Environmental Benefits of Lithium Iron Phosphate Battery Use

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LFP Battery Evolution and Objectives

Lithium Iron Phosphate (LFP) batteries have emerged as a significant player in the energy storage landscape, particularly in the context of environmental sustainability. The evolution of LFP technology can be traced back to the early 1990s when researchers at the University of Texas first discovered the potential of LiFePO4 as a cathode material. Since then, the technology has undergone substantial improvements in performance, safety, and cost-effectiveness.

The primary objective of LFP battery development has been to create a more sustainable and environmentally friendly alternative to traditional lithium-ion batteries. This goal aligns with the global push for cleaner energy solutions and reduced carbon emissions. LFP batteries offer several environmental benefits, including lower toxicity, improved safety, and the use of more abundant and less controversial raw materials compared to other lithium-ion chemistries.

One of the key evolutionary milestones in LFP technology was the development of nano-scale phosphate cathode material, which significantly enhanced the battery's power density and charge-discharge capabilities. This breakthrough, achieved in the early 2000s, paved the way for LFP batteries to become viable options for electric vehicles and large-scale energy storage systems.

Another critical objective in the evolution of LFP batteries has been to increase their energy density while maintaining their inherent safety advantages. Recent advancements in electrode materials and cell design have led to substantial improvements in this area, making LFP batteries increasingly competitive with other lithium-ion chemistries in terms of energy storage capacity.

The environmental objectives of LFP battery technology extend beyond just the operational phase. Researchers and manufacturers have been focusing on developing more sustainable production processes and improving the recyclability of LFP batteries. This holistic approach aims to minimize the environmental impact across the entire lifecycle of the battery, from raw material extraction to end-of-life disposal or recycling.

Looking forward, the evolution of LFP batteries is expected to continue with a focus on further enhancing energy density, reducing production costs, and improving overall environmental performance. Objectives include developing new doping techniques to increase conductivity, exploring advanced manufacturing methods to reduce energy consumption during production, and creating more efficient recycling processes to recover and reuse valuable materials.

The primary objective of LFP battery development has been to create a more sustainable and environmentally friendly alternative to traditional lithium-ion batteries. This goal aligns with the global push for cleaner energy solutions and reduced carbon emissions. LFP batteries offer several environmental benefits, including lower toxicity, improved safety, and the use of more abundant and less controversial raw materials compared to other lithium-ion chemistries.

One of the key evolutionary milestones in LFP technology was the development of nano-scale phosphate cathode material, which significantly enhanced the battery's power density and charge-discharge capabilities. This breakthrough, achieved in the early 2000s, paved the way for LFP batteries to become viable options for electric vehicles and large-scale energy storage systems.

Another critical objective in the evolution of LFP batteries has been to increase their energy density while maintaining their inherent safety advantages. Recent advancements in electrode materials and cell design have led to substantial improvements in this area, making LFP batteries increasingly competitive with other lithium-ion chemistries in terms of energy storage capacity.

The environmental objectives of LFP battery technology extend beyond just the operational phase. Researchers and manufacturers have been focusing on developing more sustainable production processes and improving the recyclability of LFP batteries. This holistic approach aims to minimize the environmental impact across the entire lifecycle of the battery, from raw material extraction to end-of-life disposal or recycling.

Looking forward, the evolution of LFP batteries is expected to continue with a focus on further enhancing energy density, reducing production costs, and improving overall environmental performance. Objectives include developing new doping techniques to increase conductivity, exploring advanced manufacturing methods to reduce energy consumption during production, and creating more efficient recycling processes to recover and reuse valuable materials.

Market Demand Analysis for LFP Batteries

The market demand for Lithium Iron Phosphate (LFP) batteries has been experiencing significant growth, driven by the increasing adoption of electric vehicles (EVs) and renewable energy storage systems. This surge in demand is primarily attributed to the environmental benefits and superior safety characteristics of LFP batteries compared to other lithium-ion battery chemistries.

In the automotive sector, LFP batteries are gaining traction due to their lower cost, longer cycle life, and improved safety profile. Major EV manufacturers, including Tesla and Volkswagen, have announced plans to incorporate LFP batteries into their mass-market vehicle models. This shift is expected to drive substantial market growth in the coming years.

