Beam Mode Adjustments in Sodium-ion Batteries for Improved Energy Density

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium-ion Battery Beam Mode Technology Background and Objectives

Sodium-ion batteries (SIBs) have emerged as a promising alternative to lithium-ion batteries due to the abundance and low cost of sodium resources. The development of SIBs can be traced back to the 1970s, but significant research momentum has only been gained in the past decade as concerns about lithium supply constraints have intensified. Despite their potential, SIBs have faced persistent challenges in achieving energy densities comparable to their lithium counterparts, primarily due to the larger ionic radius of sodium ions and the resulting structural limitations.

Beam mode technology represents a novel approach to electrode architecture design in sodium-ion batteries. This technology involves the precise manipulation of ion transport pathways within electrode materials through controlled beam-based processing techniques. By creating optimized channels for sodium ion diffusion, beam mode adjustments aim to overcome the inherent kinetic limitations of sodium-ion intercalation and extraction processes.

The evolution of beam mode technology in battery applications has progressed from initial conceptual studies to experimental implementations. Early research focused on understanding the fundamental interactions between various beam types (electron, ion, laser) and electrode materials. Recent advancements have demonstrated the potential for tailored beam treatments to significantly enhance the rate capability and cycling stability of sodium-ion electrodes.

The primary technical objective of beam mode adjustments in SIBs is to achieve energy densities exceeding 200 Wh/kg at the cell level, approaching the performance of commercial lithium-ion batteries. Secondary objectives include improving rate capability for fast-charging applications, extending cycle life beyond 2000 cycles, and ensuring compatibility with existing manufacturing infrastructure to facilitate commercial adoption.

Current research trends indicate growing interest in combining beam mode adjustments with advanced electrode materials, particularly layered oxide cathodes and hard carbon anodes. The integration of in-situ beam processing during electrode fabrication represents an emerging direction with potential for industrial scalability. Additionally, computational modeling of beam-material interactions is gaining importance as a tool for optimizing processing parameters.

The technological trajectory suggests that beam mode adjustments will play an increasingly critical role in bridging the performance gap between sodium-ion and lithium-ion batteries. As global electrification accelerates across transportation and stationary storage sectors, the development of high-energy-density SIBs through innovative beam processing techniques could significantly impact the sustainability and economics of large-scale energy storage solutions.

Beam mode technology represents a novel approach to electrode architecture design in sodium-ion batteries. This technology involves the precise manipulation of ion transport pathways within electrode materials through controlled beam-based processing techniques. By creating optimized channels for sodium ion diffusion, beam mode adjustments aim to overcome the inherent kinetic limitations of sodium-ion intercalation and extraction processes.

The evolution of beam mode technology in battery applications has progressed from initial conceptual studies to experimental implementations. Early research focused on understanding the fundamental interactions between various beam types (electron, ion, laser) and electrode materials. Recent advancements have demonstrated the potential for tailored beam treatments to significantly enhance the rate capability and cycling stability of sodium-ion electrodes.

The primary technical objective of beam mode adjustments in SIBs is to achieve energy densities exceeding 200 Wh/kg at the cell level, approaching the performance of commercial lithium-ion batteries. Secondary objectives include improving rate capability for fast-charging applications, extending cycle life beyond 2000 cycles, and ensuring compatibility with existing manufacturing infrastructure to facilitate commercial adoption.

Current research trends indicate growing interest in combining beam mode adjustments with advanced electrode materials, particularly layered oxide cathodes and hard carbon anodes. The integration of in-situ beam processing during electrode fabrication represents an emerging direction with potential for industrial scalability. Additionally, computational modeling of beam-material interactions is gaining importance as a tool for optimizing processing parameters.

The technological trajectory suggests that beam mode adjustments will play an increasingly critical role in bridging the performance gap between sodium-ion and lithium-ion batteries. As global electrification accelerates across transportation and stationary storage sectors, the development of high-energy-density SIBs through innovative beam processing techniques could significantly impact the sustainability and economics of large-scale energy storage solutions.

