Balancing Capacity and Longevity in Lithium Iron Phosphate Batteries

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LFP Battery Evolution

Lithium Iron Phosphate (LFP) batteries have undergone significant evolution since their inception in the late 1990s. Initially developed as a safer alternative to traditional lithium-ion batteries, LFP technology has seen continuous improvements in performance, cost-effectiveness, and manufacturing processes.

The early 2000s marked the beginning of commercial production for LFP batteries, primarily focused on small-scale applications. During this period, researchers concentrated on enhancing the material's conductivity and energy density, which were initially lower compared to other lithium-ion chemistries.

A major breakthrough came in the mid-2000s with the development of nano-scale LFP particles. This innovation dramatically improved the battery's power capability and charge-discharge rates, opening up new possibilities for electric vehicle applications. Concurrently, advancements in carbon coating techniques further enhanced the material's conductivity and stability.

The late 2000s and early 2010s saw a surge in LFP battery adoption, particularly in the Chinese electric vehicle market. This period was characterized by significant improvements in manufacturing processes, leading to reduced production costs and increased energy density. The introduction of cell-to-pack technology in the late 2010s marked another milestone, allowing for more efficient use of space and further improvements in energy density at the pack level.

Recent years have witnessed a renewed global interest in LFP batteries, driven by their improved performance, lower cost, and superior safety characteristics. Innovations in doping techniques, such as the addition of manganese or silicon, have pushed the boundaries of LFP's energy density. Additionally, advancements in electrolyte formulations have contributed to enhanced longevity and performance at extreme temperatures.

The evolution of LFP batteries has been marked by a continuous balancing act between capacity and longevity. Early iterations prioritized safety and longevity at the expense of energy density. However, subsequent developments have successfully increased capacity while maintaining the inherent stability and long cycle life of LFP chemistry.

Looking forward, the LFP battery evolution is expected to continue with a focus on further increasing energy density, improving fast-charging capabilities, and enhancing performance in extreme conditions. Emerging research areas include solid-state LFP batteries and the integration of artificial intelligence for better battery management and predictive maintenance.

The early 2000s marked the beginning of commercial production for LFP batteries, primarily focused on small-scale applications. During this period, researchers concentrated on enhancing the material's conductivity and energy density, which were initially lower compared to other lithium-ion chemistries.

A major breakthrough came in the mid-2000s with the development of nano-scale LFP particles. This innovation dramatically improved the battery's power capability and charge-discharge rates, opening up new possibilities for electric vehicle applications. Concurrently, advancements in carbon coating techniques further enhanced the material's conductivity and stability.

The late 2000s and early 2010s saw a surge in LFP battery adoption, particularly in the Chinese electric vehicle market. This period was characterized by significant improvements in manufacturing processes, leading to reduced production costs and increased energy density. The introduction of cell-to-pack technology in the late 2010s marked another milestone, allowing for more efficient use of space and further improvements in energy density at the pack level.

Recent years have witnessed a renewed global interest in LFP batteries, driven by their improved performance, lower cost, and superior safety characteristics. Innovations in doping techniques, such as the addition of manganese or silicon, have pushed the boundaries of LFP's energy density. Additionally, advancements in electrolyte formulations have contributed to enhanced longevity and performance at extreme temperatures.

The evolution of LFP batteries has been marked by a continuous balancing act between capacity and longevity. Early iterations prioritized safety and longevity at the expense of energy density. However, subsequent developments have successfully increased capacity while maintaining the inherent stability and long cycle life of LFP chemistry.

Looking forward, the LFP battery evolution is expected to continue with a focus on further increasing energy density, improving fast-charging capabilities, and enhancing performance in extreme conditions. Emerging research areas include solid-state LFP batteries and the integration of artificial intelligence for better battery management and predictive maintenance.

Market Demand Analysis

The market demand for lithium iron phosphate (LFP) batteries has been experiencing significant growth, driven by the increasing adoption of electric vehicles (EVs) and renewable energy storage systems. The global LFP battery market is projected to expand rapidly in the coming years, with a compound annual growth rate (CAGR) exceeding 20% through 2030. This surge in demand is primarily attributed to the unique advantages of LFP batteries, including their enhanced safety profile, longer cycle life, and lower cost compared to other lithium-ion battery chemistries.

