Thermal Management Techniques in Sodium-ion Batteries for Extended Use

SEP 19, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium-ion Battery Thermal Management Background and Objectives

Sodium-ion batteries (SIBs) have emerged as a promising alternative to lithium-ion batteries due to the abundance and low cost of sodium resources. The development of SIBs can be traced back to the 1970s, but significant research momentum has only been gained in the past decade. This renewed interest stems from concerns about lithium resource limitations and the increasing demand for energy storage solutions in various applications, including electric vehicles, grid storage, and portable electronics.

Thermal management in sodium-ion batteries represents a critical aspect of their development and commercialization. Unlike lithium-ion batteries, SIBs exhibit different thermal behaviors due to the larger ionic radius of sodium ions and the distinct electrode materials used. These differences necessitate specialized thermal management strategies to ensure safety, longevity, and optimal performance under various operating conditions.

The evolution of thermal management techniques in SIBs has progressed from basic passive cooling methods to more sophisticated active and hybrid systems. Early research focused primarily on understanding the fundamental thermal characteristics of sodium-ion cells, while recent advancements have shifted toward developing integrated thermal management solutions that address the specific challenges posed by sodium-ion chemistry.

Current technological trends indicate a growing emphasis on advanced cooling strategies, thermal runaway prevention, and the development of thermally stable electrode materials and electrolytes specifically designed for SIBs. Additionally, there is increasing interest in computational modeling and simulation tools to predict thermal behavior and optimize battery design before physical prototyping.

The primary objectives of thermal management in sodium-ion batteries include maintaining optimal operating temperatures (typically between 20-40°C), minimizing temperature gradients within cells and packs, preventing thermal runaway events, and extending battery lifespan through reduced thermal degradation. These objectives must be achieved while considering cost constraints, as one of the main advantages of SIBs is their potential economic competitiveness.

Another crucial goal is to develop thermal management solutions that can be effectively scaled from laboratory prototypes to commercial applications. This includes addressing challenges related to manufacturing processes, material availability, and integration with existing battery management systems. The ultimate aim is to create thermal management technologies that enable sodium-ion batteries to operate reliably under diverse environmental conditions and usage scenarios.

Furthermore, thermal management research aims to support the broader adoption of sodium-ion batteries by enhancing their safety profile, which is particularly important for applications in transportation and stationary storage where thermal incidents could have severe consequences. By establishing robust thermal management frameworks, the technology can overcome one of the key barriers to widespread commercial implementation.

Thermal management in sodium-ion batteries represents a critical aspect of their development and commercialization. Unlike lithium-ion batteries, SIBs exhibit different thermal behaviors due to the larger ionic radius of sodium ions and the distinct electrode materials used. These differences necessitate specialized thermal management strategies to ensure safety, longevity, and optimal performance under various operating conditions.

The evolution of thermal management techniques in SIBs has progressed from basic passive cooling methods to more sophisticated active and hybrid systems. Early research focused primarily on understanding the fundamental thermal characteristics of sodium-ion cells, while recent advancements have shifted toward developing integrated thermal management solutions that address the specific challenges posed by sodium-ion chemistry.

Current technological trends indicate a growing emphasis on advanced cooling strategies, thermal runaway prevention, and the development of thermally stable electrode materials and electrolytes specifically designed for SIBs. Additionally, there is increasing interest in computational modeling and simulation tools to predict thermal behavior and optimize battery design before physical prototyping.

The primary objectives of thermal management in sodium-ion batteries include maintaining optimal operating temperatures (typically between 20-40°C), minimizing temperature gradients within cells and packs, preventing thermal runaway events, and extending battery lifespan through reduced thermal degradation. These objectives must be achieved while considering cost constraints, as one of the main advantages of SIBs is their potential economic competitiveness.

