Barriers to Widespread Lithium Iron Phosphate Battery Usage

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LFP Battery Evolution

The evolution of Lithium Iron Phosphate (LFP) batteries has been marked by significant technological advancements and market shifts. Initially developed in the 1990s, LFP batteries emerged as a safer and more stable alternative to traditional lithium-ion batteries. Their early adoption was limited due to lower energy density compared to other lithium-ion chemistries.

A major breakthrough came in the early 2000s with the development of nano-scale phosphate cathode materials, which dramatically improved the power density and rate capability of LFP batteries. This innovation opened up new applications, particularly in electric vehicles and energy storage systems.

The mid-2000s saw increased commercial production of LFP batteries, primarily led by Chinese manufacturers. This period was characterized by rapid improvements in manufacturing processes, resulting in reduced costs and increased production capacity. However, the widespread adoption of LFP batteries was still hindered by their lower energy density compared to nickel-based lithium-ion batteries.

A significant turning point occurred in the 2010s with the introduction of cell-to-pack (CTP) technology. This innovation allowed for more efficient packaging of LFP cells, effectively increasing the energy density at the pack level and making LFP batteries more competitive in the electric vehicle market.

Recent years have witnessed a resurgence of interest in LFP batteries, driven by several factors. The increasing focus on safety in electric vehicles has highlighted the inherent safety advantages of LFP chemistry. Additionally, concerns over the supply chain and environmental impact of cobalt and nickel have made LFP an attractive alternative.

Technological advancements have continued to address the energy density limitations of LFP batteries. The development of silicon-doped anodes and advanced electrolytes has further improved their performance, narrowing the gap with other lithium-ion chemistries.

The evolution of LFP batteries has also been influenced by policy changes, particularly in China, where government incentives have favored the adoption of LFP batteries in electric vehicles. This has led to increased investment in LFP technology and manufacturing capacity, further driving down costs and improving performance.

Looking forward, the LFP battery evolution is expected to continue with focus on further increasing energy density, improving fast-charging capabilities, and extending cycle life. Emerging technologies such as solid-state electrolytes and advanced cathode coatings hold promise for addressing remaining challenges and expanding the application range of LFP batteries.

A major breakthrough came in the early 2000s with the development of nano-scale phosphate cathode materials, which dramatically improved the power density and rate capability of LFP batteries. This innovation opened up new applications, particularly in electric vehicles and energy storage systems.

The mid-2000s saw increased commercial production of LFP batteries, primarily led by Chinese manufacturers. This period was characterized by rapid improvements in manufacturing processes, resulting in reduced costs and increased production capacity. However, the widespread adoption of LFP batteries was still hindered by their lower energy density compared to nickel-based lithium-ion batteries.

A significant turning point occurred in the 2010s with the introduction of cell-to-pack (CTP) technology. This innovation allowed for more efficient packaging of LFP cells, effectively increasing the energy density at the pack level and making LFP batteries more competitive in the electric vehicle market.

Recent years have witnessed a resurgence of interest in LFP batteries, driven by several factors. The increasing focus on safety in electric vehicles has highlighted the inherent safety advantages of LFP chemistry. Additionally, concerns over the supply chain and environmental impact of cobalt and nickel have made LFP an attractive alternative.

Technological advancements have continued to address the energy density limitations of LFP batteries. The development of silicon-doped anodes and advanced electrolytes has further improved their performance, narrowing the gap with other lithium-ion chemistries.

The evolution of LFP batteries has also been influenced by policy changes, particularly in China, where government incentives have favored the adoption of LFP batteries in electric vehicles. This has led to increased investment in LFP technology and manufacturing capacity, further driving down costs and improving performance.

Looking forward, the LFP battery evolution is expected to continue with focus on further increasing energy density, improving fast-charging capabilities, and extending cycle life. Emerging technologies such as solid-state electrolytes and advanced cathode coatings hold promise for addressing remaining challenges and expanding the application range of LFP batteries.

Market Demand Analysis

The market demand for lithium iron phosphate (LFP) batteries has been steadily increasing in recent years, driven by their superior safety, longer lifespan, and lower cost compared to other lithium-ion battery chemistries. This growth is particularly evident in the electric vehicle (EV) sector, where LFP batteries are gaining traction due to their cost-effectiveness and stability.

