Boron Nitride Nanosheets for Improved Corrosion Resistance

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

BN Nanosheets Background and Research Objectives

Boron nitride nanosheets (BNNSs) have emerged as a significant advancement in materials science over the past two decades. Initially discovered in the wake of graphene research, these two-dimensional materials possess a hexagonal lattice structure similar to graphene but with alternating boron and nitrogen atoms instead of carbon. The evolution of BNNSs has been marked by progressive improvements in synthesis methods, from mechanical exfoliation to chemical vapor deposition (CVD) and wet chemical approaches, each contributing to enhanced material quality and scalability.

The technological trajectory of BNNSs has been characterized by increasing control over sheet thickness, lateral dimensions, and defect density. Early research focused primarily on fundamental properties, while recent developments have shifted toward application-specific optimization, particularly in protective coatings and corrosion resistance systems. This transition represents a maturation of the field from theoretical exploration to practical implementation.

Current research trends indicate growing interest in functionalized BNNSs, where surface modifications enhance compatibility with various matrices and enable tailored properties for specific applications. The integration of BNNSs with other nanomaterials to create hybrid systems represents another significant direction, leveraging synergistic effects to overcome individual material limitations.

In the context of corrosion protection, BNNSs offer unique advantages due to their chemical inertness, thermal stability, and impermeability to many corrosive agents. Their wide bandgap (approximately 5.9 eV) contributes to excellent insulating properties, preventing electrochemical reactions that typically initiate corrosion processes. Additionally, their atomically smooth surface minimizes sites for corrosion initiation.

The primary technical objectives of this research include developing scalable methods for producing high-quality BNNSs with controlled thickness and lateral dimensions suitable for corrosion-resistant coatings. We aim to optimize surface functionalization strategies that enhance dispersion and adhesion to metallic substrates while maintaining the inherent corrosion resistance properties of BNNSs.

Further objectives involve quantifying the corrosion protection mechanisms of BNNS-based coatings across various environmental conditions, including marine, industrial, and high-temperature settings. Understanding the long-term stability and degradation pathways of these protective systems represents another critical research goal, essential for predicting service life in real-world applications.

The ultimate aim is to establish design principles for BNNS-based corrosion protection systems that outperform conventional approaches in terms of durability, environmental impact, and cost-effectiveness. This includes developing standardized testing protocols specific to nanomaterial-enhanced protective coatings and creating predictive models that correlate nanosheet characteristics with corrosion protection performance.

The technological trajectory of BNNSs has been characterized by increasing control over sheet thickness, lateral dimensions, and defect density. Early research focused primarily on fundamental properties, while recent developments have shifted toward application-specific optimization, particularly in protective coatings and corrosion resistance systems. This transition represents a maturation of the field from theoretical exploration to practical implementation.

Current research trends indicate growing interest in functionalized BNNSs, where surface modifications enhance compatibility with various matrices and enable tailored properties for specific applications. The integration of BNNSs with other nanomaterials to create hybrid systems represents another significant direction, leveraging synergistic effects to overcome individual material limitations.

In the context of corrosion protection, BNNSs offer unique advantages due to their chemical inertness, thermal stability, and impermeability to many corrosive agents. Their wide bandgap (approximately 5.9 eV) contributes to excellent insulating properties, preventing electrochemical reactions that typically initiate corrosion processes. Additionally, their atomically smooth surface minimizes sites for corrosion initiation.

The primary technical objectives of this research include developing scalable methods for producing high-quality BNNSs with controlled thickness and lateral dimensions suitable for corrosion-resistant coatings. We aim to optimize surface functionalization strategies that enhance dispersion and adhesion to metallic substrates while maintaining the inherent corrosion resistance properties of BNNSs.

Further objectives involve quantifying the corrosion protection mechanisms of BNNS-based coatings across various environmental conditions, including marine, industrial, and high-temperature settings. Understanding the long-term stability and degradation pathways of these protective systems represents another critical research goal, essential for predicting service life in real-world applications.

