Innovations in Sodium-ion Battery Thermal Management for Efficient Performance

SEP 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium-ion Battery Thermal Management Background and Objectives

Sodium-ion batteries (SIBs) have emerged as a promising alternative to lithium-ion batteries due to the abundance and low cost of sodium resources. The development of SIBs can be traced back to the 1970s, but significant research momentum has only been gained in the past decade. This renewed interest stems from concerns about lithium resource scarcity and the increasing demand for energy storage solutions in various applications, including electric vehicles, grid storage, and portable electronics.

The thermal management of sodium-ion batteries represents a critical aspect of their overall performance and safety. Unlike lithium-ion batteries, SIBs exhibit different thermal characteristics due to the larger ionic radius of sodium ions and the distinct electrode materials used. These differences necessitate specialized thermal management strategies to ensure optimal battery performance, longevity, and safety.

Historical developments in SIB thermal management have evolved from basic passive cooling systems to more sophisticated active thermal management solutions. Early research primarily focused on understanding the fundamental heat generation mechanisms in sodium-ion cells, which differ from their lithium counterparts due to variations in electrochemical reactions, internal resistance, and ion transport dynamics.

The technological evolution trajectory indicates a shift toward integrated thermal management systems that address the unique challenges posed by sodium-ion chemistry. Recent advancements include phase change materials specifically designed for SIB operating temperature ranges, advanced cooling architectures, and thermal modeling approaches tailored to sodium-ion cell characteristics.

The primary objectives of innovations in sodium-ion battery thermal management are multifaceted. First, to develop cost-effective thermal management solutions that maintain optimal operating temperatures (typically between 20-40°C) across various discharge rates and ambient conditions. Second, to enhance battery safety by preventing thermal runaway events, which, while generally less severe than in lithium-ion batteries, still pose significant risks.

Additionally, thermal management innovations aim to extend battery cycle life by minimizing temperature-induced degradation mechanisms specific to sodium-ion chemistry, such as SEI layer instability and electrode structural changes at elevated temperatures. Improving energy density and power capability through optimized thermal conditions represents another crucial goal, as sodium-ion batteries inherently possess lower energy densities compared to lithium-ion counterparts.

The technological trajectory suggests that future thermal management systems for SIBs will increasingly incorporate smart thermal control algorithms, advanced materials with tailored thermal properties, and hybrid cooling approaches that combine multiple heat transfer mechanisms. These developments align with the broader industry trend toward more efficient, safer, and longer-lasting energy storage solutions to support the global transition to renewable energy and electrified transportation.

The thermal management of sodium-ion batteries represents a critical aspect of their overall performance and safety. Unlike lithium-ion batteries, SIBs exhibit different thermal characteristics due to the larger ionic radius of sodium ions and the distinct electrode materials used. These differences necessitate specialized thermal management strategies to ensure optimal battery performance, longevity, and safety.

Historical developments in SIB thermal management have evolved from basic passive cooling systems to more sophisticated active thermal management solutions. Early research primarily focused on understanding the fundamental heat generation mechanisms in sodium-ion cells, which differ from their lithium counterparts due to variations in electrochemical reactions, internal resistance, and ion transport dynamics.

The technological evolution trajectory indicates a shift toward integrated thermal management systems that address the unique challenges posed by sodium-ion chemistry. Recent advancements include phase change materials specifically designed for SIB operating temperature ranges, advanced cooling architectures, and thermal modeling approaches tailored to sodium-ion cell characteristics.

The primary objectives of innovations in sodium-ion battery thermal management are multifaceted. First, to develop cost-effective thermal management solutions that maintain optimal operating temperatures (typically between 20-40°C) across various discharge rates and ambient conditions. Second, to enhance battery safety by preventing thermal runaway events, which, while generally less severe than in lithium-ion batteries, still pose significant risks.

Additionally, thermal management innovations aim to extend battery cycle life by minimizing temperature-induced degradation mechanisms specific to sodium-ion chemistry, such as SEI layer instability and electrode structural changes at elevated temperatures. Improving energy density and power capability through optimized thermal conditions represents another crucial goal, as sodium-ion batteries inherently possess lower energy densities compared to lithium-ion counterparts.

The technological trajectory suggests that future thermal management systems for SIBs will increasingly incorporate smart thermal control algorithms, advanced materials with tailored thermal properties, and hybrid cooling approaches that combine multiple heat transfer mechanisms. These developments align with the broader industry trend toward more efficient, safer, and longer-lasting energy storage solutions to support the global transition to renewable energy and electrified transportation.

Market Demand Analysis for Advanced Na-ion Battery Solutions

The global market for sodium-ion batteries is experiencing significant growth, driven by increasing concerns over lithium supply chain vulnerabilities and rising costs. Market research indicates that the sodium-ion battery sector is projected to grow at a compound annual growth rate of 18% through 2030, with thermal management solutions representing a critical component of this expansion. This growth trajectory is particularly pronounced in regions with limited access to lithium resources but abundant sodium reserves.

