Technical Challenges in Boron Nitride Nanosheets Manufacturing

OCT 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

BN Nanosheets Manufacturing Background and Objectives

Boron Nitride (BN) nanosheets have emerged as a revolutionary two-dimensional material with exceptional properties, drawing significant attention in materials science and engineering fields over the past decade. These atomically thin sheets, structurally analogous to graphene but composed of alternating boron and nitrogen atoms, exhibit remarkable thermal conductivity, electrical insulation, mechanical strength, and chemical stability, making them highly promising for numerous advanced applications.

The evolution of BN nanosheets technology can be traced back to the early 2000s, following the groundbreaking discovery of graphene. Initial research focused primarily on theoretical studies and fundamental property investigations. By the mid-2010s, various synthesis methods began to emerge, including chemical vapor deposition (CVD), liquid-phase exfoliation, and chemical blowing techniques, marking significant milestones in manufacturing capabilities.

Current technological trends indicate a shift toward scalable and cost-effective production methods, with increasing emphasis on precise control over nanosheet thickness, lateral dimensions, and defect density. The field is progressively moving from laboratory-scale synthesis to industrial-scale manufacturing processes, driven by growing commercial interest in thermal management materials, electronic substrates, and composite reinforcements.

The primary technical objectives in BN nanosheets manufacturing research include developing reproducible synthesis methods capable of yielding high-quality nanosheets with controlled thickness and lateral dimensions at commercially viable scales. Researchers aim to reduce production costs while maintaining structural integrity and purity, as current high-quality manufacturing processes remain prohibitively expensive for mass-market applications.

Another critical objective involves enhancing the compatibility of BN nanosheets with various matrices for composite applications, requiring surface functionalization techniques that do not compromise the intrinsic properties of the nanosheets. This includes developing methods to prevent agglomeration during processing and ensuring uniform dispersion in polymer, ceramic, or metal matrices.

The field also seeks to establish standardized characterization protocols and quality control metrics to facilitate consistent evaluation across different production methods and research groups. This standardization is essential for industrial adoption and commercialization of BN nanosheet-based technologies.

Long-term technical goals include achieving atomically precise control over nanosheet edges and defects, developing continuous manufacturing processes for industrial-scale production, and creating multifunctional BN nanosheets with tailored properties for specific applications through controlled doping or hybridization with other nanomaterials.

The evolution of BN nanosheets technology can be traced back to the early 2000s, following the groundbreaking discovery of graphene. Initial research focused primarily on theoretical studies and fundamental property investigations. By the mid-2010s, various synthesis methods began to emerge, including chemical vapor deposition (CVD), liquid-phase exfoliation, and chemical blowing techniques, marking significant milestones in manufacturing capabilities.

Current technological trends indicate a shift toward scalable and cost-effective production methods, with increasing emphasis on precise control over nanosheet thickness, lateral dimensions, and defect density. The field is progressively moving from laboratory-scale synthesis to industrial-scale manufacturing processes, driven by growing commercial interest in thermal management materials, electronic substrates, and composite reinforcements.

The primary technical objectives in BN nanosheets manufacturing research include developing reproducible synthesis methods capable of yielding high-quality nanosheets with controlled thickness and lateral dimensions at commercially viable scales. Researchers aim to reduce production costs while maintaining structural integrity and purity, as current high-quality manufacturing processes remain prohibitively expensive for mass-market applications.

Another critical objective involves enhancing the compatibility of BN nanosheets with various matrices for composite applications, requiring surface functionalization techniques that do not compromise the intrinsic properties of the nanosheets. This includes developing methods to prevent agglomeration during processing and ensuring uniform dispersion in polymer, ceramic, or metal matrices.

The field also seeks to establish standardized characterization protocols and quality control metrics to facilitate consistent evaluation across different production methods and research groups. This standardization is essential for industrial adoption and commercialization of BN nanosheet-based technologies.

Long-term technical goals include achieving atomically precise control over nanosheet edges and defects, developing continuous manufacturing processes for industrial-scale production, and creating multifunctional BN nanosheets with tailored properties for specific applications through controlled doping or hybridization with other nanomaterials.

Market Applications and Demand Analysis for BN Nanosheets

The global market for boron nitride nanosheets (BNNSs) has been experiencing significant growth, driven primarily by their exceptional thermal conductivity, electrical insulation properties, and mechanical strength. Current market analysis indicates that the electronics industry represents the largest application segment, with BNNSs being increasingly incorporated into thermal management solutions for high-performance electronic devices. This demand is particularly pronounced in regions with advanced semiconductor manufacturing capabilities such as East Asia, North America, and Western Europe.

The aerospace and defense sectors have emerged as another substantial market for BNNSs, utilizing these materials in high-temperature components, radiation shields, and lightweight structural elements. Market research suggests that this sector's demand is growing at a compound annual rate exceeding that of traditional materials, reflecting the critical performance advantages offered by BNNSs in extreme operating environments.

Energy storage applications represent a rapidly expanding market segment, with BNNSs being evaluated for use in next-generation batteries and supercapacitors. Their thermal stability and electrical insulation properties make them particularly valuable as separator materials and protective coatings in high-energy-density storage systems. This application area is projected to show the highest growth rate among all market segments over the next five years.