In the EV market, LFP batteries are becoming increasingly popular, especially in China, where they account for a significant portion of the electric vehicle battery market. Major automakers, including Tesla, Volkswagen, and Ford, have announced plans to incorporate LFP batteries into their vehicle lineups, indicating a growing acceptance of this technology in the automotive industry.

The energy storage sector is another key driver of LFP battery demand. As renewable energy sources become more prevalent, the need for efficient and cost-effective energy storage solutions has grown. LFP batteries are well-suited for stationary energy storage applications due to their long cycle life and thermal stability, making them attractive for both residential and utility-scale projects.

Consumer electronics represent another potential growth area for LFP batteries. While currently dominated by other lithium-ion chemistries, there is increasing interest in LFP batteries for applications where safety and longevity are paramount, such as in medical devices and industrial equipment.

Despite the growing demand, there are still barriers to widespread adoption. One significant challenge is the lower energy density of LFP batteries compared to other lithium-ion chemistries, which can limit their application in certain high-performance or space-constrained scenarios. This has led to ongoing research and development efforts to improve the energy density of LFP batteries while maintaining their other advantageous properties.

The global supply chain for LFP batteries is also a factor influencing market demand. Currently, the production of LFP batteries is heavily concentrated in China, which has raised concerns about supply chain resilience and geopolitical risks. This has prompted efforts to diversify production and establish manufacturing capabilities in other regions, potentially affecting future market dynamics.

Regulatory factors play a crucial role in shaping the demand for LFP batteries. Government policies promoting electric vehicles and renewable energy storage, such as subsidies and emissions regulations, have a significant impact on the adoption of LFP technology. As these policies evolve, they will continue to influence the market demand for LFP batteries across various sectors.

In the EV market, LFP batteries are becoming increasingly popular, especially in China, where they account for a significant portion of the electric vehicle battery market. Major automakers, including Tesla, Volkswagen, and Ford, have announced plans to incorporate LFP batteries into their vehicle lineups, indicating a growing acceptance of this technology in the automotive industry.

The energy storage sector is another key driver of LFP battery demand. As renewable energy sources become more prevalent, the need for efficient and cost-effective energy storage solutions has grown. LFP batteries are well-suited for stationary energy storage applications due to their long cycle life and thermal stability, making them attractive for both residential and utility-scale projects.

Consumer electronics represent another potential growth area for LFP batteries. While currently dominated by other lithium-ion chemistries, there is increasing interest in LFP batteries for applications where safety and longevity are paramount, such as in medical devices and industrial equipment.

Despite the growing demand, there are still barriers to widespread adoption. One significant challenge is the lower energy density of LFP batteries compared to other lithium-ion chemistries, which can limit their application in certain high-performance or space-constrained scenarios. This has led to ongoing research and development efforts to improve the energy density of LFP batteries while maintaining their other advantageous properties.

The global supply chain for LFP batteries is also a factor influencing market demand. Currently, the production of LFP batteries is heavily concentrated in China, which has raised concerns about supply chain resilience and geopolitical risks. This has prompted efforts to diversify production and establish manufacturing capabilities in other regions, potentially affecting future market dynamics.

Regulatory factors play a crucial role in shaping the demand for LFP batteries. Government policies promoting electric vehicles and renewable energy storage, such as subsidies and emissions regulations, have a significant impact on the adoption of LFP technology. As these policies evolve, they will continue to influence the market demand for LFP batteries across various sectors.

Technical Challenges

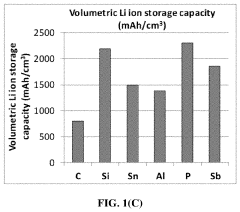

Despite the numerous advantages of Lithium Iron Phosphate (LFP) batteries, several technical challenges hinder their widespread adoption. One of the primary obstacles is the lower energy density compared to other lithium-ion battery chemistries. LFP batteries typically have an energy density of 90-120 Wh/kg, while nickel-based lithium-ion batteries can reach 200-260 Wh/kg. This limitation results in larger and heavier battery packs for equivalent energy storage, which is particularly problematic for electric vehicles where weight and space are critical factors.

Another significant challenge is the relatively low electrical conductivity of LFP materials. This characteristic leads to reduced power output and slower charging rates compared to other lithium-ion technologies. To mitigate this issue, manufacturers often need to implement complex electrode designs or incorporate conductive additives, which can increase production costs and complexity.