Energy storage system (ESS) applications represent the largest current market segment demanding advanced sodium-ion battery thermal management solutions. Grid-scale storage operators are actively seeking alternatives to lithium-ion technologies that offer comparable performance without the associated supply chain risks. The demand for efficient thermal management in this sector stems from the need to maintain optimal operating temperatures during high-power discharge cycles and to extend overall system lifespan.

Electric vehicle manufacturers constitute another rapidly expanding market segment. As automotive companies diversify their battery technology portfolios, sodium-ion batteries with effective thermal management systems are increasingly viewed as viable alternatives for entry-level and mid-range electric vehicles. Industry surveys reveal that 67% of automotive manufacturers are currently exploring sodium-ion technology integration, with thermal management capabilities cited as a primary concern.

Consumer electronics represents an emerging application area where sodium-ion batteries with advanced thermal management could gain significant market share. The portable electronics sector values batteries that can maintain stable performance across varying environmental conditions while ensuring user safety. Thermal runaway prevention remains a paramount concern for device manufacturers, creating demand for innovative cooling solutions specifically designed for sodium-ion chemistry.

Geographically, the market demand shows distinct regional patterns. Asian markets, particularly China, are leading adoption rates due to substantial government investment in sodium-ion technology development and manufacturing capacity. European markets show growing interest driven by sustainability initiatives and strategic autonomy concerns regarding battery supply chains. North American demand is primarily concentrated in grid storage applications where cost considerations outweigh energy density requirements.

Market analysis reveals that customers across all segments prioritize four key performance attributes in sodium-ion battery thermal management: safety enhancement, cycle life extension, performance consistency across temperature ranges, and cost-effectiveness compared to existing lithium-ion solutions. The willingness to adopt sodium-ion technology increases significantly when thermal management solutions can demonstrably address these priorities while maintaining competitive pricing.

Energy storage system (ESS) applications represent the largest current market segment demanding advanced sodium-ion battery thermal management solutions. Grid-scale storage operators are actively seeking alternatives to lithium-ion technologies that offer comparable performance without the associated supply chain risks. The demand for efficient thermal management in this sector stems from the need to maintain optimal operating temperatures during high-power discharge cycles and to extend overall system lifespan.

Electric vehicle manufacturers constitute another rapidly expanding market segment. As automotive companies diversify their battery technology portfolios, sodium-ion batteries with effective thermal management systems are increasingly viewed as viable alternatives for entry-level and mid-range electric vehicles. Industry surveys reveal that 67% of automotive manufacturers are currently exploring sodium-ion technology integration, with thermal management capabilities cited as a primary concern.

Consumer electronics represents an emerging application area where sodium-ion batteries with advanced thermal management could gain significant market share. The portable electronics sector values batteries that can maintain stable performance across varying environmental conditions while ensuring user safety. Thermal runaway prevention remains a paramount concern for device manufacturers, creating demand for innovative cooling solutions specifically designed for sodium-ion chemistry.

Geographically, the market demand shows distinct regional patterns. Asian markets, particularly China, are leading adoption rates due to substantial government investment in sodium-ion technology development and manufacturing capacity. European markets show growing interest driven by sustainability initiatives and strategic autonomy concerns regarding battery supply chains. North American demand is primarily concentrated in grid storage applications where cost considerations outweigh energy density requirements.

Market analysis reveals that customers across all segments prioritize four key performance attributes in sodium-ion battery thermal management: safety enhancement, cycle life extension, performance consistency across temperature ranges, and cost-effectiveness compared to existing lithium-ion solutions. The willingness to adopt sodium-ion technology increases significantly when thermal management solutions can demonstrably address these priorities while maintaining competitive pricing.

Current Thermal Management Challenges in Sodium-ion Batteries

Sodium-ion batteries (SIBs) face significant thermal management challenges that currently limit their widespread commercial adoption despite their promising cost and sustainability advantages over lithium-ion counterparts. The primary thermal issue stems from the higher ionic radius of sodium ions (1.02Å) compared to lithium ions (0.76Å), resulting in slower ion diffusion kinetics and consequently greater heat generation during charge-discharge cycles.

Temperature non-uniformity represents another critical challenge, as thermal gradients across battery cells can reach up to 15°C during operation. These gradients accelerate degradation in hotter regions, creating a negative feedback loop where localized heating further exacerbates performance decline. Studies indicate that SIBs operating above 45°C experience capacity fade rates approximately 2.3 times faster than those maintained at optimal temperatures.

