Automotive Industry Transition to PNP Transistors: Market Dynamics

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PNP Transistor Adoption in Automotive Electronics

The automotive industry is witnessing a significant shift towards the adoption of PNP transistors in electronic systems. This transition is driven by the increasing demand for more efficient and reliable electronic components in modern vehicles. PNP transistors, known for their ability to control current flow and amplify signals, are becoming integral to various automotive applications.

The market dynamics surrounding this transition are complex and multifaceted. As vehicles become more technologically advanced, the need for sophisticated electronic systems has grown exponentially. PNP transistors offer advantages in terms of power management, signal processing, and overall system performance, making them attractive to automotive manufacturers seeking to enhance their vehicles' capabilities.

One of the key factors driving the adoption of PNP transistors is the push for electrification in the automotive sector. Electric and hybrid vehicles require advanced power management systems, where PNP transistors play a crucial role in controlling battery charge and discharge cycles, as well as managing power distribution throughout the vehicle.

Furthermore, the increasing integration of advanced driver assistance systems (ADAS) and autonomous driving technologies has created a demand for more robust and reliable electronic components. PNP transistors are well-suited for these applications due to their ability to handle high-frequency signals and operate efficiently in demanding environments.

The market for PNP transistors in automotive electronics is also influenced by regulatory pressures. Stricter emissions standards and safety regulations are pushing manufacturers to develop more sophisticated engine management systems and safety features, many of which rely on PNP transistors for precise control and monitoring.

Supply chain considerations are another critical aspect of this market dynamic. As the demand for PNP transistors in automotive applications grows, manufacturers are working to secure reliable sources of these components. This has led to increased collaboration between semiconductor companies and automotive manufacturers, as well as investments in expanding production capacities.

The competitive landscape is evolving as well, with established semiconductor companies and new entrants vying for market share in the automotive PNP transistor segment. This competition is driving innovation in transistor design, leading to improvements in performance, reliability, and cost-effectiveness.

The market dynamics surrounding this transition are complex and multifaceted. As vehicles become more technologically advanced, the need for sophisticated electronic systems has grown exponentially. PNP transistors offer advantages in terms of power management, signal processing, and overall system performance, making them attractive to automotive manufacturers seeking to enhance their vehicles' capabilities.

One of the key factors driving the adoption of PNP transistors is the push for electrification in the automotive sector. Electric and hybrid vehicles require advanced power management systems, where PNP transistors play a crucial role in controlling battery charge and discharge cycles, as well as managing power distribution throughout the vehicle.

Furthermore, the increasing integration of advanced driver assistance systems (ADAS) and autonomous driving technologies has created a demand for more robust and reliable electronic components. PNP transistors are well-suited for these applications due to their ability to handle high-frequency signals and operate efficiently in demanding environments.

The market for PNP transistors in automotive electronics is also influenced by regulatory pressures. Stricter emissions standards and safety regulations are pushing manufacturers to develop more sophisticated engine management systems and safety features, many of which rely on PNP transistors for precise control and monitoring.

Supply chain considerations are another critical aspect of this market dynamic. As the demand for PNP transistors in automotive applications grows, manufacturers are working to secure reliable sources of these components. This has led to increased collaboration between semiconductor companies and automotive manufacturers, as well as investments in expanding production capacities.

The competitive landscape is evolving as well, with established semiconductor companies and new entrants vying for market share in the automotive PNP transistor segment. This competition is driving innovation in transistor design, leading to improvements in performance, reliability, and cost-effectiveness.

Automotive PNP Transistor Market Analysis

The automotive industry's transition to PNP transistors represents a significant shift in the market dynamics of semiconductor components used in vehicle electronics. This transition is driven by the increasing demand for more efficient and reliable electronic systems in modern vehicles. PNP transistors, known for their ability to handle higher voltages and currents, are becoming increasingly crucial in automotive applications such as power management, motor control, and battery management systems.