The voltage plateau of LFP batteries presents a unique challenge for accurate state-of-charge (SOC) estimation. Unlike other lithium-ion chemistries that exhibit a more linear voltage decline during discharge, LFP batteries maintain a relatively flat voltage profile for much of their discharge cycle. This makes it difficult to precisely determine the remaining capacity, potentially leading to range anxiety in electric vehicle applications and complicating battery management systems.

LFP batteries also face challenges related to their temperature sensitivity. While they generally perform well at high temperatures, their performance can degrade significantly in cold conditions. This limitation can result in reduced range and power output in colder climates, necessitating the implementation of thermal management systems, which add complexity and cost to battery pack designs.

The manufacturing process for LFP batteries presents its own set of challenges. The synthesis of high-quality LFP cathode materials often requires precise control of particle size, morphology, and carbon coating. These requirements can lead to increased production costs and potential scalability issues, particularly when compared to more established lithium-ion chemistries.

Lastly, the raw material supply chain for LFP batteries faces some uncertainties. While iron and phosphate are abundant, the production of high-purity lithium carbonate or lithium hydroxide required for battery-grade materials can be subject to supply constraints and price volatility. This factor can impact the long-term cost competitiveness of LFP batteries compared to other energy storage technologies.

Another significant challenge is the relatively low electrical conductivity of LFP materials. This characteristic leads to reduced power output and slower charging rates compared to other lithium-ion technologies. To mitigate this issue, manufacturers often need to implement complex electrode designs or incorporate conductive additives, which can increase production costs and complexity.

The voltage plateau of LFP batteries presents a unique challenge for accurate state-of-charge (SOC) estimation. Unlike other lithium-ion chemistries that exhibit a more linear voltage decline during discharge, LFP batteries maintain a relatively flat voltage profile for much of their discharge cycle. This makes it difficult to precisely determine the remaining capacity, potentially leading to range anxiety in electric vehicle applications and complicating battery management systems.

LFP batteries also face challenges related to their temperature sensitivity. While they generally perform well at high temperatures, their performance can degrade significantly in cold conditions. This limitation can result in reduced range and power output in colder climates, necessitating the implementation of thermal management systems, which add complexity and cost to battery pack designs.

The manufacturing process for LFP batteries presents its own set of challenges. The synthesis of high-quality LFP cathode materials often requires precise control of particle size, morphology, and carbon coating. These requirements can lead to increased production costs and potential scalability issues, particularly when compared to more established lithium-ion chemistries.

Lastly, the raw material supply chain for LFP batteries faces some uncertainties. While iron and phosphate are abundant, the production of high-purity lithium carbonate or lithium hydroxide required for battery-grade materials can be subject to supply constraints and price volatility. This factor can impact the long-term cost competitiveness of LFP batteries compared to other energy storage technologies.

Current LFP Solutions

01 Electrode material composition and preparation

Lithium iron phosphate (LiFePO4) is a key cathode material for lithium-ion batteries. The composition and preparation methods of this material significantly influence battery performance. Techniques such as doping, coating, and particle size control are employed to enhance conductivity, stability, and capacity of the electrode material.- Electrode material composition and preparation: Lithium iron phosphate (LiFePO4) is a key cathode material for lithium-ion batteries. The composition and preparation methods of this material significantly impact battery performance. Techniques include doping with other elements, controlling particle size and morphology, and using various synthesis methods to enhance conductivity and capacity.

- Battery structure and assembly: The design and assembly of lithium iron phosphate batteries play a crucial role in their performance and safety. This includes innovations in electrode stacking, separator materials, electrolyte composition, and overall cell construction to improve energy density, cycle life, and thermal management.

- Electrolyte formulations: Developing advanced electrolyte formulations is essential for enhancing the performance of lithium iron phosphate batteries. This includes using novel solvents, additives, and ionic liquids to improve ionic conductivity, reduce side reactions, and enhance the stability of the solid electrolyte interphase (SEI) layer.

- Battery management systems: Sophisticated battery management systems are crucial for optimizing the performance and longevity of lithium iron phosphate batteries. These systems monitor and control charging/discharging processes, temperature, and cell balancing to ensure safe operation and maximize battery life.

- Application-specific battery designs: Tailoring lithium iron phosphate batteries for specific applications such as electric vehicles, renewable energy storage, and portable electronics involves optimizing various parameters. This includes adjusting energy density, power output, cycle life, and form factor to meet the unique requirements of each application.