In the automotive sector, LFP batteries are gaining traction, particularly in the mass-market EV segment. Major automakers are increasingly incorporating LFP batteries into their electric vehicle lineups, recognizing the technology's potential to reduce overall vehicle costs while maintaining acceptable range and performance. This trend is especially pronounced in China, where LFP batteries have already captured a significant market share in the EV industry.

The stationary energy storage market is another key driver for LFP battery demand. Grid-scale energy storage projects and residential solar-plus-storage systems are increasingly utilizing LFP batteries due to their long cycle life and improved safety characteristics. As countries worldwide push for greater integration of renewable energy sources, the demand for reliable and cost-effective energy storage solutions is expected to fuel further growth in the LFP battery market.

However, the market demand for LFP batteries is not without challenges. The primary limitation of LFP technology is its lower energy density compared to other lithium-ion chemistries, such as nickel-manganese-cobalt (NMC) or nickel-cobalt-aluminum (NCA) batteries. This constraint has historically restricted the use of LFP batteries in applications requiring high energy density, such as long-range electric vehicles or portable electronics.

The industry trend of balancing capacity and longevity in LFP batteries is driven by the need to address this energy density limitation while maintaining the technology's inherent advantages. Researchers and manufacturers are focusing on developing advanced LFP battery designs that can increase energy density without compromising the long cycle life and safety features that make LFP batteries attractive.

As the demand for sustainable and cost-effective energy storage solutions continues to grow, the market for LFP batteries is expected to evolve. Innovations in cell design, manufacturing processes, and material science are likely to play crucial roles in expanding the application range of LFP batteries and meeting the diverse needs of various industries.

In the automotive sector, LFP batteries are gaining traction, particularly in the mass-market EV segment. Major automakers are increasingly incorporating LFP batteries into their electric vehicle lineups, recognizing the technology's potential to reduce overall vehicle costs while maintaining acceptable range and performance. This trend is especially pronounced in China, where LFP batteries have already captured a significant market share in the EV industry.

The stationary energy storage market is another key driver for LFP battery demand. Grid-scale energy storage projects and residential solar-plus-storage systems are increasingly utilizing LFP batteries due to their long cycle life and improved safety characteristics. As countries worldwide push for greater integration of renewable energy sources, the demand for reliable and cost-effective energy storage solutions is expected to fuel further growth in the LFP battery market.

However, the market demand for LFP batteries is not without challenges. The primary limitation of LFP technology is its lower energy density compared to other lithium-ion chemistries, such as nickel-manganese-cobalt (NMC) or nickel-cobalt-aluminum (NCA) batteries. This constraint has historically restricted the use of LFP batteries in applications requiring high energy density, such as long-range electric vehicles or portable electronics.

The industry trend of balancing capacity and longevity in LFP batteries is driven by the need to address this energy density limitation while maintaining the technology's inherent advantages. Researchers and manufacturers are focusing on developing advanced LFP battery designs that can increase energy density without compromising the long cycle life and safety features that make LFP batteries attractive.

As the demand for sustainable and cost-effective energy storage solutions continues to grow, the market for LFP batteries is expected to evolve. Innovations in cell design, manufacturing processes, and material science are likely to play crucial roles in expanding the application range of LFP batteries and meeting the diverse needs of various industries.

Technical Challenges

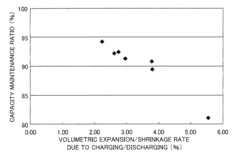

Lithium Iron Phosphate (LiFePO4) batteries face several technical challenges in balancing capacity and longevity. One of the primary issues is the inherent trade-off between energy density and cycle life. As manufacturers strive to increase the capacity of these batteries, they often encounter difficulties in maintaining the same level of longevity.

The cathode material's structure plays a crucial role in this balance. LiFePO4 cathodes have a stable olivine structure, which contributes to their excellent cycle life. However, this same structure limits the theoretical capacity of the battery. Attempts to modify the cathode composition to increase capacity often result in decreased structural stability, leading to faster capacity fade over time.

Another significant challenge lies in the electrolyte formulation. The electrolyte must facilitate efficient ion transport while also forming a stable solid electrolyte interphase (SEI) layer on the electrode surfaces. Achieving this balance is particularly difficult as higher capacity often requires more aggressive electrolyte compositions, which can lead to accelerated degradation of the electrodes and reduced battery lifespan.

