Understanding Regulatory Compliance for Boron Nitride Nanosheets

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Boron Nitride Nanosheets Regulatory Background and Objectives

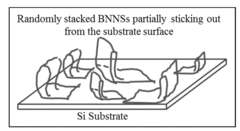

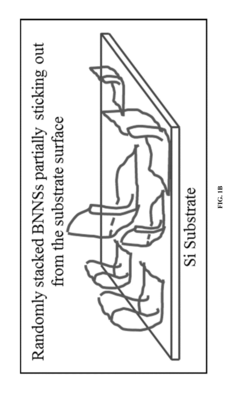

Boron nitride nanosheets (BNNSs) have emerged as a significant material in the field of nanotechnology since their initial isolation in 2005. These two-dimensional materials, often referred to as "white graphene," possess remarkable properties including high thermal conductivity, excellent mechanical strength, electrical insulation, and chemical stability. The evolution of BNNS technology has accelerated dramatically over the past decade, with research publications increasing exponentially as scientists explore their potential applications across multiple industries.

The regulatory landscape surrounding nanomaterials has developed in parallel with technological advancements, though often lagging behind innovation. Early regulatory frameworks from the 2000s were primarily focused on carbon-based nanomaterials, with boron nitride receiving less specific attention. By 2010, regulatory bodies including the US Environmental Protection Agency (EPA), European Chemicals Agency (ECHA), and various Asian regulatory authorities began developing more comprehensive approaches to nanomaterial governance.

Current regulatory trends indicate a shift toward more specific guidelines for different classes of nanomaterials, moving away from one-size-fits-all approaches. This evolution reflects growing recognition that nanomaterials like BNNSs present unique regulatory challenges due to their distinctive physical and chemical properties, which can differ substantially from bulk materials of identical chemical composition.

The primary objective of this technical research report is to provide a comprehensive understanding of the current regulatory compliance landscape for boron nitride nanosheets across major global markets. This includes identifying applicable regulations, standards, and guidelines that govern the research, production, commercialization, and disposal of BNNSs and BNNS-containing products.

Secondary objectives include mapping jurisdictional variations in regulatory approaches, identifying potential regulatory gaps or inconsistencies that may impact BNNS development, and forecasting likely regulatory developments based on current scientific understanding of BNNS safety profiles and environmental impacts.

The report aims to establish a clear timeline of regulatory milestones affecting BNNSs, from early nanomaterial regulations to current specialized frameworks. Additionally, it seeks to identify emerging regulatory trends that may shape future compliance requirements, particularly as BNNSs move from research settings into commercial applications across electronics, thermal management systems, composite materials, and biomedical devices.

Understanding these regulatory frameworks is crucial as BNNSs transition from laboratory research to industrial scale production and commercial applications. This transition necessitates navigating complex regulatory environments that continue to evolve in response to new scientific data on nanomaterial safety, environmental impact, and life cycle considerations.

The regulatory landscape surrounding nanomaterials has developed in parallel with technological advancements, though often lagging behind innovation. Early regulatory frameworks from the 2000s were primarily focused on carbon-based nanomaterials, with boron nitride receiving less specific attention. By 2010, regulatory bodies including the US Environmental Protection Agency (EPA), European Chemicals Agency (ECHA), and various Asian regulatory authorities began developing more comprehensive approaches to nanomaterial governance.

Current regulatory trends indicate a shift toward more specific guidelines for different classes of nanomaterials, moving away from one-size-fits-all approaches. This evolution reflects growing recognition that nanomaterials like BNNSs present unique regulatory challenges due to their distinctive physical and chemical properties, which can differ substantially from bulk materials of identical chemical composition.

The primary objective of this technical research report is to provide a comprehensive understanding of the current regulatory compliance landscape for boron nitride nanosheets across major global markets. This includes identifying applicable regulations, standards, and guidelines that govern the research, production, commercialization, and disposal of BNNSs and BNNS-containing products.

Secondary objectives include mapping jurisdictional variations in regulatory approaches, identifying potential regulatory gaps or inconsistencies that may impact BNNS development, and forecasting likely regulatory developments based on current scientific understanding of BNNS safety profiles and environmental impacts.

The report aims to establish a clear timeline of regulatory milestones affecting BNNSs, from early nanomaterial regulations to current specialized frameworks. Additionally, it seeks to identify emerging regulatory trends that may shape future compliance requirements, particularly as BNNSs move from research settings into commercial applications across electronics, thermal management systems, composite materials, and biomedical devices.

