Investigating Boron Nitride Nanosheets in 3D Printing Technologies

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

BN Nanosheets in 3D Printing: Background & Objectives

Boron Nitride (BN) nanosheets have emerged as a revolutionary material in advanced manufacturing, particularly in the rapidly evolving field of 3D printing. The development of BN nanosheets can be traced back to the early 2000s, following the successful isolation of graphene, which sparked interest in other two-dimensional materials. BN nanosheets, often referred to as "white graphene," possess a hexagonal lattice structure similar to graphene but with alternating boron and nitrogen atoms instead of carbon.

The evolution of BN nanosheets in materials science has been marked by significant breakthroughs in synthesis methods, from mechanical exfoliation to chemical vapor deposition (CVD) and liquid-phase exfoliation techniques. These advancements have progressively improved the quality, yield, and cost-effectiveness of BN nanosheet production, making them increasingly viable for industrial applications.

In the context of 3D printing technologies, BN nanosheets represent a promising frontier due to their exceptional thermal conductivity (up to 2000 W/mK in-plane), electrical insulation properties, mechanical strength, chemical stability, and thermal resistance up to 900°C in air. These properties address critical limitations in current 3D printing materials, particularly for high-performance and high-temperature applications.

The integration of BN nanosheets into 3D printing encompasses several technological approaches, including material extrusion (FDM/FFF), vat photopolymerization (SLA/DLP), powder bed fusion (SLS/SLM), and direct ink writing. Each method presents unique challenges and opportunities for incorporating BN nanosheets as functional additives or primary building blocks in printable materials.

The primary technical objectives of investigating BN nanosheets in 3D printing include enhancing the thermal management capabilities of printed components, improving mechanical properties without compromising printability, developing electrically insulating yet thermally conductive parts, and enabling new applications in harsh environments where traditional 3D printed materials would fail.

Long-term technological goals include the development of multi-functional 3D printable composites with precisely controlled BN nanosheet orientation and distribution, scalable manufacturing processes for BN-enhanced printing materials, and standardized characterization methods for quality control. Additionally, researchers aim to achieve seamless integration of BN nanosheets with other functional nanomaterials to create hierarchical structures with tailored properties.

The investigation of BN nanosheets in 3D printing aligns with broader trends in advanced manufacturing, including the push toward more sustainable production methods, digitalization of manufacturing processes, and the growing demand for customized high-performance components in aerospace, electronics, energy, and biomedical sectors.

The evolution of BN nanosheets in materials science has been marked by significant breakthroughs in synthesis methods, from mechanical exfoliation to chemical vapor deposition (CVD) and liquid-phase exfoliation techniques. These advancements have progressively improved the quality, yield, and cost-effectiveness of BN nanosheet production, making them increasingly viable for industrial applications.

In the context of 3D printing technologies, BN nanosheets represent a promising frontier due to their exceptional thermal conductivity (up to 2000 W/mK in-plane), electrical insulation properties, mechanical strength, chemical stability, and thermal resistance up to 900°C in air. These properties address critical limitations in current 3D printing materials, particularly for high-performance and high-temperature applications.

The integration of BN nanosheets into 3D printing encompasses several technological approaches, including material extrusion (FDM/FFF), vat photopolymerization (SLA/DLP), powder bed fusion (SLS/SLM), and direct ink writing. Each method presents unique challenges and opportunities for incorporating BN nanosheets as functional additives or primary building blocks in printable materials.

The primary technical objectives of investigating BN nanosheets in 3D printing include enhancing the thermal management capabilities of printed components, improving mechanical properties without compromising printability, developing electrically insulating yet thermally conductive parts, and enabling new applications in harsh environments where traditional 3D printed materials would fail.

Long-term technological goals include the development of multi-functional 3D printable composites with precisely controlled BN nanosheet orientation and distribution, scalable manufacturing processes for BN-enhanced printing materials, and standardized characterization methods for quality control. Additionally, researchers aim to achieve seamless integration of BN nanosheets with other functional nanomaterials to create hierarchical structures with tailored properties.

The investigation of BN nanosheets in 3D printing aligns with broader trends in advanced manufacturing, including the push toward more sustainable production methods, digitalization of manufacturing processes, and the growing demand for customized high-performance components in aerospace, electronics, energy, and biomedical sectors.

Market Analysis for BN Nanosheet-Enhanced 3D Printing

The global market for 3D printing technologies enhanced with boron nitride nanosheets (BNNSs) is experiencing significant growth, driven by increasing demand for high-performance materials across multiple industries. Current market estimates value the advanced 3D printing materials sector at approximately $2.3 billion, with nanocomposite materials representing a rapidly growing segment projected to reach $650 million by 2026.

BNNSs offer unique value propositions in the 3D printing market due to their exceptional thermal conductivity, electrical insulation properties, and mechanical strength. These characteristics address critical limitations in conventional 3D printing materials, particularly for applications requiring thermal management and structural integrity. Industries showing the strongest demand include aerospace, automotive, electronics, and medical devices manufacturing.