The anode material, typically graphite in LiFePO4 batteries, also presents challenges. While graphite anodes offer good stability, they have limited capacity. Alternative anode materials with higher capacity, such as silicon-based composites, are being explored. However, these materials often suffer from significant volume changes during cycling, leading to mechanical stress and degradation of the electrode structure.

Temperature management is another critical factor affecting both capacity and longevity. LiFePO4 batteries generally have good thermal stability, but operating at high temperatures to achieve higher power output can accelerate capacity fade. Conversely, low-temperature operation reduces capacity but may extend overall battery life. Developing effective thermal management systems that can maintain optimal operating temperatures across various usage scenarios remains a significant challenge.

The charging protocol also plays a vital role in balancing capacity and longevity. Fast charging techniques, while desirable for many applications, can lead to increased stress on the battery components and accelerated aging. Developing charging algorithms that can maximize capacity utilization without compromising long-term stability is an ongoing area of research and development.

Lastly, manufacturing processes and quality control present their own set of challenges. Achieving consistent performance across large-scale production batches while maintaining high energy density and long cycle life requires precise control over material synthesis, electrode fabrication, and cell assembly processes. Any variations in these processes can lead to inconsistencies in battery performance and lifespan.

The cathode material's structure plays a crucial role in this balance. LiFePO4 cathodes have a stable olivine structure, which contributes to their excellent cycle life. However, this same structure limits the theoretical capacity of the battery. Attempts to modify the cathode composition to increase capacity often result in decreased structural stability, leading to faster capacity fade over time.

Another significant challenge lies in the electrolyte formulation. The electrolyte must facilitate efficient ion transport while also forming a stable solid electrolyte interphase (SEI) layer on the electrode surfaces. Achieving this balance is particularly difficult as higher capacity often requires more aggressive electrolyte compositions, which can lead to accelerated degradation of the electrodes and reduced battery lifespan.

The anode material, typically graphite in LiFePO4 batteries, also presents challenges. While graphite anodes offer good stability, they have limited capacity. Alternative anode materials with higher capacity, such as silicon-based composites, are being explored. However, these materials often suffer from significant volume changes during cycling, leading to mechanical stress and degradation of the electrode structure.

Temperature management is another critical factor affecting both capacity and longevity. LiFePO4 batteries generally have good thermal stability, but operating at high temperatures to achieve higher power output can accelerate capacity fade. Conversely, low-temperature operation reduces capacity but may extend overall battery life. Developing effective thermal management systems that can maintain optimal operating temperatures across various usage scenarios remains a significant challenge.

The charging protocol also plays a vital role in balancing capacity and longevity. Fast charging techniques, while desirable for many applications, can lead to increased stress on the battery components and accelerated aging. Developing charging algorithms that can maximize capacity utilization without compromising long-term stability is an ongoing area of research and development.

Lastly, manufacturing processes and quality control present their own set of challenges. Achieving consistent performance across large-scale production batches while maintaining high energy density and long cycle life requires precise control over material synthesis, electrode fabrication, and cell assembly processes. Any variations in these processes can lead to inconsistencies in battery performance and lifespan.

Current LFP Solutions

01 Electrode material composition optimization

Improving the composition of electrode materials, particularly the cathode, can enhance the capacity and longevity of Lithium Iron Phosphate (LFP) batteries. This includes optimizing particle size, morphology, and doping with other elements to improve conductivity and stability.- Improved cathode materials for enhanced capacity: Development of advanced cathode materials, such as doped or coated lithium iron phosphate, to increase the energy density and capacity of LiFePO4 batteries. These modifications can improve the electronic conductivity and lithium-ion diffusion, resulting in higher capacity and better performance.

- Nanostructured LiFePO4 for increased longevity: Utilization of nanostructured lithium iron phosphate particles to enhance the battery's cycle life and longevity. The reduced particle size increases the surface area for reactions, improves lithium-ion transport, and reduces structural stress during charge-discharge cycles.

- Electrolyte optimization for improved performance: Development of advanced electrolyte formulations to enhance the capacity and longevity of LiFePO4 batteries. These optimized electrolytes can improve ionic conductivity, reduce side reactions, and enhance the stability of the electrode-electrolyte interface.

- Battery management systems for extended lifespan: Implementation of sophisticated battery management systems to optimize charging and discharging processes, monitor cell health, and balance voltage across cells. These systems can significantly extend the lifespan of LiFePO4 batteries by preventing overcharging, over-discharging, and uneven wear.

