of chemical vapor deposition (CVD) methods has facilitated the production of large-area, high-quality BNNSs with consistent hydrophobic characteristics. Concurrently, liquid-phase exfoliation techniques have evolved to provide scalable production routes for BNNS-based hydrophobic materials.

The primary technical objectives of current research on BNNS hydrophobicity include understanding the fundamental mechanisms governing water-BNNS interactions at the molecular level, developing methods to enhance and stabilize hydrophobic properties under various environmental conditions, and exploring novel applications that leverage these unique surface characteristics. Researchers aim to achieve superhydrophobic surfaces (contact angles >150°) using BNNS-based materials while maintaining other desirable properties such as thermal stability and mechanical strength.

Additionally, there is growing interest in creating stimuli-responsive BNNS surfaces with switchable wetting behaviors, which could enable advanced microfluidic devices and smart coating technologies. The development of environmentally friendly and cost-effective production methods for hydrophobic BNNS materials represents another critical objective, as current techniques often involve hazardous chemicals or energy-intensive processes.

As global water scarcity concerns intensify, research on BNNS hydrophobicity is increasingly aligned with sustainable development goals, particularly in water purification and conservation technologies. The unique combination of hydrophobicity with other exceptional properties positions BNNSs as a promising material for addressing complex environmental and industrial challenges in the coming decades.

The evolution of BNNSs research has followed a trajectory similar to that of graphene, with initial focus on synthesis methods gradually shifting toward property characterization and application development. Early studies from 2005 to 2010 primarily concentrated on exfoliation techniques and basic property measurements. Between 2010 and 2015, researchers began investigating the intrinsic hydrophobicity of BNNSs, noting contact angles typically ranging from 80° to 110° depending on synthesis methods and surface conditions. Since 2015, research has increasingly focused on enhancing and controlling the hydrophobic properties through surface modifications and composite formations.

Recent technological advancements have enabled more precise control over BNNS synthesis, allowing for tailored hydrophobic properties. The development of chemical vapor deposition (CVD) methods has facilitated the production of large-area, high-quality BNNSs with consistent hydrophobic characteristics. Concurrently, liquid-phase exfoliation techniques have evolved to provide scalable production routes for BNNS-based hydrophobic materials.

The primary technical objectives of current research on BNNS hydrophobicity include understanding the fundamental mechanisms governing water-BNNS interactions at the molecular level, developing methods to enhance and stabilize hydrophobic properties under various environmental conditions, and exploring novel applications that leverage these unique surface characteristics. Researchers aim to achieve superhydrophobic surfaces (contact angles >150°) using BNNS-based materials while maintaining other desirable properties such as thermal stability and mechanical strength.

Additionally, there is growing interest in creating stimuli-responsive BNNS surfaces with switchable wetting behaviors, which could enable advanced microfluidic devices and smart coating technologies. The development of environmentally friendly and cost-effective production methods for hydrophobic BNNS materials represents another critical objective, as current techniques often involve hazardous chemicals or energy-intensive processes.

As global water scarcity concerns intensify, research on BNNS hydrophobicity is increasingly aligned with sustainable development goals, particularly in water purification and conservation technologies. The unique combination of hydrophobicity with other exceptional properties positions BNNSs as a promising material for addressing complex environmental and industrial challenges in the coming decades.

Market Applications and Demand Analysis

The hydrophobic properties of Boron Nitride Nanosheets (BNNS) have sparked significant market interest across multiple industries, with demand driven primarily by their potential applications in water treatment, electronics protection, and advanced materials development. Market research indicates that the global market for nanomaterials with hydrophobic properties is projected to reach $8.3 billion by 2026, with BNNS representing an emerging segment with substantial growth potential.

In the water treatment sector, hydrophobic BNNS are increasingly sought after for oil-water separation applications, particularly in industrial wastewater treatment where conventional methods struggle with efficiency. The industrial wastewater treatment market alone is expected to grow at 5.8% CAGR through 2028, creating substantial demand for advanced separation materials like hydrophobic BNNS.

