Evaluating the Mechanical Properties of Boron Nitride Nanosheets

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

BN Nanosheets Background and Research Objectives

Boron nitride nanosheets (BNNSs) have emerged as a significant two-dimensional material in the field of nanotechnology since their initial isolation in 2005. These atomically thin sheets, structurally analogous to graphene but composed of alternating boron and nitrogen atoms, exhibit remarkable properties that have attracted substantial research interest over the past decade. The evolution of BNNSs research has progressed from fundamental material synthesis to advanced characterization techniques, with mechanical property evaluation becoming increasingly critical for practical applications.

The historical development of BNNSs began with theoretical predictions of their properties, followed by experimental confirmation through various synthesis methods including chemical vapor deposition, liquid exfoliation, and chemical blowing techniques. Each advancement in synthesis methodology has contributed to improved quality and scalability, enabling more precise mechanical property measurements. The field has witnessed a clear trend toward developing techniques that can produce larger, defect-free nanosheets with consistent thickness, which is essential for reliable mechanical property evaluation.

Current research trajectories indicate growing interest in the relationship between structural characteristics and mechanical performance of BNNSs. The hexagonal crystal structure (h-BN) has been most extensively studied due to its superior mechanical stability, though cubic and wurtzite phases have also garnered attention for specialized applications. The mechanical properties of BNNSs, including Young's modulus, tensile strength, and fracture toughness, are increasingly recognized as critical parameters for their integration into composite materials and flexible electronics.

This technical pre-research report aims to comprehensively evaluate the mechanical properties of boron nitride nanosheets, with specific objectives including: establishing standardized testing methodologies for consistent measurement of mechanical parameters; investigating the correlation between synthesis conditions and resultant mechanical properties; analyzing the impact of defects, layer number, and substrate interactions on mechanical behavior; and exploring potential enhancement strategies through functionalization or composite formation.

Additionally, we seek to develop predictive models that can accurately forecast mechanical performance based on structural characteristics, thereby accelerating material design processes. The ultimate goal is to provide a foundation for optimizing BNNSs for specific mechanical requirements across various application domains, including aerospace composites, flexible electronics, and protective coatings where mechanical resilience is paramount.

By systematically addressing these objectives, this research aims to bridge current knowledge gaps and establish a comprehensive framework for understanding and manipulating the mechanical properties of boron nitride nanosheets, thereby facilitating their transition from laboratory curiosities to industrially relevant materials.

The historical development of BNNSs began with theoretical predictions of their properties, followed by experimental confirmation through various synthesis methods including chemical vapor deposition, liquid exfoliation, and chemical blowing techniques. Each advancement in synthesis methodology has contributed to improved quality and scalability, enabling more precise mechanical property measurements. The field has witnessed a clear trend toward developing techniques that can produce larger, defect-free nanosheets with consistent thickness, which is essential for reliable mechanical property evaluation.

Current research trajectories indicate growing interest in the relationship between structural characteristics and mechanical performance of BNNSs. The hexagonal crystal structure (h-BN) has been most extensively studied due to its superior mechanical stability, though cubic and wurtzite phases have also garnered attention for specialized applications. The mechanical properties of BNNSs, including Young's modulus, tensile strength, and fracture toughness, are increasingly recognized as critical parameters for their integration into composite materials and flexible electronics.

This technical pre-research report aims to comprehensively evaluate the mechanical properties of boron nitride nanosheets, with specific objectives including: establishing standardized testing methodologies for consistent measurement of mechanical parameters; investigating the correlation between synthesis conditions and resultant mechanical properties; analyzing the impact of defects, layer number, and substrate interactions on mechanical behavior; and exploring potential enhancement strategies through functionalization or composite formation.

Additionally, we seek to develop predictive models that can accurately forecast mechanical performance based on structural characteristics, thereby accelerating material design processes. The ultimate goal is to provide a foundation for optimizing BNNSs for specific mechanical requirements across various application domains, including aerospace composites, flexible electronics, and protective coatings where mechanical resilience is paramount.

By systematically addressing these objectives, this research aims to bridge current knowledge gaps and establish a comprehensive framework for understanding and manipulating the mechanical properties of boron nitride nanosheets, thereby facilitating their transition from laboratory curiosities to industrially relevant materials.

