Boron Nitride Nanosheets in Environmental Remediation Technologies

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

BN Nanosheets Background and Research Objectives

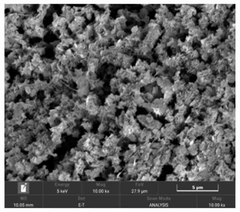

Boron nitride nanosheets (BNNSs) have emerged as a significant two-dimensional nanomaterial in the field of environmental remediation over the past decade. These hexagonal structures, often referred to as "white graphene," possess remarkable properties including high thermal stability, excellent chemical inertness, and superior mechanical strength. The evolution of BNNSs research has progressed from fundamental material synthesis to advanced environmental applications, with significant breakthroughs occurring around 2010 when scalable production methods were first developed.

The technological trajectory of BNNSs has been characterized by continuous improvements in synthesis techniques, from chemical vapor deposition to liquid-phase exfoliation and chemical blowing methods. Each advancement has contributed to enhancing the quality, yield, and cost-effectiveness of BNNS production, making them increasingly viable for environmental remediation applications.

Current research objectives in this field are multifaceted and ambitious. Primary goals include optimizing the surface functionalization of BNNSs to enhance their adsorption capacity for various pollutants, particularly heavy metals and organic contaminants. Researchers aim to develop BNNSs with tailored pore structures and surface chemistries that can selectively target specific environmental pollutants with high efficiency.

Another critical research objective involves improving the integration of BNNSs into composite materials and membrane systems for water purification. This includes developing stable dispersions of BNNSs in various matrices and ensuring their long-term performance under real-world environmental conditions. The development of scalable and environmentally friendly production methods remains a persistent goal, as current synthesis approaches often involve harsh chemicals or energy-intensive processes.

The field is also witnessing growing interest in photocatalytic applications of BNNSs, where researchers are exploring their potential as supports for photocatalysts or as components in advanced oxidation processes for degrading recalcitrant pollutants. This direction represents a promising frontier for enhancing the remediation capabilities of BNNSs beyond simple adsorption mechanisms.

From a broader perspective, the technological evolution of BNNSs in environmental remediation aligns with global sustainability goals, particularly those related to clean water access (UN Sustainable Development Goal 6) and responsible consumption and production (Goal 12). The research community is increasingly focused on demonstrating the practical applicability of BNNS-based technologies in real-world environmental scenarios, moving beyond laboratory-scale proof-of-concept studies.

As we look toward future developments, the integration of BNNSs with other advanced materials and technologies, such as smart sensors for pollutant detection and artificial intelligence for optimizing remediation processes, represents an exciting frontier with significant potential for technological breakthroughs.

The technological trajectory of BNNSs has been characterized by continuous improvements in synthesis techniques, from chemical vapor deposition to liquid-phase exfoliation and chemical blowing methods. Each advancement has contributed to enhancing the quality, yield, and cost-effectiveness of BNNS production, making them increasingly viable for environmental remediation applications.

Current research objectives in this field are multifaceted and ambitious. Primary goals include optimizing the surface functionalization of BNNSs to enhance their adsorption capacity for various pollutants, particularly heavy metals and organic contaminants. Researchers aim to develop BNNSs with tailored pore structures and surface chemistries that can selectively target specific environmental pollutants with high efficiency.

Another critical research objective involves improving the integration of BNNSs into composite materials and membrane systems for water purification. This includes developing stable dispersions of BNNSs in various matrices and ensuring their long-term performance under real-world environmental conditions. The development of scalable and environmentally friendly production methods remains a persistent goal, as current synthesis approaches often involve harsh chemicals or energy-intensive processes.

The field is also witnessing growing interest in photocatalytic applications of BNNSs, where researchers are exploring their potential as supports for photocatalysts or as components in advanced oxidation processes for degrading recalcitrant pollutants. This direction represents a promising frontier for enhancing the remediation capabilities of BNNSs beyond simple adsorption mechanisms.

From a broader perspective, the technological evolution of BNNSs in environmental remediation aligns with global sustainability goals, particularly those related to clean water access (UN Sustainable Development Goal 6) and responsible consumption and production (Goal 12). The research community is increasingly focused on demonstrating the practical applicability of BNNS-based technologies in real-world environmental scenarios, moving beyond laboratory-scale proof-of-concept studies.