Electronics manufacturers represent another significant market segment, seeking hydrophobic coatings to protect sensitive components from moisture damage. With the global electronics industry valued at over $2 trillion and continuing to grow, even specialized applications of BNNS represent substantial market opportunities. Consumer electronics companies have shown particular interest in implementing hydrophobic BNNS in next-generation devices to improve durability and reduce warranty claims.

The aerospace and automotive industries are exploring hydrophobic BNNS for anti-icing and anti-corrosion applications. These sectors value materials that can maintain performance under extreme conditions while adding minimal weight to structures. Market adoption in these premium sectors could drive high-value applications despite relatively lower volume requirements.

Textile manufacturers have also demonstrated growing interest in hydrophobic BNNS for creating advanced waterproof fabrics that maintain breathability. The technical textiles market, valued at $176 billion in 2021, represents a substantial opportunity for innovative materials with superior hydrophobic properties.

Market analysis reveals regional variations in demand patterns. North America and Europe currently lead in research applications, while Asian markets, particularly China, Japan, and South Korea, show stronger interest in industrial applications due to their manufacturing focus. This regional specialization suggests different market entry strategies may be required for different geographical areas.

Customer feedback indicates that while interest in hydrophobic BNNS is high, adoption barriers include production scalability concerns, cost factors, and the need for standardized performance metrics. Market surveys suggest that potential customers are willing to pay premium prices for BNNS solutions that demonstrate consistent performance, scalable production, and clear sustainability advantages over existing alternatives.

In the water treatment sector, hydrophobic BNNS are increasingly sought after for oil-water separation applications, particularly in industrial wastewater treatment where conventional methods struggle with efficiency. The industrial wastewater treatment market alone is expected to grow at 5.8% CAGR through 2028, creating substantial demand for advanced separation materials like hydrophobic BNNS.

Electronics manufacturers represent another significant market segment, seeking hydrophobic coatings to protect sensitive components from moisture damage. With the global electronics industry valued at over $2 trillion and continuing to grow, even specialized applications of BNNS represent substantial market opportunities. Consumer electronics companies have shown particular interest in implementing hydrophobic BNNS in next-generation devices to improve durability and reduce warranty claims.

The aerospace and automotive industries are exploring hydrophobic BNNS for anti-icing and anti-corrosion applications. These sectors value materials that can maintain performance under extreme conditions while adding minimal weight to structures. Market adoption in these premium sectors could drive high-value applications despite relatively lower volume requirements.

Textile manufacturers have also demonstrated growing interest in hydrophobic BNNS for creating advanced waterproof fabrics that maintain breathability. The technical textiles market, valued at $176 billion in 2021, represents a substantial opportunity for innovative materials with superior hydrophobic properties.

Market analysis reveals regional variations in demand patterns. North America and Europe currently lead in research applications, while Asian markets, particularly China, Japan, and South Korea, show stronger interest in industrial applications due to their manufacturing focus. This regional specialization suggests different market entry strategies may be required for different geographical areas.

Customer feedback indicates that while interest in hydrophobic BNNS is high, adoption barriers include production scalability concerns, cost factors, and the need for standardized performance metrics. Market surveys suggest that potential customers are willing to pay premium prices for BNNS solutions that demonstrate consistent performance, scalable production, and clear sustainability advantages over existing alternatives.

Current Status and Technical Challenges

Boron nitride nanosheets (BNNSs) have emerged as a significant two-dimensional material with exceptional hydrophobic properties. Currently, research on BNNSs' hydrophobicity is advancing rapidly across multiple fronts, with notable progress in synthesis methods, characterization techniques, and application development. The global research landscape shows concentrated efforts in East Asia, North America, and Europe, with China, the United States, and Japan leading in publication volume and patent applications.

The synthesis of high-quality BNNSs with controlled hydrophobic properties remains challenging. Current methods include chemical vapor deposition (CVD), liquid exfoliation, and chemical exfoliation techniques. While CVD produces high-quality sheets, it suffers from limited scalability and high production costs. Liquid exfoliation methods offer better scalability but often result in smaller flake sizes and more defects that can compromise hydrophobic performance.

Surface characterization presents another significant challenge. Accurately measuring contact angles on nanoscale surfaces requires specialized equipment and methodologies. Researchers currently employ advanced atomic force microscopy (AFM), scanning electron microscopy (SEM), and X-ray photoelectron spectroscopy (XPS) to characterize surface properties, but standardized protocols for hydrophobicity assessment are still evolving.