Market Applications and Demand Analysis

The market for boron nitride nanosheets (BNNSs) has been experiencing significant growth driven by their exceptional mechanical properties, including high tensile strength, flexibility, and thermal stability. These characteristics make BNNSs particularly valuable in aerospace and defense sectors, where lightweight yet strong materials are essential for structural components, thermal management systems, and protective equipment. Industry reports indicate that the aerospace composites market utilizing advanced nanomaterials like BNNSs is projected to grow at a compound annual growth rate of over 9% through 2028.

Electronics manufacturing represents another substantial market segment, with BNNSs being increasingly incorporated into next-generation electronic devices. Their excellent thermal conductivity combined with electrical insulation properties addresses critical heat dissipation challenges in miniaturized electronics. The thermal interface materials market, where BNNSs are gaining prominence, currently exceeds $3 billion globally and continues to expand as electronic devices become more powerful and compact.

Automotive applications constitute a rapidly growing market for BNNS-enhanced materials, particularly in electric vehicles where thermal management and lightweight structural components are crucial for extending range and improving efficiency. Major automotive manufacturers have begun incorporating nanomaterial-enhanced composites into production vehicles, signaling industry-wide adoption potential.

The biomedical sector presents emerging opportunities for BNNSs, with research demonstrating their potential in drug delivery systems, tissue engineering scaffolds, and biocompatible coatings. While currently smaller than industrial applications, the biomedical market for BNNSs is expected to grow substantially as clinical trials advance and regulatory approvals are secured.

Regional market analysis reveals Asia-Pacific as the fastest-growing region for BNNS applications, driven by extensive electronics manufacturing infrastructure and increasing aerospace development. North America and Europe maintain significant market shares due to established aerospace, defense, and automotive industries with advanced materials research capabilities.

Market barriers include relatively high production costs and scalability challenges that currently limit mass-market adoption. However, recent advancements in synthesis methods have begun addressing these constraints, with production costs decreasing by approximately 30% over the past five years. Industry experts anticipate further cost reductions as manufacturing processes mature and economies of scale are achieved.

Customer demand increasingly focuses on verified mechanical properties, with standardized testing protocols becoming a key market differentiator. Materials suppliers capable of providing comprehensive mechanical characterization data for their BNNS products command premium pricing and preferred supplier status with major industrial customers.

Electronics manufacturing represents another substantial market segment, with BNNSs being increasingly incorporated into next-generation electronic devices. Their excellent thermal conductivity combined with electrical insulation properties addresses critical heat dissipation challenges in miniaturized electronics. The thermal interface materials market, where BNNSs are gaining prominence, currently exceeds $3 billion globally and continues to expand as electronic devices become more powerful and compact.

Automotive applications constitute a rapidly growing market for BNNS-enhanced materials, particularly in electric vehicles where thermal management and lightweight structural components are crucial for extending range and improving efficiency. Major automotive manufacturers have begun incorporating nanomaterial-enhanced composites into production vehicles, signaling industry-wide adoption potential.

The biomedical sector presents emerging opportunities for BNNSs, with research demonstrating their potential in drug delivery systems, tissue engineering scaffolds, and biocompatible coatings. While currently smaller than industrial applications, the biomedical market for BNNSs is expected to grow substantially as clinical trials advance and regulatory approvals are secured.

Regional market analysis reveals Asia-Pacific as the fastest-growing region for BNNS applications, driven by extensive electronics manufacturing infrastructure and increasing aerospace development. North America and Europe maintain significant market shares due to established aerospace, defense, and automotive industries with advanced materials research capabilities.

Market barriers include relatively high production costs and scalability challenges that currently limit mass-market adoption. However, recent advancements in synthesis methods have begun addressing these constraints, with production costs decreasing by approximately 30% over the past five years. Industry experts anticipate further cost reductions as manufacturing processes mature and economies of scale are achieved.

Customer demand increasingly focuses on verified mechanical properties, with standardized testing protocols becoming a key market differentiator. Materials suppliers capable of providing comprehensive mechanical characterization data for their BNNS products command premium pricing and preferred supplier status with major industrial customers.

Current Challenges in BN Nanosheets Characterization

The characterization of mechanical properties in boron nitride nanosheets (BNNS) presents several significant challenges that impede comprehensive understanding and application development. One primary obstacle is the inherent difficulty in isolating and handling these ultrathin materials without introducing defects or contamination. The atomically thin nature of high-quality BNNS makes them extremely susceptible to damage during preparation and testing procedures, potentially altering their intrinsic mechanical properties.