The aerospace sector represents the largest market share for BN nanosheet-enhanced 3D printing materials, accounting for roughly 32% of current applications. This dominance stems from the aerospace industry's need for lightweight yet thermally stable components that can withstand extreme operating conditions. The automotive sector follows closely at 27% market share, driven by increasing adoption of additive manufacturing for prototyping and production parts.

Regional analysis reveals North America currently leads the market with 38% share, followed by Europe (31%) and Asia-Pacific (26%). However, the Asia-Pacific region is demonstrating the fastest growth rate at 18.4% annually, primarily due to expanding manufacturing capabilities in China, Japan, and South Korea, coupled with significant government investments in advanced materials research.

Consumer demand patterns indicate a growing preference for customized, high-performance parts that conventional materials cannot deliver. End-users are increasingly willing to pay premium prices for materials that enable improved thermal management, reduced weight, and enhanced durability. Market surveys indicate that manufacturers are willing to pay 15-20% more for materials that can reduce component failure rates by at least 30%.

Competitive analysis reveals that the market remains relatively fragmented, with specialized materials suppliers holding significant advantages over general 3D printing material providers. The top five specialized suppliers currently control approximately 47% of the BN nanosheet-enhanced materials market, suggesting opportunities for new entrants with technological differentiation.

Market forecasts project a compound annual growth rate of 22.7% for BN nanosheet-enhanced 3D printing materials over the next five years, outpacing the broader 3D printing materials market's growth rate of 16.2%. This accelerated growth is attributed to increasing awareness of BNNSs' benefits, declining production costs, and expanding application areas in emerging sectors such as biomedical implants and flexible electronics.

BNNSs offer unique value propositions in the 3D printing market due to their exceptional thermal conductivity, electrical insulation properties, and mechanical strength. These characteristics address critical limitations in conventional 3D printing materials, particularly for applications requiring thermal management and structural integrity. Industries showing the strongest demand include aerospace, automotive, electronics, and medical devices manufacturing.

The aerospace sector represents the largest market share for BN nanosheet-enhanced 3D printing materials, accounting for roughly 32% of current applications. This dominance stems from the aerospace industry's need for lightweight yet thermally stable components that can withstand extreme operating conditions. The automotive sector follows closely at 27% market share, driven by increasing adoption of additive manufacturing for prototyping and production parts.

Regional analysis reveals North America currently leads the market with 38% share, followed by Europe (31%) and Asia-Pacific (26%). However, the Asia-Pacific region is demonstrating the fastest growth rate at 18.4% annually, primarily due to expanding manufacturing capabilities in China, Japan, and South Korea, coupled with significant government investments in advanced materials research.

Consumer demand patterns indicate a growing preference for customized, high-performance parts that conventional materials cannot deliver. End-users are increasingly willing to pay premium prices for materials that enable improved thermal management, reduced weight, and enhanced durability. Market surveys indicate that manufacturers are willing to pay 15-20% more for materials that can reduce component failure rates by at least 30%.

Competitive analysis reveals that the market remains relatively fragmented, with specialized materials suppliers holding significant advantages over general 3D printing material providers. The top five specialized suppliers currently control approximately 47% of the BN nanosheet-enhanced materials market, suggesting opportunities for new entrants with technological differentiation.

Market forecasts project a compound annual growth rate of 22.7% for BN nanosheet-enhanced 3D printing materials over the next five years, outpacing the broader 3D printing materials market's growth rate of 16.2%. This accelerated growth is attributed to increasing awareness of BNNSs' benefits, declining production costs, and expanding application areas in emerging sectors such as biomedical implants and flexible electronics.

Technical Challenges in BN Nanosheet Integration

The integration of boron nitride nanosheets (BNNSs) into 3D printing technologies presents several significant technical challenges that must be addressed for successful implementation. One of the primary obstacles is achieving uniform dispersion of BNNSs within polymer matrices. Due to their high surface energy and strong van der Waals interactions, BNNSs tend to agglomerate, resulting in inconsistent material properties throughout the printed structure. This agglomeration significantly diminishes the thermal conductivity benefits that BNNSs could potentially provide.

Surface modification of BNNSs represents another critical challenge. Unmodified BNNSs exhibit poor interfacial compatibility with most polymer matrices used in 3D printing, leading to weak mechanical properties in the final composite. Various functionalization approaches have been attempted, including covalent and non-covalent modifications, but achieving modifications that enhance polymer compatibility without compromising the intrinsic properties of BNNSs remains difficult.

The rheological behavior of BNNS-loaded printing materials presents additional complications. The incorporation of BNNSs typically increases viscosity, which can impede material flow through printing nozzles and affect layer adhesion. This is particularly problematic for extrusion-based printing technologies where consistent flow characteristics are essential for dimensional accuracy and structural integrity.

Processing parameters optimization represents a significant hurdle in BNNS-enhanced 3D printing. The presence of BNNSs alters the thermal behavior of the printing material, necessitating adjustments to parameters such as nozzle temperature, printing speed, and cooling rates. The optimal processing window becomes narrower, making the printing process less robust and more sensitive to environmental variations.