- Thermal management for improved longevity: Development of effective thermal management solutions to maintain optimal operating temperatures for LiFePO4 batteries. Proper thermal control can prevent capacity degradation, extend battery life, and enhance overall performance by mitigating the negative effects of temperature extremes.

02 Electrolyte formulation enhancements

Developing advanced electrolyte formulations can significantly improve the performance and lifespan of LFP batteries. This involves using additives, optimizing salt concentrations, and exploring novel electrolyte compositions to enhance ionic conductivity and reduce side reactions.Expand Specific Solutions03 Battery management system optimization

Implementing sophisticated battery management systems (BMS) can extend the life and improve the capacity utilization of LFP batteries. This includes advanced algorithms for charge-discharge control, temperature management, and state-of-health monitoring.Expand Specific Solutions04 Structural design improvements

Enhancing the structural design of LFP batteries can lead to better capacity and longevity. This involves optimizing cell packaging, improving current collector designs, and developing novel electrode architectures to facilitate better ion transport and reduce degradation.Expand Specific Solutions05 Nano-engineering of active materials

Utilizing nano-engineering techniques to modify LFP active materials can significantly boost battery performance. This includes creating nanostructured particles, core-shell structures, and carbon coatings to enhance conductivity, stability, and overall electrochemical properties.Expand Specific Solutions

Key Industry Players

The market for lithium iron phosphate (LFP) batteries is experiencing rapid growth, driven by increasing demand for electric vehicles and energy storage systems. The industry is in a mature growth phase, with a global market size expected to reach $10 billion by 2025. Technological advancements are focused on improving energy density and cycle life while maintaining the inherent safety advantages of LFP chemistry. Key players like CATL, BYD, and LG Energy Solution are investing heavily in R&D to enhance LFP performance. Emerging companies such as StoreDot and Saft are also contributing innovative solutions. The competitive landscape is characterized by a mix of established battery manufacturers and newer entrants, all striving to balance capacity and longevity in their LFP offerings.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed advanced LFP battery technology that focuses on balancing capacity and longevity. Their approach includes the use of high-purity raw materials and precise control of particle size distribution in cathode materials to enhance capacity. LG has also implemented advanced coating technologies for both cathode and anode materials, which help to stabilize the electrode-electrolyte interface and reduce capacity fade over time[5]. Their battery management system incorporates machine learning algorithms to optimize charging protocols and predict battery health, further extending battery life. LG's LFP batteries have achieved energy densities of up to 155 Wh/kg while maintaining a cycle life of over 4000 cycles at 80% depth of discharge[6].

Strengths: High energy density, long cycle life, and advanced BMS for optimized performance. Weaknesses: Higher production costs due to advanced materials and processes, potential supply chain dependencies for specialized materials.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed advanced LFP battery technology focusing on balancing capacity and longevity. Their CTP (cell-to-pack) technology integrates cells directly into the battery pack, increasing energy density by 10-15% and improving space utilization by 40% compared to conventional designs[1]. CATL's LFP batteries utilize nano-scale cathode materials and proprietary electrolyte formulations to enhance capacity retention. They've also implemented advanced battery management systems (BMS) that optimize charging and discharging cycles, effectively extending battery life. Recent developments include their third-generation CTP technology, which achieves an energy density of up to 160 Wh/kg in LFP batteries, approaching the energy density of some ternary lithium batteries[2].

Strengths: High energy density, improved space utilization, and advanced BMS for longevity. Weaknesses: Higher initial cost compared to traditional LFP batteries, and potential thermal management challenges in high-density packs.

Core LFP Innovations

Lithium iron phosphate battery and hybrid vehicle

PatentPendingEP4567928A1

Innovation

- The lithium iron phosphate battery incorporates both large-particle and small-particle cathode and anode active materials, combining their advantages to improve rate performance, cycle performance, and energy efficiency.

Cathode active material, cathode, and nonaqueous secondary battery

PatentInactiveUS20100124703A1

Innovation

- A cathode active material represented by the general formula Li1-xAxFe1-yMyP1-zAlzO4, where A and M are selected elements from specific groups, with partial substitution of P with Al and either Li or Fe sites, to suppress volumetric changes and enhance structural stability.

Environmental Impact

The environmental impact of lithium iron phosphate (LFP) batteries is a crucial consideration in the ongoing efforts to balance capacity and longevity. These batteries have gained significant attention due to their potential for sustainable energy storage solutions. When compared to other lithium-ion battery chemistries, LFP batteries demonstrate several environmental advantages.