The stationary energy storage market is another key driver for LFP battery demand. As countries worldwide push for greater integration of renewable energy sources into their power grids, the need for efficient and reliable energy storage solutions has increased. LFP batteries are well-suited for grid-scale applications due to their stability, long lifespan, and lower environmental impact compared to traditional lead-acid batteries.

The industrial and commercial sectors are also contributing to the rising demand for LFP batteries. These batteries are increasingly being used in forklifts, automated guided vehicles, and other material handling equipment, replacing lead-acid batteries due to their faster charging capabilities and longer operational life.

Geographically, China remains the largest market for LFP batteries, with a well-established supply chain and strong government support for EV adoption. However, other regions, particularly Europe and North America, are showing rapid growth in demand as they accelerate their transition to electric mobility and renewable energy.

The environmental benefits of LFP batteries are a significant factor driving market demand. These batteries are cobalt-free, reducing the environmental and social concerns associated with cobalt mining. Additionally, LFP batteries have a lower carbon footprint in production compared to other lithium-ion chemistries, aligning with the growing emphasis on sustainable manufacturing practices.

Market analysts project that the global LFP battery market will continue to expand at a compound annual growth rate (CAGR) of over 20% in the next five years. This growth is supported by ongoing technological advancements that are improving the energy density and performance of LFP batteries, making them increasingly competitive with other battery chemistries across various applications.

In the automotive sector, LFP batteries are gaining traction due to their lower cost, longer cycle life, and improved safety profile. Major EV manufacturers, including Tesla and Volkswagen, have announced plans to incorporate LFP batteries into their mass-market vehicle models. This shift is expected to drive substantial market growth in the coming years.

The stationary energy storage market is another key driver for LFP battery demand. As countries worldwide push for greater integration of renewable energy sources into their power grids, the need for efficient and reliable energy storage solutions has increased. LFP batteries are well-suited for grid-scale applications due to their stability, long lifespan, and lower environmental impact compared to traditional lead-acid batteries.

The industrial and commercial sectors are also contributing to the rising demand for LFP batteries. These batteries are increasingly being used in forklifts, automated guided vehicles, and other material handling equipment, replacing lead-acid batteries due to their faster charging capabilities and longer operational life.

Geographically, China remains the largest market for LFP batteries, with a well-established supply chain and strong government support for EV adoption. However, other regions, particularly Europe and North America, are showing rapid growth in demand as they accelerate their transition to electric mobility and renewable energy.

The environmental benefits of LFP batteries are a significant factor driving market demand. These batteries are cobalt-free, reducing the environmental and social concerns associated with cobalt mining. Additionally, LFP batteries have a lower carbon footprint in production compared to other lithium-ion chemistries, aligning with the growing emphasis on sustainable manufacturing practices.

Market analysts project that the global LFP battery market will continue to expand at a compound annual growth rate (CAGR) of over 20% in the next five years. This growth is supported by ongoing technological advancements that are improving the energy density and performance of LFP batteries, making them increasingly competitive with other battery chemistries across various applications.

LFP Technology Status and Challenges

Lithium Iron Phosphate (LFP) battery technology has made significant strides in recent years, positioning itself as a promising solution for various applications, particularly in electric vehicles and renewable energy storage systems. The current status of LFP technology is characterized by its improved safety, longer cycle life, and lower cost compared to other lithium-ion battery chemistries.

One of the key advantages of LFP batteries is their thermal stability, which significantly reduces the risk of thermal runaway and fire hazards. This has made them increasingly attractive for large-scale energy storage projects and electric vehicles where safety is paramount. Additionally, LFP batteries have demonstrated excellent cycle life, often exceeding 2000 cycles, which contributes to their long-term cost-effectiveness.

However, LFP technology still faces several challenges that hinder its widespread adoption. The primary limitation is its relatively low energy density compared to other lithium-ion chemistries such as NMC (Nickel Manganese Cobalt) or NCA (Nickel Cobalt Aluminum). This results in larger and heavier battery packs for equivalent energy storage, which can be a drawback in weight-sensitive applications like electric vehicles.

Another challenge is the lower voltage of LFP cells (3.2V nominal) compared to other lithium-ion chemistries (3.6-3.7V), which necessitates more cells in series to achieve higher system voltages. This can increase complexity and cost in battery management systems.