Understanding these regulatory frameworks is crucial as BNNSs transition from laboratory research to industrial scale production and commercial applications. This transition necessitates navigating complex regulatory environments that continue to evolve in response to new scientific data on nanomaterial safety, environmental impact, and life cycle considerations.

Market Demand Analysis for Compliant BNNS Applications

The global market for Boron Nitride Nanosheets (BNNS) applications that meet regulatory compliance standards is experiencing significant growth, driven by increasing demand across multiple industries. Current market assessments indicate that the compliant BNNS market is expanding at a compound annual growth rate exceeding 20%, with particularly strong demand in electronics, aerospace, and biomedical sectors.

In the electronics industry, regulatory-compliant BNNS is increasingly sought after for thermal management applications in next-generation devices. As electronic components continue to miniaturize while processing power increases, manufacturers face critical thermal challenges that BNNS can address while meeting stringent environmental and safety regulations. This segment represents approximately one-third of the current compliant BNNS market demand.

The aerospace and defense sectors demonstrate growing interest in BNNS applications that meet their rigorous regulatory requirements. These industries value BNNS for its exceptional thermal stability, mechanical strength, and chemical resistance in extreme environments. Market analysis reveals that aerospace applications for compliant BNNS are projected to double within the next five years, particularly for components requiring high-temperature resistance and lightweight properties.

Healthcare and biomedical applications represent an emerging market segment with substantial growth potential. Regulatory-compliant BNNS is being explored for drug delivery systems, biomedical imaging, and therapeutic applications. This sector's demand is expected to grow rapidly as regulatory frameworks for nanomaterials in medical applications become more established and standardized globally.

Industrial applications, including lubricants, coatings, and composites, constitute another significant market segment. Manufacturers are increasingly seeking BNNS materials that comply with workplace safety regulations and environmental protection standards. This segment shows steady growth as industries transition toward more sustainable and environmentally friendly materials.

Regional market analysis indicates that North America and Europe currently lead in demand for compliant BNNS applications, primarily due to their stringent regulatory environments and advanced manufacturing sectors. However, the Asia-Pacific region is experiencing the fastest growth rate, driven by expanding electronics manufacturing and increasing regulatory oversight in countries like China, Japan, and South Korea.

Market challenges include price sensitivity, as compliance with various regulatory frameworks often increases production costs. Additionally, inconsistent global regulations create market fragmentation, requiring manufacturers to develop different formulations for different regions. Despite these challenges, the overall market trajectory remains strongly positive as industries increasingly recognize the value of regulatory-compliant advanced materials.

In the electronics industry, regulatory-compliant BNNS is increasingly sought after for thermal management applications in next-generation devices. As electronic components continue to miniaturize while processing power increases, manufacturers face critical thermal challenges that BNNS can address while meeting stringent environmental and safety regulations. This segment represents approximately one-third of the current compliant BNNS market demand.

The aerospace and defense sectors demonstrate growing interest in BNNS applications that meet their rigorous regulatory requirements. These industries value BNNS for its exceptional thermal stability, mechanical strength, and chemical resistance in extreme environments. Market analysis reveals that aerospace applications for compliant BNNS are projected to double within the next five years, particularly for components requiring high-temperature resistance and lightweight properties.

Healthcare and biomedical applications represent an emerging market segment with substantial growth potential. Regulatory-compliant BNNS is being explored for drug delivery systems, biomedical imaging, and therapeutic applications. This sector's demand is expected to grow rapidly as regulatory frameworks for nanomaterials in medical applications become more established and standardized globally.

Industrial applications, including lubricants, coatings, and composites, constitute another significant market segment. Manufacturers are increasingly seeking BNNS materials that comply with workplace safety regulations and environmental protection standards. This segment shows steady growth as industries transition toward more sustainable and environmentally friendly materials.

Regional market analysis indicates that North America and Europe currently lead in demand for compliant BNNS applications, primarily due to their stringent regulatory environments and advanced manufacturing sectors. However, the Asia-Pacific region is experiencing the fastest growth rate, driven by expanding electronics manufacturing and increasing regulatory oversight in countries like China, Japan, and South Korea.

Market challenges include price sensitivity, as compliance with various regulatory frameworks often increases production costs. Additionally, inconsistent global regulations create market fragmentation, requiring manufacturers to develop different formulations for different regions. Despite these challenges, the overall market trajectory remains strongly positive as industries increasingly recognize the value of regulatory-compliant advanced materials.