One of the primary environmental benefits of LFP batteries is their lower carbon footprint during production. The manufacturing process for LFP cathodes requires less energy and produces fewer emissions compared to other lithium-ion battery types. This reduced environmental impact extends throughout the battery's lifecycle, from raw material extraction to end-of-life disposal.

LFP batteries also offer improved safety characteristics, which indirectly contribute to their environmental friendliness. Their thermal stability and resistance to thermal runaway reduce the risk of fires or explosions, potentially minimizing environmental damage caused by accidents during use or transportation.

The longevity of LFP batteries further enhances their environmental profile. With a higher cycle life compared to many other battery chemistries, LFP batteries can withstand more charge-discharge cycles before significant capacity degradation occurs. This extended lifespan reduces the frequency of battery replacements, thereby decreasing the overall environmental impact associated with battery production and disposal.

In terms of raw materials, LFP batteries utilize more abundant and less controversial elements compared to other lithium-ion batteries. The absence of cobalt, a material often associated with ethical and environmental concerns in its mining practices, is a notable advantage. The use of iron and phosphate, which are more readily available and have less environmental impact in their extraction, contributes to the sustainability of LFP battery production.

However, the environmental impact of LFP batteries is not without challenges. The extraction and processing of lithium, while less intensive than for other battery types, still poses environmental concerns. Additionally, the recycling infrastructure for LFP batteries is less developed compared to other lithium-ion chemistries, presenting a potential end-of-life environmental issue.

As research continues to improve the capacity and longevity of LFP batteries, efforts are also being made to enhance their environmental performance. Innovations in recycling technologies specific to LFP batteries are emerging, aiming to recover and reuse materials more efficiently. Furthermore, advancements in manufacturing processes are focusing on reducing energy consumption and minimizing waste, further decreasing the environmental footprint of LFP battery production.

In conclusion, while LFP batteries offer significant environmental advantages in terms of production emissions, safety, longevity, and raw material sourcing, ongoing efforts are necessary to address remaining environmental challenges, particularly in end-of-life management and recycling. The continued focus on balancing capacity and longevity in LFP batteries must be coupled with a commitment to minimizing environmental impact throughout the battery's lifecycle.

One of the primary environmental benefits of LFP batteries is their lower carbon footprint during production. The manufacturing process for LFP cathodes requires less energy and produces fewer emissions compared to other lithium-ion battery types. This reduced environmental impact extends throughout the battery's lifecycle, from raw material extraction to end-of-life disposal.

LFP batteries also offer improved safety characteristics, which indirectly contribute to their environmental friendliness. Their thermal stability and resistance to thermal runaway reduce the risk of fires or explosions, potentially minimizing environmental damage caused by accidents during use or transportation.

The longevity of LFP batteries further enhances their environmental profile. With a higher cycle life compared to many other battery chemistries, LFP batteries can withstand more charge-discharge cycles before significant capacity degradation occurs. This extended lifespan reduces the frequency of battery replacements, thereby decreasing the overall environmental impact associated with battery production and disposal.

In terms of raw materials, LFP batteries utilize more abundant and less controversial elements compared to other lithium-ion batteries. The absence of cobalt, a material often associated with ethical and environmental concerns in its mining practices, is a notable advantage. The use of iron and phosphate, which are more readily available and have less environmental impact in their extraction, contributes to the sustainability of LFP battery production.

However, the environmental impact of LFP batteries is not without challenges. The extraction and processing of lithium, while less intensive than for other battery types, still poses environmental concerns. Additionally, the recycling infrastructure for LFP batteries is less developed compared to other lithium-ion chemistries, presenting a potential end-of-life environmental issue.

As research continues to improve the capacity and longevity of LFP batteries, efforts are also being made to enhance their environmental performance. Innovations in recycling technologies specific to LFP batteries are emerging, aiming to recover and reuse materials more efficiently. Furthermore, advancements in manufacturing processes are focusing on reducing energy consumption and minimizing waste, further decreasing the environmental footprint of LFP battery production.

In conclusion, while LFP batteries offer significant environmental advantages in terms of production emissions, safety, longevity, and raw material sourcing, ongoing efforts are necessary to address remaining environmental challenges, particularly in end-of-life management and recycling. The continued focus on balancing capacity and longevity in LFP batteries must be coupled with a commitment to minimizing environmental impact throughout the battery's lifecycle.