The biomedical field has begun exploring BNNSs for drug delivery systems, biosensors, and tissue engineering scaffolds, though this remains a nascent market with significant research still underway. Early clinical trials suggest promising biocompatibility profiles, potentially opening substantial new market opportunities in the medical device and pharmaceutical industries.

Industrial applications, including polymer composites, lubricants, and protective coatings, constitute a diverse but substantial market segment. The demand in this sector is characterized by requirements for large-volume production at competitive price points, presenting both challenges and opportunities for manufacturers focused on scaling production technologies.

Market barriers to wider adoption include the current high production costs, inconsistent quality in large-scale manufacturing, and limited standardization across the industry. These factors have restricted BNNSs primarily to high-value applications where performance requirements justify premium pricing. However, as manufacturing technologies mature and economies of scale develop, broader market penetration is anticipated.

Regional market analysis reveals that Asia-Pacific currently leads in both production capacity and consumption, followed by North America and Europe. Emerging economies, particularly India and Brazil, are showing accelerating demand growth rates as their advanced manufacturing sectors expand, suggesting potential new market opportunities for producers able to establish early presence in these regions.

The aerospace and defense sectors have emerged as another substantial market for BNNSs, utilizing these materials in high-temperature components, radiation shields, and lightweight structural elements. Market research suggests that this sector's demand is growing at a compound annual rate exceeding that of traditional materials, reflecting the critical performance advantages offered by BNNSs in extreme operating environments.

Energy storage applications represent a rapidly expanding market segment, with BNNSs being evaluated for use in next-generation batteries and supercapacitors. Their thermal stability and electrical insulation properties make them particularly valuable as separator materials and protective coatings in high-energy-density storage systems. This application area is projected to show the highest growth rate among all market segments over the next five years.

The biomedical field has begun exploring BNNSs for drug delivery systems, biosensors, and tissue engineering scaffolds, though this remains a nascent market with significant research still underway. Early clinical trials suggest promising biocompatibility profiles, potentially opening substantial new market opportunities in the medical device and pharmaceutical industries.

Industrial applications, including polymer composites, lubricants, and protective coatings, constitute a diverse but substantial market segment. The demand in this sector is characterized by requirements for large-volume production at competitive price points, presenting both challenges and opportunities for manufacturers focused on scaling production technologies.

Market barriers to wider adoption include the current high production costs, inconsistent quality in large-scale manufacturing, and limited standardization across the industry. These factors have restricted BNNSs primarily to high-value applications where performance requirements justify premium pricing. However, as manufacturing technologies mature and economies of scale develop, broader market penetration is anticipated.

Regional market analysis reveals that Asia-Pacific currently leads in both production capacity and consumption, followed by North America and Europe. Emerging economies, particularly India and Brazil, are showing accelerating demand growth rates as their advanced manufacturing sectors expand, suggesting potential new market opportunities for producers able to establish early presence in these regions.

Current Manufacturing Challenges and Technical Limitations

The manufacturing of boron nitride nanosheets (BNNSs) faces significant technical challenges that currently limit their widespread industrial application despite their exceptional properties. The primary obstacle lies in the scalability of production methods, with most current techniques confined to laboratory-scale yields that are insufficient for commercial demands. Existing methods such as chemical vapor deposition (CVD), mechanical exfoliation, and liquid-phase exfoliation each present their own limitations in terms of throughput, quality, and cost-effectiveness.

CVD processes, while capable of producing high-quality BNNSs with controlled thickness and crystallinity, require expensive equipment, high temperatures (typically 900-1100°C), and ultra-high vacuum conditions. These requirements translate to high energy consumption and substantial capital investment, making large-scale production economically challenging. Additionally, the growth rate is relatively slow, further limiting industrial viability.

Mechanical exfoliation techniques, though simple in principle, suffer from extremely low yields and poor reproducibility. The process is inherently labor-intensive and difficult to automate, making it unsuitable for mass production scenarios. The resulting nanosheets also exhibit inconsistent thickness and lateral dimensions, creating quality control issues for applications requiring uniform material properties.

Liquid-phase exfoliation methods offer better scalability potential but encounter challenges in achieving complete exfoliation while maintaining the structural integrity of the nanosheets. The use of harsh solvents or surfactants introduces contamination issues that can compromise the intrinsic properties of BNNSs. Post-processing purification steps add complexity and cost to the manufacturing process while potentially reducing yield.

Another significant technical limitation is the difficulty in precisely controlling the thickness, lateral size, and edge structure of BNNSs during production. These parameters critically influence the material's properties and performance in various applications. Current manufacturing methods provide limited control over these structural features, resulting in batches with heterogeneous characteristics that require additional sorting or selection processes.

The formation of defects during synthesis represents another major challenge. Structural imperfections such as vacancies, substitutional impurities, and grain boundaries can significantly alter the electrical, thermal, and mechanical properties of BNNSs. Minimizing these defects while maintaining high production rates remains a delicate balance that has not been fully optimized in existing manufacturing processes.