Global Regulatory Landscape and Technical Challenges

The regulatory landscape for boron nitride nanosheets (BNNS) remains fragmented globally, with significant variations in approach across different jurisdictions. In the United States, the Environmental Protection Agency (EPA) regulates nanomaterials primarily through the Toxic Substances Control Act (TSCA), requiring manufacturers to submit premanufacture notices for new chemical substances, including nanomaterials like BNNS. The EPA has established specific reporting rules for nanomaterials under the TSCA Section 8(a), demanding detailed information on production volumes, manufacturing processes, exposure data, and available health and safety studies.

The European Union implements a more comprehensive framework through the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation. BNNS manufacturers must register their materials when production exceeds one ton annually, providing extensive safety data packages. The EU has also introduced nano-specific amendments to REACH, requiring additional characterization data for nanomaterials, including particle size distribution, surface functionalization, and dustiness.

In Asia, regulatory approaches vary significantly. Japan employs a chemical substance notification system under the Chemical Substances Control Law, while China has implemented new chemical substance notification requirements through MEP Order No. 7. South Korea's K-REACH closely mirrors the European approach but with distinct reporting thresholds and data requirements specific to nanomaterials.

Technical challenges in achieving regulatory compliance for BNNS include standardization issues in characterization methodologies. Different regulatory bodies require varying analytical techniques for particle size measurement, surface area determination, and purity assessment, creating inconsistencies in compliance documentation. The lack of internationally harmonized test guidelines specifically designed for two-dimensional nanomaterials like BNNS further complicates regulatory submissions.

Exposure assessment presents another significant challenge. Quantifying potential worker exposure during BNNS manufacturing and processing requires specialized monitoring equipment and methodologies not yet standardized across industries. Environmental fate modeling for BNNS remains underdeveloped, hampering accurate environmental risk assessments required by multiple regulatory frameworks.

Toxicological data generation faces substantial hurdles due to the unique physicochemical properties of BNNS. Standard toxicity testing protocols may require adaptation to account for the distinctive biological interactions of sheet-like nanomaterials. The potential for BNNS to transform under environmental conditions or within biological systems creates additional complexity in hazard characterization, as regulatory frameworks increasingly demand data on the material throughout its lifecycle.

Cross-border compliance represents a growing challenge as global supply chains incorporate BNNS into various products. Manufacturers must navigate multiple regulatory systems simultaneously, often with contradictory requirements, creating significant administrative and technical burdens that particularly impact smaller enterprises and research institutions working with these advanced materials.

The European Union implements a more comprehensive framework through the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation. BNNS manufacturers must register their materials when production exceeds one ton annually, providing extensive safety data packages. The EU has also introduced nano-specific amendments to REACH, requiring additional characterization data for nanomaterials, including particle size distribution, surface functionalization, and dustiness.

In Asia, regulatory approaches vary significantly. Japan employs a chemical substance notification system under the Chemical Substances Control Law, while China has implemented new chemical substance notification requirements through MEP Order No. 7. South Korea's K-REACH closely mirrors the European approach but with distinct reporting thresholds and data requirements specific to nanomaterials.

Technical challenges in achieving regulatory compliance for BNNS include standardization issues in characterization methodologies. Different regulatory bodies require varying analytical techniques for particle size measurement, surface area determination, and purity assessment, creating inconsistencies in compliance documentation. The lack of internationally harmonized test guidelines specifically designed for two-dimensional nanomaterials like BNNS further complicates regulatory submissions.

Exposure assessment presents another significant challenge. Quantifying potential worker exposure during BNNS manufacturing and processing requires specialized monitoring equipment and methodologies not yet standardized across industries. Environmental fate modeling for BNNS remains underdeveloped, hampering accurate environmental risk assessments required by multiple regulatory frameworks.

Toxicological data generation faces substantial hurdles due to the unique physicochemical properties of BNNS. Standard toxicity testing protocols may require adaptation to account for the distinctive biological interactions of sheet-like nanomaterials. The potential for BNNS to transform under environmental conditions or within biological systems creates additional complexity in hazard characterization, as regulatory frameworks increasingly demand data on the material throughout its lifecycle.

Cross-border compliance represents a growing challenge as global supply chains incorporate BNNS into various products. Manufacturers must navigate multiple regulatory systems simultaneously, often with contradictory requirements, creating significant administrative and technical burdens that particularly impact smaller enterprises and research institutions working with these advanced materials.