02 Battery cell structure and assembly

The design and assembly of lithium iron phosphate battery cells play a crucial role in overall battery performance. This includes optimizing electrode stacking or winding, electrolyte composition, separator selection, and current collector design. Innovations in cell structure aim to improve energy density, cycle life, and safety of the battery.Expand Specific Solutions03 Thermal management and safety features

Effective thermal management is essential for lithium iron phosphate batteries to maintain optimal performance and ensure safety. This involves the development of cooling systems, heat dissipation materials, and safety mechanisms to prevent thermal runaway. Innovations in this area focus on improving battery stability under various operating conditions.Expand Specific Solutions04 Battery management systems and control algorithms

Advanced battery management systems (BMS) and control algorithms are crucial for optimizing the performance and lifespan of lithium iron phosphate batteries. These systems monitor and control various parameters such as state of charge, temperature, and voltage balance. Innovations in this area aim to improve charging efficiency, extend battery life, and enhance overall system reliability.Expand Specific Solutions05 Manufacturing processes and scalability

Advancements in manufacturing processes for lithium iron phosphate batteries focus on improving production efficiency, reducing costs, and ensuring consistent quality. This includes innovations in material synthesis, electrode coating, cell assembly, and quality control methods. Scalable manufacturing techniques are essential for meeting the growing demand for these batteries in various applications.Expand Specific Solutions

Key Industry Players

The lithium iron phosphate (LFP) battery market is in a growth phase, with increasing adoption in electric vehicles and energy storage systems. The global market size is projected to expand significantly, driven by the batteries' safety, long cycle life, and cost-effectiveness. Technologically, LFP batteries are relatively mature, but ongoing research aims to improve energy density and performance. Key players like BYD, CATL, and LG Chem are investing heavily in LFP technology, while companies such as Honeycomb Battery and Guangdong Bangpu are focusing on innovative materials and recycling processes. Despite advancements, barriers to widespread adoption include lower energy density compared to other lithium-ion chemistries and the need for further cost reductions in production and raw materials.

BYD Co., Ltd.

Technical Solution: BYD has developed a revolutionary Blade Battery technology based on lithium iron phosphate (LFP) chemistry. This innovation addresses several key barriers to widespread LFP battery usage. The Blade Battery features a unique cell-to-pack design that increases energy density by 50% compared to traditional LFP batteries[1]. BYD's approach eliminates the need for module housings, improving space utilization and reducing overall battery weight. The company has also implemented advanced manufacturing processes to enhance the consistency and quality of LFP cells, resulting in improved performance and longevity[2]. Additionally, BYD has focused on thermal management, incorporating a novel cooling system that maintains optimal operating temperatures, thus addressing concerns about LFP batteries' performance in extreme conditions[3].

Strengths: Higher energy density, improved safety, and better thermal management. Weaknesses: Still slightly lower energy density compared to some other lithium-ion chemistries, and potential higher initial production costs due to specialized manufacturing processes.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed a cutting-edge cell-to-pack (CTP) technology for LFP batteries, addressing energy density limitations. Their third-generation CTP technology, known as Qilin, achieves a volume utilization efficiency of 72% and an energy density of up to 255 Wh/kg, rivaling some NCM batteries[4]. CATL has also focused on improving the low-temperature performance of LFP batteries through electrolyte optimization and surface modification of cathode materials[5]. To address cost concerns, CATL has invested in large-scale production facilities and vertical integration of the supply chain, reducing manufacturing expenses. Furthermore, CATL has developed fast-charging capabilities for their LFP batteries, enabling up to 80% charge in 15 minutes, which helps overcome range anxiety issues[6].

Strengths: High energy density for LFP, improved low-temperature performance, and fast-charging capabilities. Weaknesses: Higher production costs compared to traditional LFP batteries, and potential challenges in scaling up the new technologies.

Core LFP Innovations

Lithium and sodium batteries with polysulfide electrolyte

PatentInactiveUS20190312301A1

Innovation

- The integration of a polysulfide anion-based electrolyte, specifically lithium polysulfide (Li2S8), with a carbon nanotube-modified separator and a cathode material like LFP, enhances lithium ion and sulfur battery performance by reducing polarization and improving cycle stability, leading to a hybrid battery with increased capacity and energy density.