Furthermore, the integration of BNNSs into practical devices and composite materials presents additional challenges. Issues such as poor dispersion in polymer matrices, weak interfacial bonding, and difficulties in alignment and orientation control limit the effective transfer of the nanosheets' exceptional properties to the final products. These integration challenges further complicate the development of commercially viable applications.

CVD processes, while capable of producing high-quality BNNSs with controlled thickness and crystallinity, require expensive equipment, high temperatures (typically 900-1100°C), and ultra-high vacuum conditions. These requirements translate to high energy consumption and substantial capital investment, making large-scale production economically challenging. Additionally, the growth rate is relatively slow, further limiting industrial viability.

Mechanical exfoliation techniques, though simple in principle, suffer from extremely low yields and poor reproducibility. The process is inherently labor-intensive and difficult to automate, making it unsuitable for mass production scenarios. The resulting nanosheets also exhibit inconsistent thickness and lateral dimensions, creating quality control issues for applications requiring uniform material properties.

Liquid-phase exfoliation methods offer better scalability potential but encounter challenges in achieving complete exfoliation while maintaining the structural integrity of the nanosheets. The use of harsh solvents or surfactants introduces contamination issues that can compromise the intrinsic properties of BNNSs. Post-processing purification steps add complexity and cost to the manufacturing process while potentially reducing yield.

Another significant technical limitation is the difficulty in precisely controlling the thickness, lateral size, and edge structure of BNNSs during production. These parameters critically influence the material's properties and performance in various applications. Current manufacturing methods provide limited control over these structural features, resulting in batches with heterogeneous characteristics that require additional sorting or selection processes.

The formation of defects during synthesis represents another major challenge. Structural imperfections such as vacancies, substitutional impurities, and grain boundaries can significantly alter the electrical, thermal, and mechanical properties of BNNSs. Minimizing these defects while maintaining high production rates remains a delicate balance that has not been fully optimized in existing manufacturing processes.

Furthermore, the integration of BNNSs into practical devices and composite materials presents additional challenges. Issues such as poor dispersion in polymer matrices, weak interfacial bonding, and difficulties in alignment and orientation control limit the effective transfer of the nanosheets' exceptional properties to the final products. These integration challenges further complicate the development of commercially viable applications.

Current Manufacturing Approaches and Scalability Issues

01 Synthesis methods for boron nitride nanosheets

Various methods can be employed to synthesize boron nitride nanosheets, including chemical vapor deposition, exfoliation techniques, and thermal treatments. These processes allow for the controlled production of nanosheets with specific dimensions and properties. The synthesis methods can be optimized to yield high-quality nanosheets with uniform thickness and large lateral dimensions, which are crucial for their applications in various fields.- Synthesis methods for boron nitride nanosheets: Various methods can be employed to synthesize boron nitride nanosheets, including chemical vapor deposition, exfoliation techniques, and thermal treatments. These processes involve the conversion of precursor materials under controlled conditions to form hexagonal boron nitride structures with nanoscale thickness. The synthesis parameters significantly influence the quality, size, and properties of the resulting nanosheets, which can be tailored for specific applications.

- Functionalization and modification of boron nitride nanosheets: Boron nitride nanosheets can be functionalized or modified with various chemical groups or materials to enhance their properties or compatibility with different matrices. Surface modifications can improve dispersion in solvents or polymers, while functionalization with specific groups can introduce new properties such as enhanced thermal conductivity, electrical properties, or chemical reactivity. These modifications expand the range of potential applications for boron nitride nanosheets.

- Composite materials incorporating boron nitride nanosheets: Boron nitride nanosheets can be incorporated into various matrices to form composite materials with enhanced properties. These composites often exhibit improved thermal conductivity, mechanical strength, and thermal stability compared to the base materials. Common matrices include polymers, ceramics, and metals. The unique properties of boron nitride nanosheets, such as their high thermal conductivity and electrical insulation, make them valuable fillers for creating advanced composite materials for thermal management applications.

- Applications of boron nitride nanosheets in thermal management: Boron nitride nanosheets are extensively used in thermal management applications due to their exceptional thermal conductivity and electrical insulation properties. They can be incorporated into thermal interface materials, heat spreaders, and cooling systems for electronic devices. The high surface area and thermal conductivity of these nanosheets allow for efficient heat dissipation, making them valuable components in addressing thermal challenges in miniaturized and high-power electronic devices.

- Environmental and energy applications of boron nitride nanosheets: Boron nitride nanosheets have emerging applications in environmental remediation and energy storage/conversion technologies. They can be used as adsorbents for pollutant removal, catalysts or catalyst supports for various reactions, and components in energy storage devices such as supercapacitors and batteries. Their chemical stability, large surface area, and unique electronic properties make them promising materials for addressing environmental challenges and improving energy technologies.