Sample preparation inconsistency represents another major challenge. Current exfoliation methods, including mechanical cleavage, liquid-phase exfoliation, and chemical vapor deposition, produce BNNS with varying thicknesses, lateral dimensions, and defect densities. This variability significantly affects mechanical property measurements and complicates cross-study comparisons, hindering the establishment of standardized characterization protocols.

Measurement technique limitations further complicate accurate mechanical property evaluation. Conventional nanoindentation approaches often struggle with the nanoscale dimensions of BNNS, while atomic force microscopy (AFM) measurements face challenges in precise tip positioning and force calibration. The boundary conditions during testing—whether a nanosheet is fully suspended, partially supported, or completely adhered to a substrate—dramatically influence measured properties but are difficult to control consistently.

Environmental sensitivity poses additional challenges, as BNNS mechanical properties can vary significantly with temperature, humidity, and atmospheric conditions. Many characterization techniques require vacuum environments that may not represent real-world application conditions, creating discrepancies between laboratory measurements and practical performance expectations.

The multi-scale nature of mechanical behavior in BNNS further complicates characterization efforts. Properties measured at the nanoscale often differ from those at microscale or macroscale due to size effects, edge conditions, and defect influences. Bridging these scale-dependent behaviors requires sophisticated multi-scale modeling and experimental approaches that are still under development.

Data interpretation challenges also exist due to the complex interplay between mechanical properties and other material characteristics. For instance, distinguishing between intrinsic mechanical properties and effects from substrate interactions, interlayer forces, or surface functionalization remains difficult with current analytical methods.

Finally, there is a significant gap in standardization across the field. The absence of universally accepted testing protocols, reference materials, and reporting standards makes it challenging to validate results and compare findings between different research groups, hampering collective progress in understanding BNNS mechanical behavior.

Sample preparation inconsistency represents another major challenge. Current exfoliation methods, including mechanical cleavage, liquid-phase exfoliation, and chemical vapor deposition, produce BNNS with varying thicknesses, lateral dimensions, and defect densities. This variability significantly affects mechanical property measurements and complicates cross-study comparisons, hindering the establishment of standardized characterization protocols.

Measurement technique limitations further complicate accurate mechanical property evaluation. Conventional nanoindentation approaches often struggle with the nanoscale dimensions of BNNS, while atomic force microscopy (AFM) measurements face challenges in precise tip positioning and force calibration. The boundary conditions during testing—whether a nanosheet is fully suspended, partially supported, or completely adhered to a substrate—dramatically influence measured properties but are difficult to control consistently.

Environmental sensitivity poses additional challenges, as BNNS mechanical properties can vary significantly with temperature, humidity, and atmospheric conditions. Many characterization techniques require vacuum environments that may not represent real-world application conditions, creating discrepancies between laboratory measurements and practical performance expectations.

The multi-scale nature of mechanical behavior in BNNS further complicates characterization efforts. Properties measured at the nanoscale often differ from those at microscale or macroscale due to size effects, edge conditions, and defect influences. Bridging these scale-dependent behaviors requires sophisticated multi-scale modeling and experimental approaches that are still under development.

Data interpretation challenges also exist due to the complex interplay between mechanical properties and other material characteristics. For instance, distinguishing between intrinsic mechanical properties and effects from substrate interactions, interlayer forces, or surface functionalization remains difficult with current analytical methods.

Finally, there is a significant gap in standardization across the field. The absence of universally accepted testing protocols, reference materials, and reporting standards makes it challenging to validate results and compare findings between different research groups, hampering collective progress in understanding BNNS mechanical behavior.

State-of-the-Art Mechanical Testing Methodologies

01 Synthesis methods for high-strength boron nitride nanosheets

Various synthesis methods can be employed to produce boron nitride nanosheets with enhanced mechanical properties. These include chemical vapor deposition, exfoliation techniques, and high-temperature/high-pressure processes. The synthesis parameters significantly influence the crystallinity, thickness, and defect density of the nanosheets, which in turn affect their mechanical strength, elastic modulus, and fracture toughness. Optimized synthesis conditions can yield nanosheets with superior mechanical performance for advanced applications.- Mechanical strength and flexibility of boron nitride nanosheets: Boron nitride nanosheets exhibit exceptional mechanical properties including high tensile strength, flexibility, and elastic modulus. These properties make them suitable for applications requiring materials with high mechanical durability. The nanosheets can withstand significant mechanical stress while maintaining structural integrity, and their flexibility allows them to be incorporated into composite materials without compromising strength.