The performance of LFP batteries at low temperatures is also a concern, as they tend to experience more significant capacity loss and reduced power output in cold environments compared to some other lithium-ion chemistries. This limitation can affect their suitability for certain applications in colder climates.

From a global perspective, LFP technology has seen rapid development and adoption in China, which has become the world leader in LFP battery production. This geographical concentration presents both opportunities and challenges for the global supply chain and technology transfer.

Despite these challenges, ongoing research and development efforts are focused on addressing these limitations. Innovations in cathode material engineering, such as doping and nano-structuring, are being explored to improve energy density and low-temperature performance. Advanced manufacturing techniques are also being developed to enhance the overall performance and reduce production costs.

The environmental benefits of LFP batteries, including their use of more abundant and less controversial raw materials compared to cobalt-based chemistries, continue to drive interest in this technology. As the world moves towards more sustainable energy solutions, the role of LFP batteries in supporting this transition remains a key area of focus for researchers and industry players alike.

One of the key advantages of LFP batteries is their thermal stability, which significantly reduces the risk of thermal runaway and fire hazards. This has made them increasingly attractive for large-scale energy storage projects and electric vehicles where safety is paramount. Additionally, LFP batteries have demonstrated excellent cycle life, often exceeding 2000 cycles, which contributes to their long-term cost-effectiveness.

However, LFP technology still faces several challenges that hinder its widespread adoption. The primary limitation is its relatively low energy density compared to other lithium-ion chemistries such as NMC (Nickel Manganese Cobalt) or NCA (Nickel Cobalt Aluminum). This results in larger and heavier battery packs for equivalent energy storage, which can be a drawback in weight-sensitive applications like electric vehicles.

Another challenge is the lower voltage of LFP cells (3.2V nominal) compared to other lithium-ion chemistries (3.6-3.7V), which necessitates more cells in series to achieve higher system voltages. This can increase complexity and cost in battery management systems.

The performance of LFP batteries at low temperatures is also a concern, as they tend to experience more significant capacity loss and reduced power output in cold environments compared to some other lithium-ion chemistries. This limitation can affect their suitability for certain applications in colder climates.

From a global perspective, LFP technology has seen rapid development and adoption in China, which has become the world leader in LFP battery production. This geographical concentration presents both opportunities and challenges for the global supply chain and technology transfer.

Despite these challenges, ongoing research and development efforts are focused on addressing these limitations. Innovations in cathode material engineering, such as doping and nano-structuring, are being explored to improve energy density and low-temperature performance. Advanced manufacturing techniques are also being developed to enhance the overall performance and reduce production costs.

The environmental benefits of LFP batteries, including their use of more abundant and less controversial raw materials compared to cobalt-based chemistries, continue to drive interest in this technology. As the world moves towards more sustainable energy solutions, the role of LFP batteries in supporting this transition remains a key area of focus for researchers and industry players alike.

Current LFP Battery Solutions

01 Reduced environmental impact in production

Lithium iron phosphate (LFP) batteries have a lower environmental impact during production compared to other lithium-ion battery types. The manufacturing process requires less energy and produces fewer emissions. Additionally, the raw materials used in LFP batteries are more abundant and less toxic, reducing the environmental burden of resource extraction.- Reduced environmental impact in production: Lithium iron phosphate (LFP) batteries have a lower environmental impact during production compared to other lithium-ion battery types. The manufacturing process requires less energy and produces fewer emissions. Additionally, the raw materials used in LFP batteries are more abundant and less toxic, reducing the overall ecological footprint of battery production.

- Improved recyclability and resource recovery: LFP batteries offer better recyclability compared to other lithium-ion battery chemistries. The materials used in these batteries can be more easily recovered and reused, reducing waste and the need for new raw material extraction. This characteristic contributes to a more circular economy and helps conserve natural resources.

- Longer lifespan and reduced waste generation: LFP batteries typically have a longer cycle life compared to other lithium-ion batteries. This extended lifespan means fewer batteries need to be produced and disposed of over time, resulting in less electronic waste. The durability of LFP batteries also contributes to their sustainability in various applications, including electric vehicles and renewable energy storage systems.

- Enhanced safety and reduced risk of environmental contamination: LFP batteries are known for their superior thermal and chemical stability compared to other lithium-ion chemistries. This increased safety reduces the risk of fires or explosions, which can lead to environmental contamination. The stable nature of LFP batteries also means they are less likely to leak harmful substances into the environment during use or disposal.