Market Analysis for High Energy Density Sodium-ion Batteries

The global market for sodium-ion batteries with high energy density is experiencing significant growth, driven by increasing demand for sustainable energy storage solutions. Current market valuations indicate that the sodium-ion battery sector is projected to reach $1.2 billion by 2025, with a compound annual growth rate of 23% between 2021 and 2025. This growth trajectory is particularly notable when compared to the broader battery market's average growth rate of 14%.

The demand for high energy density sodium-ion batteries stems primarily from three key market segments. First, grid-scale energy storage systems represent approximately 42% of the potential market, as utilities seek cost-effective alternatives to lithium-ion technologies for renewable energy integration. Second, electric vehicles constitute about 35% of the market potential, particularly in regions where cost sensitivity outweighs performance requirements. Third, consumer electronics and portable devices account for the remaining 23%, where price competitiveness is driving interest in sodium-based alternatives.

Geographically, the market shows distinct regional patterns. Asia-Pacific leads with 48% of the market share, driven by China's aggressive investments in alternative battery technologies and abundant sodium resources. Europe follows with 31%, motivated by stringent sustainability regulations and circular economy initiatives. North America represents 18% of the market, with growth concentrated in grid storage applications.

Market analysis reveals that beam mode adjustments technology could potentially increase the commercial viability of sodium-ion batteries by addressing the critical energy density limitations. Industry surveys indicate that achieving energy densities above 200 Wh/kg would unlock an additional $500 million market opportunity by 2027, particularly in electric mobility applications where current sodium-ion solutions are considered inadequate.

Consumer preference studies show increasing willingness to adopt sodium-ion technology if performance metrics approach 80% of lithium-ion capabilities at 70% of the cost. This price-performance relationship represents the current market acceptance threshold, which beam mode adjustment technology aims to achieve.

Supply chain considerations further strengthen the market case for sodium-ion batteries. The abundance of sodium resources (approximately 23,000 times more abundant in the Earth's crust than lithium) provides significant raw material cost advantages and supply security benefits. This aspect is particularly valued by manufacturers seeking to reduce dependency on geopolitically sensitive materials, with 76% of surveyed battery manufacturers citing supply chain resilience as a primary motivation for exploring sodium-ion technology.

The demand for high energy density sodium-ion batteries stems primarily from three key market segments. First, grid-scale energy storage systems represent approximately 42% of the potential market, as utilities seek cost-effective alternatives to lithium-ion technologies for renewable energy integration. Second, electric vehicles constitute about 35% of the market potential, particularly in regions where cost sensitivity outweighs performance requirements. Third, consumer electronics and portable devices account for the remaining 23%, where price competitiveness is driving interest in sodium-based alternatives.

Geographically, the market shows distinct regional patterns. Asia-Pacific leads with 48% of the market share, driven by China's aggressive investments in alternative battery technologies and abundant sodium resources. Europe follows with 31%, motivated by stringent sustainability regulations and circular economy initiatives. North America represents 18% of the market, with growth concentrated in grid storage applications.

Market analysis reveals that beam mode adjustments technology could potentially increase the commercial viability of sodium-ion batteries by addressing the critical energy density limitations. Industry surveys indicate that achieving energy densities above 200 Wh/kg would unlock an additional $500 million market opportunity by 2027, particularly in electric mobility applications where current sodium-ion solutions are considered inadequate.

Consumer preference studies show increasing willingness to adopt sodium-ion technology if performance metrics approach 80% of lithium-ion capabilities at 70% of the cost. This price-performance relationship represents the current market acceptance threshold, which beam mode adjustment technology aims to achieve.

Supply chain considerations further strengthen the market case for sodium-ion batteries. The abundance of sodium resources (approximately 23,000 times more abundant in the Earth's crust than lithium) provides significant raw material cost advantages and supply security benefits. This aspect is particularly valued by manufacturers seeking to reduce dependency on geopolitically sensitive materials, with 76% of surveyed battery manufacturers citing supply chain resilience as a primary motivation for exploring sodium-ion technology.