Current Compliance Strategies for Nanomaterials

01 Safety assessment and toxicity evaluation of boron nitride nanosheets

Regulatory compliance for boron nitride nanosheets requires comprehensive safety assessments and toxicity evaluations. These evaluations examine potential health hazards, environmental impacts, and biocompatibility of the nanomaterials. Testing protocols typically include cytotoxicity studies, genotoxicity assessments, and environmental fate analyses to ensure that boron nitride nanosheets meet safety standards before commercial applications.- Safety assessment and toxicological evaluation of boron nitride nanosheets: Regulatory compliance for boron nitride nanosheets requires comprehensive safety assessments and toxicological evaluations. These evaluations examine potential health hazards, environmental impacts, and biocompatibility of the nanomaterials. Testing protocols typically include cytotoxicity studies, genotoxicity assessments, and environmental fate analyses to ensure the nanosheets meet safety standards for their intended applications.

- Manufacturing standards and quality control for regulatory compliance: Compliance with regulatory requirements necessitates adherence to strict manufacturing standards and quality control protocols for boron nitride nanosheets. This includes standardized production methods, purity specifications, size distribution control, and contamination prevention measures. Manufacturers must implement robust quality management systems with appropriate documentation and traceability to demonstrate compliance with relevant industry standards and regulations.

- Environmental regulations and sustainable production methods: Regulatory frameworks for boron nitride nanosheets include environmental protection requirements addressing production waste management, emissions control, and ecological impact mitigation. Sustainable manufacturing approaches focus on reducing environmental footprint through green synthesis methods, recycling of precursors, energy efficiency improvements, and minimizing hazardous waste generation. Compliance with these regulations is essential for market authorization in environmentally conscious jurisdictions.

- Product labeling and documentation requirements: Regulatory compliance for boron nitride nanosheets involves specific labeling and documentation requirements. This includes safety data sheets (SDS), hazard classifications, handling instructions, and appropriate warning symbols. Documentation must detail the nanomaterial characteristics, composition, potential risks, and safe handling procedures. Proper classification according to chemical regulations such as REACH in Europe, TSCA in the US, or similar frameworks in other regions is mandatory for legal distribution and use.

- Application-specific regulatory frameworks for boron nitride nanosheets: Different applications of boron nitride nanosheets are subject to distinct regulatory requirements. In biomedical applications, additional biocompatibility testing and clinical evaluation may be necessary. For electronic or industrial uses, performance standards and electrical safety regulations apply. Food contact or cosmetic applications face particularly stringent safety assessments. Companies must navigate these sector-specific regulatory frameworks and obtain appropriate certifications based on the intended use of their boron nitride nanosheet products.

02 Manufacturing standards and quality control protocols

Regulatory frameworks require adherence to specific manufacturing standards and quality control protocols for boron nitride nanosheets. These standards govern production methods, purity levels, dimensional consistency, and structural integrity. Manufacturers must implement robust quality management systems, conduct regular testing, and maintain detailed documentation of production processes to ensure compliance with regulatory requirements for nanomaterial production.Expand Specific Solutions03 Environmental regulations and waste management

Compliance with environmental regulations is essential for boron nitride nanosheet production and application. These regulations address potential environmental impacts, including air and water emissions, waste disposal, and ecosystem effects. Manufacturers must develop proper waste management protocols, implement pollution prevention measures, and conduct environmental impact assessments to ensure that boron nitride nanosheet production and disposal comply with environmental protection standards.Expand Specific Solutions04 Product labeling and safety data sheet requirements

Regulatory compliance for boron nitride nanosheets includes specific requirements for product labeling and safety data sheets. These requirements ensure that users receive comprehensive information about composition, potential hazards, handling precautions, and emergency procedures. Manufacturers must accurately classify nanomaterials, provide detailed hazard information, and update safety documentation as new data becomes available to maintain compliance with global chemical regulations.Expand Specific Solutions05 Registration and reporting obligations for nanomaterials

Boron nitride nanosheets are subject to registration and reporting obligations under various regulatory frameworks for nanomaterials. These obligations may include pre-market notifications, substance registrations, and periodic reporting of production volumes and uses. Manufacturers and importers must identify applicable regulations in different jurisdictions, submit required documentation, and maintain records of compliance activities to legally market products containing boron nitride nanosheets.Expand Specific Solutions