The stability of hydrophobic properties under various environmental conditions represents a critical technical hurdle. BNNSs can experience degradation in hydrophobicity when exposed to UV radiation, high temperatures, or certain chemical environments. Long-term stability testing protocols are not yet standardized across the field, making comparative analysis difficult.

Integration of BNNSs into practical applications faces challenges related to adhesion, durability, and cost-effectiveness. While laboratory demonstrations show promising hydrophobic performance, translating these results into commercial products requires overcoming issues of mechanical robustness and manufacturing scalability.

Computational modeling of BNNS hydrophobicity has advanced significantly but still struggles with accurately predicting behavior at different scales. Molecular dynamics simulations provide insights at the nanoscale, but bridging to macroscale properties remains computationally intensive and sometimes inaccurate.

The environmental impact and toxicology of BNNSs represent emerging concerns that require further investigation. While initial studies suggest relatively low toxicity compared to other nanomaterials, comprehensive long-term studies are lacking, potentially limiting regulatory approval for certain applications.

Funding for BNNS research shows geographic disparities, with Asian countries, particularly China, investing heavily in fundamental research and applications development. This has created an uneven global research landscape that may influence future technology transfer and commercialization pathways.

The synthesis of high-quality BNNSs with controlled hydrophobic properties remains challenging. Current methods include chemical vapor deposition (CVD), liquid exfoliation, and chemical exfoliation techniques. While CVD produces high-quality sheets, it suffers from limited scalability and high production costs. Liquid exfoliation methods offer better scalability but often result in smaller flake sizes and more defects that can compromise hydrophobic performance.

Surface characterization presents another significant challenge. Accurately measuring contact angles on nanoscale surfaces requires specialized equipment and methodologies. Researchers currently employ advanced atomic force microscopy (AFM), scanning electron microscopy (SEM), and X-ray photoelectron spectroscopy (XPS) to characterize surface properties, but standardized protocols for hydrophobicity assessment are still evolving.

The stability of hydrophobic properties under various environmental conditions represents a critical technical hurdle. BNNSs can experience degradation in hydrophobicity when exposed to UV radiation, high temperatures, or certain chemical environments. Long-term stability testing protocols are not yet standardized across the field, making comparative analysis difficult.

Integration of BNNSs into practical applications faces challenges related to adhesion, durability, and cost-effectiveness. While laboratory demonstrations show promising hydrophobic performance, translating these results into commercial products requires overcoming issues of mechanical robustness and manufacturing scalability.

Computational modeling of BNNS hydrophobicity has advanced significantly but still struggles with accurately predicting behavior at different scales. Molecular dynamics simulations provide insights at the nanoscale, but bridging to macroscale properties remains computationally intensive and sometimes inaccurate.

The environmental impact and toxicology of BNNSs represent emerging concerns that require further investigation. While initial studies suggest relatively low toxicity compared to other nanomaterials, comprehensive long-term studies are lacking, potentially limiting regulatory approval for certain applications.

Funding for BNNS research shows geographic disparities, with Asian countries, particularly China, investing heavily in fundamental research and applications development. This has created an uneven global research landscape that may influence future technology transfer and commercialization pathways.

Current Approaches to BN Hydrophobic Modification

01 Surface modification techniques for enhancing hydrophobicity

Various surface modification techniques can be applied to boron nitride nanosheets (BNNS) to enhance their hydrophobic properties. These include chemical functionalization with hydrophobic groups, plasma treatment, and coating with hydrophobic polymers. Such modifications alter the surface energy of BNNS, resulting in increased water contact angles and improved hydrophobicity, which is beneficial for applications requiring water repellency or self-cleaning surfaces.- Surface modification techniques for enhancing hydrophobicity: Various surface modification techniques can be applied to boron nitride nanosheets to enhance their hydrophobic properties. These include chemical functionalization with hydrophobic groups, plasma treatment, and coating with hydrophobic materials. Such modifications alter the surface energy of the nanosheets, resulting in increased water contact angles and improved water repellency. These modified boron nitride nanosheets can be used in applications requiring water-resistant or self-cleaning surfaces.