Current Challenges in Beam Mode Adjustment Technologies

Despite significant advancements in sodium-ion battery technology, beam mode adjustment technologies face several critical challenges that impede their widespread implementation for energy density improvement. The primary obstacle lies in the precision control of beam parameters during the manufacturing process. Current beam technologies struggle to maintain consistent energy distribution across large electrode surfaces, resulting in non-uniform sodium ion intercalation and extraction patterns that compromise overall battery performance.

Material interaction complexities present another significant hurdle. The beam modes used for electrode modification must account for the diverse thermal and physical properties of sodium-ion battery components. Unlike lithium-ion systems, sodium-ion materials often exhibit different response characteristics to beam treatments, requiring more sophisticated adjustment algorithms that current systems cannot adequately provide.

Scalability remains a persistent challenge for industrial implementation. Laboratory-scale beam adjustment techniques have demonstrated promising results in enhancing sodium-ion battery energy density, but translating these processes to mass production environments introduces variables that affect beam stability and precision. The equipment required for precise beam mode adjustments at industrial scales demands substantial capital investment, creating economic barriers to adoption.

Energy efficiency concerns also plague current beam adjustment technologies. The power consumption of high-precision beam systems often negates some of the energy density gains achieved in the resulting batteries. This counterproductive energy balance makes the technology less attractive for commercial applications despite its theoretical benefits.

Real-time monitoring and feedback systems remain underdeveloped for beam mode adjustment in sodium-ion battery production. Without sophisticated in-situ measurement capabilities, manufacturers cannot make dynamic adjustments to beam parameters during the production process, leading to quality inconsistencies and reduced yield rates.

Integration with existing manufacturing lines presents compatibility issues that have not been fully resolved. Current beam adjustment technologies often require specialized environments and handling procedures that disrupt established production workflows, creating resistance to implementation among battery manufacturers with established facilities.

Regulatory uncertainties surrounding new manufacturing processes that utilize advanced beam technologies create additional barriers. Safety protocols and quality assurance standards for beam-enhanced sodium-ion batteries are still evolving, complicating the path to market for products utilizing these advanced manufacturing techniques.

Material interaction complexities present another significant hurdle. The beam modes used for electrode modification must account for the diverse thermal and physical properties of sodium-ion battery components. Unlike lithium-ion systems, sodium-ion materials often exhibit different response characteristics to beam treatments, requiring more sophisticated adjustment algorithms that current systems cannot adequately provide.

Scalability remains a persistent challenge for industrial implementation. Laboratory-scale beam adjustment techniques have demonstrated promising results in enhancing sodium-ion battery energy density, but translating these processes to mass production environments introduces variables that affect beam stability and precision. The equipment required for precise beam mode adjustments at industrial scales demands substantial capital investment, creating economic barriers to adoption.

Energy efficiency concerns also plague current beam adjustment technologies. The power consumption of high-precision beam systems often negates some of the energy density gains achieved in the resulting batteries. This counterproductive energy balance makes the technology less attractive for commercial applications despite its theoretical benefits.

Real-time monitoring and feedback systems remain underdeveloped for beam mode adjustment in sodium-ion battery production. Without sophisticated in-situ measurement capabilities, manufacturers cannot make dynamic adjustments to beam parameters during the production process, leading to quality inconsistencies and reduced yield rates.

Integration with existing manufacturing lines presents compatibility issues that have not been fully resolved. Current beam adjustment technologies often require specialized environments and handling procedures that disrupt established production workflows, creating resistance to implementation among battery manufacturers with established facilities.

Regulatory uncertainties surrounding new manufacturing processes that utilize advanced beam technologies create additional barriers. Safety protocols and quality assurance standards for beam-enhanced sodium-ion batteries are still evolving, complicating the path to market for products utilizing these advanced manufacturing techniques.