02 Functionalization of boron nitride nanosheets

Boron nitride nanosheets can be functionalized with various chemical groups to enhance their properties and compatibility with different matrices. Functionalization can improve dispersion in solvents, increase binding with polymers, and introduce new properties such as enhanced thermal conductivity or electrical insulation. Different functional groups can be attached to the surface of boron nitride nanosheets through covalent or non-covalent interactions.Expand Specific Solutions03 Applications in thermal management and heat dissipation

Boron nitride nanosheets exhibit excellent thermal conductivity and electrical insulation properties, making them ideal for thermal management applications. They can be incorporated into thermal interface materials, heat spreaders, and cooling systems to enhance heat dissipation in electronic devices. The high thermal conductivity of boron nitride nanosheets allows for efficient heat transfer, while their electrical insulation properties prevent short circuits in electronic components.Expand Specific Solutions04 Polymer composites reinforced with boron nitride nanosheets

Incorporating boron nitride nanosheets into polymer matrices creates composites with enhanced mechanical, thermal, and barrier properties. These composites can be used in various applications, including aerospace, automotive, and electronics industries. The nanosheets provide reinforcement to the polymer matrix, improving strength and stiffness while also enhancing thermal conductivity and reducing thermal expansion. The resulting composites often show improved flame retardancy and resistance to environmental degradation.Expand Specific Solutions05 Environmental and energy applications of boron nitride nanosheets

Boron nitride nanosheets have promising applications in environmental remediation and energy storage/conversion. They can be used as adsorbents for pollutant removal, catalysts or catalyst supports for various reactions, and components in energy storage devices such as supercapacitors and batteries. Their high surface area, chemical stability, and unique electronic properties make them suitable for these applications. Additionally, they can be used in water purification systems and as membranes for gas separation.Expand Specific Solutions

Key Industry Players and Research Institutions

The boron nitride nanosheets (BNNS) manufacturing landscape is currently in a transitional phase between early development and commercial scaling. The global market for BNNS is projected to reach approximately $200 million by 2025, driven by increasing applications in thermal management, electronics, and composites. Technologically, the field remains challenging with varying degrees of maturity across synthesis methods. Leading research institutions like NASA, National Institute for Materials Science, and SINANO are advancing fundamental research, while companies such as BNNT Materials LLC and Momentive Performance Materials are working toward commercial production. Academic players including Deakin University, Shandong University, and KAIST are contributing significant innovations in scalable manufacturing techniques. The primary technical hurdles remain in achieving consistent quality, large-scale production, and cost-effectiveness.

Suzhou Institute of Nano-Tech & Nano-Bionics (SINANO)

Technical Solution: SINANO has developed an innovative liquid-phase exfoliation technique for mass production of high-quality boron nitride nanosheets (BNNSs). Their approach utilizes specialized ionic liquids and sonication parameters optimized through machine learning algorithms to achieve controlled exfoliation of bulk h-BN into few-layer nanosheets. The institute has engineered a continuous flow system that allows for scalable production with precise control over nanosheet thickness (2-5 layers) and lateral dimensions (1-10 μm). Their process incorporates a unique centrifugation cascade to separate nanosheets by size and thickness with high precision. SINANO has also pioneered environmentally friendly solvent recovery systems that reduce waste and lower production costs by over 40%[2]. Their manufacturing protocol includes surface functionalization techniques that enhance dispersibility and compatibility with various matrices for advanced composite applications.

Strengths: Scalable liquid-phase exfoliation with high yield (>30%); environmentally friendly processing with solvent recovery; precise control over nanosheet dimensions and quality; lower energy requirements than high-temperature methods. Weaknesses: Potential for solvent contamination requiring extensive purification steps; challenges in achieving single-layer sheets consistently; limited oxidation resistance of sheets produced through wet chemistry methods.

Momentive Performance Materials, Inc.

Technical Solution: Momentive Performance Materials has developed a chemical vapor deposition (CVD) platform for synthesizing large-area boron nitride nanosheets with controlled thickness and crystallinity. Their proprietary process utilizes specialized precursors (including modified borazine compounds) and precisely controlled reaction conditions to grow BN films directly on various substrates. The company has engineered a roll-to-roll CVD system capable of producing continuous BN films with thicknesses ranging from 1-10 nm and lateral dimensions limited only by substrate size. Their manufacturing approach incorporates in-situ doping capabilities to tailor electronic and thermal properties for specific applications. Momentive has also developed transfer techniques that preserve nanosheet integrity when moving from growth substrates to target applications[4]. Their technology includes specialized surface treatments that enhance adhesion and compatibility with polymer matrices, enabling advanced composite materials with superior thermal management properties.

Strengths: Produces large-area continuous BN films with excellent uniformity; precise control over thickness and composition; scalable manufacturing compatible with semiconductor industry standards; capability for direct growth on various substrates. Weaknesses: High capital equipment costs; energy-intensive process; challenges in transferring films without introducing defects; limited to relatively flat substrate geometries.

Critical Patents and Breakthroughs in BN Nanosheets Production

Production of boron nitride nanosheets

PatentPendingAU2021345495A9

Innovation

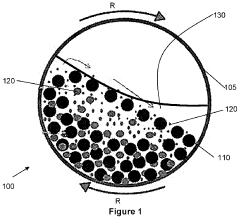

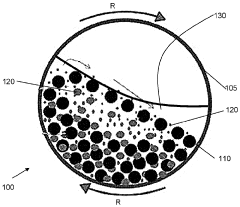

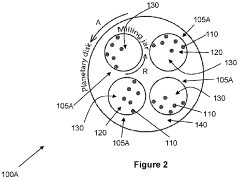

- A low-impact ball milling process using a viscous liquid medium with a viscosity of 100 to 100,000 mPa-s, combined with polymeric milling balls and vessels, to reduce energy transfer and enhance the size and quality of boron nitride nanosheets.