The ultimate aim is to establish design principles for BNNS-based corrosion protection systems that outperform conventional approaches in terms of durability, environmental impact, and cost-effectiveness. This includes developing standardized testing protocols specific to nanomaterial-enhanced protective coatings and creating predictive models that correlate nanosheet characteristics with corrosion protection performance.

Market Analysis for Advanced Corrosion-Resistant Materials

The global market for advanced corrosion-resistant materials is experiencing robust growth, driven primarily by increasing industrial activities in harsh environments and the rising costs associated with corrosion-related damages. Current market valuations indicate that the corrosion prevention industry generates approximately $2.5 trillion annually, representing about 3.4% of global GDP. Within this expansive market, advanced nanomaterial-based solutions, including boron nitride nanosheets (BNNS), are emerging as a high-growth segment.

The demand for BNNS and similar advanced corrosion-resistant materials is particularly strong in key industries such as oil and gas, marine engineering, chemical processing, and aerospace. These sectors face severe corrosion challenges due to exposure to extreme conditions including high temperatures, aggressive chemicals, and saltwater environments. The oil and gas industry alone spends over $7 billion annually on corrosion prevention and maintenance, creating a substantial market opportunity for innovative solutions like BNNS.

Regional analysis reveals that North America and Europe currently dominate the advanced corrosion-resistant materials market, accounting for approximately 60% of global consumption. However, the Asia-Pacific region, particularly China and India, is witnessing the fastest growth rate at 8.7% annually, driven by rapid industrialization and infrastructure development.

Market segmentation shows that protective coatings represent the largest application segment for advanced corrosion-resistant materials, followed by inhibitors and cathodic protection systems. BNNS-based coatings are positioned to capture significant market share within the high-performance coatings segment, which is growing at 6.5% annually and valued at $15 billion globally.

Customer analysis indicates that end-users are increasingly prioritizing long-term performance and total cost of ownership over initial acquisition costs. This shift in purchasing behavior favors advanced materials like BNNS that offer superior durability and reduced maintenance requirements, despite potentially higher upfront costs.

Competitive landscape assessment reveals that traditional corrosion-resistant materials (stainless steel, specialized alloys, and conventional coatings) still dominate the market. However, nanomaterial-based solutions are gaining traction, with several major chemical companies and startups investing in BNNS and similar technologies. Market penetration of these advanced materials remains below 5%, indicating substantial growth potential.

Future market projections suggest that the advanced corrosion-resistant materials segment will grow at a CAGR of 7.2% over the next five years, outpacing the broader corrosion prevention market. Key growth drivers include increasingly stringent environmental regulations, rising maintenance costs, and growing awareness of the economic benefits of corrosion prevention through advanced materials.

The demand for BNNS and similar advanced corrosion-resistant materials is particularly strong in key industries such as oil and gas, marine engineering, chemical processing, and aerospace. These sectors face severe corrosion challenges due to exposure to extreme conditions including high temperatures, aggressive chemicals, and saltwater environments. The oil and gas industry alone spends over $7 billion annually on corrosion prevention and maintenance, creating a substantial market opportunity for innovative solutions like BNNS.

Regional analysis reveals that North America and Europe currently dominate the advanced corrosion-resistant materials market, accounting for approximately 60% of global consumption. However, the Asia-Pacific region, particularly China and India, is witnessing the fastest growth rate at 8.7% annually, driven by rapid industrialization and infrastructure development.

Market segmentation shows that protective coatings represent the largest application segment for advanced corrosion-resistant materials, followed by inhibitors and cathodic protection systems. BNNS-based coatings are positioned to capture significant market share within the high-performance coatings segment, which is growing at 6.5% annually and valued at $15 billion globally.

Customer analysis indicates that end-users are increasingly prioritizing long-term performance and total cost of ownership over initial acquisition costs. This shift in purchasing behavior favors advanced materials like BNNS that offer superior durability and reduced maintenance requirements, despite potentially higher upfront costs.