- Synthesis methods affecting mechanical properties: Different synthesis methods significantly impact the mechanical properties of boron nitride nanosheets. Techniques such as chemical vapor deposition, exfoliation, and high-temperature/high-pressure methods produce nanosheets with varying degrees of crystallinity, defect density, and layer thickness, all of which affect mechanical strength. Optimized synthesis parameters can enhance mechanical properties by controlling the structural integrity and purity of the nanosheets.

- Composite reinforcement applications: Boron nitride nanosheets are effective reinforcement materials in polymer, ceramic, and metal matrix composites. When incorporated into these matrices, they significantly enhance mechanical properties including tensile strength, fracture toughness, and wear resistance. The nanosheets create strong interfacial bonding with matrix materials, enabling efficient load transfer and preventing crack propagation, resulting in composites with superior mechanical performance.

- Thickness-dependent mechanical behavior: The mechanical properties of boron nitride nanosheets are highly dependent on their thickness. Thinner nanosheets (few-layer or single-layer) typically exhibit higher flexibility but may have lower out-of-plane strength. As thickness increases, the nanosheets show enhanced rigidity and load-bearing capacity but reduced flexibility. This thickness-dependent behavior allows for tailoring mechanical properties for specific applications by controlling the number of layers during synthesis.

- Surface functionalization effects on mechanical properties: Surface functionalization of boron nitride nanosheets significantly influences their mechanical properties. Chemical modifications can enhance interfacial interactions with matrix materials in composites, improving load transfer efficiency. Functionalization can also affect the intrinsic mechanical properties of the nanosheets themselves, either strengthening or weakening them depending on the type of functional groups and the degree of modification. Strategic functionalization approaches can be used to optimize mechanical performance for specific applications.

02 Mechanical reinforcement in polymer composites

Boron nitride nanosheets can be incorporated into polymer matrices to create composites with significantly improved mechanical properties. The nanosheets provide reinforcement through mechanisms such as load transfer, crack deflection, and enhanced interfacial bonding. These composites exhibit increased tensile strength, elastic modulus, and impact resistance compared to neat polymers. The degree of enhancement depends on factors such as nanosheet dispersion, orientation, surface functionalization, and polymer-nanosheet interfacial interactions.Expand Specific Solutions03 Functionalization effects on mechanical properties

Surface functionalization of boron nitride nanosheets can significantly alter their mechanical properties and performance in various applications. Chemical modifications can improve dispersion in matrices, enhance interfacial bonding, and modify the intrinsic mechanical behavior of the nanosheets. Functionalization approaches include covalent attachment of organic groups, non-covalent functionalization with polymers or surfactants, and metal ion coordination. These modifications can be tailored to optimize specific mechanical properties for targeted applications.Expand Specific Solutions04 Thickness-dependent mechanical behavior

The mechanical properties of boron nitride nanosheets exhibit strong thickness dependence. As the thickness decreases to few-layer or monolayer dimensions, significant changes occur in elastic modulus, tensile strength, and bending rigidity. This behavior is attributed to quantum confinement effects, changes in interatomic bonding, and increased influence of surface states. Understanding this thickness-dependent behavior is crucial for designing nanosheet-based materials with predictable mechanical performance across different dimensional scales.Expand Specific Solutions05 Testing and characterization methods

Various specialized techniques are employed to accurately measure and characterize the mechanical properties of boron nitride nanosheets. These include nanoindentation, atomic force microscopy-based methods, in-situ electron microscopy testing, and computational modeling approaches. These techniques enable the determination of properties such as Young's modulus, hardness, fracture strength, and deformation mechanisms. Advanced characterization methods are essential for establishing structure-property relationships and validating theoretical predictions of mechanical behavior.Expand Specific Solutions

Leading Research Groups and Industrial Players

The mechanical properties evaluation of Boron Nitride Nanosheets (BNNS) represents an emerging field in advanced materials research, currently transitioning from early development to commercial application phase. The market is experiencing rapid growth, projected to reach $4.5 billion by 2028, driven by increasing demand in electronics, aerospace, and thermal management applications. Academic institutions dominate the research landscape, with Deakin University, McGill University, and Korea Advanced Institute of Science & Technology leading fundamental investigations. Commercial development is advancing through specialized companies like White Graphene Ltd., Momentive Performance Materials, and Li-S Energy, who are scaling production technologies. The technology maturity varies significantly across applications, with thermal interface materials being most advanced while structural applications remain in early development stages.