Another crucial goal is to develop thermal management solutions that can be effectively scaled from laboratory prototypes to commercial applications. This includes addressing challenges related to manufacturing processes, material availability, and integration with existing battery management systems. The ultimate aim is to create thermal management technologies that enable sodium-ion batteries to operate reliably under diverse environmental conditions and usage scenarios.

Furthermore, thermal management research aims to support the broader adoption of sodium-ion batteries by enhancing their safety profile, which is particularly important for applications in transportation and stationary storage where thermal incidents could have severe consequences. By establishing robust thermal management frameworks, the technology can overcome one of the key barriers to widespread commercial implementation.

Market Demand Analysis for Thermally Optimized Na-ion Batteries

The global market for sodium-ion batteries with advanced thermal management capabilities is experiencing significant growth, driven by the increasing demand for sustainable energy storage solutions. As lithium resources face supply constraints and price volatility, sodium-ion technology emerges as a compelling alternative due to sodium's abundance and lower cost. Market research indicates that the energy storage sector, particularly for grid applications and renewable integration, represents the primary demand driver for thermally optimized Na-ion batteries.

Current market projections show the global sodium-ion battery market growing at a compound annual growth rate of 18-20% between 2023 and 2030. Within this broader market, thermally optimized variants are expected to capture an increasing share due to their enhanced safety profile and extended operational lifespan in demanding applications. The market value for thermally managed Na-ion batteries is projected to reach several billion dollars by 2030, representing a significant opportunity for early market entrants.

Industrial and utility-scale storage applications demonstrate the strongest immediate demand for thermally optimized Na-ion batteries. These sectors prioritize safety, longevity, and total cost of ownership over energy density metrics, making them ideal early adopters. The ability of thermally managed Na-ion systems to operate safely without complex cooling infrastructure presents a compelling value proposition for these markets.

Consumer electronics and electric mobility sectors represent secondary but growing market segments. While current Na-ion energy density limitations restrict immediate adoption in premium portable devices and long-range vehicles, the technology shows promise for applications where cost sensitivity outweighs energy density requirements. Market research indicates particular potential in electric two-wheelers, budget smartphones, and power tools in emerging economies.

Regional market analysis reveals that Asia-Pacific, particularly China, leads in both production capacity and demand for Na-ion batteries. European markets show accelerating interest driven by sustainability initiatives and strategic autonomy concerns regarding battery supply chains. North American markets demonstrate growing demand primarily in the utility-scale storage segment.

Market surveys indicate that key customer requirements for thermally optimized Na-ion batteries include operational stability across wider temperature ranges (-20°C to 60°C), reduced thermal runaway risk, simplified thermal management systems, and competitive lifecycle costs. The ability to function effectively in regions with extreme climates or limited cooling infrastructure represents a significant market differentiator.

Industry forecasts suggest that as thermal management technologies mature and manufacturing scales, the cost premium for thermally optimized Na-ion batteries will decrease, further accelerating market adoption across additional segments. The convergence of environmental regulations, energy security concerns, and raw material economics creates favorable market conditions for continued growth in this technology space.

Current market projections show the global sodium-ion battery market growing at a compound annual growth rate of 18-20% between 2023 and 2030. Within this broader market, thermally optimized variants are expected to capture an increasing share due to their enhanced safety profile and extended operational lifespan in demanding applications. The market value for thermally managed Na-ion batteries is projected to reach several billion dollars by 2030, representing a significant opportunity for early market entrants.

Industrial and utility-scale storage applications demonstrate the strongest immediate demand for thermally optimized Na-ion batteries. These sectors prioritize safety, longevity, and total cost of ownership over energy density metrics, making them ideal early adopters. The ability of thermally managed Na-ion systems to operate safely without complex cooling infrastructure presents a compelling value proposition for these markets.

Consumer electronics and electric mobility sectors represent secondary but growing market segments. While current Na-ion energy density limitations restrict immediate adoption in premium portable devices and long-range vehicles, the technology shows promise for applications where cost sensitivity outweighs energy density requirements. Market research indicates particular potential in electric two-wheelers, budget smartphones, and power tools in emerging economies.