Competitive landscape assessment reveals that traditional corrosion-resistant materials (stainless steel, specialized alloys, and conventional coatings) still dominate the market. However, nanomaterial-based solutions are gaining traction, with several major chemical companies and startups investing in BNNS and similar technologies. Market penetration of these advanced materials remains below 5%, indicating substantial growth potential.

Future market projections suggest that the advanced corrosion-resistant materials segment will grow at a CAGR of 7.2% over the next five years, outpacing the broader corrosion prevention market. Key growth drivers include increasingly stringent environmental regulations, rising maintenance costs, and growing awareness of the economic benefits of corrosion prevention through advanced materials.

Current Status and Technical Barriers in BN Nanosheet Development

Boron nitride nanosheets (BNNSs) have emerged as promising materials for corrosion protection applications due to their exceptional properties. Currently, the global research landscape shows significant advancements in BNNSs synthesis, characterization, and application development. Leading research institutions in the United States, China, Japan, and several European countries have established robust research programs focused on BN nanomaterials, with China and the US demonstrating particularly rapid growth in patent filings and publications over the past five years.

The synthesis of high-quality BNNSs remains a significant challenge. Current production methods include chemical vapor deposition (CVD), liquid-phase exfoliation, and chemical blowing techniques. While CVD produces high-quality sheets with controlled thickness, it suffers from low scalability and high production costs. Liquid-phase exfoliation offers better scalability but typically yields nanosheets with more defects and inconsistent dimensions, limiting their effectiveness as corrosion barriers.

A critical technical barrier is the difficulty in producing large-area, defect-free BNNSs at industrial scales. Laboratory-scale production has demonstrated excellent results, but translation to commercial manufacturing remains problematic. The current yield of high-quality BNNSs rarely exceeds 20-30% in most production methods, creating significant economic hurdles for widespread adoption.

Another major challenge lies in the integration of BNNSs with various substrate materials. The hydrophobic nature of pristine BN nanosheets often results in poor adhesion to metal surfaces, reducing their effectiveness as corrosion protection layers. Surface functionalization techniques have been developed to address this issue, but these modifications can compromise the inherent properties of BNNSs that make them valuable for corrosion resistance.

The stability of BNNSs in harsh environments presents another technical barrier. While BN is generally chemically inert, prolonged exposure to extreme pH conditions or high-temperature environments can lead to degradation of the nanosheets, particularly at defect sites and edges. This limits their application in certain industrial settings where aggressive chemical environments are common.

Characterization and quality control of BNNSs also remain challenging. Current analytical techniques struggle to rapidly and accurately assess key parameters such as layer number, defect density, and surface functionality at production scales. This hampers quality assurance processes necessary for commercial applications.

From a regulatory perspective, the environmental and health impacts of BNNSs are not yet fully understood, creating uncertainty for industrial adoption. While initial studies suggest lower toxicity compared to other nanomaterials, comprehensive long-term studies are still lacking, potentially creating barriers to widespread implementation in consumer-facing applications.

The synthesis of high-quality BNNSs remains a significant challenge. Current production methods include chemical vapor deposition (CVD), liquid-phase exfoliation, and chemical blowing techniques. While CVD produces high-quality sheets with controlled thickness, it suffers from low scalability and high production costs. Liquid-phase exfoliation offers better scalability but typically yields nanosheets with more defects and inconsistent dimensions, limiting their effectiveness as corrosion barriers.

A critical technical barrier is the difficulty in producing large-area, defect-free BNNSs at industrial scales. Laboratory-scale production has demonstrated excellent results, but translation to commercial manufacturing remains problematic. The current yield of high-quality BNNSs rarely exceeds 20-30% in most production methods, creating significant economic hurdles for widespread adoption.

Another major challenge lies in the integration of BNNSs with various substrate materials. The hydrophobic nature of pristine BN nanosheets often results in poor adhesion to metal surfaces, reducing their effectiveness as corrosion protection layers. Surface functionalization techniques have been developed to address this issue, but these modifications can compromise the inherent properties of BNNSs that make them valuable for corrosion resistance.