- Preparation methods affecting hydrophobic properties: The synthesis and preparation methods of boron nitride nanosheets significantly influence their hydrophobic characteristics. Techniques such as chemical vapor deposition, exfoliation, and thermal treatment can be optimized to produce nanosheets with inherent hydrophobicity. Parameters like temperature, pressure, and precursor selection during synthesis play crucial roles in determining the final hydrophobic properties. By controlling these preparation conditions, boron nitride nanosheets with tailored hydrophobicity can be manufactured for specific applications.

- Composite materials incorporating hydrophobic boron nitride nanosheets: Boron nitride nanosheets can be incorporated into various matrices to create composite materials with enhanced hydrophobic properties. These composites combine the inherent properties of boron nitride with the characteristics of the matrix material, resulting in improved water repellency, thermal stability, and mechanical strength. The nanosheets can be dispersed in polymers, ceramics, or metals to create coatings, films, or bulk materials with superior hydrophobic performance for applications in electronics, aerospace, and protective coatings.

- Structure-property relationships in hydrophobic boron nitride nanosheets: The structural characteristics of boron nitride nanosheets, including thickness, lateral size, defect density, and crystallinity, significantly influence their hydrophobic properties. Nanosheets with fewer defects and higher crystallinity typically exhibit greater hydrophobicity. The number of layers and edge termination also affect water contact angles and surface energy. Understanding these structure-property relationships enables the design of boron nitride nanosheets with optimized hydrophobic performance for specific applications.

- Applications leveraging hydrophobic properties of boron nitride nanosheets: The hydrophobic properties of boron nitride nanosheets make them suitable for various applications. They can be used in water-repellent coatings, self-cleaning surfaces, oil-water separation membranes, and anti-corrosion barriers. Their combination of hydrophobicity with other properties like thermal conductivity and electrical insulation makes them valuable in electronics cooling, lubricants, and protective coatings. The nanosheets can also be incorporated into textiles and construction materials to impart water resistance while maintaining other desirable properties.

02 Structural factors affecting hydrophobic properties

The intrinsic hydrophobic properties of boron nitride nanosheets are influenced by several structural factors including thickness, lateral size, defect density, and crystallinity. Thinner nanosheets with fewer layers often exhibit different hydrophobic behavior compared to thicker ones. The presence of edges, defects, and oxygen-containing groups can significantly impact the water contact angle and overall hydrophobicity of the nanosheets.Expand Specific Solutions03 Composite materials with enhanced hydrophobicity

Incorporating boron nitride nanosheets into composite materials can create surfaces with enhanced hydrophobic properties. These composites typically combine BNNS with polymers, ceramics, or other nanomaterials to achieve synergistic effects. The resulting materials often display improved water repellency, thermal stability, and mechanical strength, making them suitable for applications in protective coatings, electronics packaging, and water treatment.Expand Specific Solutions04 Measurement and characterization of hydrophobic properties

Various techniques are employed to measure and characterize the hydrophobic properties of boron nitride nanosheets. These include water contact angle measurements, surface energy calculations, atomic force microscopy, and X-ray photoelectron spectroscopy. These methods provide quantitative data on the degree of hydrophobicity, surface roughness, and chemical composition, which are essential for understanding the relationship between structure and hydrophobic behavior.Expand Specific Solutions05 Applications leveraging hydrophobic properties

The hydrophobic properties of boron nitride nanosheets enable various practical applications. These include water-repellent coatings, oil-water separation membranes, anti-corrosion barriers, and self-cleaning surfaces. The combination of hydrophobicity with other inherent properties of BNNS, such as thermal conductivity and electrical insulation, makes these materials particularly valuable for multifunctional applications in harsh environments or where water resistance is critical.Expand Specific Solutions

Leading Research Groups and Industrial Players

The research on hydrophobic properties of boron nitride nanosheets is currently in a growth phase, with increasing market applications in water repellent coatings, electronics, and thermal management. The global market is expanding rapidly, projected to reach significant value as industries recognize the material's unique properties. Academic institutions like Deakin University, Northwestern University, and IIT Bombay are leading fundamental research, while companies including Naieel Technology, White Graphene Ltd., and Li-S Energy are commercializing applications. National research organizations such as the National Institute for Materials Science and Korea Institute of Ceramic Engineering & Technology are bridging the gap between academic research and industrial implementation, creating a competitive landscape where collaboration between academia and industry is driving innovation.