- Support for renewable energy integration: LFP batteries play a crucial role in supporting the integration of renewable energy sources into the power grid. Their ability to provide stable and long-duration energy storage helps balance the intermittent nature of solar and wind power. By enabling greater adoption of renewable energy, LFP batteries indirectly contribute to reducing greenhouse gas emissions and combating climate change.

02 Improved recyclability and resource recovery

LFP batteries are more easily recyclable than other lithium-ion battery chemistries. The materials used in these batteries can be more efficiently recovered and reused, reducing waste and the need for new raw material extraction. This contributes to a more circular economy and helps conserve natural resources.Expand Specific Solutions03 Longer lifespan and reduced waste generation

LFP batteries typically have a longer cycle life compared to other lithium-ion batteries. This extended lifespan means fewer batteries need to be produced and disposed of over time, reducing overall waste generation and the environmental impact associated with battery disposal.Expand Specific Solutions04 Lower risk of thermal runaway and improved safety

LFP batteries have a higher thermal and chemical stability, reducing the risk of thermal runaway and fire. This improved safety profile not only protects users but also minimizes the potential for environmental contamination due to battery failures or accidents.Expand Specific Solutions05 Potential for grid energy storage and renewable energy integration

The characteristics of LFP batteries make them well-suited for large-scale energy storage applications. This capability supports the integration of renewable energy sources into the power grid, potentially reducing reliance on fossil fuels and lowering overall carbon emissions in the energy sector.Expand Specific Solutions

Key Players in LFP Battery Industry

The environmental benefits of lithium iron phosphate (LFP) batteries are gaining attention in a rapidly evolving market. The industry is in a growth phase, with increasing adoption in electric vehicles and energy storage systems. Market size is expanding, driven by demand for sustainable energy solutions. Technologically, LFP batteries are maturing, with companies like Contemporary Amperex Technology Co., Ltd. (CATL) and LG Energy Solution leading innovation. These firms, along with others such as Guangdong Bangpu Recycling Technology and Hunan Bangpu Recycling Technology, are advancing recycling processes, further enhancing the environmental credentials of LFP batteries. The competitive landscape is dynamic, with established players and new entrants focusing on improving performance, cost-effectiveness, and sustainability.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed high-performance LFP batteries with enhanced environmental benefits. Their LFP cells incorporate advanced nano-coating technology, which improves the cathode's conductivity and stability, resulting in better overall battery performance[4]. The company's LFP batteries demonstrate a 10% increase in energy density compared to conventional LFP cells, while maintaining excellent thermal stability and safety characteristics[5]. LG Energy Solution has also implemented a green manufacturing process, reducing carbon emissions in battery production by up to 40% through the use of renewable energy and optimized production techniques[6]. Additionally, their LFP batteries are designed for easy disassembly and recycling, with over 95% of materials recoverable at end-of-life[7].

Strengths: Improved energy density, enhanced safety, and eco-friendly manufacturing process. Weaknesses: Higher production costs and potential limitations in extreme low-temperature performance.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: Contemporary Amperex Technology Co., Ltd. (CATL) has developed advanced Lithium Iron Phosphate (LFP) batteries with significant environmental benefits. Their LFP batteries utilize a unique cell-to-pack (CTP) technology, which increases energy density by 15-20% compared to conventional LFP batteries[1]. This improvement allows for longer driving ranges in electric vehicles while maintaining the inherent safety and longevity advantages of LFP chemistry. CATL's LFP batteries also demonstrate excellent cycle life, retaining over 80% capacity after 3000 charge-discharge cycles[2]. The company has implemented a closed-loop recycling system, recovering over 99% of valuable metals from spent batteries, significantly reducing the environmental impact of battery production[3].

Strengths: High energy density, excellent cycle life, and efficient recycling process. Weaknesses: Higher initial production costs compared to traditional lithium-ion batteries, and potential supply chain constraints for raw materials.

Core LFP Battery Innovations

Cathode slurry composition, and lithium secondary battery manufactured using same

PatentPendingEP4283712A1

Innovation

- Incorporating a dispersant with a weight-average molecular weight of 10,000 g/mol to 150,000 g/mol into the positive electrode slurry composition to improve dispersibility and prevent particle agglomeration, while minimizing the surface area of conductive material agglomerates, thereby enhancing the electrical conductivity and stability of the positive electrode.