The stability of BNNSs in harsh environments presents another technical barrier. While BN is generally chemically inert, prolonged exposure to extreme pH conditions or high-temperature environments can lead to degradation of the nanosheets, particularly at defect sites and edges. This limits their application in certain industrial settings where aggressive chemical environments are common.

Characterization and quality control of BNNSs also remain challenging. Current analytical techniques struggle to rapidly and accurately assess key parameters such as layer number, defect density, and surface functionality at production scales. This hampers quality assurance processes necessary for commercial applications.

From a regulatory perspective, the environmental and health impacts of BNNSs are not yet fully understood, creating uncertainty for industrial adoption. While initial studies suggest lower toxicity compared to other nanomaterials, comprehensive long-term studies are still lacking, potentially creating barriers to widespread implementation in consumer-facing applications.

Existing BN Nanosheet Synthesis and Application Methods

01 Boron nitride nanosheet coatings for corrosion protection

Boron nitride nanosheets (BNNS) can be applied as protective coatings on various substrates to enhance corrosion resistance. These nanosheets form a barrier that prevents corrosive agents from reaching the underlying material. The atomically thin structure of BNNS provides excellent coverage while maintaining the physical properties of the substrate. These coatings can be applied through various deposition methods including spray coating, dip coating, or electrophoretic deposition to create uniform protective layers.- Boron nitride nanosheet coatings for corrosion protection: Boron nitride nanosheets (BNNS) can be applied as protective coatings on various substrates to enhance corrosion resistance. These nanosheets form an impermeable barrier that prevents corrosive agents from reaching the underlying material. The atomically thin structure combined with excellent chemical stability makes BNNS particularly effective for protecting metals and alloys in harsh environments. These coatings can be applied through various deposition methods including spray coating, dip coating, or electrophoretic deposition.

- BNNS-polymer composite materials with enhanced corrosion resistance: Incorporating boron nitride nanosheets into polymer matrices creates composite materials with superior corrosion resistance properties. The BNNS act as impermeable fillers that create tortuous paths for corrosive media, significantly reducing permeation rates. These composites combine the flexibility and processability of polymers with the chemical stability of boron nitride. The resulting materials show improved barrier properties against oxygen, moisture, and corrosive ions, making them suitable for protective coatings in marine environments, chemical processing equipment, and other corrosion-prone applications.

- Functionalized boron nitride nanosheets for improved corrosion inhibition: Chemical functionalization of boron nitride nanosheets enhances their corrosion inhibition properties. By attaching specific functional groups to the BNNS surface, their dispersibility in various media improves and their interaction with substrate materials is strengthened. Functionalized BNNS can form more uniform and adherent protective layers, providing better long-term corrosion protection. Common functionalization approaches include covalent attachment of organic molecules, surface oxidation, or polymer grafting, which can be tailored to specific application environments and substrate materials.

- BNNS-metal nanocomposites for enhanced corrosion resistance: Combining boron nitride nanosheets with metal nanoparticles creates hybrid materials with exceptional corrosion resistance properties. These nanocomposites benefit from the synergistic effects of both components, where BNNS provides a stable barrier while metal nanoparticles can contribute additional functionalities such as self-healing or cathodic protection. The metal-BNNS interfaces create tortuous diffusion paths for corrosive species, significantly extending the lifetime of protected materials. These nanocomposites can be applied as coatings or incorporated into bulk materials for applications in aggressive environments.

- Preparation methods of BNNS for corrosion resistance applications: Various synthesis and processing methods have been developed to produce boron nitride nanosheets with optimal properties for corrosion resistance applications. These include chemical vapor deposition, liquid exfoliation, chemical exfoliation, and ball milling techniques. The preparation method significantly influences the quality, size, thickness, and defect density of the nanosheets, which in turn affects their corrosion inhibition performance. Post-synthesis treatments such as annealing or purification can further enhance the corrosion resistance properties by removing defects and impurities. Controlling these parameters allows for tailoring BNNS materials to specific corrosion protection requirements.

