The Patent Contributions to Boron Nitride Nanosheets in Aerospace

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

BN Nanosheets in Aerospace: Background and Objectives

Boron Nitride Nanosheets (BNNS) represent a revolutionary class of two-dimensional nanomaterials that have gained significant attention in aerospace applications over the past decade. The unique hexagonal structure of BNNS, similar to graphene but composed of alternating boron and nitrogen atoms, provides exceptional thermal stability, mechanical strength, and chemical resistance properties that are particularly valuable in extreme aerospace environments.

The evolution of BNNS technology can be traced back to the early 2000s when researchers first successfully isolated single-layer BN sheets. However, it was not until the 2010s that significant breakthroughs in synthesis methods enabled the production of high-quality BNNS at scales relevant for aerospace applications. The technology has since progressed from laboratory curiosity to a material with genuine industrial potential.

Current technological trends indicate a growing focus on developing scalable manufacturing processes for BNNS and enhancing their integration capabilities with traditional aerospace materials. Patent activities have shown a consistent upward trajectory, with particular acceleration in the past five years, signaling increasing industrial interest and investment in this technology domain.

The primary technical objectives for BNNS in aerospace applications center around several key areas. First, enhancing the thermal management capabilities of aerospace components, where BNNS's exceptional thermal conductivity (up to 2000 W/mK) and stability at high temperatures (exceeding 900°C in air) offer significant advantages over conventional materials. Second, improving the mechanical properties of composite structures through BNNS reinforcement, potentially increasing strength-to-weight ratios critical for aerospace design.

Additionally, researchers aim to leverage BNNS's excellent dielectric properties for electromagnetic interference shielding in sensitive avionics systems, addressing a growing concern as electronic components become more densely packed in modern aircraft. The radiation resistance properties of BNNS also present opportunities for developing protective materials for space applications, where exposure to cosmic radiation poses significant challenges.

Patent contributions in this field have been instrumental in advancing these objectives, with innovations spanning synthesis methods, functionalization techniques, and composite integration approaches. The intellectual property landscape reveals a strategic focus on overcoming key technical barriers, particularly in areas of dispersion, interfacial adhesion, and scalable production.

Looking forward, the technology roadmap for BNNS in aerospace applications aims to achieve full industrial implementation by 2030, with intermediate milestones focused on standardization of material specifications, qualification testing protocols, and demonstration in non-critical aerospace components by 2025.

The evolution of BNNS technology can be traced back to the early 2000s when researchers first successfully isolated single-layer BN sheets. However, it was not until the 2010s that significant breakthroughs in synthesis methods enabled the production of high-quality BNNS at scales relevant for aerospace applications. The technology has since progressed from laboratory curiosity to a material with genuine industrial potential.

Current technological trends indicate a growing focus on developing scalable manufacturing processes for BNNS and enhancing their integration capabilities with traditional aerospace materials. Patent activities have shown a consistent upward trajectory, with particular acceleration in the past five years, signaling increasing industrial interest and investment in this technology domain.

The primary technical objectives for BNNS in aerospace applications center around several key areas. First, enhancing the thermal management capabilities of aerospace components, where BNNS's exceptional thermal conductivity (up to 2000 W/mK) and stability at high temperatures (exceeding 900°C in air) offer significant advantages over conventional materials. Second, improving the mechanical properties of composite structures through BNNS reinforcement, potentially increasing strength-to-weight ratios critical for aerospace design.

Additionally, researchers aim to leverage BNNS's excellent dielectric properties for electromagnetic interference shielding in sensitive avionics systems, addressing a growing concern as electronic components become more densely packed in modern aircraft. The radiation resistance properties of BNNS also present opportunities for developing protective materials for space applications, where exposure to cosmic radiation poses significant challenges.

Patent contributions in this field have been instrumental in advancing these objectives, with innovations spanning synthesis methods, functionalization techniques, and composite integration approaches. The intellectual property landscape reveals a strategic focus on overcoming key technical barriers, particularly in areas of dispersion, interfacial adhesion, and scalable production.

Looking forward, the technology roadmap for BNNS in aerospace applications aims to achieve full industrial implementation by 2030, with intermediate milestones focused on standardization of material specifications, qualification testing protocols, and demonstration in non-critical aerospace components by 2025.