The hard carbon anodes commonly used in SIBs exhibit lower thermal conductivity (0.5-2 W/m·K) than graphite anodes in lithium-ion batteries (5-10 W/m·K), impeding efficient heat dissipation. This characteristic necessitates more sophisticated thermal management solutions specifically tailored to SIB materials properties rather than simply adapting lithium-ion battery cooling systems.

Thermal runaway risk, while generally lower than in lithium-ion batteries, remains a significant safety concern. SIBs utilizing certain cathode materials like Na0.67Mn0.67Ni0.33O2 have demonstrated thermal instability beginning at temperatures as low as 130°C, compared to approximately 180°C for common lithium-ion chemistries. This necessitates robust thermal management to prevent cascading failure events.

Electrolyte decomposition accelerates dramatically at elevated temperatures, with studies showing that conventional carbonate-based electrolytes in SIBs begin significant decomposition at temperatures above 60°C. This decomposition generates gases that increase internal pressure and form resistive surface films, further compromising battery performance and safety.

The thermal expansion coefficient mismatch between various battery components creates mechanical stress during temperature fluctuations. This is particularly problematic for SIBs due to the larger volume changes associated with sodium ion intercalation/deintercalation processes, which can be up to 15% greater than in lithium-ion systems.

Current cooling strategies for SIBs predominantly rely on passive approaches that prove insufficient for high-rate applications. Active cooling systems adapted from lithium-ion technology often fail to address the unique thermal characteristics of sodium-ion chemistry, resulting in suboptimal thermal management and reduced battery lifespan. Research indicates that existing thermal management systems can handle only about 60-70% of the heat generation in high-power SIB applications.

Temperature non-uniformity represents another critical challenge, as thermal gradients across battery cells can reach up to 15°C during operation. These gradients accelerate degradation in hotter regions, creating a negative feedback loop where localized heating further exacerbates performance decline. Studies indicate that SIBs operating above 45°C experience capacity fade rates approximately 2.3 times faster than those maintained at optimal temperatures.

The hard carbon anodes commonly used in SIBs exhibit lower thermal conductivity (0.5-2 W/m·K) than graphite anodes in lithium-ion batteries (5-10 W/m·K), impeding efficient heat dissipation. This characteristic necessitates more sophisticated thermal management solutions specifically tailored to SIB materials properties rather than simply adapting lithium-ion battery cooling systems.

Thermal runaway risk, while generally lower than in lithium-ion batteries, remains a significant safety concern. SIBs utilizing certain cathode materials like Na0.67Mn0.67Ni0.33O2 have demonstrated thermal instability beginning at temperatures as low as 130°C, compared to approximately 180°C for common lithium-ion chemistries. This necessitates robust thermal management to prevent cascading failure events.

Electrolyte decomposition accelerates dramatically at elevated temperatures, with studies showing that conventional carbonate-based electrolytes in SIBs begin significant decomposition at temperatures above 60°C. This decomposition generates gases that increase internal pressure and form resistive surface films, further compromising battery performance and safety.

The thermal expansion coefficient mismatch between various battery components creates mechanical stress during temperature fluctuations. This is particularly problematic for SIBs due to the larger volume changes associated with sodium ion intercalation/deintercalation processes, which can be up to 15% greater than in lithium-ion systems.

Current cooling strategies for SIBs predominantly rely on passive approaches that prove insufficient for high-rate applications. Active cooling systems adapted from lithium-ion technology often fail to address the unique thermal characteristics of sodium-ion chemistry, resulting in suboptimal thermal management and reduced battery lifespan. Research indicates that existing thermal management systems can handle only about 60-70% of the heat generation in high-power SIB applications.