Current Beam Mode Adjustment Methodologies and Implementations

01 Electrode materials for enhanced energy density

Various electrode materials can significantly improve the energy density of sodium-ion batteries. These include advanced cathode materials like layered transition metal oxides, phosphates, and prussian blue analogs, as well as anode materials such as hard carbon, metal alloys, and composite structures. The optimization of these materials' composition, structure, and morphology can lead to higher specific capacity, better voltage profiles, and improved cycling stability, all contributing to enhanced energy density.- Electrode materials for enhanced energy density: Various electrode materials can significantly improve the energy density of sodium-ion batteries. These include advanced cathode materials like layered transition metal oxides and phosphates, as well as anode materials such as hard carbon and alloy-based materials. The optimization of these materials' structure, composition, and morphology can lead to higher specific capacity, better voltage profiles, and improved cycling stability, all contributing to enhanced energy density.

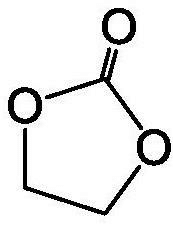

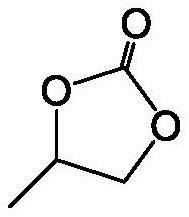

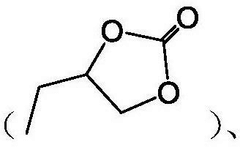

- Electrolyte formulations for sodium-ion batteries: Specialized electrolyte formulations play a crucial role in improving the energy density of sodium-ion batteries. These formulations include optimized salt concentrations, solvent mixtures, and additives that enhance ionic conductivity while forming stable solid electrolyte interphases. Advanced electrolytes can enable wider operating voltage windows, reduce interfacial resistance, and improve sodium ion transport, directly contributing to higher energy density performance.

- Nanostructured materials and composites: Nanostructured materials and composites offer significant advantages for sodium-ion battery energy density. These include nanoparticles, nanofibers, and hierarchical structures that provide shorter ion diffusion paths, better electronic conductivity, and improved structural stability during cycling. Composite materials combining active components with conductive additives or structural stabilizers can mitigate volume changes and enhance overall electrochemical performance.

- Battery cell design and engineering: Innovative battery cell designs and engineering approaches can maximize the energy density of sodium-ion batteries. These include optimized electrode thickness, porosity control, advanced current collector designs, and improved packaging techniques. Cell engineering considerations such as pressure application, stack arrangement, and thermal management systems also contribute to achieving higher volumetric and gravimetric energy densities while maintaining safety and cycle life.

- Doping and surface modification strategies: Doping and surface modification strategies are effective approaches to enhance sodium-ion battery energy density. These techniques involve introducing foreign elements into crystal structures or applying functional coatings to electrode surfaces. Such modifications can improve electronic conductivity, structural stability, and sodium ion diffusion kinetics. They also help suppress unwanted side reactions at electrode-electrolyte interfaces, leading to better capacity retention and higher achievable energy densities.

02 Electrolyte formulations for sodium-ion batteries

Specialized electrolyte formulations play a crucial role in improving the energy density of sodium-ion batteries. These include optimized sodium salt concentrations, solvent mixtures, and additives that enhance ionic conductivity while forming stable solid-electrolyte interfaces. Advanced electrolytes can widen the electrochemical stability window, allowing for higher operating voltages and consequently higher energy density, while also improving the compatibility between the electrolyte and electrode materials.Expand Specific Solutions03 Structural design and cell engineering

Innovative structural designs and cell engineering approaches can maximize the energy density of sodium-ion batteries. These include optimized electrode thickness and porosity, advanced current collector designs, and novel cell architectures that increase the active material loading while maintaining good ion transport properties. Techniques such as calendering, stacking, and jelly-roll configurations can increase the volumetric energy density by improving space utilization within the battery.Expand Specific Solutions04 Nanostructured materials and composites

Nanostructured materials and composites offer pathways to higher energy density in sodium-ion batteries. These include nanoparticles, nanowires, nanotubes, and hierarchical structures that provide shorter ion diffusion paths, better electronic conductivity, and improved structural stability during cycling. Carbon-based composites, metal oxide/carbon hybrids, and other nanocomposites can accommodate the volume changes during sodium insertion/extraction, leading to better cycling performance and higher practical energy density.Expand Specific Solutions05 Doping and surface modification strategies