Boron nitride nanosheet, method for producing boron nitride nanosheet thereof and composition containing boron nitride nanosheet thereof

PatentInactiveUS20110086965A1

Innovation

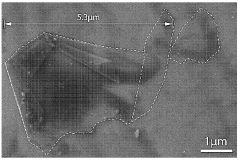

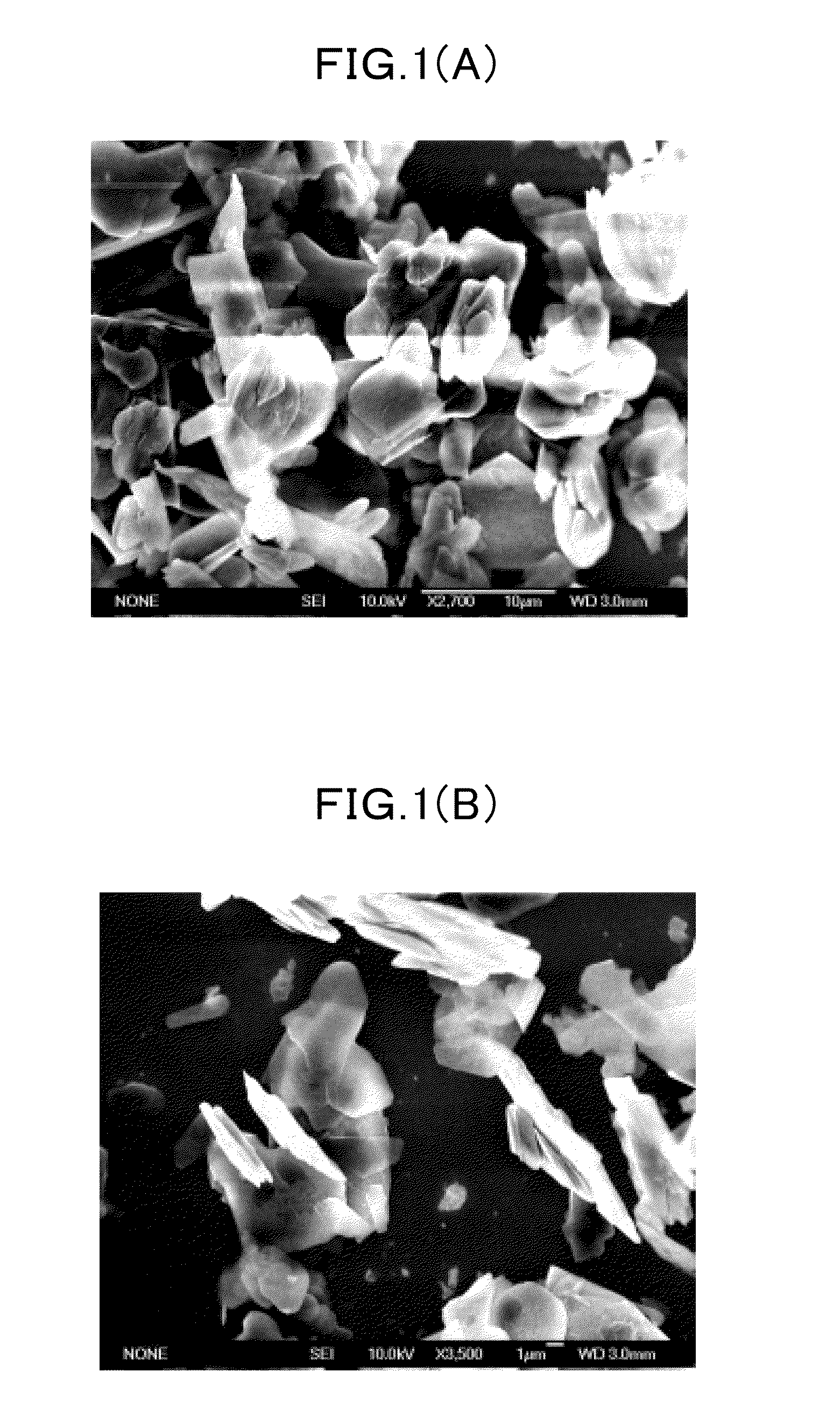

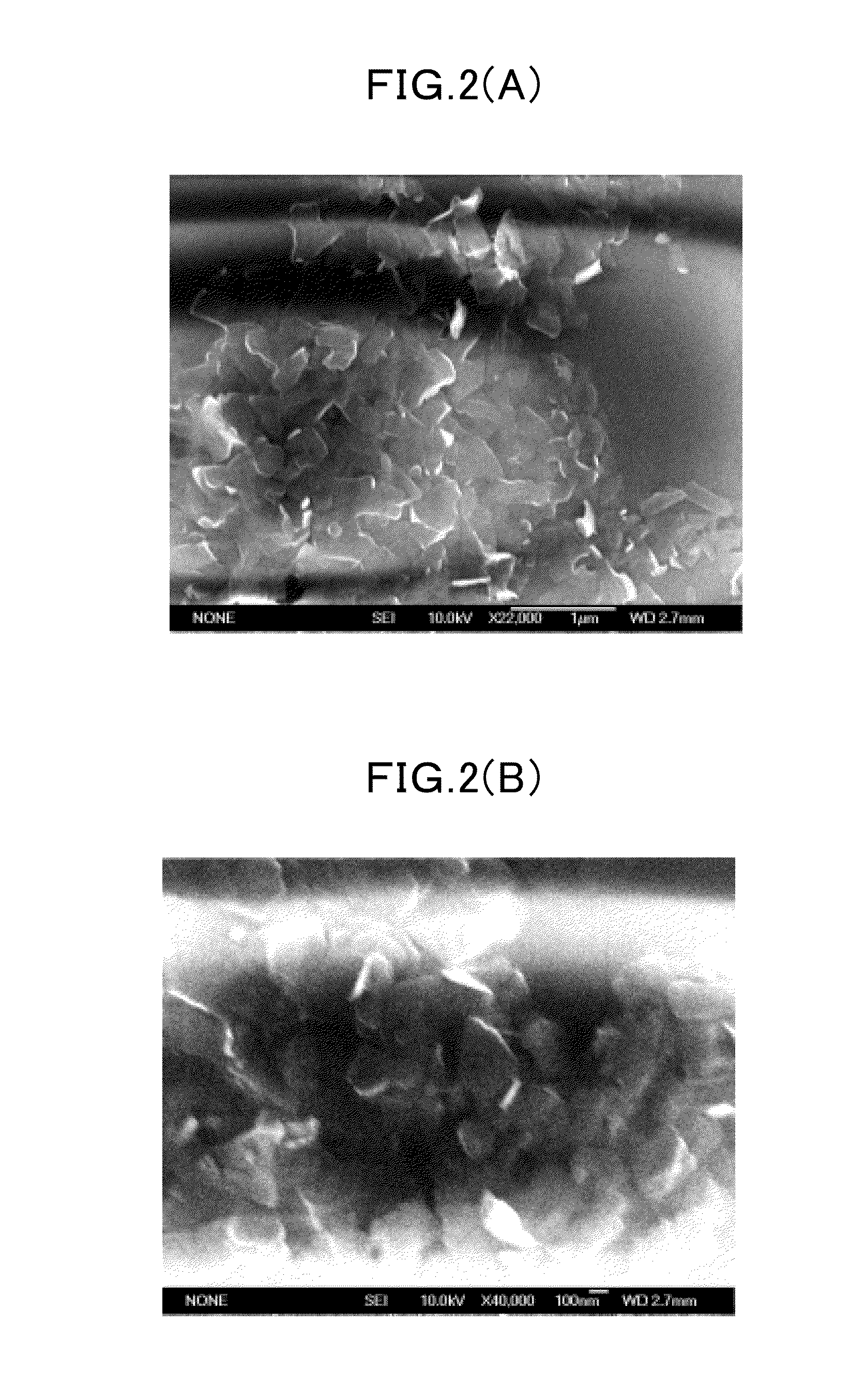

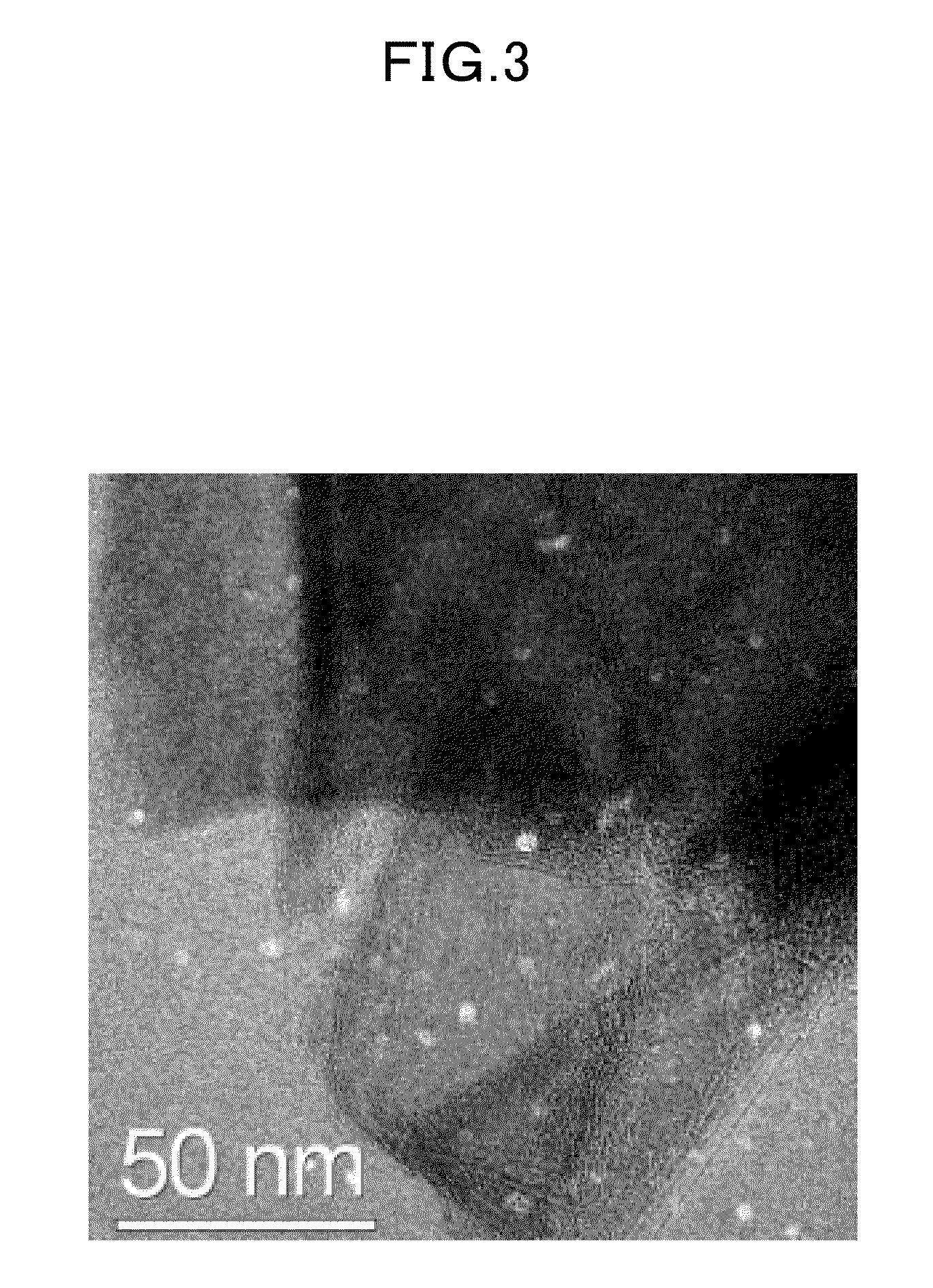

- A method involving the dispersion of hexagonal boron nitride powder in an organic solvent followed by ultrasonication to peel layers, resulting in a three-layered boron nitride nanosheet with a specific surface area significantly larger than bulk hexagonal boron nitride, which can be used as a filler to improve polymeric composite properties.

Environmental and Safety Considerations in Production

The manufacturing of Boron Nitride Nanosheets (BNNS) presents significant environmental and safety challenges that require careful consideration. The production process involves potentially hazardous chemicals, high-temperature treatments, and nanomaterials handling, all of which pose risks to both workers and the environment. Chemical vapor deposition (CVD) methods, commonly used in BNNS synthesis, often utilize precursors such as borazine, ammonia borane, and diborane that are toxic, flammable, and in some cases, pyrophoric. These chemicals require specialized containment systems, proper ventilation, and rigorous handling protocols to prevent accidental exposure or release.