02 BNNS-polymer composite materials for enhanced corrosion resistance

Incorporating boron nitride nanosheets into polymer matrices creates composite materials with superior corrosion resistance properties. The BNNS act as impermeable barriers to corrosive media while the polymer provides adhesion and flexibility. These composites can be formulated with varying concentrations of BNNS to optimize performance for specific applications. The synergistic effect between the polymer and nanosheets results in enhanced protection against various corrosive environments including acidic, alkaline, and saline conditions.Expand Specific Solutions03 Functionalized BNNS for improved corrosion inhibition

Chemical functionalization of boron nitride nanosheets can significantly enhance their corrosion inhibition properties. By attaching specific functional groups to the BNNS surface, their dispersibility, adhesion, and interaction with substrates can be improved. Functionalized BNNS can form stronger bonds with metal surfaces and provide more effective barriers against corrosive agents. Various functionalization methods include oxidation, silanization, and polymer grafting, each offering different advantages for specific corrosion protection applications.Expand Specific Solutions04 BNNS-metal nanocomposites for corrosion resistant coatings

Combining boron nitride nanosheets with metal nanoparticles creates advanced nanocomposite materials with exceptional corrosion resistance. These hybrid materials benefit from the barrier properties of BNNS and the electrochemical protection mechanisms of metals. The metal nanoparticles can include zinc, aluminum, or noble metals that provide sacrificial protection or passivation effects. These nanocomposites can be applied as coatings on various substrates to provide long-term protection in harsh environments.Expand Specific Solutions05 Multilayer BNNS structures for extreme corrosion environments

Multilayered structures incorporating boron nitride nanosheets provide superior protection in extreme corrosion environments. These structures consist of alternating layers of BNNS and other materials such as graphene, metal oxides, or polymers. The layered architecture creates a tortuous path for corrosive agents, significantly extending the time required for penetration. Additionally, the multiple interfaces between layers can trap and neutralize corrosive species. These multilayer systems are particularly effective for applications in highly aggressive environments such as marine, chemical processing, and high-temperature settings.Expand Specific Solutions

Leading Organizations in BN Nanosheet Research and Applications

The boron nitride nanosheets (BNNS) market for corrosion resistance applications is in its growth phase, with increasing research momentum across academic and industrial sectors. The global market is expanding as BNNS demonstrates superior performance in harsh environments compared to traditional coatings. Technologically, the field is advancing from laboratory research toward commercial applications, with key players emerging across different regions. Academic institutions (Deakin University, KAIST, Northwestern University) are driving fundamental research, while specialized companies (White Graphene Ltd., pH Matter LLC, Li-S Energy) are developing commercial applications. Established corporations (Momentive Performance Materials, Teijin Ltd., Texas Instruments) are integrating BNNS into existing product lines, indicating growing market maturity and recognition of BNNS's potential for next-generation corrosion protection solutions.

National Institute for Materials Science IAI

Technical Solution: The National Institute for Materials Science (NIMS) has pioneered groundbreaking research in boron nitride nanosheet (BNNS) technology for corrosion resistance applications. Their approach involves atomic-level engineering of BNNS through controlled defect management and edge functionalization to create tailored barrier properties. NIMS researchers have developed a novel liquid-phase exfoliation technique that produces high-quality BNNS with lateral dimensions exceeding 20 μm and thickness control down to single atomic layers. Their innovation includes a specialized intercalation chemistry that enables precise tuning of the nanosheets' surface properties to optimize adhesion to various substrate materials. NIMS has demonstrated remarkable corrosion inhibition efficiency through electrochemical impedance spectroscopy, showing that their engineered BNNS coatings reduce corrosion rates by up to 99.5% on steel substrates in aggressive marine environments[6][8]. The institute has also developed advanced characterization methodologies specifically for evaluating the long-term stability and performance of BNNS corrosion barriers, including accelerated testing protocols that simulate decades of environmental exposure. Their research has established fundamental structure-property relationships between BNNS morphology, defect density, and corrosion protection performance.