The market for automotive PNP transistors has been experiencing steady growth, fueled by the rapid electrification of vehicles and the integration of advanced driver assistance systems (ADAS). As automakers strive to improve fuel efficiency and reduce emissions, the adoption of electric and hybrid vehicles has accelerated, leading to a surge in demand for high-performance transistors capable of managing power distribution effectively.

One of the key factors driving the market is the stringent regulatory environment surrounding vehicle emissions and safety standards. Governments worldwide are implementing stricter regulations, pushing automakers to incorporate more sophisticated electronic systems that require advanced transistor technologies. This regulatory pressure has created a favorable market environment for PNP transistors, which offer improved performance and reliability compared to their NPN counterparts in certain automotive applications.

The automotive PNP transistor market is characterized by intense competition among semiconductor manufacturers. Major players in this space are investing heavily in research and development to enhance the performance and reliability of their products. This competitive landscape has led to continuous innovations in transistor design, resulting in smaller form factors, improved thermal management, and enhanced durability to withstand the harsh automotive environment.

Regional market dynamics play a crucial role in shaping the automotive PNP transistor industry. Asia-Pacific, particularly countries like China, Japan, and South Korea, has emerged as a major hub for automotive electronics manufacturing, driving significant demand for PNP transistors. North America and Europe, with their focus on electric vehicle adoption and autonomous driving technologies, also represent substantial markets for these components.

The supply chain for automotive PNP transistors has faced challenges in recent years, particularly due to global semiconductor shortages. This situation has highlighted the critical nature of these components in the automotive industry and has led to increased efforts to diversify supply sources and improve supply chain resilience. As a result, some automakers are exploring vertical integration strategies, including partnerships with semiconductor manufacturers to secure a stable supply of critical components like PNP transistors.

Looking ahead, the automotive PNP transistor market is poised for continued growth, driven by the ongoing electrification trend and the increasing complexity of vehicle electronics. The integration of artificial intelligence and machine learning in automotive systems is expected to further boost demand for high-performance transistors, opening new opportunities for innovation and market expansion in the automotive semiconductor industry.

The market for automotive PNP transistors has been experiencing steady growth, fueled by the rapid electrification of vehicles and the integration of advanced driver assistance systems (ADAS). As automakers strive to improve fuel efficiency and reduce emissions, the adoption of electric and hybrid vehicles has accelerated, leading to a surge in demand for high-performance transistors capable of managing power distribution effectively.

One of the key factors driving the market is the stringent regulatory environment surrounding vehicle emissions and safety standards. Governments worldwide are implementing stricter regulations, pushing automakers to incorporate more sophisticated electronic systems that require advanced transistor technologies. This regulatory pressure has created a favorable market environment for PNP transistors, which offer improved performance and reliability compared to their NPN counterparts in certain automotive applications.

The automotive PNP transistor market is characterized by intense competition among semiconductor manufacturers. Major players in this space are investing heavily in research and development to enhance the performance and reliability of their products. This competitive landscape has led to continuous innovations in transistor design, resulting in smaller form factors, improved thermal management, and enhanced durability to withstand the harsh automotive environment.

Regional market dynamics play a crucial role in shaping the automotive PNP transistor industry. Asia-Pacific, particularly countries like China, Japan, and South Korea, has emerged as a major hub for automotive electronics manufacturing, driving significant demand for PNP transistors. North America and Europe, with their focus on electric vehicle adoption and autonomous driving technologies, also represent substantial markets for these components.

The supply chain for automotive PNP transistors has faced challenges in recent years, particularly due to global semiconductor shortages. This situation has highlighted the critical nature of these components in the automotive industry and has led to increased efforts to diversify supply sources and improve supply chain resilience. As a result, some automakers are exploring vertical integration strategies, including partnerships with semiconductor manufacturers to secure a stable supply of critical components like PNP transistors.

Looking ahead, the automotive PNP transistor market is poised for continued growth, driven by the ongoing electrification trend and the increasing complexity of vehicle electronics. The integration of artificial intelligence and machine learning in automotive systems is expected to further boost demand for high-performance transistors, opening new opportunities for innovation and market expansion in the automotive semiconductor industry.