Regional market analysis reveals that Asia-Pacific, particularly China, leads in both production capacity and demand for Na-ion batteries. European markets show accelerating interest driven by sustainability initiatives and strategic autonomy concerns regarding battery supply chains. North American markets demonstrate growing demand primarily in the utility-scale storage segment.

Market surveys indicate that key customer requirements for thermally optimized Na-ion batteries include operational stability across wider temperature ranges (-20°C to 60°C), reduced thermal runaway risk, simplified thermal management systems, and competitive lifecycle costs. The ability to function effectively in regions with extreme climates or limited cooling infrastructure represents a significant market differentiator.

Industry forecasts suggest that as thermal management technologies mature and manufacturing scales, the cost premium for thermally optimized Na-ion batteries will decrease, further accelerating market adoption across additional segments. The convergence of environmental regulations, energy security concerns, and raw material economics creates favorable market conditions for continued growth in this technology space.

Current Thermal Management Challenges in Sodium-ion Technology

Despite the promising advantages of sodium-ion batteries (SIBs) as alternatives to lithium-ion batteries, thermal management remains a critical challenge that impedes their widespread adoption. SIBs experience significant thermal issues during operation, particularly at high charge/discharge rates, which can lead to accelerated degradation, reduced cycle life, and safety concerns. The thermal behavior of SIBs differs from lithium-ion counterparts due to the larger ionic radius of sodium ions, resulting in distinct heat generation patterns during intercalation and de-intercalation processes.

Current thermal management systems for SIBs face several technical limitations. Passive cooling methods, while cost-effective, often prove insufficient for high-power applications where heat generation exceeds dissipation capabilities. Active cooling systems, though more effective, introduce complexity, additional weight, and parasitic energy consumption that reduces overall system efficiency. The integration of phase change materials (PCMs) shows promise but struggles with thermal conductivity limitations and volume expansion issues during phase transitions.

Temperature gradients within sodium-ion cells present another significant challenge. These gradients lead to uneven aging, localized hotspots, and potential thermal runaway conditions. Current battery management systems (BMS) lack sophisticated thermal monitoring capabilities specific to sodium-ion chemistry, resulting in suboptimal thermal control strategies that fail to address the unique thermal characteristics of these batteries.

The electrolyte stability in SIBs presents additional thermal management complications. Conventional electrolytes exhibit narrow temperature operating windows, with accelerated decomposition at elevated temperatures generating additional heat and potentially triggering thermal runaway. While flame-retardant additives improve safety margins, they often compromise electrochemical performance and introduce new thermal management considerations.

Manufacturing inconsistencies further exacerbate thermal management challenges. Variations in electrode thickness, particle size distribution, and electrolyte distribution create unpredictable thermal behaviors that current thermal models fail to accurately predict. This unpredictability complicates the design of effective thermal management systems and increases safety risks during extended operation.

Fast-charging capabilities, a key market requirement for battery technologies, intensify thermal management challenges in SIBs. The higher current densities during fast charging generate substantial heat that current thermal management solutions struggle to dissipate effectively. This limitation significantly restricts the practical implementation of rapid charging protocols for sodium-ion batteries in commercial applications.

The scaling of thermal management solutions from cell to pack level introduces additional complexities. Current approaches that work effectively at the cell level often prove inadequate when implemented in large-scale battery packs, where heat accumulation and thermal propagation between cells create more severe thermal management challenges requiring innovative system-level solutions.

Current thermal management systems for SIBs face several technical limitations. Passive cooling methods, while cost-effective, often prove insufficient for high-power applications where heat generation exceeds dissipation capabilities. Active cooling systems, though more effective, introduce complexity, additional weight, and parasitic energy consumption that reduces overall system efficiency. The integration of phase change materials (PCMs) shows promise but struggles with thermal conductivity limitations and volume expansion issues during phase transitions.