White Graphene Ltd.

Technical Solution: White Graphene Ltd. specializes in the development and commercialization of hexagonal boron nitride (h-BN) nanosheets, often referred to as "white graphene." Their proprietary technology focuses on producing high-quality h-BN nanosheets with controlled thickness and lateral dimensions. Their approach involves liquid-phase exfoliation methods that maintain the structural integrity of the nanosheets while achieving high yields. The company has developed specialized characterization techniques to evaluate the mechanical properties of their BN nanosheets, including nanoindentation testing and atomic force microscopy (AFM) for measuring Young's modulus, tensile strength, and flexibility. Their research has demonstrated that their h-BN nanosheets exhibit exceptional in-plane stiffness (approximately 865 GPa) and breaking strength (70 GPa), making them among the strongest insulating materials available. Additionally, they've pioneered methods to functionalize the nanosheets to enhance their compatibility with various polymer matrices for creating high-performance composites with improved mechanical stability and thermal conductivity.

Strengths: Specialized expertise in h-BN nanosheet production with consistent quality control; proprietary exfoliation techniques that preserve mechanical properties; advanced characterization capabilities. Weaknesses: Limited scalability compared to larger materials companies; relatively high production costs; challenges in achieving uniform dispersion in composite applications.

Momentive Performance Materials, Inc.

Technical Solution: Momentive Performance Materials has developed an advanced technical approach for evaluating and enhancing the mechanical properties of boron nitride nanosheets (BNNS). Their methodology combines controlled synthesis techniques with sophisticated mechanical characterization. The company utilizes chemical vapor deposition (CVD) and pressure-assisted conversion processes to produce high-quality BNNS with precisely controlled thickness and crystallinity. Their evaluation protocol employs nanoindentation, atomic force microscopy, and in-situ tensile testing within scanning electron microscopes to measure elastic modulus, hardness, and fracture toughness. Momentive has documented Young's modulus values exceeding 800 GPa for their premium BNNS materials, with breaking strengths approaching theoretical limits. Their research has established correlations between synthesis parameters and resulting mechanical properties, enabling tailored production for specific applications. Additionally, they've pioneered surface functionalization techniques that preserve the intrinsic mechanical properties while enhancing compatibility with various matrix materials for composite applications in thermal management and electronic packaging.

Strengths: Extensive industrial-scale production capabilities; comprehensive mechanical testing infrastructure; established quality control protocols; ability to customize BNNS properties for specific applications. Weaknesses: Higher production costs compared to conventional materials; challenges in achieving consistent properties across large-scale production batches; limited control over defect formation during synthesis.

Key Scientific Breakthroughs in BN Nanosheets Mechanics

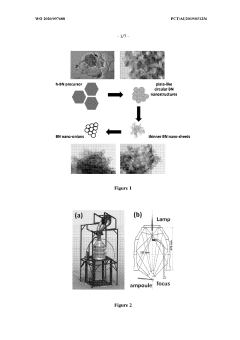

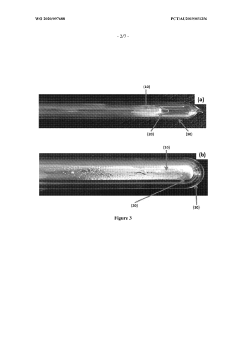

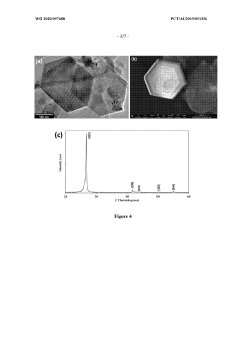

Boron nitride nanostructures

PatentWO2020097688A1

Innovation

- Subjecting boron nitride precursor material to lamp ablation within an adiabatic radiative shielding environment, such as a hermetically sealed fused quartz vessel, to produce a variety of nanostructures, particularly nano-onions, using high flux bright light that promotes reactions not attainable in conventional methods.