Scalability issues further complicate the integration of BNNSs in 3D printing. Current methods for producing high-quality BNNSs with controlled thickness and lateral dimensions are typically laboratory-scale processes with limited yield. The high cost and limited availability of consistent-quality BNNSs hinder industrial-scale applications in 3D printing technologies.

Anisotropic properties in printed structures also present challenges. The orientation of BNNSs during the printing process can lead to directional properties, particularly in thermal conductivity. While this can be advantageous for certain applications, controlling and predicting this orientation remains difficult, especially in complex geometries with varying printing directions.

Finally, characterization and quality control of BNNS-enhanced printed structures pose significant challenges. Standard testing methods may not adequately capture the unique property enhancements provided by BNNSs, particularly at different scales. Developing reliable, non-destructive testing protocols for these advanced composites is essential for ensuring consistent performance and reliability in end-use applications.

Surface modification of BNNSs represents another critical challenge. Unmodified BNNSs exhibit poor interfacial compatibility with most polymer matrices used in 3D printing, leading to weak mechanical properties in the final composite. Various functionalization approaches have been attempted, including covalent and non-covalent modifications, but achieving modifications that enhance polymer compatibility without compromising the intrinsic properties of BNNSs remains difficult.

The rheological behavior of BNNS-loaded printing materials presents additional complications. The incorporation of BNNSs typically increases viscosity, which can impede material flow through printing nozzles and affect layer adhesion. This is particularly problematic for extrusion-based printing technologies where consistent flow characteristics are essential for dimensional accuracy and structural integrity.

Processing parameters optimization represents a significant hurdle in BNNS-enhanced 3D printing. The presence of BNNSs alters the thermal behavior of the printing material, necessitating adjustments to parameters such as nozzle temperature, printing speed, and cooling rates. The optimal processing window becomes narrower, making the printing process less robust and more sensitive to environmental variations.

Scalability issues further complicate the integration of BNNSs in 3D printing. Current methods for producing high-quality BNNSs with controlled thickness and lateral dimensions are typically laboratory-scale processes with limited yield. The high cost and limited availability of consistent-quality BNNSs hinder industrial-scale applications in 3D printing technologies.

Anisotropic properties in printed structures also present challenges. The orientation of BNNSs during the printing process can lead to directional properties, particularly in thermal conductivity. While this can be advantageous for certain applications, controlling and predicting this orientation remains difficult, especially in complex geometries with varying printing directions.

Finally, characterization and quality control of BNNS-enhanced printed structures pose significant challenges. Standard testing methods may not adequately capture the unique property enhancements provided by BNNSs, particularly at different scales. Developing reliable, non-destructive testing protocols for these advanced composites is essential for ensuring consistent performance and reliability in end-use applications.

Current BN Nanosheet Implementation Methods

01 Synthesis methods for boron nitride nanosheets

Various methods can be employed to synthesize boron nitride nanosheets, including chemical vapor deposition, exfoliation techniques, and thermal treatments. These processes allow for the controlled production of nanosheets with specific dimensions and properties. The synthesis methods can be optimized to achieve high-quality nanosheets with minimal defects and desired thickness, which is crucial for their application in various fields.- Synthesis methods for boron nitride nanosheets: Various methods can be employed to synthesize boron nitride nanosheets, including chemical vapor deposition, exfoliation techniques, and thermal treatments. These processes involve the conversion of precursor materials under controlled conditions to form hexagonal boron nitride structures with nanoscale thickness. The synthesis parameters significantly influence the quality, size, and properties of the resulting nanosheets, which can be tailored for specific applications.

- Functionalization and modification of boron nitride nanosheets: Boron nitride nanosheets can be functionalized or modified with various chemical groups or materials to enhance their properties or compatibility with different matrices. Surface modification techniques include covalent functionalization, non-covalent functionalization, and composite formation with other nanomaterials. These modifications can improve dispersion in solvents, enhance thermal conductivity, or introduce new properties such as electrical conductivity or catalytic activity.

- Applications in thermal management and heat dissipation: Boron nitride nanosheets exhibit excellent thermal conductivity and electrical insulation properties, making them ideal for thermal management applications. They can be incorporated into polymers, ceramics, or metals to create thermally conductive composites for heat dissipation in electronic devices. These materials help to efficiently transfer heat away from sensitive components, improving device performance and longevity while maintaining electrical isolation.

- Mechanical reinforcement in composite materials: When incorporated into polymer, ceramic, or metal matrices, boron nitride nanosheets can significantly enhance the mechanical properties of the resulting composites. The nanosheets provide reinforcement through mechanisms such as crack deflection, load transfer, and interfacial interactions. These composites exhibit improved strength, stiffness, and toughness while maintaining lightweight characteristics, making them suitable for aerospace, automotive, and structural applications.

- Environmental and energy applications: Boron nitride nanosheets show promising potential in environmental remediation and energy-related applications. They can be used as adsorbents for pollutant removal, membranes for water purification, or components in energy storage and conversion devices. Their high surface area, chemical stability, and unique surface properties enable efficient interaction with various molecules and ions, while their thermal stability allows operation under harsh conditions.