Technical Challenges in PNP Transistor Integration

The integration of PNP transistors in the automotive industry presents several significant technical challenges. One of the primary obstacles is the inherent lower carrier mobility of holes compared to electrons, which affects the performance of PNP transistors. This limitation results in reduced switching speeds and higher power consumption, potentially impacting the overall efficiency of automotive electronic systems.

Another critical challenge lies in the thermal management of PNP transistors. Automotive environments often subject electronic components to extreme temperature fluctuations and prolonged exposure to high temperatures. PNP transistors are generally more sensitive to temperature variations, which can lead to performance degradation and reliability issues over time. Engineers must develop robust thermal management solutions to ensure consistent operation across diverse automotive conditions.

The miniaturization of PNP transistors for automotive applications poses additional difficulties. As vehicle manufacturers strive for more compact and lightweight designs, the need for smaller transistors increases. However, scaling down PNP transistors while maintaining their performance characteristics and reliability is a complex task. Issues such as increased leakage current and reduced breakdown voltage become more pronounced at smaller scales, requiring innovative design approaches and advanced manufacturing techniques.

Compatibility with existing automotive electronic systems is another hurdle in PNP transistor integration. Many current vehicle designs are optimized for NPN transistor-based circuits. Transitioning to PNP transistors may require significant redesigns of circuit layouts and power management systems, potentially increasing development costs and time-to-market for new vehicle models.

The automotive industry's stringent reliability and durability requirements further complicate PNP transistor integration. These transistors must withstand harsh environmental conditions, including vibrations, electromagnetic interference, and chemical exposure, while maintaining consistent performance over the vehicle's lifespan. Developing PNP transistors that meet these rigorous standards demands extensive testing and validation processes.

Lastly, the challenge of cost-effective manufacturing at scale cannot be overlooked. While PNP transistors offer certain advantages, their production processes may be more complex or costly compared to traditional NPN transistors. Automotive manufacturers must balance the potential benefits of PNP transistors against the increased production costs to ensure economic viability in a highly competitive market.

Another critical challenge lies in the thermal management of PNP transistors. Automotive environments often subject electronic components to extreme temperature fluctuations and prolonged exposure to high temperatures. PNP transistors are generally more sensitive to temperature variations, which can lead to performance degradation and reliability issues over time. Engineers must develop robust thermal management solutions to ensure consistent operation across diverse automotive conditions.

The miniaturization of PNP transistors for automotive applications poses additional difficulties. As vehicle manufacturers strive for more compact and lightweight designs, the need for smaller transistors increases. However, scaling down PNP transistors while maintaining their performance characteristics and reliability is a complex task. Issues such as increased leakage current and reduced breakdown voltage become more pronounced at smaller scales, requiring innovative design approaches and advanced manufacturing techniques.

Compatibility with existing automotive electronic systems is another hurdle in PNP transistor integration. Many current vehicle designs are optimized for NPN transistor-based circuits. Transitioning to PNP transistors may require significant redesigns of circuit layouts and power management systems, potentially increasing development costs and time-to-market for new vehicle models.

The automotive industry's stringent reliability and durability requirements further complicate PNP transistor integration. These transistors must withstand harsh environmental conditions, including vibrations, electromagnetic interference, and chemical exposure, while maintaining consistent performance over the vehicle's lifespan. Developing PNP transistors that meet these rigorous standards demands extensive testing and validation processes.

Lastly, the challenge of cost-effective manufacturing at scale cannot be overlooked. While PNP transistors offer certain advantages, their production processes may be more complex or costly compared to traditional NPN transistors. Automotive manufacturers must balance the potential benefits of PNP transistors against the increased production costs to ensure economic viability in a highly competitive market.