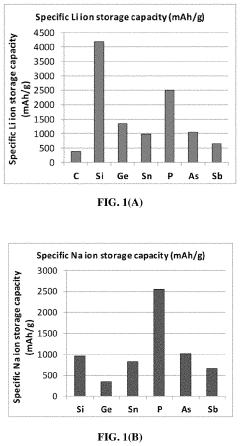

Graphene Foam-Protected Phosphorus Material for Lithium-Ion or Sodium-Ion Batteries

PatentActiveUS20210143409A1

Innovation

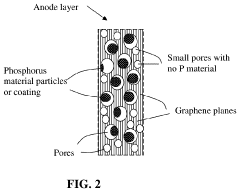

- A graphene foam-protected phosphorus anode layer is developed, where phosphorus material is embedded in a solid graphene foam with interconnected pores, preventing direct contact with electrolytes and accommodating volume expansion, thereby enhancing conductivity and stability.

Raw Material Supply

The raw material supply for lithium iron phosphate (LFP) batteries plays a crucial role in their widespread adoption. While LFP batteries offer several advantages, including improved safety and longer lifespan compared to other lithium-ion chemistries, the availability and cost of raw materials present significant challenges.

Iron and phosphate, two primary components of LFP batteries, are relatively abundant and widely distributed globally. This abundance contributes to the potential for lower production costs and reduced geopolitical risks associated with raw material sourcing. However, the lithium supply chain remains a critical concern for the LFP battery industry.

Lithium, a key ingredient in all lithium-ion batteries, faces supply constraints due to limited production capacity and geographical concentration. The majority of lithium reserves are located in South America's "Lithium Triangle" (Chile, Argentina, and Bolivia) and Australia. This concentration of resources creates potential supply chain vulnerabilities and price volatility.

The extraction and processing of lithium also present environmental challenges. Traditional lithium extraction methods, such as evaporation ponds, consume large amounts of water and can negatively impact local ecosystems. Developing more sustainable extraction techniques, such as direct lithium extraction (DLE), is crucial for ensuring a stable and environmentally responsible supply chain.

Another factor affecting raw material supply is the competition for lithium from other battery chemistries and industries. As the demand for electric vehicles and energy storage systems grows, the pressure on lithium resources intensifies, potentially leading to supply shortages and price increases.

To address these challenges, several strategies are being pursued. Recycling of lithium-ion batteries, including LFP batteries, is gaining traction as a means to recover valuable materials and reduce reliance on primary raw material sources. Additionally, efforts to develop alternative battery chemistries that use more abundant materials, such as sodium-ion batteries, are ongoing.

Expanding lithium production capacity is also a focus for many countries and companies. Investments in new mining projects and processing facilities aim to diversify the supply chain and increase overall production. However, these efforts often face long lead times and regulatory hurdles.

In conclusion, while the raw material supply for LFP batteries benefits from the abundance of iron and phosphate, the lithium supply chain remains a significant barrier to widespread adoption. Addressing these challenges through sustainable extraction methods, recycling initiatives, and supply chain diversification will be crucial for the future growth of the LFP battery market.

Iron and phosphate, two primary components of LFP batteries, are relatively abundant and widely distributed globally. This abundance contributes to the potential for lower production costs and reduced geopolitical risks associated with raw material sourcing. However, the lithium supply chain remains a critical concern for the LFP battery industry.

Lithium, a key ingredient in all lithium-ion batteries, faces supply constraints due to limited production capacity and geographical concentration. The majority of lithium reserves are located in South America's "Lithium Triangle" (Chile, Argentina, and Bolivia) and Australia. This concentration of resources creates potential supply chain vulnerabilities and price volatility.

The extraction and processing of lithium also present environmental challenges. Traditional lithium extraction methods, such as evaporation ponds, consume large amounts of water and can negatively impact local ecosystems. Developing more sustainable extraction techniques, such as direct lithium extraction (DLE), is crucial for ensuring a stable and environmentally responsible supply chain.

Another factor affecting raw material supply is the competition for lithium from other battery chemistries and industries. As the demand for electric vehicles and energy storage systems grows, the pressure on lithium resources intensifies, potentially leading to supply shortages and price increases.

To address these challenges, several strategies are being pursued. Recycling of lithium-ion batteries, including LFP batteries, is gaining traction as a means to recover valuable materials and reduce reliance on primary raw material sources. Additionally, efforts to develop alternative battery chemistries that use more abundant materials, such as sodium-ion batteries, are ongoing.

Expanding lithium production capacity is also a focus for many countries and companies. Investments in new mining projects and processing facilities aim to diversify the supply chain and increase overall production. However, these efforts often face long lead times and regulatory hurdles.