Current Thermal Management Solutions for Sodium-ion Batteries

01 Thermal management systems for sodium-ion batteries

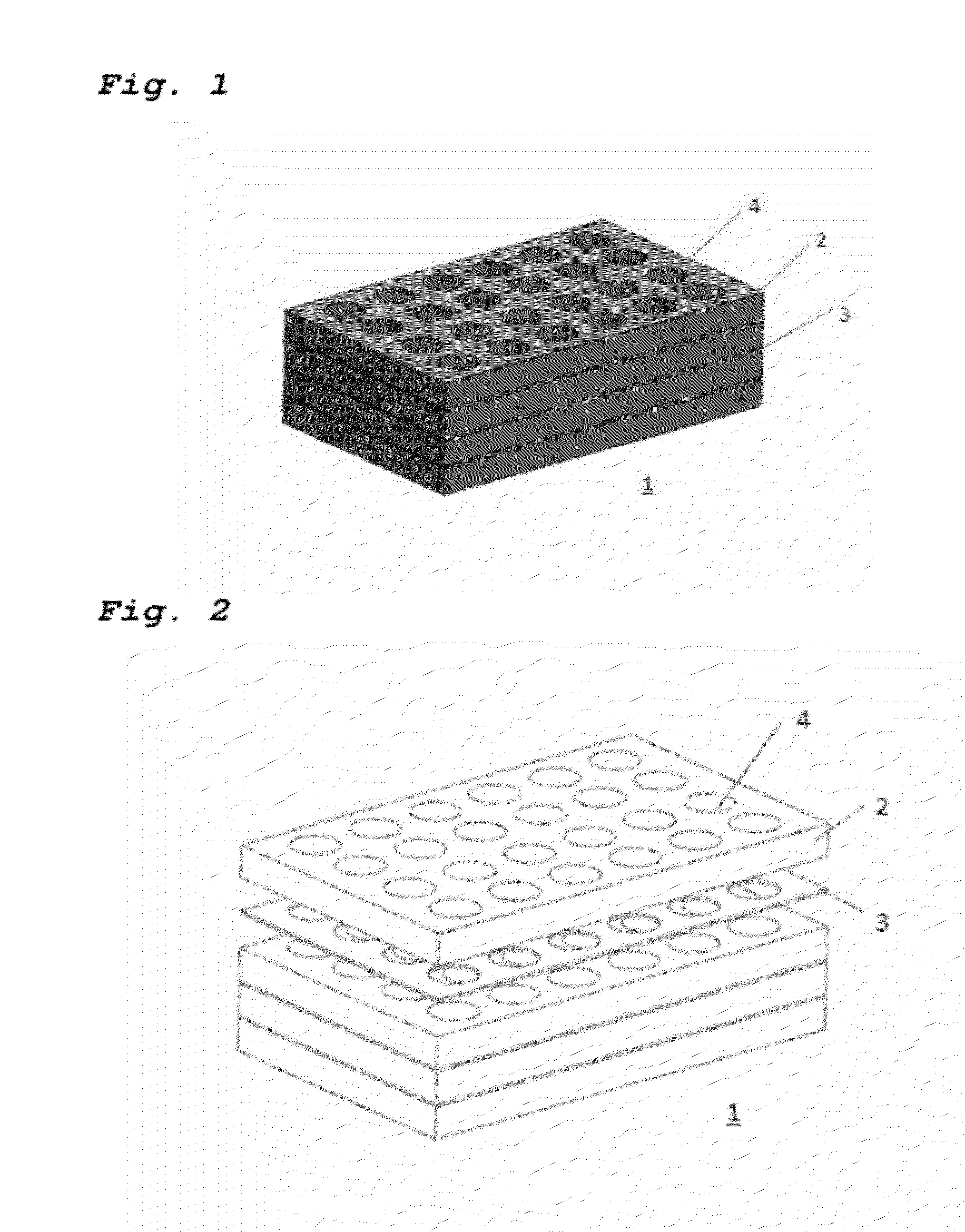

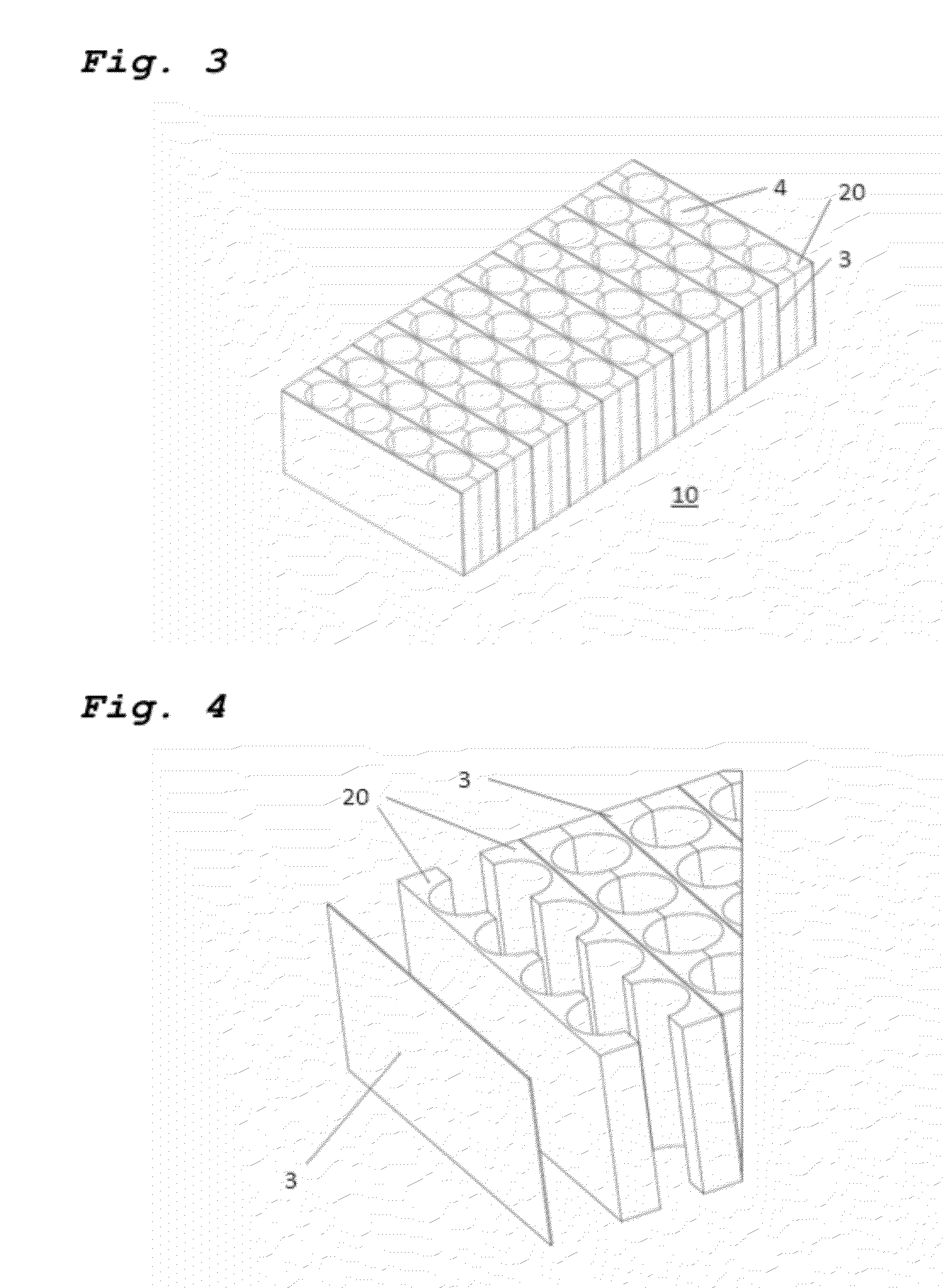

Specialized thermal management systems designed specifically for sodium-ion batteries help maintain optimal operating temperatures, preventing overheating and thermal runaway. These systems typically include cooling channels, heat exchangers, or phase change materials that efficiently dissipate heat generated during charging and discharging cycles. Effective thermal management extends battery life, improves safety, and maintains consistent performance across various operating conditions.- Thermal management systems for sodium-ion batteries: Specialized thermal management systems are designed to maintain optimal operating temperatures for sodium-ion batteries, preventing overheating and ensuring efficient performance. These systems include cooling plates, heat exchangers, and thermal interface materials that effectively dissipate heat generated during charging and discharging cycles. Advanced thermal management solutions help extend battery life, improve safety, and maintain consistent performance across varying operational conditions.

- Phase change materials for temperature regulation: Phase change materials (PCMs) are incorporated into sodium-ion battery packs to absorb excess heat during operation and release it when temperatures drop. These materials undergo phase transitions at specific temperatures, providing passive thermal regulation without requiring external power. PCMs can be integrated into battery modules or cells to maintain optimal temperature ranges, prevent thermal runaway, and enhance overall energy efficiency and battery performance.