Key Regulatory Bodies and Industry Stakeholders

The regulatory landscape for Boron Nitride Nanosheets (BNNS) is evolving as this technology transitions from research to commercialization. Currently, the market is in an early growth phase with increasing applications in electronics, thermal management, and composites. Academic institutions (Deakin University, Shandong University) are driving fundamental research while specialized companies (BNNT Materials, White Graphene Ltd., Li-S Energy) are commercializing applications. Major corporations (Texas Instruments, Microsoft, Momentive) are exploring integration into existing product lines. Research organizations (NASA, NIMS, KIST) are developing standards and safety protocols. The regulatory framework remains fragmented globally, with different approaches to nanomaterial classification, workplace exposure limits, and environmental impact assessments.

Suzhou Institute of Nano-Tech & Nano-Bionics (SINANO)

Technical Solution: SINANO has developed a comprehensive regulatory compliance framework for boron nitride nanosheets (BNNS) that integrates both Chinese national standards and international guidelines. Their approach includes systematic physicochemical characterization protocols that align with ISO/TR 13014 and ISO/TS 80004 series standards for nanomaterial characterization. SINANO has established specialized analytical methods for BNNS purity assessment, surface functionality verification, and dispersion stability evaluation that meet regulatory requirements. Their compliance strategy incorporates a tiered risk assessment methodology that begins with in vitro screening followed by targeted in vivo studies when necessary. The institute has developed standardized protocols for evaluating potential environmental release scenarios throughout the BNNS lifecycle, from production to disposal. SINANO actively participates in China's national standardization committees for nanomaterials and collaborates with international organizations like the OECD Working Party on Manufactured Nanomaterials to harmonize their compliance approaches with global developments.

Strengths: Strong integration of compliance with research capabilities; extensive analytical facilities for comprehensive nanomaterial characterization; direct connection to Chinese regulatory authorities and standards development. Weaknesses: May face challenges in navigating diverse international regulatory frameworks; potential gaps between research-oriented compliance approaches and industrial-scale implementation requirements.

National Institute for Materials Science IAI

Technical Solution: The National Institute for Materials Science (NIMS) in Japan has developed a sophisticated regulatory compliance framework for boron nitride nanosheets that serves as a model for research institutions globally. Their approach integrates Japan's chemical substances control law (CSCL) requirements with international best practices. NIMS has established standardized protocols for BNNS characterization that align with ISO technical specifications for nanomaterials (ISO/TS 80004 series) and OECD test guidelines. Their compliance strategy includes comprehensive physicochemical characterization (thickness, lateral dimensions, surface properties), systematic toxicological assessment following OECD test guidelines for nanomaterials, and environmental fate studies examining potential persistence and bioaccumulation. NIMS has developed specialized analytical methods for detecting and quantifying BNNS in environmental and biological matrices to support exposure assessment requirements. The institute maintains a dedicated regulatory science group that collaborates with Japan's Ministry of Economy, Trade and Industry (METI) and international organizations to develop science-based regulatory approaches for 2D nanomaterials.

Strengths: World-class materials characterization capabilities with specialized expertise in 2D nanomaterials; strong connection between fundamental research and regulatory science; active participation in international standardization efforts. Weaknesses: Primary focus on research applications rather than commercial-scale implementation; potential gaps in addressing market-specific regulatory requirements outside Japan.

Critical Regulatory Standards and Technical Guidelines

Boron nitride nanosheets and methods of making and using the same

PatentInactiveUS20160137502A1

Innovation

- A method for synthesizing boron nitride nanosheets with scrolled, close-ended structures using a chemical vapor deposition process involving boron, magnesium oxide, and iron oxide in a furnace with ammonia gas, which allows for better contact with hot surfaces and coolants, enabling efficient heat dissipation without being water-repelling.

