Boron Nitride Nanosheets in High-Voltage Insulation Materials

OCT 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

BN Nanosheets Technology Background and Objectives

Boron nitride nanosheets (BNNS) have emerged as a revolutionary material in the field of high-voltage insulation over the past decade. Initially discovered as a structural analog to graphene, BNNS possess a unique combination of properties including excellent thermal conductivity, outstanding electrical insulation characteristics, and remarkable mechanical strength. The evolution of BNNS technology can be traced back to the early 2000s when researchers first successfully synthesized these two-dimensional hexagonal structures, but significant breakthroughs in their application to insulation materials only gained momentum around 2010.

The technological trajectory of BNNS has been characterized by continuous improvements in synthesis methods, from mechanical exfoliation to chemical vapor deposition (CVD) and liquid-phase exfoliation techniques. Each advancement has progressively addressed key challenges in scalability, purity, and cost-effectiveness, making BNNS increasingly viable for commercial applications in high-voltage insulation materials.

Current research trends indicate a growing focus on the functionalization of BNNS to enhance their compatibility with polymer matrices, as well as the development of hybrid nanocomposites that leverage synergistic effects between BNNS and other nanomaterials. The integration of BNNS into traditional insulation systems represents a paradigm shift in addressing the limitations of conventional materials, particularly in extreme operating conditions.

The primary technical objectives for BNNS in high-voltage insulation applications include achieving uniform dispersion within polymer matrices, optimizing the interfacial interactions between nanosheets and host materials, and developing cost-effective, scalable manufacturing processes. Additionally, researchers aim to enhance the breakdown strength, reduce space charge accumulation, and improve thermal management capabilities of insulation systems through strategic incorporation of BNNS.

Long-term goals in this field encompass the development of next-generation insulation materials capable of withstanding ultra-high voltage conditions (>1000 kV), extending service lifetimes of electrical equipment, and enabling more compact designs for power transmission infrastructure. These objectives align with broader industry trends toward grid modernization and sustainable energy systems.

The transformative potential of BNNS technology extends beyond conventional applications, with emerging opportunities in flexible electronics, aerospace systems, and renewable energy infrastructure. As research continues to advance, BNNS-based insulation materials are expected to play a crucial role in addressing the increasing demands for reliable, efficient, and resilient electrical systems in the face of growing global energy consumption and the transition to smart grid technologies.

The technological trajectory of BNNS has been characterized by continuous improvements in synthesis methods, from mechanical exfoliation to chemical vapor deposition (CVD) and liquid-phase exfoliation techniques. Each advancement has progressively addressed key challenges in scalability, purity, and cost-effectiveness, making BNNS increasingly viable for commercial applications in high-voltage insulation materials.

Current research trends indicate a growing focus on the functionalization of BNNS to enhance their compatibility with polymer matrices, as well as the development of hybrid nanocomposites that leverage synergistic effects between BNNS and other nanomaterials. The integration of BNNS into traditional insulation systems represents a paradigm shift in addressing the limitations of conventional materials, particularly in extreme operating conditions.

The primary technical objectives for BNNS in high-voltage insulation applications include achieving uniform dispersion within polymer matrices, optimizing the interfacial interactions between nanosheets and host materials, and developing cost-effective, scalable manufacturing processes. Additionally, researchers aim to enhance the breakdown strength, reduce space charge accumulation, and improve thermal management capabilities of insulation systems through strategic incorporation of BNNS.

Long-term goals in this field encompass the development of next-generation insulation materials capable of withstanding ultra-high voltage conditions (>1000 kV), extending service lifetimes of electrical equipment, and enabling more compact designs for power transmission infrastructure. These objectives align with broader industry trends toward grid modernization and sustainable energy systems.

The transformative potential of BNNS technology extends beyond conventional applications, with emerging opportunities in flexible electronics, aerospace systems, and renewable energy infrastructure. As research continues to advance, BNNS-based insulation materials are expected to play a crucial role in addressing the increasing demands for reliable, efficient, and resilient electrical systems in the face of growing global energy consumption and the transition to smart grid technologies.

Market Analysis for High-Voltage Insulation Materials

The high-voltage insulation materials market is experiencing significant growth driven by expanding power infrastructure globally. Current market valuation stands at approximately $6.5 billion with projections indicating a compound annual growth rate of 6.8% through 2028. This growth is primarily fueled by increasing electricity demand, grid modernization initiatives, and the rapid expansion of renewable energy installations requiring robust transmission systems.