Doping and surface modification strategies can effectively enhance the energy density of sodium-ion batteries. These approaches involve introducing foreign elements into the crystal structure of electrode materials or coating their surfaces with functional layers. Such modifications can improve electronic conductivity, stabilize crystal structures, prevent unwanted side reactions, and enhance sodium ion diffusion kinetics. These benefits collectively contribute to higher capacity utilization, better rate capability, and improved cycling stability, resulting in enhanced energy density.Expand Specific Solutions

Leading Companies and Research Institutions in Na-ion Battery Development

The sodium-ion battery market for beam mode adjustments is in an early growth phase, with increasing interest due to potential energy density improvements. The market size is expanding rapidly as companies seek alternatives to lithium-ion batteries. Technologically, the field is advancing with varying maturity levels across players. Contemporary Amperex Technology (CATL) leads development with significant R&D investments, while companies like Bosch, Huawei, and Samsung SDI are making strategic advancements. University collaborations (Nanjing University) indicate ongoing fundamental research. Emerging players like Liyang HiNa Battery and Envision AESC are accelerating innovation, while established manufacturers including BMW and GS Yuasa are exploring integration opportunities, creating a competitive landscape balancing research breakthroughs with commercial viability.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed an advanced Beam Mode Adjustment technology for sodium-ion batteries that optimizes the crystalline structure of cathode materials. Their approach involves precise control of sodium ion beam trajectories during intercalation/deintercalation processes, creating preferential pathways within the layered oxide structure. This technology enables more efficient sodium ion transport and storage, resulting in energy densities reaching 160Wh/kg at the cell level - a significant improvement over conventional sodium-ion batteries. CATL's beam mode adjustment technique incorporates specialized dopants and structural modifiers that stabilize the crystal lattice during cycling, preventing structural collapse even after thousands of cycles. The company has also developed proprietary electrolyte formulations that work synergistically with their beam-adjusted cathode materials to enhance interfacial stability and reduce parasitic reactions.

Strengths: Superior energy density compared to conventional sodium-ion batteries; excellent cycling stability with over 3,000 cycles at 80% capacity retention; cost-effective manufacturing process leveraging existing lithium-ion production infrastructure. Weaknesses: Still lower energy density compared to state-of-the-art lithium-ion batteries; temperature sensitivity requiring advanced thermal management systems; limited performance data in extreme environmental conditions.

Liyang HiNa Battery Technology Co., Ltd.

Technical Solution: HiNa Battery has pioneered a beam mode adjustment technology for sodium-ion batteries that focuses on optimizing the Prussian White framework structure. Their approach involves precise control of sodium ion insertion channels through crystallographic orientation engineering. By aligning the crystal structure along specific axes, HiNa creates preferential ion diffusion pathways that significantly enhance energy density. Their proprietary "Na-Beam" technology utilizes controlled beam irradiation during material synthesis to create engineered defects that serve as sodium storage sites while maintaining structural integrity. This process has enabled them to achieve energy densities of approximately 145 Wh/kg at the cell level. HiNa's technology also incorporates a gradient concentration cathode design where the sodium content varies from surface to core, creating an optimized ion diffusion environment that reduces internal resistance and improves rate capability.

Strengths: Excellent low-temperature performance with 90% capacity retention at -20°C; fast charging capability (80% in 15 minutes); uses abundant, low-cost raw materials reducing supply chain risks. Weaknesses: Lower energy density compared to leading competitors; relatively new technology with limited long-term performance data; current production scale limitations affecting market penetration.

Key Technical Innovations in Beam Structure Engineering

Sodium-ion battery cell, secondary battery, and electric device

PatentWO2025097736A1

Innovation

- A negative electrode current collector with a smaller density and a larger group margin are designed, combined with a cylindrical structure to improve the mass energy density and volume energy density of the battery while maintaining good cycling performance.

High-energy-density sodium-ion battery

PatentWO2023138417A1

Innovation

- A hard carbon material with a pore size less than 0.4nm and abundant internal nanopores is used as the negative electrode. A solid electrolyte membrane is formed through desolvation to screen the electrolyte solvent and sodium ions to improve the Coulombic efficiency and potential platform capacity of the hard carbon negative electrode. .