Market Demand Analysis for Aerospace-Grade BN Nanomaterials

The aerospace industry is experiencing a significant shift towards advanced materials that can withstand extreme conditions while offering superior performance characteristics. Boron Nitride Nanosheets (BNNS) have emerged as a promising material in this sector, with market demand showing robust growth trajectories. Current market analysis indicates that the global aerospace composites market, where BNNS applications are positioned, is valued at approximately $29.5 billion, with projections suggesting growth to reach $42.8 billion by 2027.

The demand for aerospace-grade BN nanomaterials is primarily driven by the industry's push for lighter, stronger, and more heat-resistant components. Aircraft manufacturers are under increasing pressure to improve fuel efficiency, with each kilogram of weight reduction translating to substantial fuel savings over an aircraft's operational lifetime. BNNS offers weight reduction potential of up to 20% compared to traditional materials while maintaining or improving mechanical properties.

Thermal management represents another critical demand factor. Modern aerospace systems generate significant heat that must be efficiently dissipated to prevent component failure. BNNS exhibits exceptional thermal conductivity (up to 2000 W/mK) while maintaining electrical insulation properties, making it ideal for thermal interface materials in avionics and propulsion systems. Market research indicates that thermal management applications alone could represent a $3.2 billion opportunity for BN nanomaterials by 2025.

The defense aerospace sector demonstrates particularly strong demand signals, with military aircraft requiring materials capable of withstanding more extreme conditions than commercial counterparts. This segment is expected to grow at 7.8% CAGR through 2028, outpacing the overall aerospace materials market growth rate of 6.2%.

Regional analysis reveals that North America currently dominates demand for aerospace-grade BN nanomaterials, accounting for 42% of the global market, followed by Europe (28%) and Asia-Pacific (23%). However, the fastest growth is projected in the Asia-Pacific region, particularly in China and India, where aerospace manufacturing capabilities are rapidly expanding.

Supply chain considerations are increasingly influencing market dynamics. The strategic importance of advanced materials has prompted concerns about supply security, with aerospace manufacturers seeking diversified supply sources for critical materials like BNNS. This trend is accelerating research into scalable, cost-effective production methods, which patent analysis indicates is a primary focus area for industrial R&D.

Customer requirements are evolving toward more specialized performance characteristics, with aerospace OEMs seeking customized BN nanomaterial formulations for specific applications. This trend is driving the development of application-specific grades of BNNS with tailored properties, creating new market niches and opportunities for material suppliers with advanced technical capabilities.

The demand for aerospace-grade BN nanomaterials is primarily driven by the industry's push for lighter, stronger, and more heat-resistant components. Aircraft manufacturers are under increasing pressure to improve fuel efficiency, with each kilogram of weight reduction translating to substantial fuel savings over an aircraft's operational lifetime. BNNS offers weight reduction potential of up to 20% compared to traditional materials while maintaining or improving mechanical properties.

Thermal management represents another critical demand factor. Modern aerospace systems generate significant heat that must be efficiently dissipated to prevent component failure. BNNS exhibits exceptional thermal conductivity (up to 2000 W/mK) while maintaining electrical insulation properties, making it ideal for thermal interface materials in avionics and propulsion systems. Market research indicates that thermal management applications alone could represent a $3.2 billion opportunity for BN nanomaterials by 2025.

The defense aerospace sector demonstrates particularly strong demand signals, with military aircraft requiring materials capable of withstanding more extreme conditions than commercial counterparts. This segment is expected to grow at 7.8% CAGR through 2028, outpacing the overall aerospace materials market growth rate of 6.2%.

Regional analysis reveals that North America currently dominates demand for aerospace-grade BN nanomaterials, accounting for 42% of the global market, followed by Europe (28%) and Asia-Pacific (23%). However, the fastest growth is projected in the Asia-Pacific region, particularly in China and India, where aerospace manufacturing capabilities are rapidly expanding.

Supply chain considerations are increasingly influencing market dynamics. The strategic importance of advanced materials has prompted concerns about supply security, with aerospace manufacturers seeking diversified supply sources for critical materials like BNNS. This trend is accelerating research into scalable, cost-effective production methods, which patent analysis indicates is a primary focus area for industrial R&D.

Customer requirements are evolving toward more specialized performance characteristics, with aerospace OEMs seeking customized BN nanomaterial formulations for specific applications. This trend is driving the development of application-specific grades of BNNS with tailored properties, creating new market niches and opportunities for material suppliers with advanced technical capabilities.