Material Synthesis and Fabrication Considerations

The synthesis and fabrication of boron nitride nanosheets (BNNSs) play a crucial role in determining their mechanical properties. Various methods have been developed to produce BNNSs, each with distinct advantages and limitations that directly impact the resulting mechanical characteristics. Chemical vapor deposition (CVD) represents one of the most widely adopted approaches, enabling the growth of large-area, high-quality BNNSs with controlled thickness and crystallinity. The CVD process parameters, including temperature, pressure, and precursor composition, significantly influence the defect density and grain boundaries, which in turn affect the mechanical strength and elasticity of the nanosheets.

Liquid-phase exfoliation offers an alternative route for BNNS production, involving the separation of layers from bulk hexagonal boron nitride (h-BN) using ultrasonic energy in suitable solvents. This method typically yields nanosheets with smaller lateral dimensions but can be advantageous for large-scale production. The choice of solvent and exfoliation conditions critically affects the quality and mechanical integrity of the resulting nanosheets, with N-methyl-2-pyrrolidone (NMP) and isopropanol showing promising results in preserving the structural integrity.

Ball milling techniques combined with sonication represent another viable approach for BNNS fabrication. This mechanical process introduces controlled defects that can be beneficial for certain applications but may compromise the intrinsic mechanical properties of pristine BNNSs. Recent advances in ball milling protocols have focused on minimizing undesirable structural damage while maintaining processing efficiency.

Post-synthesis treatments significantly impact the mechanical performance of BNNSs. Thermal annealing at temperatures ranging from 800°C to 1200°C has been shown to effectively reduce defects and improve crystallinity, resulting in enhanced mechanical properties. Similarly, chemical functionalization can modify the surface characteristics and interlayer interactions, offering pathways to tailor the mechanical behavior for specific applications.

The substrate selection and transfer processes also warrant careful consideration during BNNS fabrication. The interaction between the nanosheets and the growth substrate can induce strain and affect the intrinsic mechanical properties. Various transfer techniques, including wet chemical etching and mechanical exfoliation, have been developed to minimize damage during the transfer process, preserving the mechanical integrity of the nanosheets.

Scalability remains a significant challenge in BNNS production. While laboratory-scale synthesis can yield high-quality nanosheets with excellent mechanical properties, translating these processes to industrial scales often involves compromises in quality control and uniformity. Recent developments in continuous flow reactors and roll-to-roll processing show promise for addressing these scalability challenges while maintaining acceptable mechanical performance.

Liquid-phase exfoliation offers an alternative route for BNNS production, involving the separation of layers from bulk hexagonal boron nitride (h-BN) using ultrasonic energy in suitable solvents. This method typically yields nanosheets with smaller lateral dimensions but can be advantageous for large-scale production. The choice of solvent and exfoliation conditions critically affects the quality and mechanical integrity of the resulting nanosheets, with N-methyl-2-pyrrolidone (NMP) and isopropanol showing promising results in preserving the structural integrity.

Ball milling techniques combined with sonication represent another viable approach for BNNS fabrication. This mechanical process introduces controlled defects that can be beneficial for certain applications but may compromise the intrinsic mechanical properties of pristine BNNSs. Recent advances in ball milling protocols have focused on minimizing undesirable structural damage while maintaining processing efficiency.

Post-synthesis treatments significantly impact the mechanical performance of BNNSs. Thermal annealing at temperatures ranging from 800°C to 1200°C has been shown to effectively reduce defects and improve crystallinity, resulting in enhanced mechanical properties. Similarly, chemical functionalization can modify the surface characteristics and interlayer interactions, offering pathways to tailor the mechanical behavior for specific applications.

The substrate selection and transfer processes also warrant careful consideration during BNNS fabrication. The interaction between the nanosheets and the growth substrate can induce strain and affect the intrinsic mechanical properties. Various transfer techniques, including wet chemical etching and mechanical exfoliation, have been developed to minimize damage during the transfer process, preserving the mechanical integrity of the nanosheets.

Scalability remains a significant challenge in BNNS production. While laboratory-scale synthesis can yield high-quality nanosheets with excellent mechanical properties, translating these processes to industrial scales often involves compromises in quality control and uniformity. Recent developments in continuous flow reactors and roll-to-roll processing show promise for addressing these scalability challenges while maintaining acceptable mechanical performance.