Current PNP Transistor Solutions for Vehicles

01 Structure and fabrication of PNP transistors

PNP transistors are semiconductor devices with specific structures and fabrication methods. They typically consist of a P-type emitter, N-type base, and P-type collector. The manufacturing process involves various steps such as doping, etching, and layering to create the desired transistor characteristics.- Structure and fabrication of PNP transistors: PNP transistors are semiconductor devices with specific structures and fabrication methods. They typically consist of a P-type emitter, N-type base, and P-type collector. The fabrication process involves various steps such as doping, etching, and layering to create the desired transistor structure.

- Applications of PNP transistors in electronic circuits: PNP transistors are widely used in various electronic circuits for amplification, switching, and signal processing. They are often employed in complementary circuits with NPN transistors, power supplies, and analog circuits. Their unique characteristics make them suitable for specific applications in electronic design.

- Performance optimization and characteristics of PNP transistors: Improving the performance of PNP transistors involves optimizing various parameters such as current gain, frequency response, and noise characteristics. This can be achieved through careful design of the transistor structure, doping profiles, and manufacturing processes. Understanding and controlling these characteristics is crucial for enhancing overall transistor performance.

- Integration of PNP transistors in semiconductor devices: PNP transistors are often integrated into larger semiconductor devices and integrated circuits. This integration requires careful consideration of layout, interconnections, and compatibility with other components. Advanced manufacturing techniques are employed to ensure proper functioning of PNP transistors within complex semiconductor structures.

- Specialized PNP transistor designs for specific applications: Various specialized PNP transistor designs have been developed for specific applications. These may include high-power PNP transistors, high-frequency PNP transistors, or PNP transistors optimized for low-noise operations. Such designs often involve modifications to the basic transistor structure or manufacturing process to achieve desired characteristics.

02 Applications of PNP transistors in electronic circuits

PNP transistors are widely used in various electronic circuits for amplification, switching, and signal processing. They are often employed in complementary circuits with NPN transistors, power supplies, and analog circuits. Their unique properties make them suitable for specific applications in both digital and analog electronics.Expand Specific Solutions03 Performance optimization and characteristics of PNP transistors

Improving the performance of PNP transistors involves optimizing various parameters such as current gain, frequency response, and noise characteristics. This can be achieved through careful design of the transistor structure, doping profiles, and manufacturing processes. Understanding and controlling these characteristics is crucial for enhancing overall device performance.Expand Specific Solutions04 Integration of PNP transistors in integrated circuits

PNP transistors play a significant role in integrated circuit design. They are often integrated alongside NPN transistors and other components to create complex circuits on a single chip. The integration process requires careful consideration of layout, parasitic effects, and thermal management to ensure optimal performance of the entire integrated circuit.Expand Specific Solutions05 Advancements in PNP transistor technology

Ongoing research and development in PNP transistor technology focus on improving device performance, reducing power consumption, and enhancing reliability. This includes exploring new materials, novel device structures, and advanced manufacturing techniques to overcome limitations and extend the capabilities of PNP transistors in modern electronic applications.Expand Specific Solutions

Key Automotive Semiconductor Manufacturers

The automotive industry's transition to PNP transistors is currently in a growth phase, with the market expanding rapidly due to increasing demand for more efficient and compact electronic systems in vehicles. The global market size for automotive PNP transistors is projected to grow significantly over the next few years, driven by the rise of electric vehicles and advanced driver assistance systems. While the technology is relatively mature, ongoing innovations are enhancing performance and reliability. Key players like Infineon Technologies, NXP Semiconductors, and Texas Instruments are leading the market with advanced PNP transistor solutions, while companies such as Renesas Electronics and ROHM Co. are also making significant contributions to the field.

Infineon Technologies AG

Technical Solution: Infineon has been at the forefront of the automotive industry's transition to PNP transistors. They have developed a range of advanced PNP transistors specifically designed for automotive applications, focusing on high reliability and performance in harsh environments. Their OptiMOS™ P-channel power MOSFET family offers low on-resistance and high current capability, crucial for automotive power management systems[1]. Infineon's PNP transistors feature enhanced Safe Operating Area (SOA) characteristics, allowing for better thermal management and increased reliability in automotive electronic control units (ECUs)[2]. The company has also integrated their PNP transistors into smart power switches, combining diagnostic and protection features, which is particularly valuable for body control modules and lighting systems in vehicles[3].