Current Status and Challenges in BN Nanosheet Technology

The global landscape of boron nitride nanosheet (BNNS) technology has witnessed significant advancements in recent years, with research institutions and companies across North America, Europe, and Asia making substantial contributions. Currently, the synthesis of high-quality BNNS with controlled thickness, size, and defect density remains a primary challenge. Various production methods have been developed, including mechanical exfoliation, chemical vapor deposition (CVD), and liquid-phase exfoliation, each with distinct advantages and limitations for aerospace applications.

The mechanical exfoliation technique, while producing high-quality nanosheets, suffers from low yield and scalability issues that hinder industrial implementation. CVD methods offer better control over nanosheet morphology but require high temperatures (typically 900-1100°C) and specialized equipment, increasing production costs and limiting large-scale manufacturing. Liquid-phase exfoliation presents a more scalable alternative but often results in smaller flake sizes and higher defect concentrations that compromise performance in demanding aerospace environments.

A significant technical barrier in BNNS development is the trade-off between production scalability and material quality. High-performance aerospace applications demand defect-free, large-area nanosheets with consistent properties, yet current mass production techniques struggle to meet these stringent requirements simultaneously. This quality-quantity dilemma represents a critical bottleneck in the technology's maturation for aerospace implementation.

Surface functionalization of BNNS presents another technical challenge. While modification is essential for improving compatibility with aerospace composite matrices, controlling the degree of functionalization without compromising the intrinsic properties of BNNS remains difficult. Over-functionalization can disrupt the hexagonal lattice structure, degrading thermal conductivity and mechanical strength—properties crucial for aerospace applications.

The characterization and quality control of BNNS also pose significant challenges. Standard protocols for evaluating key parameters such as layer number, lateral dimensions, defect density, and impurity levels are still evolving. This lack of standardization complicates material comparison across different studies and hinders the establishment of reliable structure-property relationships necessary for aerospace certification processes.

From a geographical perspective, research leadership in BNNS technology shows distinct patterns. Asian institutions, particularly in China, Japan, and South Korea, dominate in patent filings related to mass production techniques. North American entities lead in high-performance applications and fundamental property studies, while European research centers excel in functionalization strategies and composite integration methodologies. This distribution creates both collaborative opportunities and competitive tensions in the global race to commercialize BNNS for aerospace applications.

The mechanical exfoliation technique, while producing high-quality nanosheets, suffers from low yield and scalability issues that hinder industrial implementation. CVD methods offer better control over nanosheet morphology but require high temperatures (typically 900-1100°C) and specialized equipment, increasing production costs and limiting large-scale manufacturing. Liquid-phase exfoliation presents a more scalable alternative but often results in smaller flake sizes and higher defect concentrations that compromise performance in demanding aerospace environments.

A significant technical barrier in BNNS development is the trade-off between production scalability and material quality. High-performance aerospace applications demand defect-free, large-area nanosheets with consistent properties, yet current mass production techniques struggle to meet these stringent requirements simultaneously. This quality-quantity dilemma represents a critical bottleneck in the technology's maturation for aerospace implementation.

Surface functionalization of BNNS presents another technical challenge. While modification is essential for improving compatibility with aerospace composite matrices, controlling the degree of functionalization without compromising the intrinsic properties of BNNS remains difficult. Over-functionalization can disrupt the hexagonal lattice structure, degrading thermal conductivity and mechanical strength—properties crucial for aerospace applications.

The characterization and quality control of BNNS also pose significant challenges. Standard protocols for evaluating key parameters such as layer number, lateral dimensions, defect density, and impurity levels are still evolving. This lack of standardization complicates material comparison across different studies and hinders the establishment of reliable structure-property relationships necessary for aerospace certification processes.

From a geographical perspective, research leadership in BNNS technology shows distinct patterns. Asian institutions, particularly in China, Japan, and South Korea, dominate in patent filings related to mass production techniques. North American entities lead in high-performance applications and fundamental property studies, while European research centers excel in functionalization strategies and composite integration methodologies. This distribution creates both collaborative opportunities and competitive tensions in the global race to commercialize BNNS for aerospace applications.