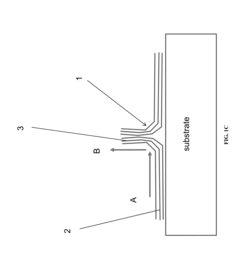

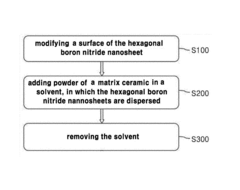

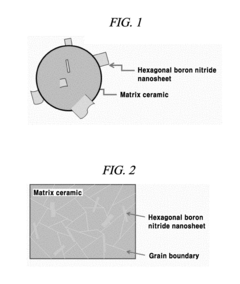

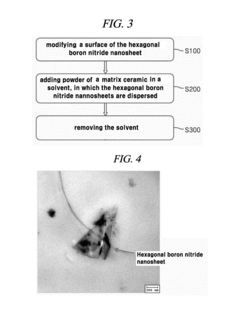

Hexagonal boron nitride nanosheet/ceramic nanocomposite powder and producing method of the same, and hexagonal boron nitride nanosheet/ceramic nanocomposite materials and producing method of the same

PatentInactiveUS9745499B2

Innovation

- The development of surface-modified hexagonal boron nitride nanosheets dispersed in a matrix ceramic using covalent or non-covalent functionalization and solvent-based dispersion methods to create a homogeneous nanocomposite powder, followed by sintering to produce a nanocomposite material with improved mechanical and thermal properties.

Environmental and Health Impact Assessment Methods

The assessment of environmental and health impacts related to Boron Nitride Nanosheets (BNNS) requires systematic methodologies that align with international standards. Current assessment frameworks typically incorporate both in vitro and in vivo toxicological studies, focusing on exposure routes including inhalation, dermal contact, and ingestion. These methodologies help establish safety thresholds and inform regulatory decisions.

Life Cycle Assessment (LCA) represents a cornerstone methodology for evaluating BNNS environmental impacts from production through disposal. This approach quantifies energy consumption, resource depletion, emissions, and waste generation across the material's entire lifecycle. Standardized LCA protocols such as ISO 14040 and 14044 provide structured frameworks that enable consistent evaluation and comparison with alternative materials.

Risk assessment protocols for BNNS typically follow a four-step process: hazard identification, dose-response assessment, exposure assessment, and risk characterization. These assessments incorporate both deterministic and probabilistic modeling approaches to account for variability and uncertainty in exposure scenarios. Specialized techniques such as high-throughput screening and computational toxicology have emerged as valuable tools for preliminary hazard identification.

Environmental fate modeling has become increasingly sophisticated for nanomaterials like BNNS. These models track potential migration pathways through air, water, and soil matrices, accounting for aggregation, sedimentation, and transformation processes. Advanced analytical techniques including electron microscopy, spectroscopy, and chromatography enable precise detection and characterization of BNNS in environmental samples, with detection limits now reaching parts-per-billion levels.

Occupational exposure assessment methodologies have evolved specifically for nanomaterials, incorporating real-time monitoring instruments and personal sampling devices. These approaches measure airborne concentrations, particle size distributions, and surface deposition rates in manufacturing and handling environments. Biomonitoring techniques are also being developed to track potential accumulation in exposed workers, though standardization remains challenging.

Emerging methodologies include adverse outcome pathway (AOP) frameworks that link molecular initiating events to adverse outcomes at organism and population levels. Additionally, grouping and read-across approaches enable the extrapolation of toxicological data between similar nanomaterials, potentially reducing testing requirements. These innovative approaches, combined with traditional assessment methods, provide a comprehensive framework for evaluating BNNS safety and environmental compatibility.

Life Cycle Assessment (LCA) represents a cornerstone methodology for evaluating BNNS environmental impacts from production through disposal. This approach quantifies energy consumption, resource depletion, emissions, and waste generation across the material's entire lifecycle. Standardized LCA protocols such as ISO 14040 and 14044 provide structured frameworks that enable consistent evaluation and comparison with alternative materials.

Risk assessment protocols for BNNS typically follow a four-step process: hazard identification, dose-response assessment, exposure assessment, and risk characterization. These assessments incorporate both deterministic and probabilistic modeling approaches to account for variability and uncertainty in exposure scenarios. Specialized techniques such as high-throughput screening and computational toxicology have emerged as valuable tools for preliminary hazard identification.

Environmental fate modeling has become increasingly sophisticated for nanomaterials like BNNS. These models track potential migration pathways through air, water, and soil matrices, accounting for aggregation, sedimentation, and transformation processes. Advanced analytical techniques including electron microscopy, spectroscopy, and chromatography enable precise detection and characterization of BNNS in environmental samples, with detection limits now reaching parts-per-billion levels.

Occupational exposure assessment methodologies have evolved specifically for nanomaterials, incorporating real-time monitoring instruments and personal sampling devices. These approaches measure airborne concentrations, particle size distributions, and surface deposition rates in manufacturing and handling environments. Biomonitoring techniques are also being developed to track potential accumulation in exposed workers, though standardization remains challenging.