Strengths: Industry-leading expertise in automotive semiconductors, wide range of PNP solutions tailored for specific automotive applications, strong focus on reliability and performance in harsh environments. Weaknesses: Higher cost compared to some competitors, potential supply chain constraints due to high demand in the automotive sector.

Texas Instruments Incorporated

Technical Solution: Texas Instruments (TI) has made significant strides in the automotive industry's transition to PNP transistors. Their automotive-qualified PNP transistors are designed to meet the stringent requirements of modern vehicles, offering high reliability and performance. TI's PNP solutions include both discrete transistors and integrated circuits that incorporate PNP structures. Their TPS92630-Q1 LED driver, for instance, utilizes PNP transistors in its design to achieve high efficiency and reliability in automotive lighting applications[4]. TI has also developed advanced bipolar-CMOS (BiCMOS) processes that integrate high-performance PNP transistors with CMOS logic, enabling more sophisticated power management and control systems for automotive electronics[5]. Additionally, their PNP transistors feature improved temperature coefficients and tight parameter distribution, ensuring consistent performance across varying automotive operating conditions[6].

Strengths: Comprehensive portfolio of automotive-qualified PNP solutions, strong integration capabilities combining PNP with other technologies, extensive experience in automotive electronics. Weaknesses: May face competition from specialized automotive semiconductor companies, potential challenges in scaling production to meet growing demand.

Innovative PNP Designs for Automotive Use

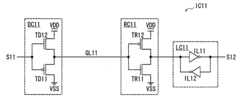

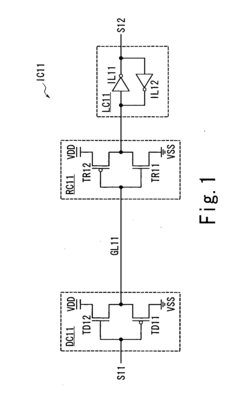

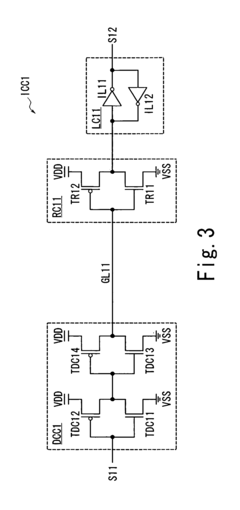

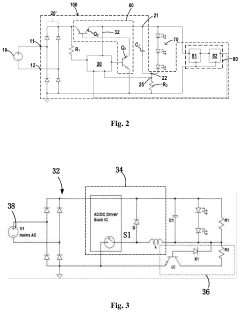

Semiconductor integrated circuit

PatentInactiveUS20070170954A1

Innovation

- Incorporating a driver circuit with p-type and n-type transistors to reduce signal amplitude, specifically connecting transistors to low and high power supply lines, and using transistors with gates receiving input signals to manage signal transmission across signal lines, thereby reducing power consumption.

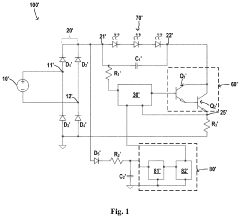

Driving circuit and associated lamp

PatentActiveUS20220232682A1

Innovation

- A driving circuit that directly charges an output capacitor from the mains supply in standby mode, maintaining a voltage lower than the LED's turn-on voltage but higher than a preset lowest voltage, allowing quick charging when switching to illumination mode, and utilizing a linear current source with zero or low voltage drop to reduce power consumption.

Environmental Impact of PNP Transistor Adoption

The adoption of PNP transistors in the automotive industry is poised to have significant environmental implications. As the industry transitions towards more sustainable practices, the environmental impact of PNP transistor adoption becomes a crucial consideration. These transistors offer improved energy efficiency compared to their predecessors, potentially reducing the overall energy consumption of vehicles.