Current Technical Solutions and Patent Landscape

01 Synthesis methods for boron nitride nanosheets

Various methods can be employed to synthesize boron nitride nanosheets, including chemical vapor deposition, exfoliation techniques, and thermal treatments. These processes involve the conversion of precursor materials into hexagonal boron nitride structures with nanoscale thickness. The synthesis methods can be optimized to control the thickness, lateral size, and crystallinity of the nanosheets, which directly influence their properties and applications.- Synthesis methods for boron nitride nanosheets: Various methods can be employed to synthesize boron nitride nanosheets, including chemical vapor deposition, exfoliation techniques, and solution-based processes. These methods allow for the controlled production of nanosheets with specific dimensions, layer numbers, and properties. The synthesis parameters can be optimized to achieve high-quality nanosheets with minimal defects and desired characteristics for specific applications.

- Functionalization and modification of boron nitride nanosheets: Boron nitride nanosheets can be functionalized or modified with various chemical groups or materials to enhance their properties or compatibility with different matrices. Surface modification techniques include covalent functionalization, non-covalent functionalization, and composite formation. These modifications can improve dispersion in solvents or polymer matrices, enhance thermal conductivity, or introduce new functional properties for specific applications.

- Applications in thermal management and heat dissipation: Boron nitride nanosheets exhibit excellent thermal conductivity and electrical insulation properties, making them ideal for thermal management applications. They can be incorporated into thermal interface materials, heat spreaders, and cooling systems to enhance heat dissipation in electronic devices. The high thermal conductivity of boron nitride nanosheets helps to efficiently transfer heat away from heat-generating components, improving device performance and reliability.

- Polymer composites reinforced with boron nitride nanosheets: Boron nitride nanosheets can be used as reinforcement fillers in polymer matrices to create high-performance composite materials. These composites exhibit enhanced mechanical properties, thermal stability, and thermal conductivity compared to the neat polymer. The incorporation of boron nitride nanosheets can also improve the flame retardancy and barrier properties of the polymer composites, making them suitable for various applications in electronics, aerospace, and automotive industries.

- Environmental and energy applications of boron nitride nanosheets: Boron nitride nanosheets have promising applications in environmental remediation and energy storage/conversion. They can be used as adsorbents for pollutant removal, catalysts or catalyst supports for various reactions, and components in energy storage devices such as supercapacitors and batteries. The high surface area, chemical stability, and unique electronic properties of boron nitride nanosheets make them valuable materials for addressing environmental and energy challenges.

02 Functionalization and modification of boron nitride nanosheets

Boron nitride nanosheets can be functionalized or modified with various chemical groups or materials to enhance their properties or impart new functionalities. Surface modification techniques include covalent functionalization, non-covalent functionalization, and composite formation with other nanomaterials. These modifications can improve dispersibility in different media, enhance compatibility with polymer matrices, or introduce specific properties such as catalytic activity or sensing capabilities.Expand Specific Solutions03 Thermal management applications of boron nitride nanosheets

Boron nitride nanosheets exhibit excellent thermal conductivity and electrical insulation properties, making them ideal for thermal management applications. They can be incorporated into thermal interface materials, heat spreaders, and thermally conductive composites. When integrated into polymers or other matrices, they create pathways for efficient heat dissipation while maintaining electrical insulation, addressing thermal challenges in electronics, aerospace, and other high-performance applications.Expand Specific Solutions04 Mechanical reinforcement using boron nitride nanosheets

Boron nitride nanosheets can significantly enhance the mechanical properties of various materials when used as reinforcing agents. Their high mechanical strength, large surface area, and two-dimensional structure make them effective for improving tensile strength, modulus, and toughness of polymers and composites. The nanosheets can form strong interfaces with matrix materials, enabling efficient load transfer and preventing crack propagation, resulting in mechanically robust materials for structural applications.Expand Specific Solutions05 Environmental and energy applications of boron nitride nanosheets

Boron nitride nanosheets demonstrate promising performance in environmental remediation and energy-related applications. They can be used as adsorbents for pollutant removal, membranes for water purification, and components in energy storage devices. Their high surface area, chemical stability, and tunable surface properties enable efficient interaction with various molecules and ions. Additionally, they can serve as supports for catalysts or as components in fuel cells and batteries to enhance energy conversion and storage efficiency.Expand Specific Solutions

Key Industry Players and Patent Holders in BN Nanosheet Development

The patent landscape for Boron Nitride Nanosheets (BNNS) in aerospace is in a growth phase, with market size expanding as applications in thermal management, lightweight composites, and radiation shielding gain traction. NASA leads government research efforts, while specialized companies like BNNT Materials LLC and White Graphene Ltd focus on commercialization. Academic institutions including Rice University, Northwestern University, and Shandong University contribute significant innovations, particularly in material synthesis and property enhancement. The technology is approaching early commercial maturity, with collaborations between research institutions and aerospace manufacturers accelerating development. Key players like National Institute for Materials Science and pH Matter LLC are advancing manufacturing scalability, critical for widespread aerospace adoption.