Traditional insulation materials like porcelain, glass, and polymer composites continue to dominate the market. However, advanced materials incorporating nanomaterials—particularly boron nitride nanosheets (BNNS)—are gaining traction due to their superior thermal conductivity, electrical insulation properties, and mechanical strength. This segment is growing at nearly twice the rate of conventional materials, reflecting industry recognition of their performance advantages.

Regional analysis reveals Asia-Pacific as the largest and fastest-growing market, accounting for approximately 40% of global demand. China and India lead this growth due to massive power infrastructure investments. North America and Europe represent mature markets with steady demand driven by grid modernization and replacement of aging infrastructure, with particular emphasis on environmentally friendly solutions.

End-user segmentation shows utilities as the primary consumers (55% market share), followed by industrial applications (25%), and renewable energy installations (15%). The remaining share is distributed across specialized applications including transportation and electronics. The utility segment's dominance stems from ongoing transmission network expansions and voltage upgrades to accommodate increasing power demands.

Key market drivers include stringent safety regulations mandating higher performance standards for insulation materials, growing renewable energy integration requiring specialized high-voltage components, and increasing focus on equipment longevity and maintenance cost reduction. Additionally, the trend toward compact substations and HVDC transmission systems is creating demand for insulation materials with enhanced performance characteristics.

Challenges facing market adoption of advanced materials like BNNS include higher initial costs compared to traditional solutions, technical complexities in manufacturing processes, and conservative industry adoption practices. The cost premium for BNNS-enhanced materials currently ranges from 30-50% above conventional alternatives, though this gap is narrowing as production scales increase.

Customer requirements are evolving toward materials offering longer service life, reduced maintenance, higher temperature stability, and environmental sustainability. This shift presents significant opportunities for BNNS-based solutions, which demonstrate superior aging resistance and thermal management capabilities compared to conventional materials.

Traditional insulation materials like porcelain, glass, and polymer composites continue to dominate the market. However, advanced materials incorporating nanomaterials—particularly boron nitride nanosheets (BNNS)—are gaining traction due to their superior thermal conductivity, electrical insulation properties, and mechanical strength. This segment is growing at nearly twice the rate of conventional materials, reflecting industry recognition of their performance advantages.

Regional analysis reveals Asia-Pacific as the largest and fastest-growing market, accounting for approximately 40% of global demand. China and India lead this growth due to massive power infrastructure investments. North America and Europe represent mature markets with steady demand driven by grid modernization and replacement of aging infrastructure, with particular emphasis on environmentally friendly solutions.

End-user segmentation shows utilities as the primary consumers (55% market share), followed by industrial applications (25%), and renewable energy installations (15%). The remaining share is distributed across specialized applications including transportation and electronics. The utility segment's dominance stems from ongoing transmission network expansions and voltage upgrades to accommodate increasing power demands.

Key market drivers include stringent safety regulations mandating higher performance standards for insulation materials, growing renewable energy integration requiring specialized high-voltage components, and increasing focus on equipment longevity and maintenance cost reduction. Additionally, the trend toward compact substations and HVDC transmission systems is creating demand for insulation materials with enhanced performance characteristics.

Challenges facing market adoption of advanced materials like BNNS include higher initial costs compared to traditional solutions, technical complexities in manufacturing processes, and conservative industry adoption practices. The cost premium for BNNS-enhanced materials currently ranges from 30-50% above conventional alternatives, though this gap is narrowing as production scales increase.

Customer requirements are evolving toward materials offering longer service life, reduced maintenance, higher temperature stability, and environmental sustainability. This shift presents significant opportunities for BNNS-based solutions, which demonstrate superior aging resistance and thermal management capabilities compared to conventional materials.

Current Status and Technical Challenges of BN Nanosheets

Boron Nitride Nanosheets (BNNS) have emerged as promising materials for high-voltage insulation applications due to their exceptional thermal conductivity, electrical insulation properties, and mechanical strength. Currently, the global research landscape shows significant advancements in BNNS synthesis methods, with chemical vapor deposition (CVD), liquid exfoliation, and mechanical cleavage being the predominant techniques. The CVD method yields high-quality nanosheets but faces scalability limitations, while liquid exfoliation offers better mass production potential despite producing smaller flakes with more defects.

