Boron Nitride Nanosheets Market Trends and Industry Standards

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

BN Nanosheets Background and Development Goals

Boron Nitride Nanosheets (BNNS) have emerged as a significant two-dimensional nanomaterial since their initial isolation in 2005, following the groundbreaking discovery of graphene. These hexagonal lattice structures, composed of alternating boron and nitrogen atoms, represent a critical advancement in materials science due to their exceptional thermal, mechanical, and electrical properties.

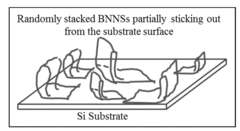

The evolution of BNNS technology has progressed through several distinct phases. Initially, research focused primarily on fundamental characterization and property analysis. This was followed by the development of various synthesis methods, including chemical vapor deposition (CVD), liquid exfoliation, and chemical blowing techniques. Recent years have witnessed a transition toward scalable production methodologies and application-specific optimization, marking a shift from purely academic interest to industrial relevance.

Current technological trajectories indicate accelerating development in BNNS applications across multiple sectors. The material's wide bandgap (5.9 eV) and excellent thermal conductivity (up to 2000 W/mK) position it uniquely for electronic applications, particularly as thermal management solutions in next-generation microelectronics. Additionally, its chemical stability and mechanical strength make it valuable for composite reinforcement and protective coatings.

The primary technological goals for BNNS development center around three critical areas. First, establishing cost-effective, environmentally sustainable mass production methods capable of yielding high-quality, defect-controlled nanosheets at industrial scale. Second, standardizing characterization protocols and quality metrics to ensure consistency across research and commercial applications. Third, developing specialized functionalization techniques to enhance compatibility with various matrices and enable tailored properties for specific applications.

International research efforts have intensified, with significant contributions from institutions in Asia, North America, and Europe. Japan and China have emerged as leaders in patent filings related to BNNS production technologies, while the United States maintains strength in application development, particularly in aerospace and defense sectors.

The technological roadmap for BNNS aims to address current limitations in sheet size, layer control, and defect management. Achieving atomically precise edge structures and controlled doping profiles represents a frontier challenge that, when overcome, could unlock novel electronic and quantum applications. Additionally, developing green synthesis routes that minimize hazardous chemicals and energy consumption aligns with broader sustainability goals in advanced materials development.

The evolution of BNNS technology has progressed through several distinct phases. Initially, research focused primarily on fundamental characterization and property analysis. This was followed by the development of various synthesis methods, including chemical vapor deposition (CVD), liquid exfoliation, and chemical blowing techniques. Recent years have witnessed a transition toward scalable production methodologies and application-specific optimization, marking a shift from purely academic interest to industrial relevance.

Current technological trajectories indicate accelerating development in BNNS applications across multiple sectors. The material's wide bandgap (5.9 eV) and excellent thermal conductivity (up to 2000 W/mK) position it uniquely for electronic applications, particularly as thermal management solutions in next-generation microelectronics. Additionally, its chemical stability and mechanical strength make it valuable for composite reinforcement and protective coatings.

The primary technological goals for BNNS development center around three critical areas. First, establishing cost-effective, environmentally sustainable mass production methods capable of yielding high-quality, defect-controlled nanosheets at industrial scale. Second, standardizing characterization protocols and quality metrics to ensure consistency across research and commercial applications. Third, developing specialized functionalization techniques to enhance compatibility with various matrices and enable tailored properties for specific applications.

International research efforts have intensified, with significant contributions from institutions in Asia, North America, and Europe. Japan and China have emerged as leaders in patent filings related to BNNS production technologies, while the United States maintains strength in application development, particularly in aerospace and defense sectors.

The technological roadmap for BNNS aims to address current limitations in sheet size, layer control, and defect management. Achieving atomically precise edge structures and controlled doping profiles represents a frontier challenge that, when overcome, could unlock novel electronic and quantum applications. Additionally, developing green synthesis routes that minimize hazardous chemicals and energy consumption aligns with broader sustainability goals in advanced materials development.

Market Demand Analysis for BN Nanosheets

The global market for Boron Nitride Nanosheets (BNNS) has witnessed significant growth in recent years, driven primarily by their exceptional thermal conductivity, electrical insulation properties, and mechanical strength. Current market analysis indicates a robust compound annual growth rate (CAGR) of approximately 15-20% for the period 2023-2028, with the market value projected to reach several hundred million dollars by 2028.

The demand for BNNS is particularly strong in the electronics sector, where thermal management remains a critical challenge. As electronic devices continue to miniaturize while increasing in processing power, the need for efficient heat dissipation materials has become paramount. BNNS, with their thermal conductivity exceeding 2000 W/mK in-plane, offer superior performance compared to traditional materials like aluminum oxide or silicon carbide.

Another significant market driver is the growing adoption of BNNS in polymer composites. Industries ranging from aerospace to automotive are increasingly incorporating BNNS into polymer matrices to enhance thermal conductivity while maintaining electrical insulation. This trend is expected to accelerate as manufacturers seek lightweight materials with enhanced thermal properties for next-generation vehicles and aircraft components.