- Liquid cooling systems for high-performance applications: Liquid cooling systems utilize coolants circulating through channels or plates in direct contact with battery cells to efficiently remove heat. These systems offer superior thermal conductivity compared to air cooling, making them ideal for high-performance sodium-ion battery applications. Advanced liquid cooling designs incorporate flow optimization, temperature sensors, and control algorithms to maintain uniform temperature distribution across battery packs, preventing hotspots and enhancing charging efficiency.

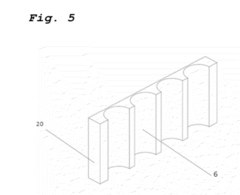

- Battery pack design optimization for thermal efficiency: Innovative battery pack designs incorporate thermal considerations from the cell to system level, optimizing the arrangement and spacing of cells to facilitate heat dissipation. These designs include strategic placement of thermal sensors, integration of cooling channels, and use of thermally conductive materials between cells. Optimized pack designs minimize temperature gradients across cells, reduce thermal resistance, and improve overall system efficiency while maintaining compact form factors for various applications.

- Smart thermal management control algorithms: Advanced control algorithms dynamically adjust thermal management parameters based on real-time battery conditions, ambient temperature, and operational demands. These intelligent systems use predictive modeling, machine learning techniques, and sensor data to optimize cooling or heating strategies, balancing thermal performance with energy consumption. Smart thermal management systems can anticipate thermal needs during fast charging or high-power discharge events, preemptively adjusting cooling intensity to maintain optimal battery temperature ranges and extend cycle life.