The manufacturing process of PNP transistors typically requires fewer raw materials and consumes less energy than traditional transistor production. This reduction in resource utilization contributes to a smaller carbon footprint associated with the production phase. Additionally, the improved efficiency of PNP transistors translates to reduced heat generation in automotive electronic systems, potentially decreasing the need for extensive cooling mechanisms and further reducing energy consumption.

The longevity and reliability of PNP transistors also play a role in their environmental impact. With increased durability, these components may require less frequent replacement, reducing electronic waste generation over the vehicle's lifecycle. This aspect aligns with the automotive industry's efforts to enhance product lifespan and minimize the environmental burden of vehicle maintenance and part replacement.

Furthermore, the adoption of PNP transistors can contribute to the overall weight reduction of vehicles. As these transistors are often smaller and more efficient than their counterparts, they allow for more compact electronic systems. Lighter vehicles generally consume less fuel, leading to reduced emissions during the operational phase of the vehicle's life.

The transition to PNP transistors also supports the broader shift towards electrification in the automotive sector. These transistors are well-suited for the high-performance requirements of electric and hybrid vehicles, facilitating the industry's move away from fossil fuel-dependent technologies. This alignment with electrification trends could accelerate the reduction of greenhouse gas emissions associated with the transportation sector.

However, it is essential to consider the potential environmental challenges associated with the widespread adoption of PNP transistors. The extraction and processing of specific materials required for these transistors may have localized environmental impacts. Additionally, the end-of-life management of vehicles equipped with advanced electronic systems incorporating PNP transistors will require careful consideration to ensure proper recycling and disposal practices.

In conclusion, while the adoption of PNP transistors in the automotive industry presents significant potential for positive environmental impact through improved efficiency and support for electrification, a holistic approach to assessing their lifecycle environmental footprint is necessary to fully understand and optimize their sustainability benefits.

The manufacturing process of PNP transistors typically requires fewer raw materials and consumes less energy than traditional transistor production. This reduction in resource utilization contributes to a smaller carbon footprint associated with the production phase. Additionally, the improved efficiency of PNP transistors translates to reduced heat generation in automotive electronic systems, potentially decreasing the need for extensive cooling mechanisms and further reducing energy consumption.

The longevity and reliability of PNP transistors also play a role in their environmental impact. With increased durability, these components may require less frequent replacement, reducing electronic waste generation over the vehicle's lifecycle. This aspect aligns with the automotive industry's efforts to enhance product lifespan and minimize the environmental burden of vehicle maintenance and part replacement.

Furthermore, the adoption of PNP transistors can contribute to the overall weight reduction of vehicles. As these transistors are often smaller and more efficient than their counterparts, they allow for more compact electronic systems. Lighter vehicles generally consume less fuel, leading to reduced emissions during the operational phase of the vehicle's life.

The transition to PNP transistors also supports the broader shift towards electrification in the automotive sector. These transistors are well-suited for the high-performance requirements of electric and hybrid vehicles, facilitating the industry's move away from fossil fuel-dependent technologies. This alignment with electrification trends could accelerate the reduction of greenhouse gas emissions associated with the transportation sector.

However, it is essential to consider the potential environmental challenges associated with the widespread adoption of PNP transistors. The extraction and processing of specific materials required for these transistors may have localized environmental impacts. Additionally, the end-of-life management of vehicles equipped with advanced electronic systems incorporating PNP transistors will require careful consideration to ensure proper recycling and disposal practices.

In conclusion, while the adoption of PNP transistors in the automotive industry presents significant potential for positive environmental impact through improved efficiency and support for electrification, a holistic approach to assessing their lifecycle environmental footprint is necessary to fully understand and optimize their sustainability benefits.