Recent breakthroughs in BNNS production have been achieved by research institutions in China, Japan, and the United States, with notable progress in controlling thickness and lateral dimensions. Industrial adoption remains in early stages, primarily constrained by production costs and integration challenges. Current commercial applications are limited to specialized high-performance electronics and aerospace components where cost concerns are secondary to performance requirements.

Despite promising developments, several technical challenges persist in BNNS implementation for high-voltage insulation. The foremost challenge involves uniform dispersion within polymer matrices, as BNNS tends to agglomerate due to strong van der Waals forces, reducing effective surface area and compromising insulation properties. Various surface functionalization approaches are being explored to address this issue, but optimal solutions balancing dispersion and electrical properties remain elusive.

Another significant hurdle is the interface engineering between BNNS and polymer matrices. Poor interfacial adhesion can create voids and defects that become pathways for electrical breakdown under high voltage conditions. Current research focuses on developing coupling agents and interface modification techniques to enhance compatibility between the hydrophilic BNNS and typically hydrophobic polymer matrices.

Scale-up production represents a critical bottleneck in widespread adoption. Laboratory-scale synthesis methods producing high-quality BNNS cannot easily transition to industrial-scale manufacturing while maintaining consistent quality and reasonable costs. The trade-off between quality and production volume remains a significant challenge for commercialization.

Long-term stability under high voltage conditions also presents concerns, as limited data exists on BNNS performance degradation over extended periods. Preliminary studies indicate potential issues with moisture absorption and oxidation under certain conditions, which could compromise insulation properties over time. Accelerated aging tests are underway at several research institutions to better understand these mechanisms.

Geographically, research leadership in BNNS technology shows distinct patterns, with fundamental materials science advances concentrated in East Asia (particularly China, Japan, and South Korea), while application-focused development is stronger in North America and Europe. This distribution creates both challenges and opportunities for global technology transfer and commercialization pathways.

Recent breakthroughs in BNNS production have been achieved by research institutions in China, Japan, and the United States, with notable progress in controlling thickness and lateral dimensions. Industrial adoption remains in early stages, primarily constrained by production costs and integration challenges. Current commercial applications are limited to specialized high-performance electronics and aerospace components where cost concerns are secondary to performance requirements.

Despite promising developments, several technical challenges persist in BNNS implementation for high-voltage insulation. The foremost challenge involves uniform dispersion within polymer matrices, as BNNS tends to agglomerate due to strong van der Waals forces, reducing effective surface area and compromising insulation properties. Various surface functionalization approaches are being explored to address this issue, but optimal solutions balancing dispersion and electrical properties remain elusive.

Another significant hurdle is the interface engineering between BNNS and polymer matrices. Poor interfacial adhesion can create voids and defects that become pathways for electrical breakdown under high voltage conditions. Current research focuses on developing coupling agents and interface modification techniques to enhance compatibility between the hydrophilic BNNS and typically hydrophobic polymer matrices.

Scale-up production represents a critical bottleneck in widespread adoption. Laboratory-scale synthesis methods producing high-quality BNNS cannot easily transition to industrial-scale manufacturing while maintaining consistent quality and reasonable costs. The trade-off between quality and production volume remains a significant challenge for commercialization.

Long-term stability under high voltage conditions also presents concerns, as limited data exists on BNNS performance degradation over extended periods. Preliminary studies indicate potential issues with moisture absorption and oxidation under certain conditions, which could compromise insulation properties over time. Accelerated aging tests are underway at several research institutions to better understand these mechanisms.

Geographically, research leadership in BNNS technology shows distinct patterns, with fundamental materials science advances concentrated in East Asia (particularly China, Japan, and South Korea), while application-focused development is stronger in North America and Europe. This distribution creates both challenges and opportunities for global technology transfer and commercialization pathways.

Current Technical Solutions for High-Voltage Insulation

01 Synthesis and preparation methods of boron nitride nanosheets

Various methods for synthesizing and preparing boron nitride nanosheets with enhanced insulation properties. These include chemical vapor deposition, exfoliation techniques, and solution-based processes that control the thickness, size, and quality of the nanosheets. The preparation methods focus on producing high-purity nanosheets with optimal thermal and electrical insulation characteristics for various applications.- Thermal insulation properties of boron nitride nanosheets: Boron nitride nanosheets exhibit excellent thermal insulation properties due to their unique two-dimensional structure and high thermal conductivity anisotropy. These nanosheets can effectively block heat transfer in the through-plane direction while allowing efficient heat dissipation in the in-plane direction. This makes them ideal for applications requiring thermal management, such as electronic devices and aerospace components. The thermal insulation efficiency can be further enhanced by controlling the thickness, size, and orientation of the nanosheets.