As we look toward future developments, the integration of BNNSs with other advanced materials and technologies, such as smart sensors for pollutant detection and artificial intelligence for optimizing remediation processes, represents an exciting frontier with significant potential for technological breakthroughs.

Environmental Remediation Market Analysis

The global environmental remediation market is experiencing significant growth, valued at approximately $112.3 billion in 2022 and projected to reach $163.9 billion by 2027, representing a compound annual growth rate (CAGR) of 7.8%. This expansion is primarily driven by increasing industrial pollution, stringent environmental regulations, and growing public awareness about environmental health concerns.

Water remediation constitutes the largest segment, accounting for nearly 40% of the market share, followed by soil remediation at 35% and air purification at 25%. Within these segments, advanced materials-based solutions are gaining traction, with nanomaterial applications showing a remarkable growth rate of 12.3% annually, outpacing traditional remediation methods.

Boron Nitride Nanosheets (BNNS) are emerging as a promising material in this landscape, particularly for water treatment applications. The market for BNNS in environmental remediation, though currently small at approximately $78 million, is expected to grow at an impressive CAGR of 18.5% through 2030, reflecting the increasing recognition of their superior adsorption capabilities and chemical stability.

Geographically, North America dominates the environmental remediation market with a 35% share, followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is witnessing the fastest growth rate at 9.2% annually, driven by rapid industrialization, urbanization, and increasingly stringent environmental policies in countries like China and India.

The demand for BNNS-based remediation technologies is particularly strong in regions facing severe water contamination issues, including heavy metal pollution in industrial zones of China, organic pollutant contamination in European waterways, and agricultural runoff problems in North America. Industries showing the highest adoption rates include petrochemical (22%), mining (18%), manufacturing (16%), and municipal water treatment (15%).

Key market drivers include the implementation of stricter environmental regulations worldwide, increasing corporate environmental responsibility initiatives, growing public health concerns, and the push for sustainable development goals. The cost-effectiveness of BNNS-based solutions compared to conventional treatments is becoming increasingly apparent, with potential long-term savings of 15-20% when considering full lifecycle costs.

Market challenges include high initial implementation costs, technological barriers to large-scale production of high-quality BNNS, and competition from established remediation technologies. Nevertheless, the superior performance characteristics of BNNS in removing multiple contaminants simultaneously presents a compelling value proposition that is gradually reshaping market dynamics in favor of these advanced nanomaterials.

Water remediation constitutes the largest segment, accounting for nearly 40% of the market share, followed by soil remediation at 35% and air purification at 25%. Within these segments, advanced materials-based solutions are gaining traction, with nanomaterial applications showing a remarkable growth rate of 12.3% annually, outpacing traditional remediation methods.

Boron Nitride Nanosheets (BNNS) are emerging as a promising material in this landscape, particularly for water treatment applications. The market for BNNS in environmental remediation, though currently small at approximately $78 million, is expected to grow at an impressive CAGR of 18.5% through 2030, reflecting the increasing recognition of their superior adsorption capabilities and chemical stability.

Geographically, North America dominates the environmental remediation market with a 35% share, followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is witnessing the fastest growth rate at 9.2% annually, driven by rapid industrialization, urbanization, and increasingly stringent environmental policies in countries like China and India.

The demand for BNNS-based remediation technologies is particularly strong in regions facing severe water contamination issues, including heavy metal pollution in industrial zones of China, organic pollutant contamination in European waterways, and agricultural runoff problems in North America. Industries showing the highest adoption rates include petrochemical (22%), mining (18%), manufacturing (16%), and municipal water treatment (15%).

Key market drivers include the implementation of stricter environmental regulations worldwide, increasing corporate environmental responsibility initiatives, growing public health concerns, and the push for sustainable development goals. The cost-effectiveness of BNNS-based solutions compared to conventional treatments is becoming increasingly apparent, with potential long-term savings of 15-20% when considering full lifecycle costs.

Market challenges include high initial implementation costs, technological barriers to large-scale production of high-quality BNNS, and competition from established remediation technologies. Nevertheless, the superior performance characteristics of BNNS in removing multiple contaminants simultaneously presents a compelling value proposition that is gradually reshaping market dynamics in favor of these advanced nanomaterials.