Temperature gradients within sodium-ion cells present another significant challenge. These gradients lead to uneven aging, localized hotspots, and potential thermal runaway conditions. Current battery management systems (BMS) lack sophisticated thermal monitoring capabilities specific to sodium-ion chemistry, resulting in suboptimal thermal control strategies that fail to address the unique thermal characteristics of these batteries.

The electrolyte stability in SIBs presents additional thermal management complications. Conventional electrolytes exhibit narrow temperature operating windows, with accelerated decomposition at elevated temperatures generating additional heat and potentially triggering thermal runaway. While flame-retardant additives improve safety margins, they often compromise electrochemical performance and introduce new thermal management considerations.

Manufacturing inconsistencies further exacerbate thermal management challenges. Variations in electrode thickness, particle size distribution, and electrolyte distribution create unpredictable thermal behaviors that current thermal models fail to accurately predict. This unpredictability complicates the design of effective thermal management systems and increases safety risks during extended operation.

Fast-charging capabilities, a key market requirement for battery technologies, intensify thermal management challenges in SIBs. The higher current densities during fast charging generate substantial heat that current thermal management solutions struggle to dissipate effectively. This limitation significantly restricts the practical implementation of rapid charging protocols for sodium-ion batteries in commercial applications.

The scaling of thermal management solutions from cell to pack level introduces additional complexities. Current approaches that work effectively at the cell level often prove inadequate when implemented in large-scale battery packs, where heat accumulation and thermal propagation between cells create more severe thermal management challenges requiring innovative system-level solutions.

Existing Thermal Management Solutions for Sodium-ion Batteries

01 Cooling systems for sodium-ion batteries

Various cooling systems are designed specifically for sodium-ion batteries to manage thermal issues during operation. These include liquid cooling circuits, air cooling systems, and heat exchangers that efficiently dissipate heat generated during charging and discharging cycles. These cooling mechanisms help maintain optimal operating temperatures, prevent thermal runaway, and extend battery life while ensuring safe operation under various load conditions.- Cooling systems for sodium-ion batteries: Various cooling systems are employed to manage the thermal behavior of sodium-ion batteries. These include liquid cooling systems that circulate coolant through channels or plates in contact with battery cells, air cooling systems that use forced convection to remove heat, and phase change materials that absorb heat during temperature spikes. These cooling mechanisms help maintain optimal operating temperatures, prevent thermal runaway, and extend battery life by reducing degradation caused by excessive heat.

- Battery pack thermal management structures: Specialized structural designs for sodium-ion battery packs incorporate thermal management features. These include thermally conductive housings, integrated heat sinks, thermal interface materials between cells, and strategic cell arrangement patterns that facilitate heat dissipation. Some designs feature modular approaches where thermal management components can be easily accessed and replaced. These structural innovations help distribute heat evenly throughout the battery pack and prevent hotspot formation.

- Thermal management control systems and algorithms: Advanced control systems and algorithms optimize thermal management in sodium-ion batteries. These systems utilize temperature sensors distributed throughout the battery pack to monitor thermal conditions in real-time. Based on this data, intelligent algorithms adjust cooling system parameters, power output, and charging rates to maintain optimal temperature ranges. Some systems incorporate predictive models that anticipate thermal behavior under various operating conditions, allowing preemptive thermal management actions.

- Thermal interface materials and coatings: Specialized materials and coatings enhance thermal management in sodium-ion batteries. These include high thermal conductivity interface materials placed between cells and cooling structures, thermally conductive adhesives that bond components while facilitating heat transfer, and specialized coatings that improve heat dissipation from cell surfaces. Some materials incorporate phase change properties that absorb heat during temperature spikes. These materials help create efficient thermal pathways that direct heat away from critical battery components.