The energy storage sector represents an emerging market for BNNS, particularly in lithium-ion battery technology. Research indicates that BNNS can effectively prevent dendrite formation in lithium metal anodes, potentially enabling higher energy density batteries with improved safety profiles. Major battery manufacturers have begun exploring BNNS incorporation in commercial products, signaling a potentially substantial market expansion in the coming years.

Regional analysis reveals Asia-Pacific as the dominant market for BNNS, accounting for over 40% of global consumption. This is attributed to the region's robust electronics manufacturing ecosystem and increasing investments in advanced materials research. North America and Europe follow, with growing applications in aerospace, defense, and high-performance computing sectors driving demand.

End-user segmentation shows electronics and semiconductor industries leading BNNS consumption, followed by aerospace, automotive, and energy storage applications. The biomedical sector represents a nascent but promising market, with research exploring BNNS applications in drug delivery systems and biomedical imaging.

Price sensitivity remains a significant market constraint, as production costs for high-quality BNNS remain relatively high. However, ongoing advancements in manufacturing technologies, particularly in chemical vapor deposition (CVD) and liquid-phase exfoliation methods, are gradually reducing production costs, which is expected to expand market accessibility across various industries.

The demand for BNNS is particularly strong in the electronics sector, where thermal management remains a critical challenge. As electronic devices continue to miniaturize while increasing in processing power, the need for efficient heat dissipation materials has become paramount. BNNS, with their thermal conductivity exceeding 2000 W/mK in-plane, offer superior performance compared to traditional materials like aluminum oxide or silicon carbide.

Another significant market driver is the growing adoption of BNNS in polymer composites. Industries ranging from aerospace to automotive are increasingly incorporating BNNS into polymer matrices to enhance thermal conductivity while maintaining electrical insulation. This trend is expected to accelerate as manufacturers seek lightweight materials with enhanced thermal properties for next-generation vehicles and aircraft components.

The energy storage sector represents an emerging market for BNNS, particularly in lithium-ion battery technology. Research indicates that BNNS can effectively prevent dendrite formation in lithium metal anodes, potentially enabling higher energy density batteries with improved safety profiles. Major battery manufacturers have begun exploring BNNS incorporation in commercial products, signaling a potentially substantial market expansion in the coming years.

Regional analysis reveals Asia-Pacific as the dominant market for BNNS, accounting for over 40% of global consumption. This is attributed to the region's robust electronics manufacturing ecosystem and increasing investments in advanced materials research. North America and Europe follow, with growing applications in aerospace, defense, and high-performance computing sectors driving demand.

End-user segmentation shows electronics and semiconductor industries leading BNNS consumption, followed by aerospace, automotive, and energy storage applications. The biomedical sector represents a nascent but promising market, with research exploring BNNS applications in drug delivery systems and biomedical imaging.

Price sensitivity remains a significant market constraint, as production costs for high-quality BNNS remain relatively high. However, ongoing advancements in manufacturing technologies, particularly in chemical vapor deposition (CVD) and liquid-phase exfoliation methods, are gradually reducing production costs, which is expected to expand market accessibility across various industries.

Technical Status and Challenges in BN Nanosheets Production

The global landscape of Boron Nitride (BN) nanosheets production has witnessed significant advancements in recent years, with research institutions and commercial entities across North America, Europe, and Asia-Pacific regions making substantial contributions. Currently, several synthesis methods dominate the production landscape, including chemical vapor deposition (CVD), liquid-phase exfoliation, and chemical blowing techniques. Each method presents distinct advantages and limitations regarding scalability, purity, and cost-effectiveness.

Despite these advancements, the industrial-scale production of high-quality BN nanosheets faces considerable challenges. The primary technical hurdle remains the difficulty in producing large-area, defect-free nanosheets with consistent thickness and properties. Current production methods often yield materials with varying quality, dimensional inconsistency, and structural defects that significantly impact performance in end applications.

Cost factors represent another substantial barrier to widespread adoption. The high-temperature processes required for synthesis, coupled with expensive precursor materials and specialized equipment, contribute to elevated production costs that limit commercial viability. Industry estimates suggest that production costs need to decrease by 40-60% to enable mass-market applications beyond current high-value niches.

Standardization issues further complicate the landscape. The absence of universally accepted quality metrics and characterization protocols creates significant challenges for material comparison and quality assurance. This lack of standardization impedes industry-wide adoption and slows integration into commercial products, as manufacturers struggle to establish reliable supply chains with consistent material specifications.

Environmental and safety concerns associated with production processes present additional challenges. Many synthesis methods involve hazardous chemicals or generate potentially harmful byproducts, necessitating sophisticated containment and waste management systems that add complexity and cost to manufacturing operations.

The scalability gap between laboratory demonstrations and industrial requirements remains substantial. While research settings have achieved impressive results with small-scale production, translating these processes to continuous, high-volume manufacturing environments introduces numerous engineering challenges related to process control, quality monitoring, and yield optimization.