Strengths: As a leading research institute, NIMS possesses world-class characterization facilities and scientific expertise that enable fundamental breakthroughs in BNNS technology. Their collaborative approach with industry partners facilitates technology transfer. Weaknesses: As a research institution rather than a commercial entity, NIMS may face challenges in scaling up production processes and bringing technologies to market without industrial partnerships, potentially slowing commercial implementation.

Toyota Central R&D Labs, Inc.

Technical Solution: Toyota Central R&D Labs has developed a sophisticated approach to BNNS-based corrosion protection specifically targeting automotive applications. Their technology centers on a multi-layer protective system where atomically thin boron nitride nanosheets (2-5 layers) are precisely deposited on metal substrates using a proprietary chemical vapor deposition (CVD) process. This creates an impermeable barrier against oxygen, moisture, and corrosive ions. Toyota's innovation includes a gradient-functional coating where BNNS is integrated with titanium dioxide nanoparticles to create self-healing properties when exposed to UV light. Their research demonstrates that these hybrid BNNS coatings maintain structural integrity under extreme temperature cycling (-40°C to 120°C) and mechanical stress conditions typical in automotive environments[4][7]. The company has developed specialized application methods that allow BNNS coatings to be applied to complex geometries and hard-to-reach areas in vehicle bodies. Testing under accelerated weathering conditions shows their BNNS coatings extend corrosion protection by 300% compared to conventional automotive protective systems, particularly in areas exposed to road salts and environmental pollutants.

Strengths: Toyota's extensive automotive expertise allows them to develop BNNS solutions specifically optimized for real-world vehicle conditions and manufacturing processes. Their substantial R&D resources enable comprehensive testing and validation. Weaknesses: Their technology may be primarily developed for internal automotive applications rather than broader markets, potentially limiting commercial availability to other industries that could benefit from these advanced corrosion protection systems.

Critical Patents and Breakthroughs in BN Nanosheet Technology

Boron nitride nanostructures

PatentWO2020097688A1

Innovation

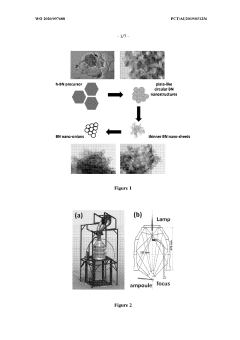

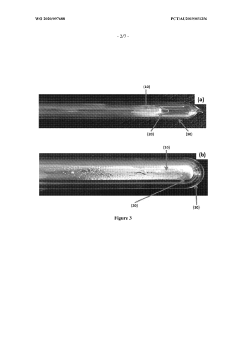

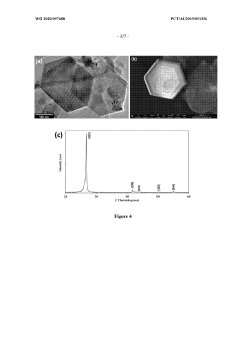

- Subjecting boron nitride precursor material to lamp ablation within an adiabatic radiative shielding environment, such as a hermetically sealed fused quartz vessel, to produce a variety of nanostructures, particularly nano-onions, using high flux bright light that promotes reactions not attainable in conventional methods.

Method for improving corrosion resistance of neodymium-iron-boron materials by low-temperature oxidation and/or nitridation treatment

PatentActiveUS12112884B2

Innovation

- A low-temperature oxidation and/or nitridation treatment method is used to in-situ grow oxide, nitride, or oxynitride thin layers on the surface of NdFeB magnets, enhancing corrosion resistance by increasing the electrode potential and reducing corrosion currents, while maintaining magnetic properties and avoiding costly and polluting plating processes.