- Electrical insulation applications of boron nitride nanosheets: Boron nitride nanosheets possess excellent electrical insulation properties with high dielectric strength and low dielectric constant. These characteristics make them suitable for various electrical insulation applications, particularly in miniaturized electronic devices and high-frequency circuits. The electrical insulation performance can be optimized by controlling the crystallinity, purity, and defect concentration of the nanosheets. Additionally, these nanosheets maintain their electrical insulation properties even at elevated temperatures, making them valuable for high-temperature electronics.

- Composite materials incorporating boron nitride nanosheets for enhanced insulation: Incorporating boron nitride nanosheets into polymer, ceramic, or metal matrices creates composite materials with superior insulation properties. These composites exhibit enhanced thermal conductivity, electrical insulation, and mechanical strength compared to conventional materials. The nanosheets can be functionalized to improve their dispersion and interfacial bonding with the matrix material. Various processing techniques, including solution mixing, melt blending, and in-situ polymerization, can be employed to fabricate these composites for applications in electronics, aerospace, and energy storage systems.

- Fabrication methods for boron nitride nanosheets with optimized insulation properties: Various fabrication methods have been developed to produce boron nitride nanosheets with optimized insulation properties. These include chemical vapor deposition, liquid exfoliation, mechanical cleavage, and chemical synthesis approaches. The processing parameters significantly influence the structural characteristics and insulation performance of the nanosheets. Post-synthesis treatments, such as annealing and chemical functionalization, can further enhance the insulation properties by removing defects and impurities. Advanced characterization techniques are employed to evaluate the quality and performance of the fabricated nanosheets.

- Surface modification of boron nitride nanosheets for improved insulation performance: Surface modification techniques can significantly enhance the insulation performance of boron nitride nanosheets. These modifications include chemical functionalization, polymer grafting, and nanoparticle decoration. Modified nanosheets exhibit improved dispersion in various matrices, enhanced interfacial interactions, and reduced thermal boundary resistance. The surface chemistry can be tailored to achieve specific insulation requirements for different applications. Additionally, surface modification can improve the moisture resistance and long-term stability of boron nitride nanosheets in harsh environments.

02 Thermal insulation applications of boron nitride nanosheets

Boron nitride nanosheets exhibit excellent thermal insulation properties due to their unique structure and high thermal conductivity anisotropy. They can be incorporated into various matrices to create thermal management materials for electronic devices, aerospace applications, and industrial equipment. These nanosheets effectively dissipate heat while providing electrical insulation, making them ideal for high-temperature environments.Expand Specific Solutions03 Electrical insulation properties and applications

Boron nitride nanosheets possess superior electrical insulation characteristics with high breakdown voltage and low leakage current. They can be used in electronic devices, power systems, and high-frequency applications where electrical insulation is critical. The nanosheets maintain their insulating properties even at high temperatures and in harsh environments, making them suitable for next-generation electronics and power devices.Expand Specific Solutions04 Composite materials with boron nitride nanosheets for enhanced insulation

Integration of boron nitride nanosheets into polymer, ceramic, or metal matrices creates composite materials with superior insulation properties. These composites exhibit enhanced thermal conductivity, electrical resistance, and mechanical strength. The nanosheets can be functionalized or modified to improve their dispersion and interfacial bonding within the matrix, resulting in materials suitable for aerospace, electronics, and energy storage applications.Expand Specific Solutions05 Surface modification and functionalization for improved insulation performance

Surface modification and functionalization techniques for boron nitride nanosheets to enhance their insulation properties and compatibility with various matrices. These methods include chemical treatments, polymer grafting, and the addition of functional groups that improve dispersion, interfacial adhesion, and overall insulation performance. Modified nanosheets show reduced agglomeration and enhanced thermal and electrical insulation properties in composite materials.Expand Specific Solutions

Key Industry Players in BN Nanosheets Development

The boron nitride nanosheets (BNNS) market for high-voltage insulation materials is in its early growth phase, characterized by increasing research activities and emerging commercial applications. The global market for advanced insulation materials is projected to reach $7-9 billion by 2027, with BNNS representing a small but rapidly growing segment. Technologically, BNNS applications are transitioning from laboratory research to early commercialization, with companies at different maturity levels. NASA and National Institute of Aerospace have pioneered fundamental research, while BNNT Materials LLC has established early commercial production capabilities. Major industrial players like Siemens, Texas Instruments, and Denka are exploring applications in electrical systems. Academic institutions including Northwestern University, Deakin University, and South China University of Technology are advancing fundamental understanding of BNNS properties, while companies like Li-S Energy are developing specialized applications in energy storage.