Computational Modeling and Simulation Approaches

Computational modeling and simulation approaches have become indispensable tools for evaluating the mechanical properties of boron nitride nanosheets (BNNSs). These methodologies offer significant advantages over experimental techniques, particularly in terms of cost-effectiveness and the ability to investigate atomic-level phenomena that are challenging to observe experimentally.

Density Functional Theory (DFT) calculations represent one of the most fundamental approaches for studying BNNSs at the quantum mechanical level. DFT simulations have been instrumental in predicting the elastic modulus, tensile strength, and fracture behavior of pristine and defective BNNSs. Recent advancements in DFT methods have enabled researchers to model larger systems with improved accuracy, providing insights into the effects of sheet thickness, defect concentration, and edge configurations on mechanical properties.

Molecular Dynamics (MD) simulations complement DFT by allowing the investigation of larger systems and longer time scales. MD studies have revealed the dynamic response of BNNSs under various loading conditions, including tension, compression, and shear. These simulations have demonstrated that BNNSs exhibit exceptional in-plane stiffness comparable to graphene, with Young's modulus values typically ranging from 700-900 GPa, depending on simulation parameters and boundary conditions.

Multiscale modeling approaches have emerged as powerful tools for bridging the gap between atomic-scale phenomena and macroscopic mechanical behavior. These methods integrate quantum mechanical calculations, molecular dynamics, and continuum mechanics to provide a comprehensive understanding of BNNS mechanical properties across different length scales. For instance, coarse-grained models derived from atomistic simulations have been developed to study the mechanical behavior of large-area BNNSs and their composites.

Machine learning (ML) algorithms are increasingly being integrated with traditional simulation methods to accelerate the discovery and optimization of BNNS-based materials. ML models trained on computational data can predict mechanical properties with remarkable accuracy while reducing computational costs. Neural network potentials, in particular, have shown promise in reproducing DFT-level accuracy at a fraction of the computational expense.

Finite Element Analysis (FEA) provides a framework for modeling complex geometries and loading conditions that are difficult to address using atomistic methods alone. FEA has been employed to study the mechanical behavior of BNNS-reinforced composites, heterogeneous structures, and devices incorporating BNNSs. These simulations have guided the design of BNNS-based materials with tailored mechanical properties for specific applications.

Density Functional Theory (DFT) calculations represent one of the most fundamental approaches for studying BNNSs at the quantum mechanical level. DFT simulations have been instrumental in predicting the elastic modulus, tensile strength, and fracture behavior of pristine and defective BNNSs. Recent advancements in DFT methods have enabled researchers to model larger systems with improved accuracy, providing insights into the effects of sheet thickness, defect concentration, and edge configurations on mechanical properties.

Molecular Dynamics (MD) simulations complement DFT by allowing the investigation of larger systems and longer time scales. MD studies have revealed the dynamic response of BNNSs under various loading conditions, including tension, compression, and shear. These simulations have demonstrated that BNNSs exhibit exceptional in-plane stiffness comparable to graphene, with Young's modulus values typically ranging from 700-900 GPa, depending on simulation parameters and boundary conditions.

Multiscale modeling approaches have emerged as powerful tools for bridging the gap between atomic-scale phenomena and macroscopic mechanical behavior. These methods integrate quantum mechanical calculations, molecular dynamics, and continuum mechanics to provide a comprehensive understanding of BNNS mechanical properties across different length scales. For instance, coarse-grained models derived from atomistic simulations have been developed to study the mechanical behavior of large-area BNNSs and their composites.

Machine learning (ML) algorithms are increasingly being integrated with traditional simulation methods to accelerate the discovery and optimization of BNNS-based materials. ML models trained on computational data can predict mechanical properties with remarkable accuracy while reducing computational costs. Neural network potentials, in particular, have shown promise in reproducing DFT-level accuracy at a fraction of the computational expense.

Finite Element Analysis (FEA) provides a framework for modeling complex geometries and loading conditions that are difficult to address using atomistic methods alone. FEA has been employed to study the mechanical behavior of BNNS-reinforced composites, heterogeneous structures, and devices incorporating BNNSs. These simulations have guided the design of BNNS-based materials with tailored mechanical properties for specific applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!