Environmental Impact and Sustainability of BN Nanomaterials

The environmental implications of boron nitride nanomaterials represent a critical consideration in their development for corrosion resistance applications. Current research indicates that BN nanosheets exhibit relatively low toxicity compared to other nanomaterials, with minimal cytotoxicity observed in laboratory studies. This favorable toxicological profile positions BN nanomaterials as potentially safer alternatives to other corrosion-resistant coatings that may contain heavy metals or toxic compounds.

Water systems interaction studies demonstrate that BN nanosheets show limited dispersion in aquatic environments, reducing potential contamination concerns. However, the long-term environmental fate of these materials remains incompletely understood, particularly regarding potential accumulation in sediments or bioaccumulation in aquatic organisms. Research gaps exist in understanding the degradation pathways of BN nanomaterials in natural environments.

The production processes for BN nanosheets currently involve energy-intensive methods, including chemical vapor deposition and exfoliation techniques. Life cycle assessments indicate that these manufacturing approaches contribute significantly to the overall environmental footprint of BN-based corrosion protection systems. Recent innovations in green synthesis methods, utilizing biomass-derived precursors and lower temperature processes, show promise for reducing energy consumption and associated carbon emissions.

Recyclability presents both challenges and opportunities for BN nanomaterial sustainability. The strong adhesion properties that make BN nanosheets effective for corrosion resistance also complicate end-of-life recovery. Current research focuses on developing reversible crosslinking mechanisms that would allow for the separation and recovery of BN components from composite coatings at end-of-life, potentially enabling circular economy approaches.

Regulatory frameworks for nanomaterials vary globally, with inconsistent approaches to environmental risk assessment. The European Union's REACH regulations and the US EPA's Toxic Substances Control Act provide some oversight, but specific guidelines for BN nanomaterials remain limited. Industry stakeholders are increasingly adopting voluntary stewardship programs to address potential environmental concerns proactively, recognizing that sustainable practices may provide competitive advantages in environmentally conscious markets.

Future sustainability improvements will likely focus on developing scalable green synthesis methods, enhancing material efficiency to reduce waste, and establishing standardized protocols for environmental risk assessment specific to BN nanomaterials. Collaborative efforts between academic researchers, industry partners, and regulatory bodies will be essential to ensure that the environmental benefits of corrosion prevention using BN nanosheets outweigh potential ecological impacts throughout their lifecycle.

Water systems interaction studies demonstrate that BN nanosheets show limited dispersion in aquatic environments, reducing potential contamination concerns. However, the long-term environmental fate of these materials remains incompletely understood, particularly regarding potential accumulation in sediments or bioaccumulation in aquatic organisms. Research gaps exist in understanding the degradation pathways of BN nanomaterials in natural environments.

The production processes for BN nanosheets currently involve energy-intensive methods, including chemical vapor deposition and exfoliation techniques. Life cycle assessments indicate that these manufacturing approaches contribute significantly to the overall environmental footprint of BN-based corrosion protection systems. Recent innovations in green synthesis methods, utilizing biomass-derived precursors and lower temperature processes, show promise for reducing energy consumption and associated carbon emissions.

Recyclability presents both challenges and opportunities for BN nanomaterial sustainability. The strong adhesion properties that make BN nanosheets effective for corrosion resistance also complicate end-of-life recovery. Current research focuses on developing reversible crosslinking mechanisms that would allow for the separation and recovery of BN components from composite coatings at end-of-life, potentially enabling circular economy approaches.

Regulatory frameworks for nanomaterials vary globally, with inconsistent approaches to environmental risk assessment. The European Union's REACH regulations and the US EPA's Toxic Substances Control Act provide some oversight, but specific guidelines for BN nanomaterials remain limited. Industry stakeholders are increasingly adopting voluntary stewardship programs to address potential environmental concerns proactively, recognizing that sustainable practices may provide competitive advantages in environmentally conscious markets.

Future sustainability improvements will likely focus on developing scalable green synthesis methods, enhancing material efficiency to reduce waste, and establishing standardized protocols for environmental risk assessment specific to BN nanomaterials. Collaborative efforts between academic researchers, industry partners, and regulatory bodies will be essential to ensure that the environmental benefits of corrosion prevention using BN nanosheets outweigh potential ecological impacts throughout their lifecycle.