Method for recycling iron phosphate waste and use thereof

PatentPendingUS20240021903A1

Innovation

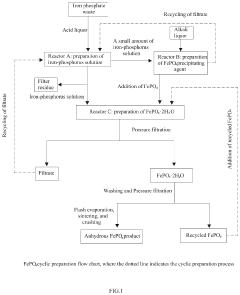

- A method involving the mixing of iron phosphate waste with an acid liquid for dissolution, followed by pH adjustment with an alkali liquid, filtration, and subsequent heating to produce an iron phosphate dihydrate precipitate, which is then dried to obtain anhydrous iron phosphate, allowing for a cyclic process with reduced alkali consumption and energy usage, suitable for large-scale industrial production.

Environmental Impact Assessment

The environmental impact assessment of lithium iron phosphate (LFP) batteries reveals significant benefits compared to traditional energy storage technologies. LFP batteries demonstrate a lower carbon footprint throughout their lifecycle, from production to end-of-life disposal. The manufacturing process of LFP batteries requires less energy and produces fewer greenhouse gas emissions than conventional lithium-ion batteries, contributing to reduced environmental impact from the outset.

During their operational phase, LFP batteries exhibit excellent thermal stability and safety characteristics, reducing the risk of thermal runaway and fire incidents. This inherent safety feature not only protects users but also minimizes potential environmental hazards associated with battery failures. Additionally, the long cycle life of LFP batteries, often exceeding 2000 cycles, extends their useful lifespan and reduces the frequency of replacements, thereby decreasing overall resource consumption and waste generation.

LFP batteries contain no toxic heavy metals such as lead, cadmium, or mercury, making them more environmentally friendly than lead-acid batteries and some other lithium-ion chemistries. The absence of cobalt in LFP batteries also addresses ethical concerns related to cobalt mining practices and reduces the environmental impact associated with cobalt extraction.

In terms of recycling and end-of-life management, LFP batteries present advantages due to their simpler and more stable chemical composition. The recycling process for LFP batteries is less complex and energy-intensive compared to other lithium-ion chemistries, facilitating higher recovery rates of valuable materials. This contributes to the circular economy and reduces the demand for virgin raw materials.

The use of LFP batteries in renewable energy storage applications further enhances their environmental benefits. By enabling more efficient integration of intermittent renewable energy sources like solar and wind into the grid, LFP batteries play a crucial role in reducing reliance on fossil fuels and lowering overall carbon emissions in the energy sector.

However, it is important to note that the environmental impact of LFP batteries is not entirely negligible. The extraction of lithium and other raw materials still has environmental consequences, including water consumption and potential ecosystem disruption in mining areas. Efforts to improve sustainable sourcing practices and develop more efficient recycling technologies are ongoing to further mitigate these impacts.

In conclusion, the environmental impact assessment of LFP batteries demonstrates their potential to significantly reduce the ecological footprint of energy storage solutions. Their lower carbon emissions, improved safety, longer lifespan, and recyclability make them a promising technology for sustainable energy systems. As research and development in this field continue, it is expected that the environmental performance of LFP batteries will further improve, solidifying their position as a key component in the transition to a more sustainable energy future.

During their operational phase, LFP batteries exhibit excellent thermal stability and safety characteristics, reducing the risk of thermal runaway and fire incidents. This inherent safety feature not only protects users but also minimizes potential environmental hazards associated with battery failures. Additionally, the long cycle life of LFP batteries, often exceeding 2000 cycles, extends their useful lifespan and reduces the frequency of replacements, thereby decreasing overall resource consumption and waste generation.

LFP batteries contain no toxic heavy metals such as lead, cadmium, or mercury, making them more environmentally friendly than lead-acid batteries and some other lithium-ion chemistries. The absence of cobalt in LFP batteries also addresses ethical concerns related to cobalt mining practices and reduces the environmental impact associated with cobalt extraction.

In terms of recycling and end-of-life management, LFP batteries present advantages due to their simpler and more stable chemical composition. The recycling process for LFP batteries is less complex and energy-intensive compared to other lithium-ion chemistries, facilitating higher recovery rates of valuable materials. This contributes to the circular economy and reduces the demand for virgin raw materials.