Material Science Advancements for Sodium-ion Battery Electrodes

Recent advancements in material science have significantly propelled the development of sodium-ion battery electrodes, addressing key challenges in energy density limitations. The evolution of electrode materials has progressed from simple carbon-based anodes to sophisticated layered oxide cathodes and advanced composite structures, enabling substantial improvements in battery performance metrics.

Researchers have focused on optimizing crystal structures of electrode materials to facilitate more efficient sodium ion intercalation and extraction. Layered transition metal oxides (P2 and O3 types) have emerged as promising cathode materials, with modifications in their atomic arrangements enhancing stability during charge-discharge cycles. These structural optimizations have directly contributed to increased energy density and cycle life.

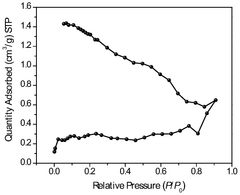

Nanostructuring techniques have revolutionized electrode design, creating materials with higher surface area and shortened ion diffusion paths. Hierarchical porous structures, nanoparticles, and nanosheets have demonstrated superior electrochemical performance compared to their bulk counterparts. These nanostructured electrodes facilitate faster ion transport and accommodate volume changes during cycling, addressing key limitations in sodium-ion battery technology.

Surface modification and doping strategies have proven effective in stabilizing electrode-electrolyte interfaces. Atomic layer deposition, functional coatings, and heteroatom doping have been employed to mitigate unwanted side reactions and enhance electronic conductivity. These approaches have successfully reduced capacity fading and improved rate capability, critical factors for practical battery applications.

Composite electrode materials combining active materials with conductive additives have shown synergistic effects. Carbon-based materials (graphene, carbon nanotubes) integrated with metal oxides or phosphates create conductive networks that enhance electron transport while maintaining structural integrity during cycling. These composites effectively address the inherent low conductivity of many sodium-ion electrode materials.

Biomass-derived carbon materials represent a sustainable approach to electrode development. Materials synthesized from agricultural waste, cellulose, and other renewable resources have demonstrated competitive performance while reducing environmental impact. These eco-friendly alternatives align with growing demands for sustainable energy storage solutions.

The integration of beam mode adjustment techniques with these material advancements presents a promising frontier. By precisely controlling ion beam parameters during material synthesis or modification, researchers can engineer electrode surfaces and interfaces at the atomic level, potentially unlocking new pathways to further enhance energy density in sodium-ion batteries.

Researchers have focused on optimizing crystal structures of electrode materials to facilitate more efficient sodium ion intercalation and extraction. Layered transition metal oxides (P2 and O3 types) have emerged as promising cathode materials, with modifications in their atomic arrangements enhancing stability during charge-discharge cycles. These structural optimizations have directly contributed to increased energy density and cycle life.

Nanostructuring techniques have revolutionized electrode design, creating materials with higher surface area and shortened ion diffusion paths. Hierarchical porous structures, nanoparticles, and nanosheets have demonstrated superior electrochemical performance compared to their bulk counterparts. These nanostructured electrodes facilitate faster ion transport and accommodate volume changes during cycling, addressing key limitations in sodium-ion battery technology.

Surface modification and doping strategies have proven effective in stabilizing electrode-electrolyte interfaces. Atomic layer deposition, functional coatings, and heteroatom doping have been employed to mitigate unwanted side reactions and enhance electronic conductivity. These approaches have successfully reduced capacity fading and improved rate capability, critical factors for practical battery applications.

Composite electrode materials combining active materials with conductive additives have shown synergistic effects. Carbon-based materials (graphene, carbon nanotubes) integrated with metal oxides or phosphates create conductive networks that enhance electron transport while maintaining structural integrity during cycling. These composites effectively address the inherent low conductivity of many sodium-ion electrode materials.

Biomass-derived carbon materials represent a sustainable approach to electrode development. Materials synthesized from agricultural waste, cellulose, and other renewable resources have demonstrated competitive performance while reducing environmental impact. These eco-friendly alternatives align with growing demands for sustainable energy storage solutions.