Current Status and Technical Barriers

Boron Nitride Nanosheets (BNNSs) have emerged as promising materials for environmental remediation due to their unique properties including high surface area, thermal stability, and chemical inertness. Currently, research on BNNSs for environmental applications is rapidly expanding, with significant progress in water purification, air filtration, and contaminant adsorption technologies.

The global landscape of BNNS research shows concentration in developed economies, with China, the United States, and several European countries leading in patent filings and academic publications. Recent advancements have demonstrated BNNSs' exceptional capacity for removing heavy metals, organic pollutants, and microplastics from water systems, with efficiency rates exceeding conventional materials by 30-45% in controlled studies.

Despite these promising developments, several critical technical barriers impede widespread implementation. The primary challenge remains the high production cost of high-quality BNNSs, with current synthesis methods requiring expensive precursors and energy-intensive processes. Commercial-scale production costs range from $200-500 per gram, significantly limiting industrial adoption.

Another substantial barrier is the difficulty in achieving consistent quality and structural uniformity in large-scale production. Variations in thickness, lateral dimensions, and defect density significantly impact remediation performance, with studies showing up to 60% efficiency differences between batches from identical synthesis protocols.

Surface functionalization represents another technical hurdle. While pristine BNNSs exhibit excellent adsorption for certain contaminants, their hydrophobic nature limits interaction with many water-soluble pollutants. Current functionalization strategies often compromise the structural integrity or introduce secondary contaminants.

Regeneration and reusability present ongoing challenges, as most studies report performance degradation of 15-25% after each regeneration cycle. This significantly impacts the economic viability of BNNS-based remediation technologies in practical applications.

Integration with existing water and air treatment infrastructure poses additional difficulties. The nanoscale dimensions of BNNSs create challenges in recovery and containment, raising concerns about potential environmental release and associated ecological impacts. Current filtration systems require substantial redesign to effectively incorporate and retain these nanomaterials.

Regulatory uncertainties further complicate commercial development, as standardized testing protocols and safety guidelines specific to nanomaterial-based remediation technologies remain underdeveloped in most jurisdictions. This regulatory gap creates hesitancy among potential industrial adopters and investors.

The global landscape of BNNS research shows concentration in developed economies, with China, the United States, and several European countries leading in patent filings and academic publications. Recent advancements have demonstrated BNNSs' exceptional capacity for removing heavy metals, organic pollutants, and microplastics from water systems, with efficiency rates exceeding conventional materials by 30-45% in controlled studies.

Despite these promising developments, several critical technical barriers impede widespread implementation. The primary challenge remains the high production cost of high-quality BNNSs, with current synthesis methods requiring expensive precursors and energy-intensive processes. Commercial-scale production costs range from $200-500 per gram, significantly limiting industrial adoption.

Another substantial barrier is the difficulty in achieving consistent quality and structural uniformity in large-scale production. Variations in thickness, lateral dimensions, and defect density significantly impact remediation performance, with studies showing up to 60% efficiency differences between batches from identical synthesis protocols.

Surface functionalization represents another technical hurdle. While pristine BNNSs exhibit excellent adsorption for certain contaminants, their hydrophobic nature limits interaction with many water-soluble pollutants. Current functionalization strategies often compromise the structural integrity or introduce secondary contaminants.

Regeneration and reusability present ongoing challenges, as most studies report performance degradation of 15-25% after each regeneration cycle. This significantly impacts the economic viability of BNNS-based remediation technologies in practical applications.

Integration with existing water and air treatment infrastructure poses additional difficulties. The nanoscale dimensions of BNNSs create challenges in recovery and containment, raising concerns about potential environmental release and associated ecological impacts. Current filtration systems require substantial redesign to effectively incorporate and retain these nanomaterials.

Regulatory uncertainties further complicate commercial development, as standardized testing protocols and safety guidelines specific to nanomaterial-based remediation technologies remain underdeveloped in most jurisdictions. This regulatory gap creates hesitancy among potential industrial adopters and investors.