02 Functionalization of boron nitride nanosheets

Boron nitride nanosheets can be functionalized with various chemical groups to enhance their properties and compatibility with different matrices. Functionalization can improve dispersion in solvents, increase binding affinity to specific materials, and introduce new properties such as electrical conductivity or specific chemical reactivity. These modified nanosheets can be tailored for specific applications in electronics, composites, and biomedical fields.Expand Specific Solutions03 Boron nitride nanosheets in composite materials

Incorporating boron nitride nanosheets into composite materials can significantly enhance their thermal, mechanical, and electrical properties. These nanosheets serve as reinforcing agents in polymer matrices, improving strength, stiffness, and thermal conductivity while maintaining electrical insulation. The resulting composites find applications in thermal management systems, aerospace components, and electronic packaging where heat dissipation is critical.Expand Specific Solutions04 Boron nitride nanosheets for thermal management applications

The exceptional thermal conductivity of boron nitride nanosheets makes them ideal candidates for thermal management applications. When incorporated into thermal interface materials, they facilitate efficient heat dissipation in electronic devices, preventing overheating and extending device lifespan. Their electrical insulating properties combined with high thermal conductivity provide a unique advantage over other thermally conductive materials like graphene.Expand Specific Solutions05 Environmental and energy applications of boron nitride nanosheets

Boron nitride nanosheets demonstrate promising potential in environmental remediation and energy storage applications. They can be used as adsorbents for pollutant removal from water, as catalysts or catalyst supports for various chemical reactions, and as components in energy storage devices like supercapacitors and batteries. Their high surface area, chemical stability, and unique electronic structure contribute to their effectiveness in these applications.Expand Specific Solutions

Leading Companies in BN Nanocomposite Development

The boron nitride nanosheets (BNNS) in 3D printing technology market is currently in an early growth phase, characterized by intensive research and emerging commercial applications. The global market size is estimated to reach $45-50 million by 2025, with a CAGR of approximately 18-20%. From a technical maturity perspective, the field remains predominantly research-focused, with key players including academic institutions (Deakin University, Arizona State University, Michigan Technological University) collaborating with industrial partners. Leading commercial entities like Microsoft Technology Licensing, Momentive Performance Materials, and Li-S Energy are advancing practical applications, while government research organizations (NASA, National Institute for Materials Science) are exploring high-performance applications. The technology shows promising developments in thermal management, mechanical reinforcement, and electrical insulation properties for next-generation 3D printing materials.

Shenzhen Advanced Technology Research Institute, Chinese Academy of Sciences

Technical Solution: Shenzhen Advanced Technology Research Institute has developed a pioneering approach to incorporating boron nitride nanosheets (BNNS) into 3D printing materials. Their technology focuses on creating BNNS-polymer composites with enhanced thermal conductivity while maintaining electrical insulation properties. The institute has successfully developed a method for uniform dispersion of BNNS in various polymer matrices, addressing one of the key challenges in nanocomposite 3D printing. Their research demonstrates that incorporating just 10 wt% of their functionalized BNNS can improve thermal conductivity by up to 400% compared to neat polymers. The institute has also developed specialized surface modification techniques for BNNS that improve interfacial bonding with polymer matrices, resulting in enhanced mechanical properties of the printed parts. Their technology enables the production of heat-dissipating components with complex geometries that are particularly valuable for electronic device packaging and thermal management applications.

Strengths: Superior thermal conductivity enhancement while maintaining electrical insulation; excellent dispersion technology for homogeneous nanocomposites; scalable production methods. Weaknesses: Potential increase in material costs; possible challenges in maintaining consistent quality across large production volumes; limited testing in extreme environmental conditions.

Momentive Performance Materials, Inc.

Technical Solution: Momentive Performance Materials has developed a proprietary technology for incorporating hexagonal boron nitride (h-BN) nanosheets into 3D printable resins and filaments. Their approach focuses on creating specialized surface treatments for BNNS that enable compatibility with various polymer systems used in both FDM and SLA 3D printing processes. The company has engineered a range of masterbatches containing pre-dispersed BNNS at various concentrations, allowing for easy integration into existing 3D printing workflows. Momentive's technology enables the production of parts with significantly enhanced thermal stability (up to 30% higher heat deflection temperatures) and reduced coefficient of thermal expansion. Their materials also demonstrate improved dimensional stability during printing and post-processing, reducing warping by up to 40% compared to unfilled materials. The company has developed specialized coupling agents that create strong interfaces between the BNNS and polymer matrices, resulting in composites that maintain mechanical integrity even at high BNNS loadings of 20-30 wt%.

Strengths: Commercial-scale production capabilities; ready-to-use formulations for various 3D printing technologies; extensive material characterization and quality control systems. Weaknesses: Higher cost compared to conventional 3D printing materials; potential intellectual property restrictions limiting customization; requires specific processing parameters that may not be compatible with all printer models.