The use of LFP batteries in renewable energy storage applications further enhances their environmental benefits. By enabling more efficient integration of intermittent renewable energy sources like solar and wind into the grid, LFP batteries play a crucial role in reducing reliance on fossil fuels and lowering overall carbon emissions in the energy sector.

However, it is important to note that the environmental impact of LFP batteries is not entirely negligible. The extraction of lithium and other raw materials still has environmental consequences, including water consumption and potential ecosystem disruption in mining areas. Efforts to improve sustainable sourcing practices and develop more efficient recycling technologies are ongoing to further mitigate these impacts.

In conclusion, the environmental impact assessment of LFP batteries demonstrates their potential to significantly reduce the ecological footprint of energy storage solutions. Their lower carbon emissions, improved safety, longer lifespan, and recyclability make them a promising technology for sustainable energy systems. As research and development in this field continue, it is expected that the environmental performance of LFP batteries will further improve, solidifying their position as a key component in the transition to a more sustainable energy future.

Regulatory Framework for LFP Batteries

The regulatory framework for Lithium Iron Phosphate (LFP) batteries is evolving rapidly as governments and international organizations recognize the environmental benefits and potential of this technology. In the United States, the Environmental Protection Agency (EPA) has established guidelines for the safe handling, transportation, and disposal of LFP batteries under the Resource Conservation and Recovery Act (RCRA). These regulations aim to minimize environmental risks associated with battery production and end-of-life management.

The European Union has implemented the Battery Directive (2006/66/EC), which sets specific requirements for battery manufacturers, including those producing LFP batteries. This directive focuses on reducing the environmental impact of batteries throughout their lifecycle, from production to disposal. It mandates minimum collection and recycling rates for batteries and prohibits the use of certain hazardous substances in battery manufacturing.

In China, the world's largest producer and consumer of LFP batteries, the government has introduced policies to promote the development and adoption of this technology. The Ministry of Industry and Information Technology (MIIT) has issued guidelines for the standardization of LFP battery production, emphasizing safety and environmental protection measures.

International standards organizations, such as the International Electrotechnical Commission (IEC) and the Society of Automotive Engineers (SAE), have developed specific standards for LFP batteries. These standards address safety, performance, and environmental aspects of battery design and usage, ensuring consistency across global markets.

Many countries have implemented incentive programs to encourage the adoption of LFP batteries in various applications, particularly in electric vehicles and renewable energy storage systems. These incentives often include tax credits, subsidies, and research grants aimed at accelerating the transition to cleaner energy technologies.

As the LFP battery market continues to grow, regulatory bodies are increasingly focusing on the entire battery lifecycle. This includes regulations on raw material sourcing, manufacturing processes, and end-of-life management. The development of a circular economy approach for LFP batteries is becoming a priority, with an emphasis on recycling and reuse strategies to maximize resource efficiency and minimize environmental impact.

The European Union has implemented the Battery Directive (2006/66/EC), which sets specific requirements for battery manufacturers, including those producing LFP batteries. This directive focuses on reducing the environmental impact of batteries throughout their lifecycle, from production to disposal. It mandates minimum collection and recycling rates for batteries and prohibits the use of certain hazardous substances in battery manufacturing.

In China, the world's largest producer and consumer of LFP batteries, the government has introduced policies to promote the development and adoption of this technology. The Ministry of Industry and Information Technology (MIIT) has issued guidelines for the standardization of LFP battery production, emphasizing safety and environmental protection measures.

International standards organizations, such as the International Electrotechnical Commission (IEC) and the Society of Automotive Engineers (SAE), have developed specific standards for LFP batteries. These standards address safety, performance, and environmental aspects of battery design and usage, ensuring consistency across global markets.

Many countries have implemented incentive programs to encourage the adoption of LFP batteries in various applications, particularly in electric vehicles and renewable energy storage systems. These incentives often include tax credits, subsidies, and research grants aimed at accelerating the transition to cleaner energy technologies.

As the LFP battery market continues to grow, regulatory bodies are increasingly focusing on the entire battery lifecycle. This includes regulations on raw material sourcing, manufacturing processes, and end-of-life management. The development of a circular economy approach for LFP batteries is becoming a priority, with an emphasis on recycling and reuse strategies to maximize resource efficiency and minimize environmental impact.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!