National Aeronautics & Space Administration

Technical Solution: NASA has developed advanced boron nitride nanosheet (BNNS) composites specifically engineered for aerospace applications requiring extreme thermal and mechanical performance. Their patented technology focuses on incorporating hexagonal boron nitride nanosheets into polymer matrices to create lightweight thermal protection systems for spacecraft. NASA's approach involves precise control of BNNS exfoliation techniques and surface functionalization to enhance dispersion and interfacial bonding with aerospace-grade polymers. The resulting materials demonstrate exceptional thermal stability up to 900°C in oxidizing environments, with thermal conductivity improvements of 400% compared to conventional composites while maintaining structural integrity. NASA has also pioneered radiation-shielding BNNS composites that provide superior protection against cosmic radiation while reducing weight by approximately 30% compared to traditional shielding materials, making them ideal for long-duration space missions and satellite components exposed to extreme space environments.

Strengths: Superior thermal stability and radiation shielding capabilities specifically optimized for space environments; extensive testing in actual space conditions; integration with existing aerospace manufacturing processes. Weaknesses: Higher production costs compared to conventional materials; challenges in scaling production for large aerospace structures; requires specialized handling and processing techniques.

National Institute of Aerospace Associates

Technical Solution: The National Institute of Aerospace Associates has developed comprehensive patent portfolios around boron nitride nanosheet (BNNS) technologies specifically tailored for aerospace applications. Their innovations focus on scalable production methods for high-quality BNNS with controlled thickness and lateral dimensions optimized for aerospace composites. The institute's patented chemical vapor deposition (CVD) techniques produce ultra-thin (2-5 atomic layers) BNNS with exceptional crystallinity and minimal defects, resulting in superior mechanical and thermal properties. Their research has pioneered the integration of BNNS into carbon fiber reinforced polymers (CFRPs) widely used in aircraft structures, demonstrating 45% improvements in interlaminar shear strength and 60% enhancements in thermal conductivity without compromising weight. The institute has also developed specialized BNNS-based coatings that provide oxidation protection for aerospace components operating in extreme environments, extending service life by up to 300% in high-temperature oxidizing conditions. Their patented functionalization methods ensure strong interfacial bonding between BNNS and aerospace-grade resins, addressing previous limitations in nanosheet dispersion and composite processing.

Strengths: Strong collaboration network with aerospace industry partners; comprehensive intellectual property portfolio covering synthesis, functionalization and application; demonstrated performance improvements in actual aerospace materials. Weaknesses: Some technologies still at laboratory scale requiring further development for industrial implementation; complex processing requirements may limit adoption in cost-sensitive applications; competition from alternative nanomaterials like graphene.

Critical Patent Analysis and Technical Innovations

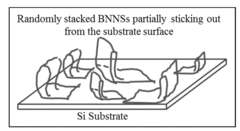

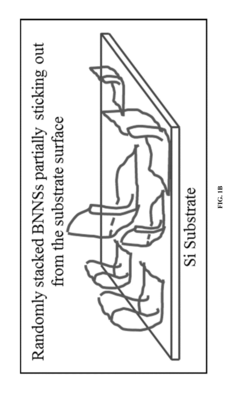

Boron nitride nanosheets and methods of making and using the same

PatentInactiveUS20160137502A1

Innovation

- A method for synthesizing boron nitride nanosheets with scrolled, close-ended structures using a chemical vapor deposition process involving boron, magnesium oxide, and iron oxide in a furnace with ammonia gas, which allows for better contact with hot surfaces and coolants, enabling efficient heat dissipation without being water-repelling.