- Safety mechanisms for thermal events: Safety systems protect sodium-ion batteries during thermal events. These include thermal fuses that disconnect electrical connections when temperatures exceed safe limits, venting mechanisms that release pressure during thermal runaway, thermal isolation barriers that prevent heat propagation between cells, and fire-retardant materials incorporated into battery components. Some systems feature active suppression mechanisms that deploy cooling agents when dangerous thermal conditions are detected, preventing catastrophic failure and enhancing overall battery safety.

02 Thermal management materials and structures

Advanced materials and structural designs are employed to enhance thermal management in sodium-ion batteries. These include phase change materials, thermally conductive layers, and specialized battery casings with heat dissipation properties. The integration of these materials helps distribute heat evenly throughout the battery pack, reducing hotspots and temperature gradients that could lead to performance degradation or safety issues.Expand Specific Solutions03 Battery management systems for thermal control

Intelligent battery management systems (BMS) are implemented to monitor and control the thermal behavior of sodium-ion batteries. These systems utilize temperature sensors, predictive algorithms, and adaptive control strategies to optimize charging/discharging rates based on thermal conditions. The BMS can preemptively adjust operating parameters to prevent overheating and ensure balanced temperature distribution across battery modules.Expand Specific Solutions04 Thermal insulation and safety mechanisms

Specialized thermal insulation techniques and safety mechanisms are incorporated into sodium-ion battery designs to prevent thermal propagation and contain potential thermal incidents. These include fire-resistant separators, thermal fuses, and compartmentalized designs that isolate battery cells. Such features help prevent cascading thermal failures and enhance the overall safety profile of sodium-ion battery systems under extreme conditions.Expand Specific Solutions05 Integrated thermal management for battery packs

Holistic approaches to thermal management consider the entire sodium-ion battery pack as an integrated system. These solutions combine multiple thermal management strategies including active and passive cooling, strategic cell arrangement, and thermal interfaces between modules. The integrated approach optimizes weight, space utilization, and energy efficiency while maintaining uniform temperature distribution across large-scale battery installations for applications such as grid storage or electric vehicles.Expand Specific Solutions

Leading Companies and Research Institutions in Na-ion Thermal Management

The sodium-ion battery thermal management technology market is in an early growth phase, characterized by increasing R&D investments and emerging commercial applications. The market is projected to expand significantly as sodium-ion batteries gain traction as a cost-effective alternative to lithium-ion technologies. Key players shaping the competitive landscape include established battery manufacturers like Samsung SDI and specialized companies such as Liyang HiNa Battery Technology. Research institutions including CEA and automotive giants like Renault, Toyota, and Stellantis are actively developing thermal management solutions to address the specific challenges of sodium-ion chemistry. The technology is approaching commercial readiness, with companies like NGK Insulators and SGL Carbon contributing materials expertise while Bosch and Google provide system integration capabilities.

Liyang HiNa Battery Technology Co., Ltd.

Technical Solution: HiNa Battery has developed an advanced thermal management system specifically for sodium-ion batteries that combines both active and passive cooling strategies. Their solution incorporates a phase-change material (PCM) layer integrated directly into the battery module design, which absorbs excess heat during high-rate charging and discharging. This is complemented by a liquid cooling circuit with optimized flow channels that targets hotspots identified through thermal modeling. HiNa's approach includes specialized battery management systems (BMS) with predictive thermal algorithms that can anticipate temperature spikes based on usage patterns and preemptively adjust cooling parameters. Their technology also features thermally conductive cell-to-cell interfaces that improve heat distribution across the module, preventing the formation of dangerous thermal gradients that can lead to accelerated degradation of sodium-ion cells.

Strengths: Superior thermal stability during fast charging (maintaining cells within ±3°C optimal range); reduced thermal runaway risk through predictive management; extended cycle life by minimizing temperature-related degradation. Weaknesses: Higher manufacturing complexity and cost compared to conventional cooling systems; additional weight from cooling components may reduce overall energy density; requires more sophisticated control systems.