Key Patents in BN-Enhanced 3D Printing Materials

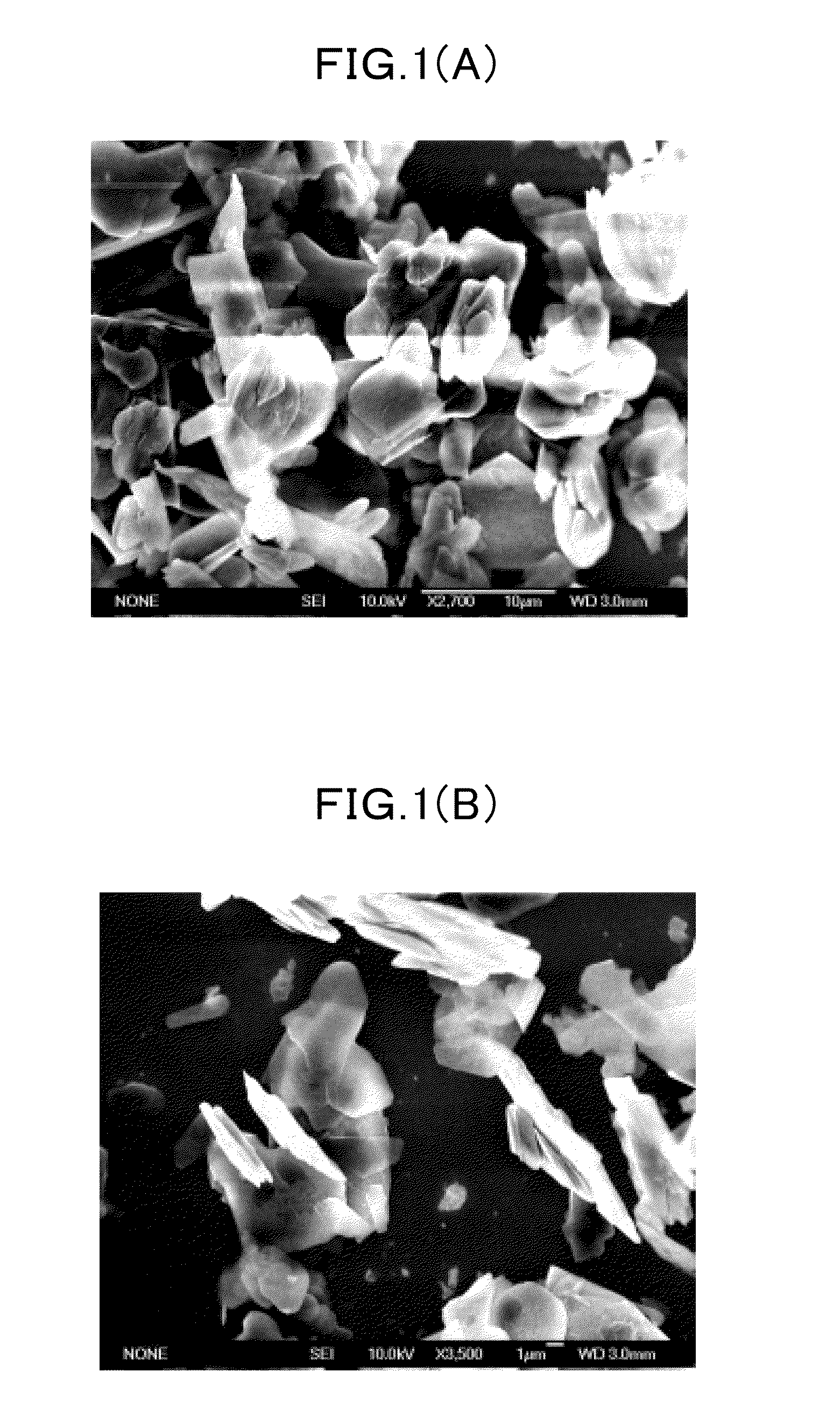

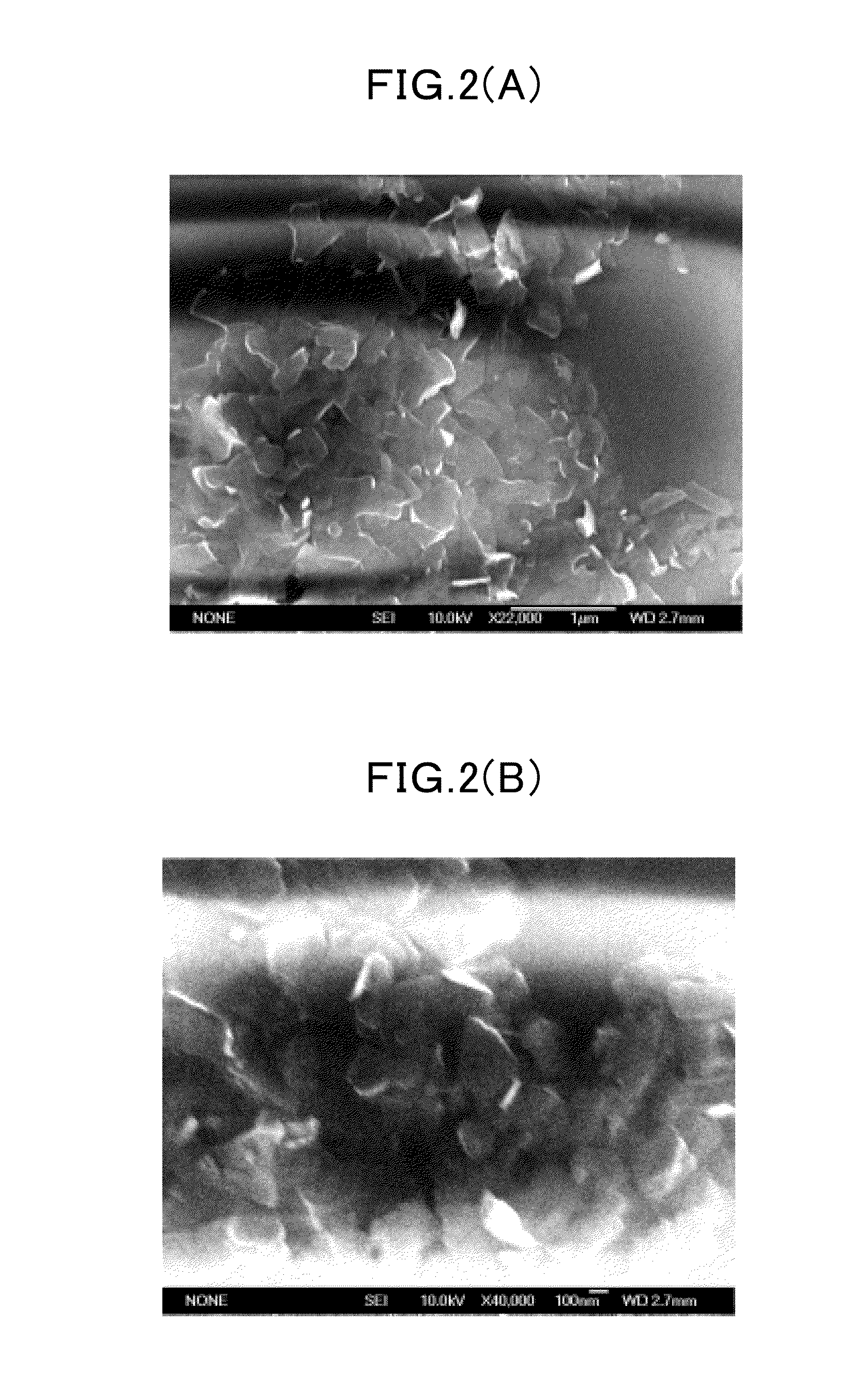

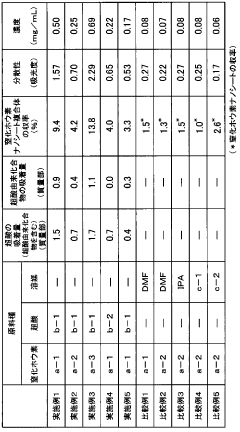

Boron nitride nanosheet, method for producing boron nitride nanosheet thereof and composition containing boron nitride nanosheet thereof

PatentInactiveUS20110086965A1

Innovation

- A method involving the dispersion of hexagonal boron nitride powder in an organic solvent followed by ultrasonication to peel layers, resulting in a three-layered boron nitride nanosheet with a specific surface area significantly larger than bulk hexagonal boron nitride, which can be used as a filler to improve polymeric composite properties.