Intellectual property landscapes surrounding BN nanosheet production technologies are increasingly complex, with patent thickets forming around key synthesis methods and applications. This fragmented IP environment creates additional barriers for new market entrants and sometimes slows collaborative innovation efforts that could otherwise accelerate technical solutions.

Despite these advancements, the industrial-scale production of high-quality BN nanosheets faces considerable challenges. The primary technical hurdle remains the difficulty in producing large-area, defect-free nanosheets with consistent thickness and properties. Current production methods often yield materials with varying quality, dimensional inconsistency, and structural defects that significantly impact performance in end applications.

Cost factors represent another substantial barrier to widespread adoption. The high-temperature processes required for synthesis, coupled with expensive precursor materials and specialized equipment, contribute to elevated production costs that limit commercial viability. Industry estimates suggest that production costs need to decrease by 40-60% to enable mass-market applications beyond current high-value niches.

Standardization issues further complicate the landscape. The absence of universally accepted quality metrics and characterization protocols creates significant challenges for material comparison and quality assurance. This lack of standardization impedes industry-wide adoption and slows integration into commercial products, as manufacturers struggle to establish reliable supply chains with consistent material specifications.

Environmental and safety concerns associated with production processes present additional challenges. Many synthesis methods involve hazardous chemicals or generate potentially harmful byproducts, necessitating sophisticated containment and waste management systems that add complexity and cost to manufacturing operations.

The scalability gap between laboratory demonstrations and industrial requirements remains substantial. While research settings have achieved impressive results with small-scale production, translating these processes to continuous, high-volume manufacturing environments introduces numerous engineering challenges related to process control, quality monitoring, and yield optimization.

Intellectual property landscapes surrounding BN nanosheet production technologies are increasingly complex, with patent thickets forming around key synthesis methods and applications. This fragmented IP environment creates additional barriers for new market entrants and sometimes slows collaborative innovation efforts that could otherwise accelerate technical solutions.

Current Manufacturing Solutions for BN Nanosheets

01 Synthesis methods for boron nitride nanosheets

Various methods have been developed for synthesizing boron nitride nanosheets with controlled properties. These include chemical vapor deposition, liquid-phase exfoliation, and chemical methods that allow for the production of high-quality nanosheets with specific dimensions and characteristics. The synthesis processes can be optimized to control thickness, lateral size, and defect density, which are crucial for specific applications.- Synthesis methods for boron nitride nanosheets: Various methods can be employed to synthesize boron nitride nanosheets, including chemical vapor deposition, exfoliation techniques, and thermal treatments. These processes involve the conversion of precursor materials into hexagonal boron nitride structures with nanoscale thickness. The synthesis methods can be optimized to control the thickness, lateral size, and crystallinity of the nanosheets, which directly influence their properties and applications.

- Functionalization and modification of boron nitride nanosheets: Boron nitride nanosheets can be functionalized or modified with various chemical groups or materials to enhance their properties or compatibility with different matrices. Surface modification techniques include covalent functionalization, non-covalent functionalization, and composite formation with other nanomaterials. These modifications can improve dispersion in solvents, enhance thermal conductivity, or introduce new properties such as electrical conductivity or catalytic activity.

- Thermal management applications of boron nitride nanosheets: Boron nitride nanosheets exhibit excellent thermal conductivity and electrical insulation properties, making them ideal for thermal management applications. They can be incorporated into polymers, ceramics, or metals to form thermally conductive composites used in electronic devices, heat sinks, and thermal interface materials. These composites help dissipate heat efficiently, improving the performance and reliability of electronic components and systems.

- Mechanical reinforcement using boron nitride nanosheets: Boron nitride nanosheets can significantly enhance the mechanical properties of various materials when used as reinforcing agents. Their high mechanical strength, flexibility, and large surface area make them effective fillers in polymer, ceramic, and metal matrix composites. The incorporation of these nanosheets can improve tensile strength, modulus, hardness, and wear resistance while maintaining or reducing the weight of the composite materials.

- Environmental and energy applications of boron nitride nanosheets: Boron nitride nanosheets have promising applications in environmental remediation and energy storage/conversion technologies. They can be used as adsorbents for pollutant removal, membranes for water purification, catalysts or catalyst supports for various reactions, and components in energy storage devices such as batteries and supercapacitors. Their chemical stability, large surface area, and unique electronic properties make them suitable for these applications.