BNNT Materials LLC

Technical Solution: BNNT Materials LLC specializes in the production and commercialization of high-quality boron nitride nanotubes (BNNTs) and related nanomaterials for high-voltage insulation applications. Their proprietary synthesis technology enables the production of highly crystalline BNNTs with exceptional electrical insulation properties, featuring dielectric breakdown strengths exceeding 800 kV/mm[1]. The company has developed a scalable manufacturing process that allows for the controlled integration of BNNTs into polymer matrices to create advanced composite insulation materials. Their technology involves the dispersion of BNNTs in various polymer systems, including epoxy, polyimide, and silicone elastomers, resulting in nanocomposites with significantly enhanced dielectric properties and thermal conductivity[2]. These materials demonstrate up to 40% improvement in breakdown voltage compared to conventional insulation materials while maintaining excellent thermal stability up to 900°C[3].

Strengths: Specialized expertise in BNNT production and functionalization; proprietary synthesis methods for high-purity materials; demonstrated significant improvements in dielectric breakdown strength. Weaknesses: Limited production scale compared to established insulation material manufacturers; higher cost of BNNT-based materials compared to traditional solutions; challenges in achieving uniform dispersion in polymer matrices at industrial scale.

Siemens AG

Technical Solution: Siemens AG has developed advanced high-voltage insulation materials incorporating boron nitride nanosheets (BNNS) for power transmission and distribution equipment. Their technology involves a multi-stage process for the exfoliation and functionalization of hexagonal boron nitride to produce nanosheets with controlled thickness and lateral dimensions[1]. These nanosheets are then incorporated into proprietary polymer blends through a specialized compounding process that ensures homogeneous dispersion. Siemens' BNNS-enhanced insulation materials demonstrate superior partial discharge resistance and increased dielectric breakdown strength (up to 35% improvement over conventional materials)[2]. The company has implemented these materials in their gas-insulated switchgear and high-voltage transformer products, where the enhanced thermal conductivity (increased by approximately 45%) helps dissipate heat more efficiently while maintaining excellent electrical insulation properties[3]. Their research has also focused on the long-term reliability of these nanocomposites under various environmental conditions, including humidity, temperature cycling, and electrical stress.

Strengths: Extensive experience in high-voltage equipment manufacturing; established global supply chain and quality control systems; comprehensive testing capabilities for insulation materials under realistic operating conditions. Weaknesses: Higher initial material costs compared to traditional insulation solutions; challenges in scaling up production of functionalized BNNS; potential regulatory hurdles for implementing new materials in established power infrastructure products.

Core Patents and Research on BN Nanosheets Applications

Boron nitride and method of producing boron nitride

PatentActiveUS20190244756A1

Innovation

- A catalyst-free, bottom-up method involving the heating of a mixture containing an alkali metal borohydride and an ammonium salt at elevated temperatures for extended periods, which produces h-BN nanosheets with controlled layer thickness and minimal metal impurities.

Boron nitride nanosheets and methods of making and using the same

PatentInactiveUS20160137502A1

Innovation

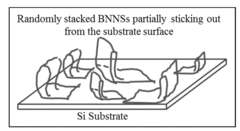

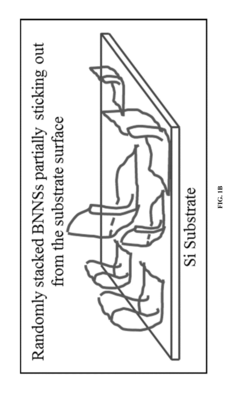

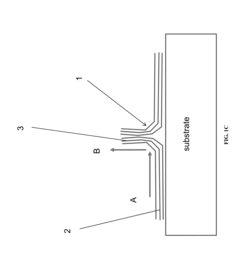

- A method for synthesizing boron nitride nanosheets with scrolled, close-ended structures using a chemical vapor deposition process involving boron, magnesium oxide, and iron oxide in a furnace with ammonia gas, which allows for better contact with hot surfaces and coolants, enabling efficient heat dissipation without being water-repelling.