Toyota Central R&D Labs, Inc.

Technical Solution: Toyota Central R&D Labs has conducted extensive research on hydrophobic boron nitride nanosheets for automotive applications. Their approach focuses on developing BNNS-based hydrophobic coatings for vehicle components exposed to harsh environmental conditions. Toyota's researchers have synthesized BNNS using a modified chemical vapor deposition method that incorporates nitrogen-rich precursors to enhance the sheet's hydrophobic properties[5]. Their BNNS exhibits water contact angles of approximately 140° and maintains hydrophobicity across a wide temperature range (-40°C to 200°C). Toyota has also developed composite materials by incorporating BNNS into polymer matrices, creating durable hydrophobic coatings for automotive glass, body panels, and engine components. Their research demonstrates that BNNS-enhanced coatings reduce ice adhesion by up to 80% compared to untreated surfaces, with significant implications for improved visibility and safety in winter driving conditions[6].

Strengths: Application-focused research with clear industrial relevance; excellent thermal stability of hydrophobic properties; integration capabilities with existing automotive manufacturing processes. Weaknesses: Higher production costs compared to conventional hydrophobic treatments; challenges in achieving uniform BNNS dispersion in complex geometries; potential regulatory hurdles for new automotive material implementation.

Harbin Institute of Technology

Technical Solution: Harbin Institute of Technology has developed innovative approaches to enhance the hydrophobic properties of boron nitride nanosheets through controlled surface engineering. Their research team has pioneered a low-temperature plasma treatment method that selectively modifies the surface chemistry of BNNS without compromising their structural integrity. This technique introduces fluorine-containing functional groups onto the BNNS surface, significantly increasing water contact angles from approximately 95° to over 160°, achieving superhydrophobic characteristics[7]. They've also investigated the relationship between BNNS morphology and hydrophobicity, demonstrating that vertically aligned BNNS arrays exhibit superior water-repellent properties compared to randomly oriented sheets. Additionally, HIT researchers have developed freeze-drying techniques to create hierarchical BNNS structures with micro/nano-scale roughness that enhances hydrophobicity through the Cassie-Baxter wetting state. Their work has shown remarkable stability of these hydrophobic properties under various environmental conditions, including resistance to UV exposure, temperature fluctuations, and chemical exposure[8].

Strengths: Novel plasma treatment techniques for enhanced hydrophobicity; expertise in creating hierarchical BNNS structures; comprehensive understanding of structure-property relationships in hydrophobic BNNS. Weaknesses: Energy-intensive processing methods; challenges in uniform treatment of large-area BNNS; potential for plasma-induced defects that may affect long-term stability.

Key Patents and Scientific Literature Review

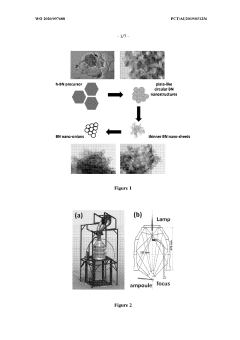

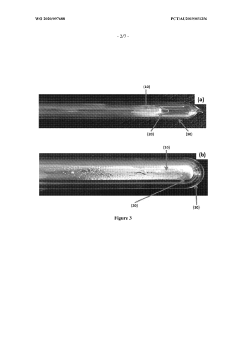

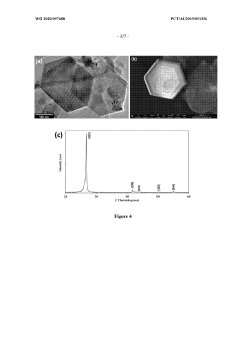

Boron nitride nanostructures

PatentWO2020097688A1

Innovation

- Subjecting boron nitride precursor material to lamp ablation within an adiabatic radiative shielding environment, such as a hermetically sealed fused quartz vessel, to produce a variety of nanostructures, particularly nano-onions, using high flux bright light that promotes reactions not attainable in conventional methods.