02 Functionalization and modification of boron nitride nanosheets

Boron nitride nanosheets can be functionalized or modified to enhance their properties for specific applications. Surface modifications can improve dispersion in various matrices, increase compatibility with other materials, and introduce new functional groups. These modifications can be achieved through chemical treatments, doping with other elements, or creating hybrid structures with other nanomaterials to tailor the properties for specific uses.Expand Specific Solutions03 Thermal management applications of boron nitride nanosheets

Boron nitride nanosheets exhibit excellent thermal conductivity and stability, making them ideal for thermal management applications. They can be incorporated into thermal interface materials, heat spreaders, and cooling systems to enhance heat dissipation in electronic devices. The high thermal conductivity combined with electrical insulation properties makes these nanosheets particularly valuable for managing heat in high-power electronics and miniaturized devices.Expand Specific Solutions04 Mechanical reinforcement in composite materials

Boron nitride nanosheets can significantly enhance the mechanical properties of composite materials. When incorporated into polymers, ceramics, or metals, they can improve strength, stiffness, and toughness. The nanosheets create strong interfaces with matrix materials and can effectively transfer loads, resulting in composites with superior mechanical performance for structural applications in aerospace, automotive, and construction industries.Expand Specific Solutions05 Environmental and energy applications of boron nitride nanosheets

Boron nitride nanosheets show promising potential in environmental remediation and energy storage applications. They can be used as adsorbents for pollutant removal, catalysts or catalyst supports for environmental remediation, and components in energy storage devices like supercapacitors and batteries. Their high surface area, chemical stability, and unique electronic properties make them effective for water purification, gas separation, and enhancing energy storage capacity and efficiency.Expand Specific Solutions

Key Industry Players in BN Nanosheets Market

The Boron Nitride Nanosheets (BNNS) market is currently in a growth phase, characterized by increasing research activities and emerging commercial applications. The market is expanding due to BNNS's exceptional thermal, mechanical, and electrical properties, with projections suggesting significant growth over the next decade. Technologically, the field remains in early-to-mid maturity, with academic institutions like Deakin University, Shandong University, and Northwestern University driving fundamental research, while companies such as Momentive Performance Materials, Teijin Ltd., and Li-S Energy are advancing commercial applications. Research institutes including SINANO and National Institute for Materials Science are bridging the gap between academic discoveries and industrial implementation, focusing on scalable production methods and novel applications in electronics, thermal management, and energy storage.