Safety Considerations

Safety considerations are paramount in the development and implementation of lithium iron phosphate (LiFePO4) batteries, particularly when balancing capacity and longevity. These batteries have gained significant attention due to their inherent safety advantages over other lithium-ion chemistries. The stable olivine crystal structure of LiFePO4 cathodes provides excellent thermal and chemical stability, reducing the risk of thermal runaway and fire hazards.

One of the primary safety features of LiFePO4 batteries is their resistance to oxygen release at high temperatures. This characteristic significantly mitigates the risk of combustion, even under extreme conditions. Additionally, the strong Fe-P-O bonds in the cathode material prevent oxygen release, further enhancing the overall safety profile of these batteries.

The use of phosphate-based cathodes also contributes to improved safety by reducing the likelihood of internal short circuits. This is particularly important when considering the balance between capacity and longevity, as higher energy densities can sometimes lead to increased safety risks in other lithium-ion chemistries.

LiFePO4 batteries exhibit excellent thermal stability, with a higher thermal runaway temperature compared to other lithium-ion technologies. This property allows for safer operation across a wider range of environmental conditions, making them suitable for various applications, including electric vehicles and stationary energy storage systems.

The safety advantages of LiFePO4 batteries extend to their charging and discharging characteristics. These batteries are less prone to overcharging and can withstand higher charging voltages without compromising safety. This resilience contributes to their longevity and allows for more flexible charging strategies without significantly increasing safety risks.

When considering the balance between capacity and longevity, it is crucial to note that LiFePO4 batteries generally have a lower energy density compared to some other lithium-ion chemistries. However, this trade-off often results in enhanced safety and longer cycle life. The lower energy density can be mitigated through careful cell design and pack configuration, allowing for increased capacity without compromising safety.

In terms of long-term safety, LiFePO4 batteries demonstrate excellent calendar life and cycle stability. This longevity reduces the frequency of battery replacements, minimizing potential safety risks associated with battery disposal and recycling processes. Furthermore, the stable chemistry of LiFePO4 batteries contributes to maintaining safety performance over extended periods, even as the battery ages.

As research continues to focus on balancing capacity and longevity in LiFePO4 batteries, safety considerations remain at the forefront. Ongoing efforts include the development of advanced battery management systems, improved thermal management techniques, and enhanced cell designs to further optimize safety while pushing the boundaries of energy density and cycle life.

One of the primary safety features of LiFePO4 batteries is their resistance to oxygen release at high temperatures. This characteristic significantly mitigates the risk of combustion, even under extreme conditions. Additionally, the strong Fe-P-O bonds in the cathode material prevent oxygen release, further enhancing the overall safety profile of these batteries.

The use of phosphate-based cathodes also contributes to improved safety by reducing the likelihood of internal short circuits. This is particularly important when considering the balance between capacity and longevity, as higher energy densities can sometimes lead to increased safety risks in other lithium-ion chemistries.

LiFePO4 batteries exhibit excellent thermal stability, with a higher thermal runaway temperature compared to other lithium-ion technologies. This property allows for safer operation across a wider range of environmental conditions, making them suitable for various applications, including electric vehicles and stationary energy storage systems.

The safety advantages of LiFePO4 batteries extend to their charging and discharging characteristics. These batteries are less prone to overcharging and can withstand higher charging voltages without compromising safety. This resilience contributes to their longevity and allows for more flexible charging strategies without significantly increasing safety risks.

When considering the balance between capacity and longevity, it is crucial to note that LiFePO4 batteries generally have a lower energy density compared to some other lithium-ion chemistries. However, this trade-off often results in enhanced safety and longer cycle life. The lower energy density can be mitigated through careful cell design and pack configuration, allowing for increased capacity without compromising safety.

In terms of long-term safety, LiFePO4 batteries demonstrate excellent calendar life and cycle stability. This longevity reduces the frequency of battery replacements, minimizing potential safety risks associated with battery disposal and recycling processes. Furthermore, the stable chemistry of LiFePO4 batteries contributes to maintaining safety performance over extended periods, even as the battery ages.

As research continues to focus on balancing capacity and longevity in LiFePO4 batteries, safety considerations remain at the forefront. Ongoing efforts include the development of advanced battery management systems, improved thermal management techniques, and enhanced cell designs to further optimize safety while pushing the boundaries of energy density and cycle life.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!