Environmental Impact and Sustainability Considerations

The integration of Boron Nitride Nanosheets (BNNS) in high-voltage insulation materials presents significant environmental and sustainability considerations that must be carefully evaluated. The production process of BNNS typically involves chemical vapor deposition or exfoliation methods that may consume substantial energy and potentially utilize hazardous chemicals. These manufacturing processes require thorough life cycle assessment to quantify their environmental footprint compared to conventional insulation materials.

When examining the raw material sourcing for BNNS production, boron availability becomes a critical factor. While boron is relatively abundant in nature, its concentrated deposits are geographically limited, raising concerns about resource security and extraction impacts. Sustainable sourcing practices and efficient utilization of boron resources are essential to mitigate potential environmental degradation associated with mining operations.

The enhanced thermal stability and electrical insulation properties of BNNS-enhanced materials contribute positively to sustainability by potentially extending the operational lifespan of high-voltage equipment. This longevity reduces waste generation and resource consumption associated with frequent replacements. Additionally, the superior thermal management capabilities of BNNS composites may improve energy efficiency in electrical systems, thereby reducing operational carbon footprints.

End-of-life considerations for BNNS-containing insulation materials present both challenges and opportunities. Current recycling infrastructure may not be adequately equipped to process these advanced nanocomposites, potentially leading to improper disposal. Research into specialized recycling technologies for nanomaterial recovery is necessary to close the material loop and prevent environmental contamination.

The potential release of nanomaterials during the product lifecycle requires careful monitoring and mitigation strategies. While preliminary studies suggest low toxicity for BNNS compared to other nanomaterials, long-term environmental fate and ecotoxicological impacts remain incompletely understood. Implementing robust containment measures during manufacturing, use, and disposal phases is crucial to prevent unintended environmental exposure.

Regulatory frameworks governing nanomaterial use in industrial applications continue to evolve globally. Proactive compliance with emerging standards and participation in developing science-based regulations can facilitate responsible innovation in BNNS applications. Industry-academic partnerships focused on green synthesis methods and benign-by-design approaches offer promising pathways to minimize environmental impacts while maximizing the technological benefits of BNNS in high-voltage insulation materials.

When examining the raw material sourcing for BNNS production, boron availability becomes a critical factor. While boron is relatively abundant in nature, its concentrated deposits are geographically limited, raising concerns about resource security and extraction impacts. Sustainable sourcing practices and efficient utilization of boron resources are essential to mitigate potential environmental degradation associated with mining operations.

The enhanced thermal stability and electrical insulation properties of BNNS-enhanced materials contribute positively to sustainability by potentially extending the operational lifespan of high-voltage equipment. This longevity reduces waste generation and resource consumption associated with frequent replacements. Additionally, the superior thermal management capabilities of BNNS composites may improve energy efficiency in electrical systems, thereby reducing operational carbon footprints.

End-of-life considerations for BNNS-containing insulation materials present both challenges and opportunities. Current recycling infrastructure may not be adequately equipped to process these advanced nanocomposites, potentially leading to improper disposal. Research into specialized recycling technologies for nanomaterial recovery is necessary to close the material loop and prevent environmental contamination.

The potential release of nanomaterials during the product lifecycle requires careful monitoring and mitigation strategies. While preliminary studies suggest low toxicity for BNNS compared to other nanomaterials, long-term environmental fate and ecotoxicological impacts remain incompletely understood. Implementing robust containment measures during manufacturing, use, and disposal phases is crucial to prevent unintended environmental exposure.

Regulatory frameworks governing nanomaterial use in industrial applications continue to evolve globally. Proactive compliance with emerging standards and participation in developing science-based regulations can facilitate responsible innovation in BNNS applications. Industry-academic partnerships focused on green synthesis methods and benign-by-design approaches offer promising pathways to minimize environmental impacts while maximizing the technological benefits of BNNS in high-voltage insulation materials.

Safety Standards and Regulatory Compliance Requirements

The integration of Boron Nitride Nanosheets (BNNS) into high-voltage insulation materials necessitates strict adherence to established safety standards and regulatory compliance requirements. The International Electrotechnical Commission (IEC) has developed specific standards for high-voltage insulation materials, including IEC 60243 for electric strength testing and IEC 60587 for tracking resistance evaluation. These standards must be rigorously applied to BNNS-enhanced materials to ensure their safety and reliability in electrical applications.