National Institute for Materials Science IAI

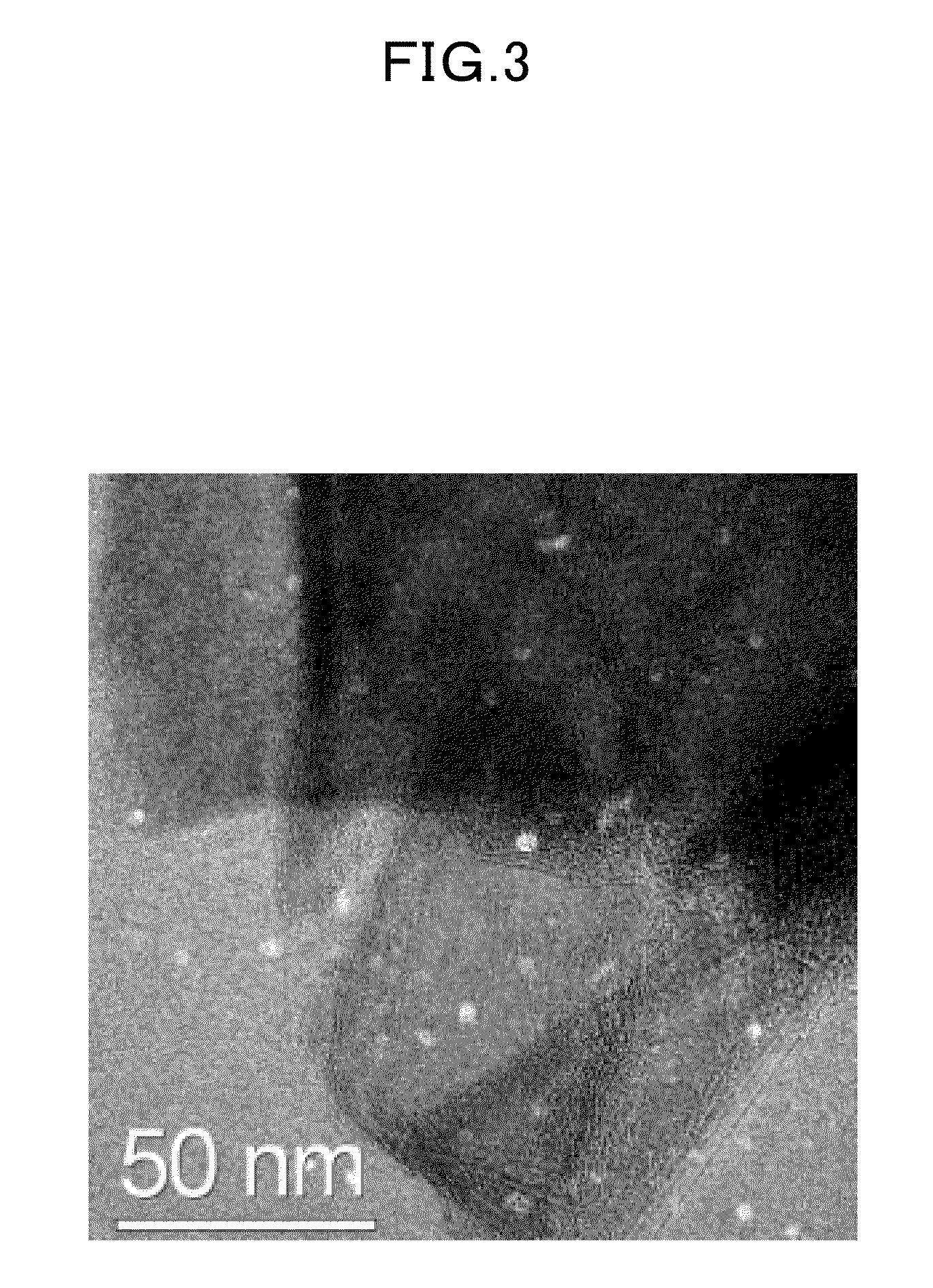

Technical Solution: The National Institute for Materials Science (NIMS) has established comprehensive research programs on boron nitride nanosheets (BNNS) with significant contributions to fundamental understanding and applications. Their advanced synthesis approaches include controlled chemical vapor deposition (CVD) methods that produce single-crystal BNNS with domain sizes exceeding 100 μm and precisely controlled layer numbers. NIMS researchers have developed innovative exfoliation techniques using ionic liquids that achieve nearly 80% yield of few-layer BNNS, substantially higher than conventional methods. Their work on BNNS functionalization has created platforms for sensing applications, including gas sensors with detection limits in the parts-per-billion range. NIMS has pioneered the integration of BNNS with other 2D materials to create heterostructures with tailored electronic and optical properties, demonstrating devices with unique functionality not achievable with single materials.

Strengths: World-class characterization facilities enable detailed material analysis; strong international collaboration network enhances research impact; comprehensive approach spanning fundamental science to applications. Weaknesses: As a research institute, faces challenges in commercial-scale production; technology transfer processes may slow market implementation; limited direct manufacturing capabilities.

Toyota Central R&D Labs, Inc.

Technical Solution: Toyota Central R&D Labs has developed an innovative approach to boron nitride nanosheet (BNNS) integration in automotive applications. Their proprietary technology focuses on BNNS-enhanced polymer composites for thermal management in electric vehicle battery systems, achieving up to 45% improvement in heat dissipation compared to conventional materials. The lab has pioneered a scalable chemical vapor deposition (CVD) process for producing large-area, uniform BNNS with controlled thickness (2-10 layers) and minimal defects. Their research has yielded BNNS-reinforced materials that maintain structural integrity at temperatures exceeding 200°C while providing electrical insulation critical for high-voltage components. Toyota's recent innovations include BNNS-based lubricant additives that reduce friction by up to 30% in engine components, contributing to improved fuel efficiency and reduced wear.

Strengths: Extensive integration with automotive applications provides clear commercialization pathways; strong financial backing enables sustained R&D investment; synergistic relationship with Toyota's manufacturing capabilities. Weaknesses: Research primarily focused on automotive applications may limit broader market exploitation; proprietary technologies may face challenges in external licensing or commercialization.

Core Patents and Technical Literature Review

Boron nitride nanosheet, method for producing boron nitride nanosheet thereof and composition containing boron nitride nanosheet thereof