Robert Bosch GmbH

Technical Solution: Bosch has engineered a comprehensive thermal management solution for sodium-ion batteries that focuses on system-level integration with vehicle thermal architecture. Their approach utilizes a dual-circuit cooling system where a primary circuit manages battery temperature directly through a specialized coolant formulation optimized for the electrochemical properties of sodium-ion cells, while a secondary circuit interfaces with the vehicle's HVAC system for heat recovery and cabin climate control. Bosch's system incorporates micro-channel cooling plates with variable flow control that can adapt to different thermal loads across the battery pack. Their technology includes thermal insulation barriers strategically positioned to isolate heat-sensitive components and prevent thermal propagation between cells. Additionally, Bosch has developed smart thermal preconditioning algorithms that prepare the battery for optimal performance based on environmental conditions and planned driving routes, ensuring efficient operation across extreme temperature ranges.

Strengths: Highly integrated with vehicle systems for overall efficiency gains; adaptive cooling response based on real-time thermal mapping; excellent cold-weather performance through preconditioning. Weaknesses: Complex integration requirements with vehicle systems may limit retrofitting capabilities; higher initial system cost compared to simpler cooling solutions; potential reliability concerns with multiple interconnected thermal circuits.

Critical Patents and Research on Na-ion Battery Cooling Technologies

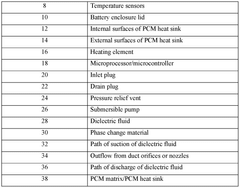

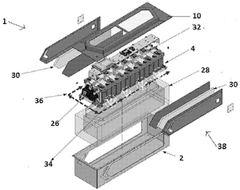

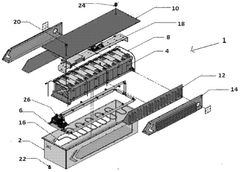

A hybrid system for thermal management of battery pack with immersion and phase change techniques

PatentWO2025046616A1

Innovation

- A hybrid system combining immersion cooling with a dielectric fluid and phase change techniques, utilizing a battery enclosure with a fluid circulation system, a heat sink integrated with phase change material, an immersed heating system, and an external airflow system, controlled by a microcontroller to manage temperature effectively.

Thermal Management System

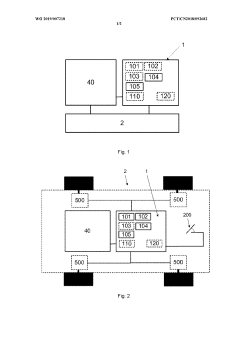

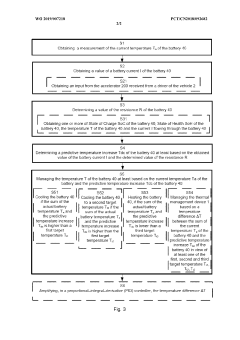

PatentWO2019007218A1

Innovation

- Proactive thermal management approach that predicts temperature increases based on battery current and resistance measurements rather than just reacting to current temperature.

- Integration of real-time battery resistance determination into the thermal management system to enable more accurate temperature prediction.

- Combined use of current temperature measurements and predictive temperature increases for comprehensive thermal management decision-making.

Safety Standards and Regulatory Framework for Na-ion Battery Systems

The regulatory landscape for sodium-ion battery systems is still evolving, with many standards initially developed for lithium-ion batteries being adapted to address the specific characteristics of Na-ion technology. The International Electrotechnical Commission (IEC) has begun incorporating sodium-ion batteries into its framework, particularly through extensions to IEC 62619 for industrial applications and IEC 62660 for electric vehicle applications. These standards are being modified to account for the different thermal behaviors and safety profiles of sodium-ion chemistry.