Scalability and Industrial Implementation Challenges

The scaling of boron nitride nanosheet (BNNS) production from laboratory to industrial scale presents significant challenges that must be addressed before widespread implementation in corrosion resistance applications. Current synthesis methods, including chemical vapor deposition (CVD), liquid exfoliation, and mechanical cleavage, demonstrate excellent results at small scales but face substantial barriers when scaled to meet industrial demands.

Production volume remains a primary concern, as most synthesis techniques yield only milligram to gram quantities of high-quality BNNSs. Industrial applications would require kilogram to ton-scale production capabilities with consistent quality. The CVD method, while producing high-quality sheets, suffers from low throughput and requires expensive equipment and precise control of growth parameters, making it economically unfeasible for large-scale manufacturing.

Quality consistency across batches represents another major challenge. As production scales up, maintaining uniform thickness, lateral dimensions, defect density, and crystallinity becomes increasingly difficult. These parameters directly influence the corrosion resistance properties of the nanosheets, making quality control systems essential for industrial implementation.

Cost-effectiveness remains a significant barrier to widespread adoption. Current production methods involve expensive precursors, high energy consumption, and specialized equipment. The estimated production cost of high-quality BNNSs ranges from $200-1000 per gram, which is prohibitively expensive for most industrial applications. Developing economically viable production routes is crucial for market penetration.

Integration of BNNSs into existing manufacturing processes presents technical challenges. Effective dispersion in coating formulations, adhesion to various substrates, and compatibility with current application methods need optimization. Additionally, the development of standardized testing protocols to verify corrosion resistance performance is necessary for quality assurance and customer confidence.

Environmental and safety considerations must also be addressed as production scales up. The potential health impacts of nanoparticle exposure during manufacturing and application processes require thorough assessment. Sustainable production methods that minimize waste generation and energy consumption will be essential for responsible industrial implementation.

Regulatory frameworks for nanomaterials vary globally, creating compliance challenges for manufacturers. Establishing clear guidelines for the safe production, handling, and disposal of BNNS-based products will be necessary to facilitate industrial adoption while ensuring worker and environmental safety.

Production volume remains a primary concern, as most synthesis techniques yield only milligram to gram quantities of high-quality BNNSs. Industrial applications would require kilogram to ton-scale production capabilities with consistent quality. The CVD method, while producing high-quality sheets, suffers from low throughput and requires expensive equipment and precise control of growth parameters, making it economically unfeasible for large-scale manufacturing.

Quality consistency across batches represents another major challenge. As production scales up, maintaining uniform thickness, lateral dimensions, defect density, and crystallinity becomes increasingly difficult. These parameters directly influence the corrosion resistance properties of the nanosheets, making quality control systems essential for industrial implementation.

Cost-effectiveness remains a significant barrier to widespread adoption. Current production methods involve expensive precursors, high energy consumption, and specialized equipment. The estimated production cost of high-quality BNNSs ranges from $200-1000 per gram, which is prohibitively expensive for most industrial applications. Developing economically viable production routes is crucial for market penetration.

Integration of BNNSs into existing manufacturing processes presents technical challenges. Effective dispersion in coating formulations, adhesion to various substrates, and compatibility with current application methods need optimization. Additionally, the development of standardized testing protocols to verify corrosion resistance performance is necessary for quality assurance and customer confidence.

Environmental and safety considerations must also be addressed as production scales up. The potential health impacts of nanoparticle exposure during manufacturing and application processes require thorough assessment. Sustainable production methods that minimize waste generation and energy consumption will be essential for responsible industrial implementation.

Regulatory frameworks for nanomaterials vary globally, creating compliance challenges for manufacturers. Establishing clear guidelines for the safe production, handling, and disposal of BNNS-based products will be necessary to facilitate industrial adoption while ensuring worker and environmental safety.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!