PatentInactiveUS20110086965A1

Innovation

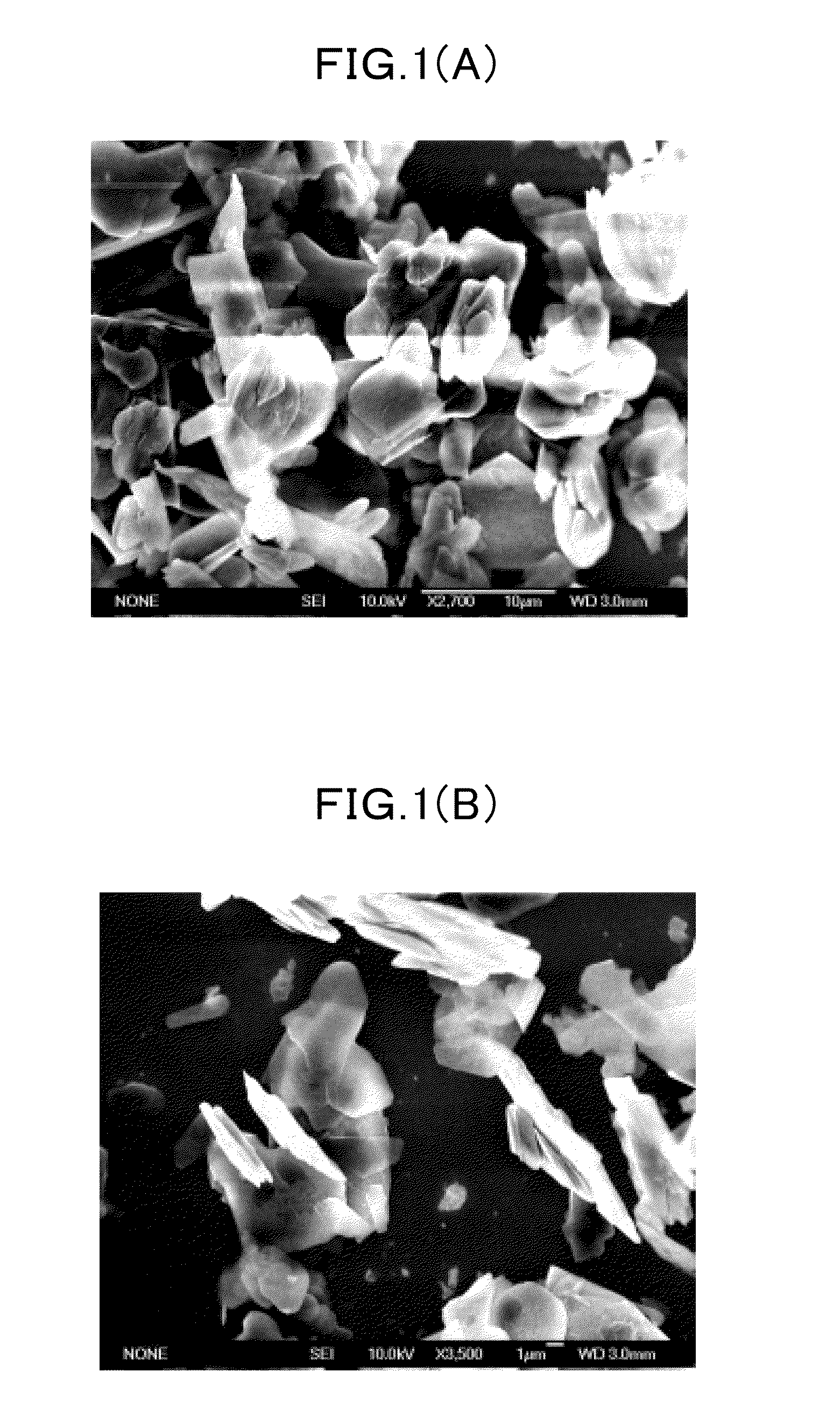

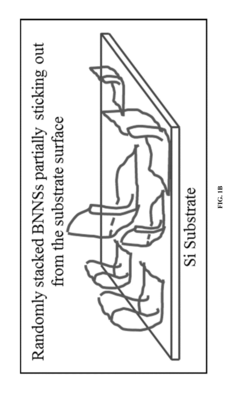

- A method involving the dispersion of hexagonal boron nitride powder in an organic solvent followed by ultrasonication to peel layers, resulting in a three-layered boron nitride nanosheet with a specific surface area significantly larger than bulk hexagonal boron nitride, which can be used as a filler to improve polymeric composite properties.