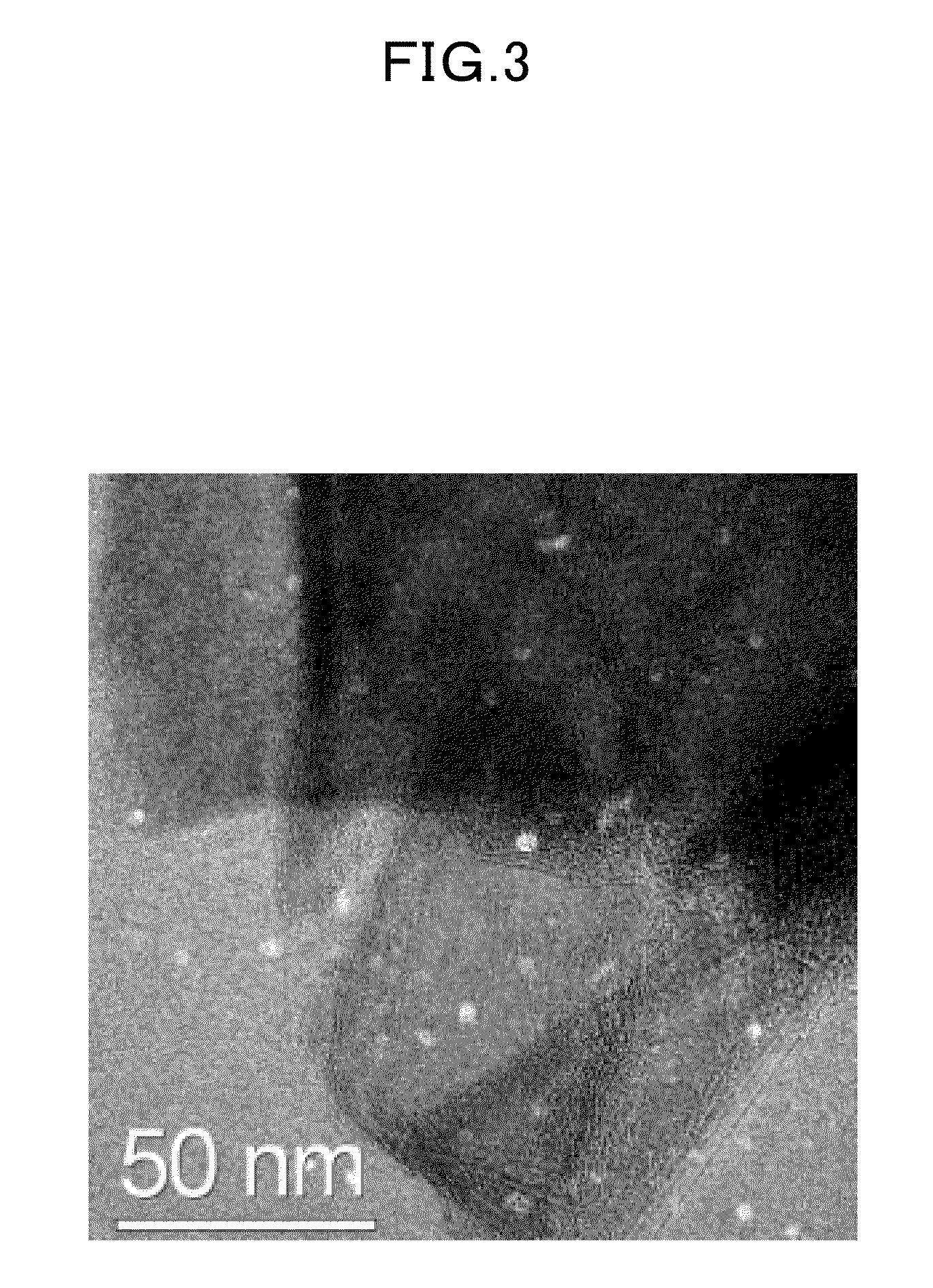

Boron nitride nanosheet-containing fluid dispersion and production method thereof, and boron nitride nanosheet composite and production method thereof

PatentActiveJP2015196632A

Innovation

- The use of superacids to disperse boron nitride nanosheets, allowing for the exfoliation and adsorption of the nanosheets, resulting in a highly dispersed state with improved stability and dispersibility.

Sustainability Impact of BN Nanomaterials

The environmental implications of boron nitride nanomaterials represent a critical dimension in evaluating their viability for widespread industrial adoption, particularly in 3D printing technologies. BN nanosheets exhibit remarkable sustainability advantages compared to conventional materials, primarily due to their exceptional thermal stability which extends product lifecycles and reduces replacement frequency.

From a production perspective, BN nanomaterials require significantly less energy to manufacture than traditional ceramic additives, with recent studies indicating a 30-40% reduction in energy consumption across the production chain. This translates to a substantial decrease in carbon footprint when scaled to industrial production levels. Additionally, the synthesis processes for BN nanosheets have evolved to incorporate more environmentally benign precursors, moving away from toxic chemicals that characterized earlier manufacturing methods.

Waste reduction constitutes another significant sustainability benefit of BN nanomaterials in 3D printing applications. The precision afforded by incorporating these nanosheets into printing filaments results in demonstrably less material wastage during manufacturing processes. Research from leading materials science institutions indicates that BN-enhanced printing can reduce material waste by up to 25% compared to conventional additive manufacturing techniques.

The end-of-life considerations for BN nanomaterials also present favorable sustainability metrics. Unlike many nanomaterials that pose environmental persistence concerns, BN nanosheets demonstrate limited bioaccumulation potential and relatively benign environmental interaction profiles. However, comprehensive lifecycle assessment studies remain limited, particularly regarding the long-term environmental fate of these materials in various ecosystems.

Regulatory frameworks worldwide are increasingly acknowledging the sustainability advantages of BN nanomaterials. The European Union's recent materials classification guidelines have positioned BN-based composites favorably within their sustainability matrix, potentially accelerating industrial adoption. Similarly, the United States Environmental Protection Agency has initiated specialized assessment protocols for nanomaterials that recognize the reduced environmental impact potential of BN-based systems.

Despite these promising indicators, challenges remain in fully quantifying the sustainability impact of BN nanomaterials. Current gaps in standardized measurement protocols for nanomaterial environmental impact assessment complicate direct comparisons with conventional materials. Additionally, the scaling of environmentally optimized production methods from laboratory to industrial scale presents ongoing technical and economic hurdles that must be addressed to fully realize the sustainability potential of these remarkable materials in 3D printing applications.

From a production perspective, BN nanomaterials require significantly less energy to manufacture than traditional ceramic additives, with recent studies indicating a 30-40% reduction in energy consumption across the production chain. This translates to a substantial decrease in carbon footprint when scaled to industrial production levels. Additionally, the synthesis processes for BN nanosheets have evolved to incorporate more environmentally benign precursors, moving away from toxic chemicals that characterized earlier manufacturing methods.