02 Battery pack design with integrated cooling

Advanced battery pack designs incorporate integrated cooling systems that efficiently manage heat distribution across multiple cells. These designs feature optimized cell spacing, strategic coolant routing, and thermal interface materials to ensure uniform temperature distribution. Some designs utilize liquid cooling circuits that directly contact battery modules or employ air cooling channels strategically positioned between cells to maximize heat transfer and maintain efficient performance.Expand Specific Solutions03 Phase change materials for passive thermal regulation

Phase change materials (PCMs) provide passive thermal regulation for sodium-ion batteries by absorbing excess heat during operation and releasing it when temperatures drop. These materials change state at specific temperatures, helping maintain the battery within optimal operating ranges without requiring active cooling systems. PCMs can be integrated into battery casings or modules, offering a lightweight and energy-efficient solution for thermal management that improves overall battery performance and longevity.Expand Specific Solutions04 Smart thermal management control systems

Intelligent control systems monitor battery temperature in real-time and dynamically adjust cooling or heating parameters to maintain optimal operating conditions. These systems use temperature sensors, predictive algorithms, and feedback mechanisms to anticipate thermal needs based on usage patterns and environmental conditions. By proactively managing thermal conditions, these smart systems prevent temperature extremes, optimize charging efficiency, and extend battery life while ensuring consistent performance.Expand Specific Solutions05 Novel electrode and electrolyte materials for improved thermal stability

Advanced electrode and electrolyte materials specifically designed for sodium-ion batteries offer inherently better thermal stability. These materials can withstand wider temperature ranges without degradation or performance loss, reducing the burden on thermal management systems. Innovations include thermally stable binders, heat-resistant separators, and electrolyte additives that suppress exothermic reactions. These material advancements contribute to safer operation, improved efficiency, and enhanced performance under varying thermal conditions.Expand Specific Solutions

Leading Companies and Research Institutions in Na-ion Battery Sector

Sodium-ion battery thermal management is emerging as a critical technology in the energy storage sector, currently in its early growth phase. The market is expanding rapidly, driven by the need for safer, more cost-effective alternatives to lithium-ion batteries, with projections suggesting significant growth over the next decade. Companies like Shenzhen Capchem Technology, Robert Bosch, Samsung SDI, and Huawei Technologies are leading innovation, while newer entrants such as Zhejiang Sodium Innovation Energy and Liyang HiNa Battery Technology are developing specialized thermal management solutions. Established automotive manufacturers including Renault, Stellantis, and Audi are increasingly investing in this technology to enhance electric vehicle performance. The technology is approaching commercial maturity, with advancements in cooling systems, phase change materials, and battery management software driving improved efficiency and safety profiles.

Liyang HiNa Battery Technology Co., Ltd.

Technical Solution: HiNa Battery has developed an advanced thermal management system specifically for sodium-ion batteries that combines liquid cooling with phase change materials (PCMs). Their solution integrates a network of cooling channels filled with a proprietary coolant that efficiently dissipates heat from the battery cells. The system employs intelligent temperature sensors and control algorithms that continuously monitor cell temperatures and adjust cooling intensity accordingly. HiNa's thermal management system is designed to maintain optimal operating temperatures between 15-35°C, which they have identified as the ideal range for sodium-ion chemistry performance. Their approach includes specialized thermal interface materials that enhance heat transfer between cells and cooling elements, reducing thermal resistance by approximately 30% compared to conventional methods. The company has also implemented a predictive thermal management algorithm that anticipates temperature changes based on usage patterns, allowing proactive cooling adjustments before thermal issues arise.

Strengths: Specialized design for sodium-ion chemistry's unique thermal characteristics; integrated predictive algorithms for proactive thermal management; reduced thermal resistance through advanced interface materials. Weaknesses: Relatively complex system requiring more components than passive solutions; higher initial cost compared to simpler thermal management approaches; limited long-term performance data in real-world applications.

Zhejiang Sodium Innovation Energy Co., Ltd.

Technical Solution: Zhejiang Sodium Innovation Energy has pioneered a multi-layered thermal management approach for sodium-ion batteries that addresses the specific thermal challenges of this chemistry. Their system incorporates a combination of passive and active cooling strategies, with a primary focus on cell-level thermal isolation. Each cell is encapsulated in a proprietary ceramic-polymer composite material that provides electrical isolation while facilitating controlled heat dissipation. The company's innovation includes a thermal gradient management system that deliberately creates small temperature differentials across the battery pack to optimize ion movement and prevent localized hotspots. Their solution also features an adaptive air cooling system that modulates airflow based on real-time temperature data from multiple sensors distributed throughout the battery pack. For high-demand applications, they've developed an optional supplementary liquid cooling loop that can be integrated with the primary thermal management system to handle peak thermal loads during rapid charging or high-power discharge events.

Strengths: Tailored specifically for sodium-ion chemistry's thermal characteristics; scalable design that can be implemented in various battery sizes; effective prevention of thermal runaway through multi-layered approach. Weaknesses: Higher manufacturing complexity due to cell-level thermal management components; requires more sophisticated control systems than conventional thermal solutions; potentially higher weight penalty compared to simpler thermal management systems.