Boron nitride nanosheets and methods of making and using the same

PatentInactiveUS20160137502A1

Innovation

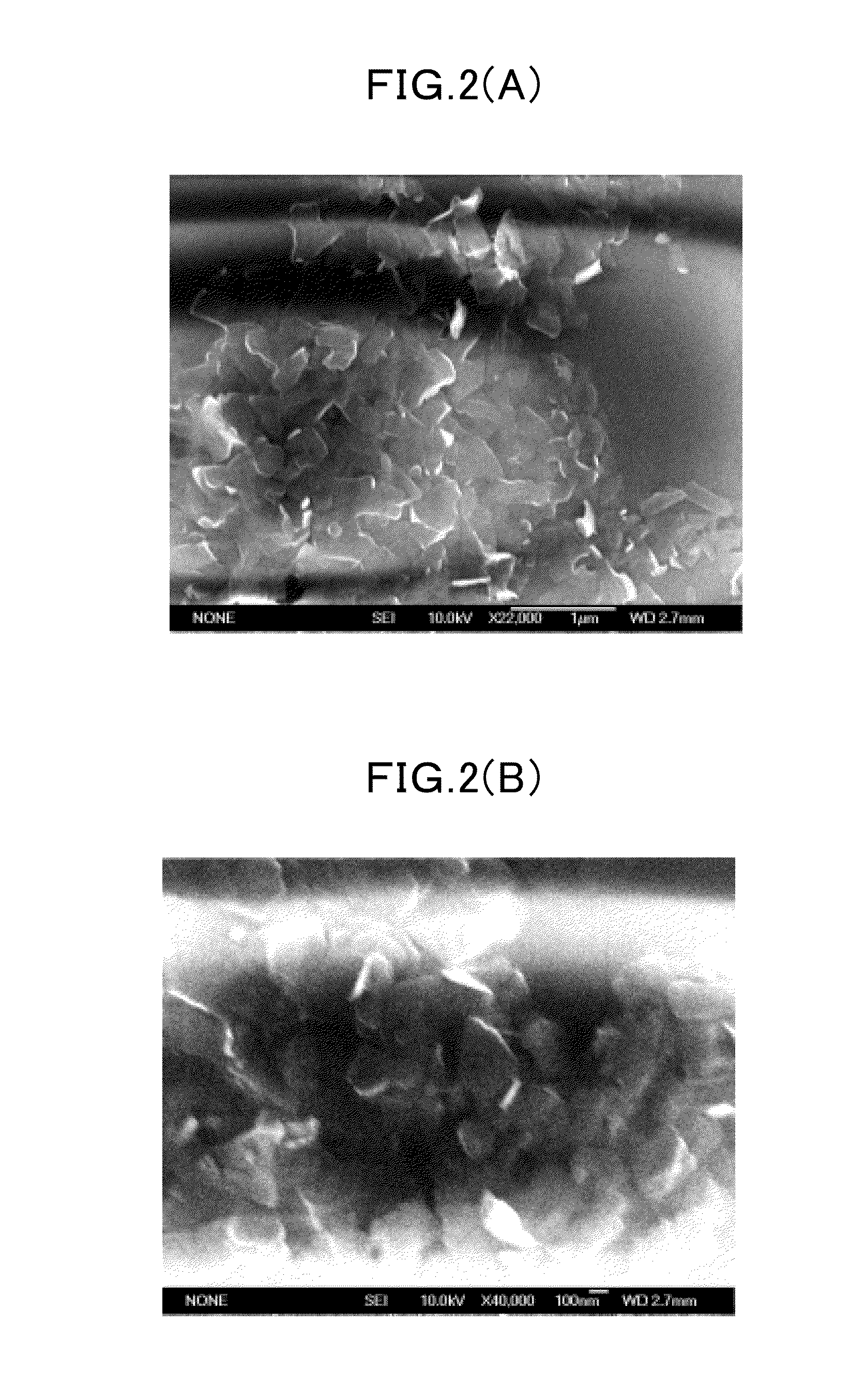

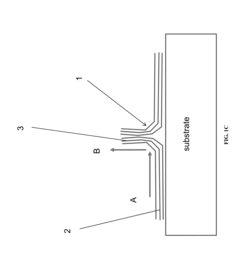

- A method for synthesizing boron nitride nanosheets with scrolled, close-ended structures using a chemical vapor deposition process involving boron, magnesium oxide, and iron oxide in a furnace with ammonia gas, which allows for better contact with hot surfaces and coolants, enabling efficient heat dissipation without being water-repelling.

Industry Standards and Certification Requirements

The standardization landscape for boron nitride nanosheets (BNNS) remains in development, with several international organizations working to establish comprehensive frameworks. The International Organization for Standardization (ISO) has implemented Technical Committee 229 specifically for nanotechnologies, which addresses terminology, measurement methodologies, and safety protocols applicable to BNNS. These standards provide crucial guidelines for manufacturers regarding particle size distribution, purity levels, and structural characterization requirements.

The American Society for Testing and Materials (ASTM) has developed the E56 committee on nanotechnology, which has published several standards relevant to BNNS production and characterization. These include protocols for surface area measurement, dispersion stability assessment, and thermal conductivity evaluation—all critical parameters for BNNS applications in thermal management systems and composite materials.

In the European Union, the European Committee for Standardization (CEN) has established Technical Committee 352 focusing on nanotechnologies, which works in coordination with ISO to harmonize standards across regions. This alignment facilitates international trade and ensures consistent quality benchmarks for BNNS products globally.

Certification requirements for BNNS vary by application sector. For electronics applications, manufacturers must often comply with IEC 62607 standards, which specify electrical characterization methods for nanomaterials. Medical applications involving BNNS require adherence to ISO 10993 series for biocompatibility assessment and FDA approval in the United States, particularly when used in drug delivery systems or biomedical devices.

Environmental and safety certifications have become increasingly stringent, with the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations in Europe requiring comprehensive safety data for nanomaterials including BNNS. Similarly, the Occupational Safety and Health Administration (OSHA) in the US has established workplace exposure limits and handling protocols for nanomaterials that apply to BNNS production facilities.

Industry-specific certifications are emerging as BNNS applications diversify. The aerospace sector, for instance, requires compliance with AS9100 quality management standards when BNNS is incorporated into composite materials for aircraft components. The semiconductor industry follows SEMI standards for materials purity and contamination control when BNNS is used in electronic applications.

Emerging certification trends include lifecycle assessment requirements and sustainability metrics, reflecting growing environmental concerns. Several certification bodies now offer "green" nanomaterial certifications that evaluate the environmental footprint of BNNS production processes, encouraging manufacturers to adopt more sustainable practices throughout the supply chain.

The American Society for Testing and Materials (ASTM) has developed the E56 committee on nanotechnology, which has published several standards relevant to BNNS production and characterization. These include protocols for surface area measurement, dispersion stability assessment, and thermal conductivity evaluation—all critical parameters for BNNS applications in thermal management systems and composite materials.

In the European Union, the European Committee for Standardization (CEN) has established Technical Committee 352 focusing on nanotechnologies, which works in coordination with ISO to harmonize standards across regions. This alignment facilitates international trade and ensures consistent quality benchmarks for BNNS products globally.