In the United States, the Department of Transportation (DOT) and the Pipeline and Hazardous Materials Safety Administration (PHMSA) have established transportation regulations that now include provisions for sodium-ion batteries, recognizing their lower fire risk compared to lithium-ion counterparts. The UN38.3 test, which evaluates the safety of batteries during transportation, has been updated with specific protocols for sodium-ion batteries, acknowledging their unique thermal management requirements.

The European Union, through its Battery Directive (2006/66/EC) and the more recent Sustainable Batteries Regulation proposal, is developing specific provisions for sodium-ion technology. These regulations emphasize thermal safety during charging, discharging, and storage, particularly focusing on preventing thermal runaway events that could compromise battery integrity.

In Asia, China has taken the lead in establishing dedicated standards for sodium-ion batteries through its GB/T framework. The China Electrical Equipment Industrial Association has published guidelines specifically addressing thermal management techniques required for sodium-ion batteries in various applications, from grid storage to electric vehicles.

Safety certification bodies such as UL (Underwriters Laboratories) have begun developing test protocols specifically for sodium-ion batteries, with UL 1973 and UL 9540A being adapted to address the thermal behavior characteristics of these systems. These standards include specific temperature thresholds, thermal cycling requirements, and heat dissipation specifications tailored to sodium-ion chemistry.

Industry consortia, including the Sodium-ion Battery Technology Consortium (SIBTC), are working collaboratively with regulatory bodies to establish consensus-based standards that address the unique thermal management challenges of sodium-ion batteries. These efforts focus particularly on defining safe operating temperature ranges, cooling system requirements, and thermal runaway prevention strategies specific to the sodium chemistry.

For extended use applications, regulatory frameworks increasingly require sophisticated battery management systems (BMS) with enhanced thermal monitoring capabilities, establishing minimum requirements for temperature sensors, cooling system response times, and thermal isolation between cells to prevent propagation of thermal events.

In the United States, the Department of Transportation (DOT) and the Pipeline and Hazardous Materials Safety Administration (PHMSA) have established transportation regulations that now include provisions for sodium-ion batteries, recognizing their lower fire risk compared to lithium-ion counterparts. The UN38.3 test, which evaluates the safety of batteries during transportation, has been updated with specific protocols for sodium-ion batteries, acknowledging their unique thermal management requirements.

The European Union, through its Battery Directive (2006/66/EC) and the more recent Sustainable Batteries Regulation proposal, is developing specific provisions for sodium-ion technology. These regulations emphasize thermal safety during charging, discharging, and storage, particularly focusing on preventing thermal runaway events that could compromise battery integrity.

In Asia, China has taken the lead in establishing dedicated standards for sodium-ion batteries through its GB/T framework. The China Electrical Equipment Industrial Association has published guidelines specifically addressing thermal management techniques required for sodium-ion batteries in various applications, from grid storage to electric vehicles.

Safety certification bodies such as UL (Underwriters Laboratories) have begun developing test protocols specifically for sodium-ion batteries, with UL 1973 and UL 9540A being adapted to address the thermal behavior characteristics of these systems. These standards include specific temperature thresholds, thermal cycling requirements, and heat dissipation specifications tailored to sodium-ion chemistry.

Industry consortia, including the Sodium-ion Battery Technology Consortium (SIBTC), are working collaboratively with regulatory bodies to establish consensus-based standards that address the unique thermal management challenges of sodium-ion batteries. These efforts focus particularly on defining safe operating temperature ranges, cooling system requirements, and thermal runaway prevention strategies specific to the sodium chemistry.

For extended use applications, regulatory frameworks increasingly require sophisticated battery management systems (BMS) with enhanced thermal monitoring capabilities, establishing minimum requirements for temperature sensors, cooling system response times, and thermal isolation between cells to prevent propagation of thermal events.

Environmental Impact and Sustainability of Thermal Management Solutions

The thermal management solutions employed in sodium-ion batteries carry significant environmental implications that must be carefully evaluated. Traditional cooling systems often rely on materials and processes with substantial ecological footprints. For instance, liquid cooling systems typically utilize glycol-based coolants which can pose environmental hazards if leaked or improperly disposed of. Similarly, phase change materials (PCMs) may contain chemicals that require special handling at end-of-life to prevent environmental contamination.