Nanomaterial particulates generated during production pose inhalation hazards to workers. BNNS, while generally considered less toxic than other nanomaterials like carbon nanotubes, still present potential respiratory concerns due to their nanoscale dimensions. Implementation of engineering controls such as enclosed production systems, local exhaust ventilation, and high-efficiency particulate air (HEPA) filtration is essential to minimize worker exposure. Personal protective equipment including respirators, gloves, and protective clothing constitutes an additional necessary layer of protection.

Waste management represents another critical environmental consideration. Chemical etchants used in exfoliation processes, particularly strong acids and oxidizing agents, require neutralization and proper disposal to prevent environmental contamination. Liquid waste streams containing nanomaterial residues must undergo specialized treatment to remove nanomaterials before discharge. Solid waste containing BNNS requires appropriate disposal methods that prevent environmental release and potential ecological impacts.

Energy consumption during BNNS production, particularly in high-temperature synthesis methods, contributes significantly to the carbon footprint of manufacturing operations. Thermal CVD processes typically operate at temperatures exceeding 1000°C, consuming substantial energy resources. Research into more energy-efficient synthesis routes, such as plasma-enhanced CVD or liquid-phase exfoliation at moderate temperatures, represents an important direction for improving environmental sustainability.

Regulatory compliance adds another layer of complexity to BNNS manufacturing. Different jurisdictions impose varying requirements regarding nanomaterial production, worker safety, and environmental protection. Manufacturers must navigate these regulations while implementing comprehensive safety management systems that include regular monitoring, exposure assessments, emergency response procedures, and worker training programs. As production scales increase from laboratory to industrial levels, these environmental and safety considerations become increasingly critical to address through systematic risk assessment and mitigation strategies.

Nanomaterial particulates generated during production pose inhalation hazards to workers. BNNS, while generally considered less toxic than other nanomaterials like carbon nanotubes, still present potential respiratory concerns due to their nanoscale dimensions. Implementation of engineering controls such as enclosed production systems, local exhaust ventilation, and high-efficiency particulate air (HEPA) filtration is essential to minimize worker exposure. Personal protective equipment including respirators, gloves, and protective clothing constitutes an additional necessary layer of protection.