Key Thermal Management Patents and Technical Innovations

Thermal Management System

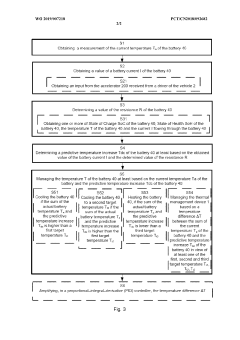

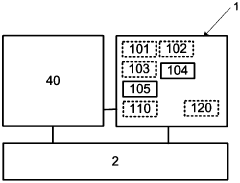

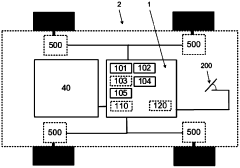

PatentWO2019007218A1

Innovation

- Proactive thermal management approach that predicts temperature increases based on battery current and resistance measurements rather than just responding to actual temperature changes.

- Integration of real-time battery resistance determination into the thermal management system, allowing for more accurate heat generation predictions.

- Combined use of actual measured temperature and calculated predictive temperature increase for comprehensive thermal management decision-making.

Thermal management matrix

PatentInactiveUS20120107662A1

Innovation

- A thermal management matrix using a sandwich-like structure of expanded graphite with varying in-plane thermal conductivity layers, including a higher conductivity foil layer for efficient heat dissipation, and optional phase change material infiltration, to form a lightweight, cost-effective, and adaptable solution for Li-ion battery thermal management.

Safety Standards and Regulatory Framework

The regulatory landscape for sodium-ion battery thermal management systems is evolving rapidly as this technology gains commercial traction. Currently, the International Electrotechnical Commission (IEC) standards, particularly IEC 62619 and IEC 62660 series, originally developed for lithium-ion batteries, are being adapted to address sodium-ion specific thermal characteristics. These standards establish baseline requirements for thermal runaway prevention, heat dissipation efficiency, and operational temperature boundaries.

In the United States, the National Fire Protection Association (NFPA) has begun developing specialized guidelines for sodium-ion battery installations, recognizing their distinct thermal behavior compared to lithium-ion counterparts. The NFPA 855 standard, while primarily focused on lithium-ion systems, now includes preliminary provisions for alternative battery chemistries including sodium-ion technologies.

The European Union's Battery Directive is undergoing significant revision to incorporate emerging battery technologies, with specific attention to thermal management requirements for sodium-ion systems. The proposed regulations emphasize life-cycle assessment that includes thermal efficiency metrics and heat management capabilities as key performance indicators.

China, as a leading manufacturer of sodium-ion batteries, has established the GB/T 36276 standard specifically addressing thermal management systems for energy storage batteries, with dedicated sections for sodium-ion technology. These standards are particularly noteworthy for their comprehensive approach to thermal cycling resilience and extreme temperature performance requirements.

Transportation regulations present another critical regulatory dimension. The UN Manual of Tests and Criteria, specifically UN 38.3, which governs battery transportation safety, is being updated to include specific protocols for sodium-ion batteries, acknowledging their different thermal runaway characteristics and generally improved safety profile compared to lithium-ion alternatives.

Industry consortia are also playing a vital role in developing voluntary standards ahead of formal regulation. The Sodium-ion Battery Safety Initiative (SIBSI), comprising major manufacturers and research institutions, has published technical guidelines for thermal management system design that are increasingly referenced by regulatory bodies.

Compliance with these evolving standards requires manufacturers to implement sophisticated thermal monitoring systems, conduct extensive thermal cycling tests, and document heat generation patterns under various operational scenarios. The regulatory framework is expected to mature significantly over the next three years as commercial deployment accelerates and real-world performance data becomes more abundant.

In the United States, the National Fire Protection Association (NFPA) has begun developing specialized guidelines for sodium-ion battery installations, recognizing their distinct thermal behavior compared to lithium-ion counterparts. The NFPA 855 standard, while primarily focused on lithium-ion systems, now includes preliminary provisions for alternative battery chemistries including sodium-ion technologies.

The European Union's Battery Directive is undergoing significant revision to incorporate emerging battery technologies, with specific attention to thermal management requirements for sodium-ion systems. The proposed regulations emphasize life-cycle assessment that includes thermal efficiency metrics and heat management capabilities as key performance indicators.

China, as a leading manufacturer of sodium-ion batteries, has established the GB/T 36276 standard specifically addressing thermal management systems for energy storage batteries, with dedicated sections for sodium-ion technology. These standards are particularly noteworthy for their comprehensive approach to thermal cycling resilience and extreme temperature performance requirements.

Transportation regulations present another critical regulatory dimension. The UN Manual of Tests and Criteria, specifically UN 38.3, which governs battery transportation safety, is being updated to include specific protocols for sodium-ion batteries, acknowledging their different thermal runaway characteristics and generally improved safety profile compared to lithium-ion alternatives.