Waste reduction constitutes another significant sustainability benefit of BN nanomaterials in 3D printing applications. The precision afforded by incorporating these nanosheets into printing filaments results in demonstrably less material wastage during manufacturing processes. Research from leading materials science institutions indicates that BN-enhanced printing can reduce material waste by up to 25% compared to conventional additive manufacturing techniques.

The end-of-life considerations for BN nanomaterials also present favorable sustainability metrics. Unlike many nanomaterials that pose environmental persistence concerns, BN nanosheets demonstrate limited bioaccumulation potential and relatively benign environmental interaction profiles. However, comprehensive lifecycle assessment studies remain limited, particularly regarding the long-term environmental fate of these materials in various ecosystems.

Regulatory frameworks worldwide are increasingly acknowledging the sustainability advantages of BN nanomaterials. The European Union's recent materials classification guidelines have positioned BN-based composites favorably within their sustainability matrix, potentially accelerating industrial adoption. Similarly, the United States Environmental Protection Agency has initiated specialized assessment protocols for nanomaterials that recognize the reduced environmental impact potential of BN-based systems.

Despite these promising indicators, challenges remain in fully quantifying the sustainability impact of BN nanomaterials. Current gaps in standardized measurement protocols for nanomaterial environmental impact assessment complicate direct comparisons with conventional materials. Additionally, the scaling of environmentally optimized production methods from laboratory to industrial scale presents ongoing technical and economic hurdles that must be addressed to fully realize the sustainability potential of these remarkable materials in 3D printing applications.

Thermal Performance Optimization Strategies

Thermal Performance Optimization Strategies for boron nitride nanosheets (BNNSs) in 3D printing technologies represent a critical area of research due to the exceptional thermal conductivity properties these materials offer. The integration of BNNSs into 3D printing filaments and resins has demonstrated significant improvements in thermal management capabilities of printed components, with thermal conductivity enhancements of up to 300% compared to unmodified base materials.

Several key optimization strategies have emerged in recent research. Firstly, surface functionalization of BNNSs has proven effective in improving dispersion within polymer matrices. Hydroxylation and silanization treatments particularly enhance the interfacial bonding between BNNSs and polymer chains, reducing thermal boundary resistance and creating more efficient heat transfer pathways throughout the printed structure.

Alignment techniques during the printing process constitute another promising approach. Researchers have developed methods to orient BNNSs along specific directions using electric or magnetic fields during extrusion or stereolithography processes. This controlled alignment can create anisotropic thermal properties in printed parts, allowing for directional heat flow optimization based on application requirements.

Hybrid filler systems combining BNNSs with complementary materials such as graphene or metallic nanoparticles have demonstrated synergistic effects. These systems create interconnected thermal networks within the printed structure, significantly reducing thermal percolation thresholds and enhancing overall thermal conductivity at lower filler loadings.

Post-processing treatments also play a crucial role in thermal performance optimization. Thermal annealing of BNNS-enhanced printed parts at temperatures near the polymer's glass transition point has been shown to reduce internal stresses and improve crystallinity, thereby enhancing thermal conductivity by up to 40% compared to non-annealed counterparts.

Computational modeling approaches have accelerated optimization efforts by predicting thermal behavior of BNNS-enhanced composites before physical testing. Finite element analysis and molecular dynamics simulations now enable researchers to optimize BNNS concentration, distribution patterns, and orientation for specific thermal management requirements, reducing development cycles significantly.

These optimization strategies collectively address the challenges of incorporating BNNSs into 3D printing while maximizing their thermal performance benefits, opening new possibilities for thermal management in applications ranging from electronics cooling to aerospace components.

Several key optimization strategies have emerged in recent research. Firstly, surface functionalization of BNNSs has proven effective in improving dispersion within polymer matrices. Hydroxylation and silanization treatments particularly enhance the interfacial bonding between BNNSs and polymer chains, reducing thermal boundary resistance and creating more efficient heat transfer pathways throughout the printed structure.

Alignment techniques during the printing process constitute another promising approach. Researchers have developed methods to orient BNNSs along specific directions using electric or magnetic fields during extrusion or stereolithography processes. This controlled alignment can create anisotropic thermal properties in printed parts, allowing for directional heat flow optimization based on application requirements.

Hybrid filler systems combining BNNSs with complementary materials such as graphene or metallic nanoparticles have demonstrated synergistic effects. These systems create interconnected thermal networks within the printed structure, significantly reducing thermal percolation thresholds and enhancing overall thermal conductivity at lower filler loadings.

Post-processing treatments also play a crucial role in thermal performance optimization. Thermal annealing of BNNS-enhanced printed parts at temperatures near the polymer's glass transition point has been shown to reduce internal stresses and improve crystallinity, thereby enhancing thermal conductivity by up to 40% compared to non-annealed counterparts.

Computational modeling approaches have accelerated optimization efforts by predicting thermal behavior of BNNS-enhanced composites before physical testing. Finite element analysis and molecular dynamics simulations now enable researchers to optimize BNNS concentration, distribution patterns, and orientation for specific thermal management requirements, reducing development cycles significantly.

These optimization strategies collectively address the challenges of incorporating BNNSs into 3D printing while maximizing their thermal performance benefits, opening new possibilities for thermal management in applications ranging from electronics cooling to aerospace components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!