When assessing the sustainability of thermal management techniques, lifecycle analysis reveals varying degrees of environmental impact. Air cooling systems generally present the lowest environmental burden due to their simplicity and minimal material requirements. However, their limited efficiency often necessitates additional battery capacity to compensate for performance losses, potentially offsetting their environmental benefits through increased resource consumption during manufacturing.

Advanced composite heat spreaders incorporating graphene or carbon nanotubes demonstrate promising thermal performance but raise sustainability concerns regarding nanomaterial production and end-of-life recovery. The energy-intensive manufacturing processes for these materials can significantly increase the carbon footprint of the thermal management system if not optimized for sustainability.

Recycling considerations represent another critical dimension of environmental assessment. Thermal management systems utilizing aluminum heat sinks or copper heat pipes benefit from established recycling infrastructures for these metals. Conversely, complex multi-material solutions may complicate disassembly and material separation, potentially reducing recyclability rates and increasing waste generation.

Water consumption emerges as a notable concern for active cooling systems in sodium-ion battery applications. Liquid cooling loops require significant water inputs during manufacturing and potentially during operation if evaporative cooling is employed. In regions facing water scarcity, this aspect becomes particularly problematic and may necessitate alternative approaches.

The energy efficiency of thermal management solutions directly impacts the overall sustainability profile of sodium-ion battery systems. Passive cooling techniques generally consume minimal operational energy but may provide insufficient thermal regulation under extreme conditions. Active systems offer superior performance but require continuous energy input, potentially reducing the net energy efficiency of the battery system unless powered by renewable sources.

Emerging bio-based PCMs and environmentally friendly coolants represent promising developments toward more sustainable thermal management. These materials, derived from renewable resources, offer reduced toxicity and improved biodegradability compared to conventional alternatives. However, their thermal performance characteristics and long-term stability require further optimization to match established solutions.

When assessing the sustainability of thermal management techniques, lifecycle analysis reveals varying degrees of environmental impact. Air cooling systems generally present the lowest environmental burden due to their simplicity and minimal material requirements. However, their limited efficiency often necessitates additional battery capacity to compensate for performance losses, potentially offsetting their environmental benefits through increased resource consumption during manufacturing.

Advanced composite heat spreaders incorporating graphene or carbon nanotubes demonstrate promising thermal performance but raise sustainability concerns regarding nanomaterial production and end-of-life recovery. The energy-intensive manufacturing processes for these materials can significantly increase the carbon footprint of the thermal management system if not optimized for sustainability.

Recycling considerations represent another critical dimension of environmental assessment. Thermal management systems utilizing aluminum heat sinks or copper heat pipes benefit from established recycling infrastructures for these metals. Conversely, complex multi-material solutions may complicate disassembly and material separation, potentially reducing recyclability rates and increasing waste generation.

Water consumption emerges as a notable concern for active cooling systems in sodium-ion battery applications. Liquid cooling loops require significant water inputs during manufacturing and potentially during operation if evaporative cooling is employed. In regions facing water scarcity, this aspect becomes particularly problematic and may necessitate alternative approaches.

The energy efficiency of thermal management solutions directly impacts the overall sustainability profile of sodium-ion battery systems. Passive cooling techniques generally consume minimal operational energy but may provide insufficient thermal regulation under extreme conditions. Active systems offer superior performance but require continuous energy input, potentially reducing the net energy efficiency of the battery system unless powered by renewable sources.

Emerging bio-based PCMs and environmentally friendly coolants represent promising developments toward more sustainable thermal management. These materials, derived from renewable resources, offer reduced toxicity and improved biodegradability compared to conventional alternatives. However, their thermal performance characteristics and long-term stability require further optimization to match established solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!