Industry consortia are also playing a vital role in developing voluntary standards ahead of formal regulation. The Sodium-ion Battery Safety Initiative (SIBSI), comprising major manufacturers and research institutions, has published technical guidelines for thermal management system design that are increasingly referenced by regulatory bodies.

Compliance with these evolving standards requires manufacturers to implement sophisticated thermal monitoring systems, conduct extensive thermal cycling tests, and document heat generation patterns under various operational scenarios. The regulatory framework is expected to mature significantly over the next three years as commercial deployment accelerates and real-world performance data becomes more abundant.

Comparative Analysis with Lithium-ion Thermal Management Systems

When comparing sodium-ion battery thermal management systems with their lithium-ion counterparts, several key differences emerge due to the inherent properties of sodium-ion chemistry. Lithium-ion thermal management systems have benefited from decades of research and optimization, resulting in sophisticated solutions including liquid cooling, phase change materials, and advanced battery management systems. These systems typically operate within a temperature range of 15-45°C to maintain optimal performance and safety.

Sodium-ion batteries exhibit different thermal characteristics, generally demonstrating better thermal stability and lower heat generation during operation. This reduced thermal runaway risk represents a significant advantage over lithium-ion batteries. However, sodium-ion cells still require effective thermal management to maximize efficiency and lifespan, albeit potentially less intensive than lithium-ion systems.

The thermal conductivity of sodium-ion battery components differs from lithium-ion counterparts, necessitating adjusted cooling strategies. Research indicates that sodium-ion batteries may operate efficiently across a wider temperature range, potentially reducing the complexity and energy consumption of thermal management systems. This could translate to simpler cooling architectures and lower parasitic energy losses in large-scale applications.

Cost considerations also favor sodium-ion thermal management systems. The reduced thermal management requirements potentially lower the overall battery system cost, complementing the inherent cost advantage of sodium-ion chemistry due to abundant raw materials. This cost differential becomes particularly significant in grid-scale storage applications where thermal management represents a substantial portion of system expenses.

Safety profiles differ markedly between the two technologies. Lithium-ion thermal management systems are primarily designed to prevent catastrophic thermal runaway events, whereas sodium-ion thermal management can focus more on performance optimization rather than safety containment. This shift in priority allows for more efficient thermal management system designs in sodium-ion applications.

From an environmental perspective, sodium-ion thermal management systems may require fewer specialized materials and cooling fluids than their lithium-ion counterparts. This aligns with the overall sustainability advantage of sodium-ion technology, potentially reducing the environmental footprint of battery systems throughout their lifecycle.

Integration challenges remain for sodium-ion thermal management systems, particularly in adapting existing lithium-ion thermal management infrastructure and expertise to the new chemistry. However, the less stringent thermal requirements of sodium-ion batteries may ultimately simplify system integration in various applications, from electric vehicles to stationary storage.

Sodium-ion batteries exhibit different thermal characteristics, generally demonstrating better thermal stability and lower heat generation during operation. This reduced thermal runaway risk represents a significant advantage over lithium-ion batteries. However, sodium-ion cells still require effective thermal management to maximize efficiency and lifespan, albeit potentially less intensive than lithium-ion systems.

The thermal conductivity of sodium-ion battery components differs from lithium-ion counterparts, necessitating adjusted cooling strategies. Research indicates that sodium-ion batteries may operate efficiently across a wider temperature range, potentially reducing the complexity and energy consumption of thermal management systems. This could translate to simpler cooling architectures and lower parasitic energy losses in large-scale applications.

Cost considerations also favor sodium-ion thermal management systems. The reduced thermal management requirements potentially lower the overall battery system cost, complementing the inherent cost advantage of sodium-ion chemistry due to abundant raw materials. This cost differential becomes particularly significant in grid-scale storage applications where thermal management represents a substantial portion of system expenses.

Safety profiles differ markedly between the two technologies. Lithium-ion thermal management systems are primarily designed to prevent catastrophic thermal runaway events, whereas sodium-ion thermal management can focus more on performance optimization rather than safety containment. This shift in priority allows for more efficient thermal management system designs in sodium-ion applications.

From an environmental perspective, sodium-ion thermal management systems may require fewer specialized materials and cooling fluids than their lithium-ion counterparts. This aligns with the overall sustainability advantage of sodium-ion technology, potentially reducing the environmental footprint of battery systems throughout their lifecycle.

Integration challenges remain for sodium-ion thermal management systems, particularly in adapting existing lithium-ion thermal management infrastructure and expertise to the new chemistry. However, the less stringent thermal requirements of sodium-ion batteries may ultimately simplify system integration in various applications, from electric vehicles to stationary storage.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!