Waste management represents another critical environmental consideration. Chemical etchants used in exfoliation processes, particularly strong acids and oxidizing agents, require neutralization and proper disposal to prevent environmental contamination. Liquid waste streams containing nanomaterial residues must undergo specialized treatment to remove nanomaterials before discharge. Solid waste containing BNNS requires appropriate disposal methods that prevent environmental release and potential ecological impacts.

Energy consumption during BNNS production, particularly in high-temperature synthesis methods, contributes significantly to the carbon footprint of manufacturing operations. Thermal CVD processes typically operate at temperatures exceeding 1000°C, consuming substantial energy resources. Research into more energy-efficient synthesis routes, such as plasma-enhanced CVD or liquid-phase exfoliation at moderate temperatures, represents an important direction for improving environmental sustainability.

Regulatory compliance adds another layer of complexity to BNNS manufacturing. Different jurisdictions impose varying requirements regarding nanomaterial production, worker safety, and environmental protection. Manufacturers must navigate these regulations while implementing comprehensive safety management systems that include regular monitoring, exposure assessments, emergency response procedures, and worker training programs. As production scales increase from laboratory to industrial levels, these environmental and safety considerations become increasingly critical to address through systematic risk assessment and mitigation strategies.

Cost Analysis and Economic Viability Assessment

The economic analysis of boron nitride nanosheets (BNNS) manufacturing reveals significant cost barriers that currently limit widespread industrial adoption. Raw material costs represent a substantial portion of production expenses, with high-purity boron and nitrogen precursors commanding premium prices in the specialty chemicals market. Current synthesis methods, particularly chemical vapor deposition (CVD) and liquid exfoliation techniques, require sophisticated equipment operating under precise conditions, resulting in high capital expenditure requirements for manufacturing facilities.

Energy consumption presents another major cost factor, as most BNNS production methods demand high temperatures (800-1000°C) and vacuum conditions, translating to considerable operational expenses. The energy intensity of these processes directly impacts the carbon footprint and sustainability metrics of BNNS manufacturing, creating additional economic considerations in regions with carbon pricing mechanisms.

Yield and quality consistency remain problematic from an economic perspective, with current manufacturing processes typically achieving 60-75% yields of desired BNNS specifications. This inefficiency necessitates additional purification and quality control steps, further increasing production costs. The specialized workforce required for BNNS manufacturing also contributes to elevated operational expenses, as skilled technicians and engineers command higher salaries compared to conventional materials production personnel.

Scale-up challenges present significant economic hurdles, with most current production methods optimized at laboratory or small batch scales. The transition to industrial volumes introduces new technical complexities that often reduce efficiency and increase per-unit costs. Market analysis indicates current BNNS production costs range from $200-500 per gram depending on quality specifications, placing these materials firmly in the specialty materials category rather than commodity chemicals.

Economic viability assessments suggest that BNNS applications must target high-value markets initially, such as advanced electronics, aerospace components, and specialized thermal management solutions where performance benefits can justify premium pricing. The path to economic viability likely requires technological breakthroughs in synthesis methods, particularly approaches that reduce energy requirements, increase yields, and enable continuous rather than batch processing.

Return on investment calculations indicate that current BNNS manufacturing ventures require 5-7 years to achieve profitability under optimistic market adoption scenarios. This extended timeline presents challenges for attracting capital investment, particularly from traditional materials manufacturing sectors accustomed to shorter payback periods. Government incentives, research grants, and strategic partnerships with end-users represent critical financial mechanisms to bridge this economic viability gap during the technology maturation phase.

Energy consumption presents another major cost factor, as most BNNS production methods demand high temperatures (800-1000°C) and vacuum conditions, translating to considerable operational expenses. The energy intensity of these processes directly impacts the carbon footprint and sustainability metrics of BNNS manufacturing, creating additional economic considerations in regions with carbon pricing mechanisms.

Yield and quality consistency remain problematic from an economic perspective, with current manufacturing processes typically achieving 60-75% yields of desired BNNS specifications. This inefficiency necessitates additional purification and quality control steps, further increasing production costs. The specialized workforce required for BNNS manufacturing also contributes to elevated operational expenses, as skilled technicians and engineers command higher salaries compared to conventional materials production personnel.

Scale-up challenges present significant economic hurdles, with most current production methods optimized at laboratory or small batch scales. The transition to industrial volumes introduces new technical complexities that often reduce efficiency and increase per-unit costs. Market analysis indicates current BNNS production costs range from $200-500 per gram depending on quality specifications, placing these materials firmly in the specialty materials category rather than commodity chemicals.

Economic viability assessments suggest that BNNS applications must target high-value markets initially, such as advanced electronics, aerospace components, and specialized thermal management solutions where performance benefits can justify premium pricing. The path to economic viability likely requires technological breakthroughs in synthesis methods, particularly approaches that reduce energy requirements, increase yields, and enable continuous rather than batch processing.

Return on investment calculations indicate that current BNNS manufacturing ventures require 5-7 years to achieve profitability under optimistic market adoption scenarios. This extended timeline presents challenges for attracting capital investment, particularly from traditional materials manufacturing sectors accustomed to shorter payback periods. Government incentives, research grants, and strategic partnerships with end-users represent critical financial mechanisms to bridge this economic viability gap during the technology maturation phase.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!