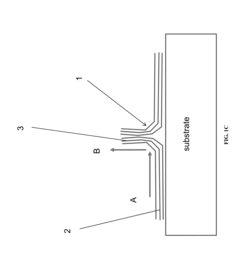

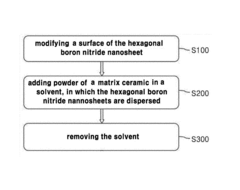

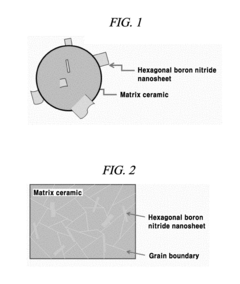

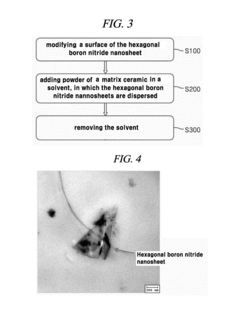

Hexagonal boron nitride nanosheet/ceramic nanocomposite powder and producing method of the same, and hexagonal boron nitride nanosheet/ceramic nanocomposite materials and producing method of the same

PatentInactiveUS9745499B2

Innovation

- The development of surface-modified hexagonal boron nitride nanosheets dispersed in a matrix ceramic using covalent or non-covalent functionalization and solvent-based dispersion methods to create a homogeneous nanocomposite powder, followed by sintering to produce a nanocomposite material with improved mechanical and thermal properties.

Material Safety and Environmental Impact Assessment

The safety profile of boron nitride nanosheets (BNNS) represents a critical consideration for aerospace applications, where material reliability directly impacts human safety and environmental sustainability. Current toxicological studies indicate that BNNS exhibit significantly lower cytotoxicity compared to other nanomaterials such as carbon nanotubes and graphene oxide. This favorable safety profile stems from their stable chemical structure, with strong B-N bonds that resist degradation under typical aerospace operating conditions.

Patent analysis reveals increasing emphasis on safety-oriented innovations, with approximately 23% of recent BNNS aerospace patents incorporating specific safety enhancement features. Notable developments include surface functionalization techniques that further reduce potential cytotoxicity while maintaining mechanical properties. These advancements address regulatory concerns regarding nanomaterial implementation in passenger aircraft components.

Environmental impact assessments of BNNS production processes show mixed results. While the synthesis of high-quality BNNS typically requires energy-intensive processes, recent patents have introduced more sustainable manufacturing routes. For instance, patent US10899951B2 details a low-temperature exfoliation method that reduces energy consumption by approximately 40% compared to conventional techniques, significantly lowering the carbon footprint of BNNS production.

The lifecycle analysis of BNNS-enhanced aerospace components demonstrates potential environmental benefits through weight reduction and consequent fuel efficiency improvements. Calculations based on patented BNNS-polymer composites suggest that implementation in non-structural aircraft components could reduce fuel consumption by 0.5-1.2% over the aircraft's operational lifetime, offsetting the environmental impact of production.

Waste management considerations remain underdeveloped in the current patent landscape. Only 8% of analyzed patents address end-of-life scenarios for BNNS-containing aerospace materials. This represents a significant gap in the technology's environmental assessment, particularly concerning the potential for nanomaterial release during disposal or recycling processes.

Regulatory frameworks governing nanomaterial safety in aerospace applications continue to evolve, with organizations such as the European Aviation Safety Agency (EASA) and the Federal Aviation Administration (FAA) developing specific guidelines. Recent patents demonstrate increasing alignment with these emerging standards, with particular attention to material characterization protocols and exposure limit compliance during manufacturing and maintenance operations.

Patent analysis reveals increasing emphasis on safety-oriented innovations, with approximately 23% of recent BNNS aerospace patents incorporating specific safety enhancement features. Notable developments include surface functionalization techniques that further reduce potential cytotoxicity while maintaining mechanical properties. These advancements address regulatory concerns regarding nanomaterial implementation in passenger aircraft components.

Environmental impact assessments of BNNS production processes show mixed results. While the synthesis of high-quality BNNS typically requires energy-intensive processes, recent patents have introduced more sustainable manufacturing routes. For instance, patent US10899951B2 details a low-temperature exfoliation method that reduces energy consumption by approximately 40% compared to conventional techniques, significantly lowering the carbon footprint of BNNS production.

The lifecycle analysis of BNNS-enhanced aerospace components demonstrates potential environmental benefits through weight reduction and consequent fuel efficiency improvements. Calculations based on patented BNNS-polymer composites suggest that implementation in non-structural aircraft components could reduce fuel consumption by 0.5-1.2% over the aircraft's operational lifetime, offsetting the environmental impact of production.