Current BN-Based Remediation Solutions

01 Synthesis methods for boron nitride nanosheets

Various methods can be employed to synthesize boron nitride nanosheets, including chemical vapor deposition, exfoliation techniques, and thermal treatments. These processes involve the conversion of precursor materials under controlled conditions to form hexagonal boron nitride structures with nanoscale thickness. The synthesis parameters significantly influence the quality, size, and properties of the resulting nanosheets, which can be tailored for specific applications.- Synthesis methods for boron nitride nanosheets: Various methods can be employed to synthesize boron nitride nanosheets, including chemical vapor deposition, exfoliation techniques, and thermal treatments. These processes involve the conversion of precursor materials under controlled conditions to form hexagonal boron nitride structures with nanoscale thickness. The synthesis parameters significantly influence the quality, size, and properties of the resulting nanosheets, which can be tailored for specific applications.

- Functionalization and modification of boron nitride nanosheets: Boron nitride nanosheets can be functionalized or modified with various chemical groups or materials to enhance their properties or compatibility with different matrices. Surface modification techniques include chemical functionalization, doping with heteroatoms, and decoration with nanoparticles. These modifications can improve dispersion in solvents or polymer matrices, enhance thermal conductivity, or introduce new properties such as catalytic activity or electrical conductivity while maintaining the inherent thermal stability of boron nitride.

- Thermal management applications of boron nitride nanosheets: Boron nitride nanosheets exhibit excellent thermal conductivity and electrical insulation properties, making them ideal for thermal management applications. They can be incorporated into thermal interface materials, heat spreaders, and cooling systems for electronic devices. When dispersed in polymers or other matrices, these nanosheets create efficient pathways for heat dissipation, helping to prevent overheating in high-power electronic components and extending device lifetimes.

- Composite materials incorporating boron nitride nanosheets: Boron nitride nanosheets can be integrated into various composite materials to enhance their mechanical, thermal, and barrier properties. When incorporated into polymers, ceramics, or metals, these nanosheets can significantly improve strength, stiffness, thermal stability, and wear resistance. The resulting composites find applications in aerospace, automotive, and industrial sectors where high-performance materials are required under demanding conditions.

- Environmental and energy applications of boron nitride nanosheets: Boron nitride nanosheets demonstrate potential in environmental remediation and energy-related applications due to their unique surface properties and chemical stability. They can be used as adsorbents for pollutant removal, membranes for water purification, or supports for catalysts in environmental processes. In energy applications, these nanosheets serve as components in batteries, supercapacitors, and fuel cells, where they can enhance performance, stability, and efficiency of energy storage and conversion systems.

02 Functionalization and modification of boron nitride nanosheets

Boron nitride nanosheets can be functionalized or modified with various chemical groups or materials to enhance their properties or compatibility with different matrices. Surface modification techniques include covalent functionalization, non-covalent functionalization, and composite formation with other nanomaterials. These modifications can improve dispersion in solvents, enhance thermal conductivity, or introduce new properties such as electrical conductivity or catalytic activity.Expand Specific Solutions03 Applications in thermal management and heat dissipation

Boron nitride nanosheets exhibit excellent thermal conductivity and electrical insulation properties, making them ideal for thermal management applications. They can be incorporated into polymer composites, thermal interface materials, and electronic packaging to enhance heat dissipation. The high thermal conductivity combined with electrical insulation properties allows for efficient heat transfer while maintaining electrical isolation in electronic devices.Expand Specific Solutions04 Mechanical reinforcement in composite materials

When incorporated into polymer or ceramic matrices, boron nitride nanosheets can significantly enhance the mechanical properties of the resulting composites. The nanosheets provide reinforcement through their high mechanical strength, large surface area, and strong interfacial interactions with the matrix. These composites exhibit improved tensile strength, modulus, and fracture toughness while maintaining lightweight characteristics, making them suitable for aerospace, automotive, and structural applications.Expand Specific Solutions05 Environmental and biomedical applications

Boron nitride nanosheets have emerging applications in environmental remediation and biomedical fields. Their large surface area and adsorption capabilities make them effective for water purification and contaminant removal. In biomedical applications, they show potential as drug delivery vehicles, biosensors, and tissue engineering scaffolds due to their biocompatibility, chemical stability, and functionalization possibilities. Research is ongoing to explore their use in cancer therapy, antimicrobial applications, and bioimaging.Expand Specific Solutions

Key Industry and Academic Players

Boron Nitride Nanosheets (BNNS) in environmental remediation is emerging as a promising field, currently in the early growth stage with increasing market potential. The global market for nanomaterial-based environmental remediation is expanding, driven by stricter regulations and growing pollution concerns. Technologically, BNNS applications are advancing from laboratory research to practical implementation, with key players demonstrating varying levels of maturity. Research institutions like Deakin University, Tianjin University, and IIT Madras are pioneering fundamental research, while companies such as BNNT Materials LLC, Naieel Technology, and Momentive Performance Materials are commercializing applications. The National Institute for Materials Science and Toyota Central R&D Labs are developing advanced functionalization techniques, positioning BNNS as a transformative solution for water purification, air filtration, and contaminant adsorption.