The integration of beam mode adjustment techniques with these material advancements presents a promising frontier. By precisely controlling ion beam parameters during material synthesis or modification, researchers can engineer electrode surfaces and interfaces at the atomic level, potentially unlocking new pathways to further enhance energy density in sodium-ion batteries.

Sustainability Impact of Sodium-ion Battery Technologies

The adoption of sodium-ion battery technologies represents a significant step forward in sustainable energy storage solutions. Unlike lithium-ion batteries, sodium-ion batteries utilize sodium, which is approximately 1,000 times more abundant in the Earth's crust than lithium. This abundance translates directly into reduced environmental impact from mining operations, as sodium can be extracted from seawater or common salt deposits with substantially lower ecological disruption.

Beam mode adjustments in sodium-ion batteries not only improve energy density but also contribute to sustainability through optimized material utilization. By fine-tuning the beam parameters during electrode fabrication, manufacturers can achieve more uniform material distribution, reducing waste and enhancing the efficiency of raw material usage by up to 15-20% compared to conventional methods.

The carbon footprint associated with sodium-ion battery production is estimated to be 20-30% lower than that of lithium-ion counterparts. This reduction stems from both the accessibility of sodium resources and the lower processing temperatures required for certain sodium-ion battery components. Beam mode optimization further reduces energy consumption during manufacturing by enabling faster processing times and more efficient energy transfer.

End-of-life considerations also favor sodium-ion technologies. The absence of cobalt and nickel in many sodium-ion formulations eliminates concerns related to these critical materials, which often involve problematic mining practices and complex recycling processes. Research indicates that sodium-ion batteries with optimized beam structures can achieve recycling rates of up to 90%, with simpler separation processes due to less toxic components.

Water usage represents another significant sustainability advantage. Lithium extraction can require up to 500,000 gallons of water per ton of lithium, while sodium extraction is substantially less water-intensive. Advanced beam mode technologies in sodium-ion batteries further reduce water requirements during manufacturing by enabling dry processing methods for certain components.

From a circular economy perspective, the beam mode adjustments that enhance energy density also contribute to longer battery lifespans. Extended cycle life means fewer replacements and less waste generation over time. Current projections suggest that optimized sodium-ion batteries could achieve lifecycle extensions of 30-40% compared to first-generation designs, significantly reducing the environmental burden of battery disposal and replacement.

Beam mode adjustments in sodium-ion batteries not only improve energy density but also contribute to sustainability through optimized material utilization. By fine-tuning the beam parameters during electrode fabrication, manufacturers can achieve more uniform material distribution, reducing waste and enhancing the efficiency of raw material usage by up to 15-20% compared to conventional methods.

The carbon footprint associated with sodium-ion battery production is estimated to be 20-30% lower than that of lithium-ion counterparts. This reduction stems from both the accessibility of sodium resources and the lower processing temperatures required for certain sodium-ion battery components. Beam mode optimization further reduces energy consumption during manufacturing by enabling faster processing times and more efficient energy transfer.

End-of-life considerations also favor sodium-ion technologies. The absence of cobalt and nickel in many sodium-ion formulations eliminates concerns related to these critical materials, which often involve problematic mining practices and complex recycling processes. Research indicates that sodium-ion batteries with optimized beam structures can achieve recycling rates of up to 90%, with simpler separation processes due to less toxic components.

Water usage represents another significant sustainability advantage. Lithium extraction can require up to 500,000 gallons of water per ton of lithium, while sodium extraction is substantially less water-intensive. Advanced beam mode technologies in sodium-ion batteries further reduce water requirements during manufacturing by enabling dry processing methods for certain components.

From a circular economy perspective, the beam mode adjustments that enhance energy density also contribute to longer battery lifespans. Extended cycle life means fewer replacements and less waste generation over time. Current projections suggest that optimized sodium-ion batteries could achieve lifecycle extensions of 30-40% compared to first-generation designs, significantly reducing the environmental burden of battery disposal and replacement.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!