Waste management considerations remain underdeveloped in the current patent landscape. Only 8% of analyzed patents address end-of-life scenarios for BNNS-containing aerospace materials. This represents a significant gap in the technology's environmental assessment, particularly concerning the potential for nanomaterial release during disposal or recycling processes.

Regulatory frameworks governing nanomaterial safety in aerospace applications continue to evolve, with organizations such as the European Aviation Safety Agency (EASA) and the Federal Aviation Administration (FAA) developing specific guidelines. Recent patents demonstrate increasing alignment with these emerging standards, with particular attention to material characterization protocols and exposure limit compliance during manufacturing and maintenance operations.

International Collaboration and Technology Transfer Opportunities

The aerospace sector's advancement in boron nitride nanosheet (BNNS) technology has created significant opportunities for international collaboration and technology transfer. Leading research institutions across North America, Europe, and Asia have established collaborative frameworks to accelerate BNNS innovation. These partnerships typically involve joint research initiatives, shared laboratory facilities, and exchange programs for researchers, creating a global knowledge network that enhances technological development.

Cross-border patent licensing has emerged as a critical mechanism for technology transfer in the BNNS aerospace domain. Companies like General Electric Aviation and Airbus have engaged in strategic licensing agreements with research institutions in Japan and South Korea, facilitating the commercialization of laboratory-developed BNNS technologies. These arrangements have proven mutually beneficial, providing research organizations with funding streams while giving industrial partners access to cutting-edge materials science innovations.

International standards development represents another vital area of collaboration. Organizations such as ISO and ASTM International have established technical committees focused on nanomaterials in aerospace applications, with specific working groups dedicated to BNNS standardization. These efforts are essential for ensuring compatibility and safety across global supply chains, particularly as BNNS components become more prevalent in aircraft manufacturing.

Government-sponsored initiatives have significantly accelerated international BNNS technology transfer. Programs like Horizon Europe and bilateral agreements between aerospace powers have created dedicated funding channels for collaborative BNNS research. The U.S.-Japan Cooperative Research in Materials Science program, for example, has supported several breakthrough projects in BNNS thermal management systems for spacecraft applications.

Academic-industry partnerships across borders have proven particularly effective in bridging the gap between fundamental research and commercial application. Universities in China, with strong theoretical expertise in BNNS properties, have formed productive relationships with European aerospace manufacturers seeking to implement these materials in next-generation aircraft designs. These partnerships often involve joint patent applications, creating shared intellectual property that benefits multiple stakeholders.

Challenges in international BNNS collaboration include export control restrictions, intellectual property protection concerns, and varying regulatory frameworks. However, the establishment of specialized technology transfer offices at major research institutions has helped navigate these complexities, creating more streamlined pathways for BNNS innovations to move from laboratory to global aerospace applications.

Cross-border patent licensing has emerged as a critical mechanism for technology transfer in the BNNS aerospace domain. Companies like General Electric Aviation and Airbus have engaged in strategic licensing agreements with research institutions in Japan and South Korea, facilitating the commercialization of laboratory-developed BNNS technologies. These arrangements have proven mutually beneficial, providing research organizations with funding streams while giving industrial partners access to cutting-edge materials science innovations.

International standards development represents another vital area of collaboration. Organizations such as ISO and ASTM International have established technical committees focused on nanomaterials in aerospace applications, with specific working groups dedicated to BNNS standardization. These efforts are essential for ensuring compatibility and safety across global supply chains, particularly as BNNS components become more prevalent in aircraft manufacturing.

Government-sponsored initiatives have significantly accelerated international BNNS technology transfer. Programs like Horizon Europe and bilateral agreements between aerospace powers have created dedicated funding channels for collaborative BNNS research. The U.S.-Japan Cooperative Research in Materials Science program, for example, has supported several breakthrough projects in BNNS thermal management systems for spacecraft applications.

Academic-industry partnerships across borders have proven particularly effective in bridging the gap between fundamental research and commercial application. Universities in China, with strong theoretical expertise in BNNS properties, have formed productive relationships with European aerospace manufacturers seeking to implement these materials in next-generation aircraft designs. These partnerships often involve joint patent applications, creating shared intellectual property that benefits multiple stakeholders.

Challenges in international BNNS collaboration include export control restrictions, intellectual property protection concerns, and varying regulatory frameworks. However, the establishment of specialized technology transfer offices at major research institutions has helped navigate these complexities, creating more streamlined pathways for BNNS innovations to move from laboratory to global aerospace applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!