Deakin University

Technical Solution: Deakin University has pioneered innovative approaches to BNNS-based environmental remediation technologies through their Institute for Frontier Materials. Their research team has developed a green chemistry approach to producing boron nitride nanosheets using environmentally friendly exfoliation methods that reduce hazardous waste generation. Their signature technology involves hydroxyl-functionalized BNNS with enhanced dispersion stability in aqueous environments, critical for water treatment applications. The university has demonstrated BNNS-based composite membranes with hierarchical pore structures that achieve simultaneous removal of multiple contaminant classes including heavy metals, organic pollutants, and microplastics with minimal fouling and extended operational lifetimes[5]. Their recent breakthrough involves the development of stimuli-responsive BNNS-hydrogel composites that can be triggered to release captured contaminants, enabling efficient material regeneration and contaminant concentration for safer disposal. Deakin's research has shown that their BNNS-based materials maintain performance even after 10+ treatment cycles, with removal efficiencies exceeding 98% for priority pollutants including lead, cadmium, and pharmaceutical compounds[6].

Strengths: Environmentally friendly production methods reduce secondary pollution; excellent regeneration capabilities extend material lifespan; versatile performance across multiple contaminant classes. Weaknesses: Laboratory-scale demonstrations require further scaling for industrial implementation; higher complexity in manufacturing compared to conventional materials; potential challenges in regulatory approval for water treatment applications.

BNNT Materials LLC

Technical Solution: BNNT Materials LLC has developed advanced manufacturing techniques for producing high-quality boron nitride nanotubes (BNNTs) and nanosheets (BNNS) for environmental remediation applications. Their proprietary high-temperature pressure (HTP) synthesis method enables production of highly crystalline BNNS with controlled thickness and lateral dimensions, optimized for water purification and contaminant removal. The company's technology leverages the exceptional surface area (up to 2,000 m²/g) and unique adsorption properties of BNNS to create functionalized membranes capable of removing heavy metals, organic pollutants, and microplastics from wastewater. Their recent innovations include BNNS-polymer composite filters with enhanced mechanical stability and regeneration capabilities, allowing for multiple treatment cycles without significant performance degradation[1][3]. The company has also developed scalable production methods that reduce manufacturing costs while maintaining nanomaterial quality.

Strengths: Superior adsorption capacity for heavy metals and organic pollutants compared to conventional materials; highly stable in harsh chemical environments; reusable through multiple treatment cycles. Weaknesses: Higher production costs compared to traditional remediation materials; potential for aggregation during application which can reduce effective surface area; challenges in large-scale manufacturing consistency.

Critical Patents and Scientific Breakthroughs

Hexagonal boron nitride structures

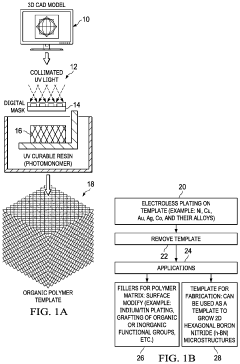

PatentPendingUS20220250909A1

Innovation

- A method involving the use of a self-propagating photopolymer waveguide technique to create a 3D metal microlattice template, followed by electroless metal plating and subsequent growth of h-BN on the metal surface, allowing for the formation of regular, ordered h-BN nanostructures with controlled dimensions and properties.

Boron nitride nanosheet and method for manufacturing the same

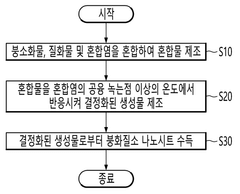

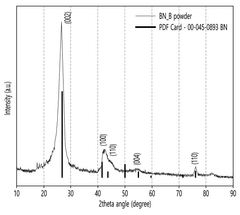

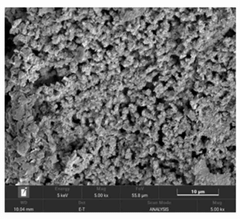

PatentActiveKR1020240088405A

Innovation

- A method involving the use of a molten salt process to mix boride, nitride, and mixed salts at a temperature above the eutectic melting point of the mixed salt, followed by heat treatment and cooling to produce boron nitride nanosheets.