In the United States, the National Electrical Manufacturers Association (NEMA) and Underwriters Laboratories (UL) have established additional requirements for insulation materials used in high-voltage applications. UL 746A specifically addresses the electrical properties of insulating materials, while NEMA standards provide guidelines for performance characteristics. BNNS-based insulation materials must meet these requirements to gain market acceptance and regulatory approval.

The European Union's regulatory framework includes the Low Voltage Directive (2014/35/EU) and the Restriction of Hazardous Substances (RoHS) Directive (2011/65/EU), which impose strict limitations on materials used in electrical equipment. Manufacturers incorporating BNNS into insulation materials must ensure compliance with these directives, particularly regarding the potential release of nanoparticles during the product lifecycle.

Safety data sheets (SDS) for BNNS-enhanced materials must be developed in accordance with the Globally Harmonized System of Classification and Labelling of Chemicals (GHS). These documents should detail handling procedures, exposure limits, and emergency response protocols specific to nanomaterials. The International Organization for Standardization (ISO) has developed standards such as ISO/TS 80004 for nanotechnology terminology and ISO/TR 13121 for nanomaterial risk evaluation, which provide essential guidance for BNNS applications.

Environmental regulations, including the Environmental Protection Agency (EPA) guidelines in the US and the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation in Europe, impose additional compliance requirements. These regulations address the potential environmental impact of nanomaterials throughout their lifecycle, from production to disposal.

Testing protocols for BNNS-enhanced insulation materials must include specialized procedures for evaluating nanocomposite performance under extreme conditions. IEEE Standard 1776-2008 provides guidelines for identifying critical electrical insulation parameters, while ASTM D149 specifies dielectric breakdown voltage testing methods. Manufacturers must document compliance with these standards to demonstrate the safety and reliability of their BNNS-enhanced products.

Ongoing regulatory developments, particularly those focused on nanomaterials in industrial applications, must be continuously monitored to ensure that BNNS-based insulation materials remain compliant with evolving standards and requirements. This proactive approach to regulatory compliance will facilitate market acceptance and minimize potential liability concerns.

In the United States, the National Electrical Manufacturers Association (NEMA) and Underwriters Laboratories (UL) have established additional requirements for insulation materials used in high-voltage applications. UL 746A specifically addresses the electrical properties of insulating materials, while NEMA standards provide guidelines for performance characteristics. BNNS-based insulation materials must meet these requirements to gain market acceptance and regulatory approval.

The European Union's regulatory framework includes the Low Voltage Directive (2014/35/EU) and the Restriction of Hazardous Substances (RoHS) Directive (2011/65/EU), which impose strict limitations on materials used in electrical equipment. Manufacturers incorporating BNNS into insulation materials must ensure compliance with these directives, particularly regarding the potential release of nanoparticles during the product lifecycle.

Safety data sheets (SDS) for BNNS-enhanced materials must be developed in accordance with the Globally Harmonized System of Classification and Labelling of Chemicals (GHS). These documents should detail handling procedures, exposure limits, and emergency response protocols specific to nanomaterials. The International Organization for Standardization (ISO) has developed standards such as ISO/TS 80004 for nanotechnology terminology and ISO/TR 13121 for nanomaterial risk evaluation, which provide essential guidance for BNNS applications.

Environmental regulations, including the Environmental Protection Agency (EPA) guidelines in the US and the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation in Europe, impose additional compliance requirements. These regulations address the potential environmental impact of nanomaterials throughout their lifecycle, from production to disposal.

Testing protocols for BNNS-enhanced insulation materials must include specialized procedures for evaluating nanocomposite performance under extreme conditions. IEEE Standard 1776-2008 provides guidelines for identifying critical electrical insulation parameters, while ASTM D149 specifies dielectric breakdown voltage testing methods. Manufacturers must document compliance with these standards to demonstrate the safety and reliability of their BNNS-enhanced products.

Ongoing regulatory developments, particularly those focused on nanomaterials in industrial applications, must be continuously monitored to ensure that BNNS-based insulation materials remain compliant with evolving standards and requirements. This proactive approach to regulatory compliance will facilitate market acceptance and minimize potential liability concerns.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!