Automotive Safety Standards for PNP Transistors

The automotive industry's transition to PNP transistors has necessitated the development and implementation of stringent safety standards to ensure the reliability and performance of these critical components in vehicle systems. These standards are designed to address the unique challenges posed by PNP transistors in automotive applications, including their sensitivity to temperature fluctuations, electromagnetic interference, and voltage spikes.

One of the primary safety standards for PNP transistors in automotive applications is the AEC-Q101 qualification, which is part of the Automotive Electronics Council's (AEC) component qualification program. This standard outlines rigorous testing procedures for discrete semiconductors, including PNP transistors, to ensure their suitability for use in harsh automotive environments. The AEC-Q101 standard includes stress tests such as temperature cycling, humidity testing, and electrostatic discharge (ESD) resistance, all of which are crucial for validating the reliability of PNP transistors in vehicle systems.

In addition to AEC-Q101, the ISO 26262 functional safety standard plays a significant role in ensuring the safe integration of PNP transistors into automotive electronic systems. This standard provides guidelines for the development of safety-critical systems, including those that incorporate PNP transistors. It emphasizes the importance of fault tolerance, redundancy, and fail-safe mechanisms in electronic components and systems.

The SAE J1211 standard, which focuses on recommended environmental practices for electronic equipment design in automotive applications, also influences the safety requirements for PNP transistors. This standard addresses issues such as temperature extremes, vibration, and electromagnetic compatibility (EMC), all of which are critical considerations in the design and implementation of PNP transistor-based circuits in vehicles.

Furthermore, the automotive industry has developed specific requirements for the packaging and handling of PNP transistors to prevent damage during manufacturing and assembly processes. These standards often include guidelines for moisture sensitivity levels (MSL) and electrostatic discharge (ESD) protection, as outlined in standards such as JEDEC J-STD-020 and ANSI/ESD S20.20.

As vehicle electrification and autonomous driving technologies continue to advance, new safety standards are emerging to address the increased use of high-power and high-frequency PNP transistors in automotive applications. These standards focus on issues such as thermal management, power cycling endurance, and electromagnetic interference (EMI) mitigation, which are becoming increasingly important as vehicles incorporate more sophisticated electronic systems.

One of the primary safety standards for PNP transistors in automotive applications is the AEC-Q101 qualification, which is part of the Automotive Electronics Council's (AEC) component qualification program. This standard outlines rigorous testing procedures for discrete semiconductors, including PNP transistors, to ensure their suitability for use in harsh automotive environments. The AEC-Q101 standard includes stress tests such as temperature cycling, humidity testing, and electrostatic discharge (ESD) resistance, all of which are crucial for validating the reliability of PNP transistors in vehicle systems.

In addition to AEC-Q101, the ISO 26262 functional safety standard plays a significant role in ensuring the safe integration of PNP transistors into automotive electronic systems. This standard provides guidelines for the development of safety-critical systems, including those that incorporate PNP transistors. It emphasizes the importance of fault tolerance, redundancy, and fail-safe mechanisms in electronic components and systems.

The SAE J1211 standard, which focuses on recommended environmental practices for electronic equipment design in automotive applications, also influences the safety requirements for PNP transistors. This standard addresses issues such as temperature extremes, vibration, and electromagnetic compatibility (EMC), all of which are critical considerations in the design and implementation of PNP transistor-based circuits in vehicles.

Furthermore, the automotive industry has developed specific requirements for the packaging and handling of PNP transistors to prevent damage during manufacturing and assembly processes. These standards often include guidelines for moisture sensitivity levels (MSL) and electrostatic discharge (ESD) protection, as outlined in standards such as JEDEC J-STD-020 and ANSI/ESD S20.20.

As vehicle electrification and autonomous driving technologies continue to advance, new safety standards are emerging to address the increased use of high-power and high-frequency PNP transistors in automotive applications. These standards focus on issues such as thermal management, power cycling endurance, and electromagnetic interference (EMI) mitigation, which are becoming increasingly important as vehicles incorporate more sophisticated electronic systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!