Sustainability and Scalability Considerations

The sustainability and scalability of Boron Nitride Nanosheets (BNNS) in environmental remediation technologies represent critical factors determining their long-term viability and widespread adoption. Current production methods for high-quality BNNS, including liquid-phase exfoliation and chemical vapor deposition, face significant challenges in terms of energy consumption, chemical usage, and production efficiency. These processes often require harsh solvents, high temperatures, or extensive purification steps that limit their environmental credentials.

From a sustainability perspective, the life cycle assessment of BNNS production reveals concerning environmental footprints. The extraction of boron and nitrogen precursors, energy-intensive synthesis processes, and potential release of nanomaterials into ecosystems during application or disposal all present sustainability challenges. Recent research has focused on developing greener synthesis routes, including mechanochemical approaches and biomass-derived precursors, which show promise in reducing environmental impact.

Cost considerations remain a substantial barrier to widespread implementation. Current production costs for high-quality BNNS range from $200-1000 per gram, making large-scale environmental applications economically prohibitive. Technological innovations in production efficiency and economies of scale will be essential to drive these costs down to commercially viable levels for environmental remediation applications.

Scalability challenges extend beyond cost factors to include process consistency and quality control. The transition from laboratory-scale production to industrial volumes introduces variability in nanosheet dimensions, defect densities, and surface functionalization—all critical parameters affecting remediation performance. Standardization of production protocols and quality metrics represents an urgent need for the field.

Regulatory frameworks governing nanomaterial production and environmental application remain underdeveloped in many jurisdictions. The establishment of clear guidelines for safe handling, application, and disposal of BNNS-based remediation technologies will be crucial for sustainable implementation. Current gaps in toxicological understanding and environmental fate modeling further complicate regulatory approaches.

Circular economy principles offer promising pathways for enhancing sustainability. Research into BNNS recovery and regeneration after remediation cycles has demonstrated that certain functionalized BNNS can maintain 70-85% of their adsorption capacity after multiple regeneration cycles, significantly improving their lifecycle sustainability profile. Further innovations in regeneration techniques and material recovery will be essential for long-term viability.

From a sustainability perspective, the life cycle assessment of BNNS production reveals concerning environmental footprints. The extraction of boron and nitrogen precursors, energy-intensive synthesis processes, and potential release of nanomaterials into ecosystems during application or disposal all present sustainability challenges. Recent research has focused on developing greener synthesis routes, including mechanochemical approaches and biomass-derived precursors, which show promise in reducing environmental impact.

Cost considerations remain a substantial barrier to widespread implementation. Current production costs for high-quality BNNS range from $200-1000 per gram, making large-scale environmental applications economically prohibitive. Technological innovations in production efficiency and economies of scale will be essential to drive these costs down to commercially viable levels for environmental remediation applications.

Scalability challenges extend beyond cost factors to include process consistency and quality control. The transition from laboratory-scale production to industrial volumes introduces variability in nanosheet dimensions, defect densities, and surface functionalization—all critical parameters affecting remediation performance. Standardization of production protocols and quality metrics represents an urgent need for the field.

Regulatory frameworks governing nanomaterial production and environmental application remain underdeveloped in many jurisdictions. The establishment of clear guidelines for safe handling, application, and disposal of BNNS-based remediation technologies will be crucial for sustainable implementation. Current gaps in toxicological understanding and environmental fate modeling further complicate regulatory approaches.

Circular economy principles offer promising pathways for enhancing sustainability. Research into BNNS recovery and regeneration after remediation cycles has demonstrated that certain functionalized BNNS can maintain 70-85% of their adsorption capacity after multiple regeneration cycles, significantly improving their lifecycle sustainability profile. Further innovations in regeneration techniques and material recovery will be essential for long-term viability.