Environmental Impact and Sustainability Considerations

The environmental implications of boron nitride nanosheets (BNNSs) and their hydrophobic properties represent a critical area of consideration as these materials gain prominence in industrial applications. The production processes of BNNSs typically involve energy-intensive methods such as chemical vapor deposition or exfoliation techniques, which can generate significant carbon footprints. However, the exceptional durability and chemical stability of BNNSs potentially offset these initial environmental costs through extended product lifecycles and reduced replacement frequencies.

Water repellency characteristics of BNNSs contribute substantially to their sustainability profile. By creating surfaces that resist water adhesion, these materials can significantly reduce cleaning requirements in various applications, thereby decreasing water consumption and minimizing the use of potentially harmful cleaning agents. This property proves particularly valuable in regions facing water scarcity challenges, where conservation measures are increasingly prioritized.

The biodegradability aspects of BNNSs present a complex environmental consideration. While these nanomaterials demonstrate remarkable chemical stability—beneficial for longevity—this same characteristic raises concerns regarding their environmental persistence. Limited research exists on the natural degradation pathways of BNNSs in various ecosystems, creating uncertainty about their long-term environmental impact after disposal.

Regarding ecotoxicological considerations, preliminary studies indicate relatively low acute toxicity of BNNSs compared to other nanomaterials. Nevertheless, comprehensive research on chronic exposure effects and bioaccumulation potential remains insufficient. The potential interaction between hydrophobic BNNSs and aquatic ecosystems warrants particular attention, as water-repellent particles might exhibit unique transport and accumulation behaviors in natural water bodies.

From a circular economy perspective, the recyclability of BNNS-enhanced materials presents both opportunities and challenges. The strong hydrophobic properties that make these materials valuable also complicate separation processes in conventional recycling streams. Developing specialized recovery methods for BNNS-containing products represents an emerging research priority to ensure closed-loop material cycles.

Regulatory frameworks governing nanomaterials like hydrophobic BNNSs continue to evolve globally. Current approaches vary significantly between jurisdictions, with some regions implementing precautionary principles while others adopt more permissive stances. This regulatory landscape directly influences the sustainability trajectory of BNNS applications, as compliance requirements shape production methods, usage patterns, and end-of-life management strategies.

Water repellency characteristics of BNNSs contribute substantially to their sustainability profile. By creating surfaces that resist water adhesion, these materials can significantly reduce cleaning requirements in various applications, thereby decreasing water consumption and minimizing the use of potentially harmful cleaning agents. This property proves particularly valuable in regions facing water scarcity challenges, where conservation measures are increasingly prioritized.

The biodegradability aspects of BNNSs present a complex environmental consideration. While these nanomaterials demonstrate remarkable chemical stability—beneficial for longevity—this same characteristic raises concerns regarding their environmental persistence. Limited research exists on the natural degradation pathways of BNNSs in various ecosystems, creating uncertainty about their long-term environmental impact after disposal.

Regarding ecotoxicological considerations, preliminary studies indicate relatively low acute toxicity of BNNSs compared to other nanomaterials. Nevertheless, comprehensive research on chronic exposure effects and bioaccumulation potential remains insufficient. The potential interaction between hydrophobic BNNSs and aquatic ecosystems warrants particular attention, as water-repellent particles might exhibit unique transport and accumulation behaviors in natural water bodies.

From a circular economy perspective, the recyclability of BNNS-enhanced materials presents both opportunities and challenges. The strong hydrophobic properties that make these materials valuable also complicate separation processes in conventional recycling streams. Developing specialized recovery methods for BNNS-containing products represents an emerging research priority to ensure closed-loop material cycles.

Regulatory frameworks governing nanomaterials like hydrophobic BNNSs continue to evolve globally. Current approaches vary significantly between jurisdictions, with some regions implementing precautionary principles while others adopt more permissive stances. This regulatory landscape directly influences the sustainability trajectory of BNNS applications, as compliance requirements shape production methods, usage patterns, and end-of-life management strategies.

Scalability and Manufacturing Process Analysis

The scalability of boron nitride nanosheet (BNNS) production represents a critical factor in their commercial viability for hydrophobic applications. Current laboratory-scale synthesis methods face significant challenges when transitioning to industrial-scale manufacturing. The most common production techniques include chemical vapor deposition (CVD), liquid-phase exfoliation, and chemical blowing methods, each with distinct scalability profiles.