In conclusion, while the raw material supply for LFP batteries benefits from the abundance of iron and phosphate, the lithium supply chain remains a significant barrier to widespread adoption. Addressing these challenges through sustainable extraction methods, recycling initiatives, and supply chain diversification will be crucial for the future growth of the LFP battery market.

Environmental Impact

The environmental impact of lithium iron phosphate (LFP) batteries is a critical consideration in their widespread adoption. While these batteries offer several advantages over other lithium-ion chemistries, their production and use still have significant environmental implications.

LFP batteries generally have a lower environmental footprint compared to other lithium-ion technologies, particularly in terms of raw material extraction. The iron and phosphate used in LFP batteries are abundant and widely distributed, reducing the environmental impact associated with mining and transportation. Additionally, LFP batteries do not contain cobalt, a metal often sourced from conflict-prone regions with questionable labor practices.

However, the production of LFP batteries still requires substantial energy input, contributing to greenhouse gas emissions. The manufacturing process involves high-temperature reactions and energy-intensive material synthesis, which can result in a significant carbon footprint if not powered by renewable energy sources. As the demand for LFP batteries grows, addressing these production-related emissions becomes increasingly important.

End-of-life management presents another environmental challenge for LFP batteries. While they are generally considered safer and more stable than other lithium-ion chemistries, proper recycling infrastructure is still developing. The recycling process for LFP batteries is more complex due to the lower value of recovered materials compared to cobalt-containing batteries. This complexity can lead to improper disposal or inefficient recycling practices, potentially resulting in environmental contamination.

Water usage and pollution are additional environmental concerns associated with LFP battery production. The manufacturing process requires significant amounts of water for cooling and material processing. Proper water treatment and recycling systems are essential to minimize the impact on local water resources and prevent the release of pollutants into aquatic ecosystems.

Despite these challenges, LFP batteries have the potential to contribute positively to environmental sustainability. Their longer lifespan and improved safety characteristics can reduce the frequency of battery replacements and the risk of hazardous incidents, ultimately lowering the overall environmental impact of battery-powered systems. Furthermore, ongoing research and development efforts are focused on improving the energy efficiency of LFP battery production and enhancing recycling technologies to create a more circular economy for these batteries.

As the adoption of LFP batteries continues to grow, it is crucial to address these environmental concerns through sustainable manufacturing practices, renewable energy integration, and the development of efficient recycling processes. By doing so, the barriers to widespread LFP battery usage related to environmental impact can be significantly reduced, paving the way for a more sustainable energy storage future.

LFP batteries generally have a lower environmental footprint compared to other lithium-ion technologies, particularly in terms of raw material extraction. The iron and phosphate used in LFP batteries are abundant and widely distributed, reducing the environmental impact associated with mining and transportation. Additionally, LFP batteries do not contain cobalt, a metal often sourced from conflict-prone regions with questionable labor practices.

However, the production of LFP batteries still requires substantial energy input, contributing to greenhouse gas emissions. The manufacturing process involves high-temperature reactions and energy-intensive material synthesis, which can result in a significant carbon footprint if not powered by renewable energy sources. As the demand for LFP batteries grows, addressing these production-related emissions becomes increasingly important.

End-of-life management presents another environmental challenge for LFP batteries. While they are generally considered safer and more stable than other lithium-ion chemistries, proper recycling infrastructure is still developing. The recycling process for LFP batteries is more complex due to the lower value of recovered materials compared to cobalt-containing batteries. This complexity can lead to improper disposal or inefficient recycling practices, potentially resulting in environmental contamination.

Water usage and pollution are additional environmental concerns associated with LFP battery production. The manufacturing process requires significant amounts of water for cooling and material processing. Proper water treatment and recycling systems are essential to minimize the impact on local water resources and prevent the release of pollutants into aquatic ecosystems.

Despite these challenges, LFP batteries have the potential to contribute positively to environmental sustainability. Their longer lifespan and improved safety characteristics can reduce the frequency of battery replacements and the risk of hazardous incidents, ultimately lowering the overall environmental impact of battery-powered systems. Furthermore, ongoing research and development efforts are focused on improving the energy efficiency of LFP battery production and enhancing recycling technologies to create a more circular economy for these batteries.

As the adoption of LFP batteries continues to grow, it is crucial to address these environmental concerns through sustainable manufacturing practices, renewable energy integration, and the development of efficient recycling processes. By doing so, the barriers to widespread LFP battery usage related to environmental impact can be significantly reduced, paving the way for a more sustainable energy storage future.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!