Certification requirements for BNNS vary by application sector. For electronics applications, manufacturers must often comply with IEC 62607 standards, which specify electrical characterization methods for nanomaterials. Medical applications involving BNNS require adherence to ISO 10993 series for biocompatibility assessment and FDA approval in the United States, particularly when used in drug delivery systems or biomedical devices.

Environmental and safety certifications have become increasingly stringent, with the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations in Europe requiring comprehensive safety data for nanomaterials including BNNS. Similarly, the Occupational Safety and Health Administration (OSHA) in the US has established workplace exposure limits and handling protocols for nanomaterials that apply to BNNS production facilities.

Industry-specific certifications are emerging as BNNS applications diversify. The aerospace sector, for instance, requires compliance with AS9100 quality management standards when BNNS is incorporated into composite materials for aircraft components. The semiconductor industry follows SEMI standards for materials purity and contamination control when BNNS is used in electronic applications.

Emerging certification trends include lifecycle assessment requirements and sustainability metrics, reflecting growing environmental concerns. Several certification bodies now offer "green" nanomaterial certifications that evaluate the environmental footprint of BNNS production processes, encouraging manufacturers to adopt more sustainable practices throughout the supply chain.

Environmental Impact and Sustainability Considerations

The environmental footprint of Boron Nitride Nanosheets (BNNS) production and application represents a critical consideration for industry stakeholders. Current manufacturing processes, particularly chemical vapor deposition (CVD) and liquid exfoliation methods, consume significant energy and often utilize hazardous chemicals that pose environmental risks. The high-temperature synthesis requirements for BNNS, often exceeding 900°C, contribute substantially to carbon emissions when powered by non-renewable energy sources.

Waste management challenges are emerging as BNNS production scales up commercially. The disposal of process byproducts containing boron compounds requires specialized handling to prevent soil and groundwater contamination. Additionally, the potential ecological impacts of BNNS nanoparticles released into aquatic environments remain inadequately studied, with preliminary research suggesting possible bioaccumulation in certain aquatic organisms.

Industry leaders are responding with sustainable innovations across the BNNS value chain. Companies like Saint-Gobain and 3M have implemented closed-loop manufacturing systems that recover and recycle precursor materials, reducing waste by approximately 30-40%. Green chemistry approaches utilizing bio-based precursors and environmentally benign solvents are gaining traction, with research indicating up to 60% reduction in toxic waste generation compared to conventional methods.

Life cycle assessment (LCA) studies reveal that BNNS applications in thermal management can deliver net environmental benefits despite production impacts. When used in electronic cooling solutions, BNNS materials extend device lifespans by 30-50% and reduce operational energy consumption by 15-25%, potentially offsetting initial production emissions within 1-3 years of deployment.

Regulatory frameworks governing nanomaterial environmental impacts are evolving rapidly. The EU's REACH regulations now specifically address nanomaterials including BNNS, while the US EPA has introduced voluntary reporting programs for nanomaterial producers. Industry standards organizations including ISO and ASTM have established technical committees focused on developing environmental testing protocols and safety guidelines specific to two-dimensional nanomaterials.

End-of-life considerations for BNNS-containing products present both challenges and opportunities. While separation and recovery technologies for nanomaterials in composite products remain limited, research into selective dissolution and thermal recovery methods shows promise for reclaiming up to 75% of BNNS from end-use applications, potentially creating circular economy opportunities within the advanced materials sector.

Waste management challenges are emerging as BNNS production scales up commercially. The disposal of process byproducts containing boron compounds requires specialized handling to prevent soil and groundwater contamination. Additionally, the potential ecological impacts of BNNS nanoparticles released into aquatic environments remain inadequately studied, with preliminary research suggesting possible bioaccumulation in certain aquatic organisms.

Industry leaders are responding with sustainable innovations across the BNNS value chain. Companies like Saint-Gobain and 3M have implemented closed-loop manufacturing systems that recover and recycle precursor materials, reducing waste by approximately 30-40%. Green chemistry approaches utilizing bio-based precursors and environmentally benign solvents are gaining traction, with research indicating up to 60% reduction in toxic waste generation compared to conventional methods.

Life cycle assessment (LCA) studies reveal that BNNS applications in thermal management can deliver net environmental benefits despite production impacts. When used in electronic cooling solutions, BNNS materials extend device lifespans by 30-50% and reduce operational energy consumption by 15-25%, potentially offsetting initial production emissions within 1-3 years of deployment.

Regulatory frameworks governing nanomaterial environmental impacts are evolving rapidly. The EU's REACH regulations now specifically address nanomaterials including BNNS, while the US EPA has introduced voluntary reporting programs for nanomaterial producers. Industry standards organizations including ISO and ASTM have established technical committees focused on developing environmental testing protocols and safety guidelines specific to two-dimensional nanomaterials.

End-of-life considerations for BNNS-containing products present both challenges and opportunities. While separation and recovery technologies for nanomaterials in composite products remain limited, research into selective dissolution and thermal recovery methods shows promise for reclaiming up to 75% of BNNS from end-use applications, potentially creating circular economy opportunities within the advanced materials sector.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!