Emerging methodologies include adverse outcome pathway (AOP) frameworks that link molecular initiating events to adverse outcomes at organism and population levels. Additionally, grouping and read-across approaches enable the extrapolation of toxicological data between similar nanomaterials, potentially reducing testing requirements. These innovative approaches, combined with traditional assessment methods, provide a comprehensive framework for evaluating BNNS safety and environmental compatibility.

International Trade Implications for BNNS Technologies

The global trade landscape for Boron Nitride Nanosheets (BNNS) technologies is increasingly complex, with regulatory frameworks varying significantly across different regions. Major trading blocs including the United States, European Union, China, and Japan have established distinct approaches to nanomaterial regulation that directly impact BNNS commercialization and international distribution.

Export control regulations present a significant consideration for BNNS technologies, particularly due to their potential dual-use applications in both civilian and military sectors. The Wassenaar Arrangement, which governs export controls for conventional arms and dual-use technologies across 42 participating states, has implications for certain high-performance BNNS applications, especially those with thermal management capabilities relevant to defense systems.

Tariff classifications for BNNS products remain inconsistent globally, creating trade barriers and compliance challenges. Most jurisdictions classify nanomaterials under the Harmonized System (HS) codes for chemicals or advanced materials, but specific subclassifications for nanomaterials like BNNS are often lacking, leading to customs interpretation variations and potential misclassification risks.

Non-tariff barriers significantly impact BNNS trade flows, with technical regulations, conformity assessment procedures, and certification requirements creating market access challenges. The EU's REACH regulation requires registration of nanomaterials exceeding one metric ton annually, while the US EPA employs the Toxic Substances Control Act (TSCA) to regulate new chemical substances, including nanomaterials like BNNS.

Trade agreements increasingly address advanced materials, with recent agreements like the CPTPP and USMCA containing provisions relevant to nanomaterial trade. These agreements aim to harmonize regulatory approaches and reduce technical barriers to trade, potentially facilitating smoother international commerce in BNNS technologies.

Intellectual property protection represents another critical dimension of international trade for BNNS technologies. Patent enforcement varies significantly across jurisdictions, with some countries offering robust protection while others present challenges in safeguarding proprietary BNNS production methods and applications. Companies must develop comprehensive IP strategies accounting for these international variations.

Supply chain considerations further complicate the international trade landscape for BNNS. The concentration of production capabilities in specific regions creates potential vulnerabilities, while increasing emphasis on supply chain resilience and transparency may drive diversification of sourcing strategies for BNNS materials and related technologies.

Export control regulations present a significant consideration for BNNS technologies, particularly due to their potential dual-use applications in both civilian and military sectors. The Wassenaar Arrangement, which governs export controls for conventional arms and dual-use technologies across 42 participating states, has implications for certain high-performance BNNS applications, especially those with thermal management capabilities relevant to defense systems.

Tariff classifications for BNNS products remain inconsistent globally, creating trade barriers and compliance challenges. Most jurisdictions classify nanomaterials under the Harmonized System (HS) codes for chemicals or advanced materials, but specific subclassifications for nanomaterials like BNNS are often lacking, leading to customs interpretation variations and potential misclassification risks.

Non-tariff barriers significantly impact BNNS trade flows, with technical regulations, conformity assessment procedures, and certification requirements creating market access challenges. The EU's REACH regulation requires registration of nanomaterials exceeding one metric ton annually, while the US EPA employs the Toxic Substances Control Act (TSCA) to regulate new chemical substances, including nanomaterials like BNNS.

Trade agreements increasingly address advanced materials, with recent agreements like the CPTPP and USMCA containing provisions relevant to nanomaterial trade. These agreements aim to harmonize regulatory approaches and reduce technical barriers to trade, potentially facilitating smoother international commerce in BNNS technologies.

Intellectual property protection represents another critical dimension of international trade for BNNS technologies. Patent enforcement varies significantly across jurisdictions, with some countries offering robust protection while others present challenges in safeguarding proprietary BNNS production methods and applications. Companies must develop comprehensive IP strategies accounting for these international variations.

Supply chain considerations further complicate the international trade landscape for BNNS. The concentration of production capabilities in specific regions creates potential vulnerabilities, while increasing emphasis on supply chain resilience and transparency may drive diversification of sourcing strategies for BNNS materials and related technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!