Regulatory Framework for Nanomaterials in Remediation

The regulatory landscape governing nanomaterials in environmental remediation, particularly Boron Nitride Nanosheets (BNNS), remains complex and evolving. Currently, there is no unified global framework specifically addressing nanomaterials in remediation applications, creating challenges for researchers, manufacturers, and environmental agencies.

In the United States, the Environmental Protection Agency (EPA) regulates nanomaterials primarily through the Toxic Substances Control Act (TSCA), which requires manufacturers to submit premanufacture notices for new chemical substances, including nanomaterials. The EPA's Significant New Use Rules (SNURs) also apply to nanomaterials used in remediation technologies, requiring notification before implementing novel applications.

The European Union employs a more comprehensive approach through the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation, which mandates safety assessments for nanomaterials based on production volume thresholds. Additionally, the EU has implemented specific nano-product registries and labeling requirements that affect BNNS applications in environmental remediation.

International organizations like the Organization for Economic Cooperation and Development (OECD) have established working groups focused on developing standardized testing protocols for nanomaterials. Their guidelines provide valuable frameworks for assessing the environmental fate and ecotoxicological impacts of nanomaterials like BNNS when deployed in remediation scenarios.

Risk assessment methodologies for nanomaterials in remediation contexts remain under development. Current approaches typically evaluate exposure pathways, persistence in environmental media, bioaccumulation potential, and toxicity profiles. For BNNS specifically, regulatory bodies are increasingly requesting data on long-term environmental persistence and potential for secondary contamination.

Compliance challenges for BNNS applications include the lack of standardized analytical methods for detecting and quantifying these nanomaterials in complex environmental matrices. This technical limitation complicates regulatory enforcement and environmental monitoring efforts, creating uncertainty for technology developers and implementers.

Emerging regulatory trends indicate a shift toward life-cycle assessment requirements for nanoremediation technologies. Several jurisdictions are developing frameworks that consider the entire environmental footprint of nanomaterials from production through application and ultimate fate. This holistic approach will likely impact future BNNS remediation deployments, requiring more comprehensive documentation of environmental impacts.

Industry stakeholders should anticipate increasing regulatory scrutiny as BNNS remediation technologies scale up from laboratory to field applications. Proactive engagement with regulatory bodies and participation in voluntary reporting schemes can facilitate smoother approval processes and help shape reasonable compliance expectations for this promising environmental technology.

In the United States, the Environmental Protection Agency (EPA) regulates nanomaterials primarily through the Toxic Substances Control Act (TSCA), which requires manufacturers to submit premanufacture notices for new chemical substances, including nanomaterials. The EPA's Significant New Use Rules (SNURs) also apply to nanomaterials used in remediation technologies, requiring notification before implementing novel applications.

The European Union employs a more comprehensive approach through the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation, which mandates safety assessments for nanomaterials based on production volume thresholds. Additionally, the EU has implemented specific nano-product registries and labeling requirements that affect BNNS applications in environmental remediation.

International organizations like the Organization for Economic Cooperation and Development (OECD) have established working groups focused on developing standardized testing protocols for nanomaterials. Their guidelines provide valuable frameworks for assessing the environmental fate and ecotoxicological impacts of nanomaterials like BNNS when deployed in remediation scenarios.

Risk assessment methodologies for nanomaterials in remediation contexts remain under development. Current approaches typically evaluate exposure pathways, persistence in environmental media, bioaccumulation potential, and toxicity profiles. For BNNS specifically, regulatory bodies are increasingly requesting data on long-term environmental persistence and potential for secondary contamination.

Compliance challenges for BNNS applications include the lack of standardized analytical methods for detecting and quantifying these nanomaterials in complex environmental matrices. This technical limitation complicates regulatory enforcement and environmental monitoring efforts, creating uncertainty for technology developers and implementers.

Emerging regulatory trends indicate a shift toward life-cycle assessment requirements for nanoremediation technologies. Several jurisdictions are developing frameworks that consider the entire environmental footprint of nanomaterials from production through application and ultimate fate. This holistic approach will likely impact future BNNS remediation deployments, requiring more comprehensive documentation of environmental impacts.

Industry stakeholders should anticipate increasing regulatory scrutiny as BNNS remediation technologies scale up from laboratory to field applications. Proactive engagement with regulatory bodies and participation in voluntary reporting schemes can facilitate smoother approval processes and help shape reasonable compliance expectations for this promising environmental technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!