CVD methods offer excellent control over BNNS thickness and quality but suffer from limited production capacity and high equipment costs. The process typically yields only milligrams to grams of material per batch, making it prohibitively expensive for mass-market applications requiring kilograms or tons of material. Recent innovations in continuous CVD processes show promise, with throughput improvements of up to 300% compared to traditional batch processes.

Liquid-phase exfoliation techniques demonstrate better scalability potential, with some research groups reporting production rates of 10-50 grams per day. This method benefits from relatively simple equipment requirements and compatibility with existing industrial infrastructure. However, challenges remain in maintaining consistent hydrophobic properties across large production volumes due to variations in exfoliation efficiency and surface functionalization.

The manufacturing process significantly impacts the hydrophobic performance of BNNSs. Process parameters such as temperature, pressure, and precursor concentration directly influence the nanosheet morphology, defect density, and surface chemistry. For instance, BNNSs produced at temperatures above 900°C typically exhibit contact angles 15-20° higher than those synthesized at lower temperatures, indicating superior hydrophobicity. Similarly, the choice of solvents and surfactants during liquid-phase exfoliation can alter the final hydrophobic characteristics.

Post-processing treatments represent another crucial aspect of the manufacturing workflow. Surface functionalization techniques, including fluorination and silane treatments, can enhance the intrinsic hydrophobicity of BNNSs. However, these additional steps increase production complexity and cost, necessitating careful optimization for large-scale implementation.

Quality control presents a significant challenge in scaled production. Current analytical methods for characterizing hydrophobic properties, such as contact angle measurements and surface energy calculations, are time-consuming and difficult to implement as in-line monitoring tools. Development of rapid, automated quality assessment techniques remains an active research area critical for industrial adoption.

Economic analysis indicates that production costs must decrease by approximately 60-75% from current levels to make BNNS-based hydrophobic coatings competitive with conventional alternatives. Achieving this cost reduction will require significant advances in process efficiency, yield optimization, and equipment design specifically tailored to BNNS production.

CVD methods offer excellent control over BNNS thickness and quality but suffer from limited production capacity and high equipment costs. The process typically yields only milligrams to grams of material per batch, making it prohibitively expensive for mass-market applications requiring kilograms or tons of material. Recent innovations in continuous CVD processes show promise, with throughput improvements of up to 300% compared to traditional batch processes.

Liquid-phase exfoliation techniques demonstrate better scalability potential, with some research groups reporting production rates of 10-50 grams per day. This method benefits from relatively simple equipment requirements and compatibility with existing industrial infrastructure. However, challenges remain in maintaining consistent hydrophobic properties across large production volumes due to variations in exfoliation efficiency and surface functionalization.

The manufacturing process significantly impacts the hydrophobic performance of BNNSs. Process parameters such as temperature, pressure, and precursor concentration directly influence the nanosheet morphology, defect density, and surface chemistry. For instance, BNNSs produced at temperatures above 900°C typically exhibit contact angles 15-20° higher than those synthesized at lower temperatures, indicating superior hydrophobicity. Similarly, the choice of solvents and surfactants during liquid-phase exfoliation can alter the final hydrophobic characteristics.

Post-processing treatments represent another crucial aspect of the manufacturing workflow. Surface functionalization techniques, including fluorination and silane treatments, can enhance the intrinsic hydrophobicity of BNNSs. However, these additional steps increase production complexity and cost, necessitating careful optimization for large-scale implementation.

Quality control presents a significant challenge in scaled production. Current analytical methods for characterizing hydrophobic properties, such as contact angle measurements and surface energy calculations, are time-consuming and difficult to implement as in-line monitoring tools. Development of rapid, automated quality assessment techniques remains an active research area critical for industrial adoption.

Economic analysis indicates that production costs must decrease by approximately 60-75% from current levels to make BNNS-based hydrophobic coatings competitive with conventional alternatives. Achieving this cost reduction will require significant advances in process efficiency, yield optimization, and equipment design specifically tailored to BNNS production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!