Porosity's Role in Sodium-ion Batteries for Renewable Integration

SEP 19, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium-ion Battery Porosity Background and Objectives

Sodium-ion batteries (SIBs) have emerged as a promising alternative to lithium-ion batteries due to the abundance and widespread distribution of sodium resources. The development of SIBs can be traced back to the 1970s, but significant research momentum has only been gained in the past decade as concerns about lithium supply constraints have intensified. The evolution of SIB technology has been marked by continuous improvements in electrode materials, electrolytes, and battery architecture, with porosity playing an increasingly recognized role in performance optimization.

Porosity, defined as the volume fraction of void space within a material, represents a critical yet often overlooked parameter in battery design. In the context of SIBs, porosity affects multiple performance aspects including ionic conductivity, electrode wetting, mechanical stability, and capacity retention. Historically, porosity control has been approached as a secondary consideration rather than a primary design parameter, limiting the potential performance gains in sodium-ion systems.

The integration of renewable energy sources such as solar and wind power into electrical grids presents unique challenges due to their intermittent nature. Energy storage systems that can efficiently buffer these fluctuations are essential for widespread renewable adoption. SIBs offer particular advantages for grid-scale storage applications due to their potentially lower cost and sustainable material profile compared to lithium-ion alternatives, making porosity optimization especially relevant for these large-scale implementations.

The technical objectives of this research focus on understanding and optimizing porosity characteristics in SIB components to enhance their suitability for renewable energy integration. Specifically, we aim to: (1) establish quantitative relationships between electrode porosity parameters and electrochemical performance metrics relevant to renewable energy applications; (2) develop methodologies for precise porosity control during manufacturing processes; (3) identify optimal porosity profiles for different operational scenarios in renewable energy systems; and (4) explore novel porous architectures that can enhance sodium-ion diffusion while maintaining structural integrity during cycling.

Recent technological breakthroughs in advanced manufacturing techniques, including 3D printing, freeze-casting, and templating methods, have opened new possibilities for creating tailored porous structures in battery components. These innovations enable unprecedented control over pore size distribution, connectivity, and tortuosity—parameters that directly influence the rate capability and cycle life of SIBs. The convergence of these manufacturing capabilities with computational modeling approaches presents an opportunity to systematically optimize porosity for specific renewable energy integration requirements.

The ultimate goal is to establish design principles for porosity engineering in SIBs that can be translated into commercially viable manufacturing processes, thereby accelerating the deployment of sodium-ion technology in renewable energy systems. This would contribute significantly to addressing the global challenges of energy sustainability and climate change mitigation through improved energy storage solutions.

Porosity, defined as the volume fraction of void space within a material, represents a critical yet often overlooked parameter in battery design. In the context of SIBs, porosity affects multiple performance aspects including ionic conductivity, electrode wetting, mechanical stability, and capacity retention. Historically, porosity control has been approached as a secondary consideration rather than a primary design parameter, limiting the potential performance gains in sodium-ion systems.

The integration of renewable energy sources such as solar and wind power into electrical grids presents unique challenges due to their intermittent nature. Energy storage systems that can efficiently buffer these fluctuations are essential for widespread renewable adoption. SIBs offer particular advantages for grid-scale storage applications due to their potentially lower cost and sustainable material profile compared to lithium-ion alternatives, making porosity optimization especially relevant for these large-scale implementations.

The technical objectives of this research focus on understanding and optimizing porosity characteristics in SIB components to enhance their suitability for renewable energy integration. Specifically, we aim to: (1) establish quantitative relationships between electrode porosity parameters and electrochemical performance metrics relevant to renewable energy applications; (2) develop methodologies for precise porosity control during manufacturing processes; (3) identify optimal porosity profiles for different operational scenarios in renewable energy systems; and (4) explore novel porous architectures that can enhance sodium-ion diffusion while maintaining structural integrity during cycling.

Recent technological breakthroughs in advanced manufacturing techniques, including 3D printing, freeze-casting, and templating methods, have opened new possibilities for creating tailored porous structures in battery components. These innovations enable unprecedented control over pore size distribution, connectivity, and tortuosity—parameters that directly influence the rate capability and cycle life of SIBs. The convergence of these manufacturing capabilities with computational modeling approaches presents an opportunity to systematically optimize porosity for specific renewable energy integration requirements.

The ultimate goal is to establish design principles for porosity engineering in SIBs that can be translated into commercially viable manufacturing processes, thereby accelerating the deployment of sodium-ion technology in renewable energy systems. This would contribute significantly to addressing the global challenges of energy sustainability and climate change mitigation through improved energy storage solutions.

Market Analysis for Na-ion Batteries in Renewable Energy

The sodium-ion battery market is experiencing significant growth, driven by the increasing demand for renewable energy storage solutions. As of 2023, the global sodium-ion battery market was valued at approximately $1.2 billion, with projections indicating a compound annual growth rate (CAGR) of 18-20% over the next decade. This growth trajectory is particularly notable in regions with ambitious renewable energy targets, such as Europe, China, and parts of North America.

The integration of sodium-ion batteries with renewable energy systems presents a compelling market opportunity. Wind and solar power generation, which accounted for over 10% of global electricity production in 2022, requires efficient energy storage solutions to address intermittency issues. Sodium-ion batteries, especially those with optimized porosity structures, are increasingly viewed as viable alternatives to lithium-ion technologies for grid-scale storage applications.

Market segmentation reveals distinct application areas where porosity-enhanced sodium-ion batteries show particular promise. Grid-scale energy storage represents the largest segment, with an estimated market share of 45%. Residential energy storage systems follow at 30%, while commercial and industrial applications account for approximately 25%. The growth in distributed energy resources and microgrids is expected to further expand these market segments.

Regional analysis indicates that Asia-Pacific currently dominates the sodium-ion battery market with approximately 50% share, led by China's aggressive development in this technology. Europe follows with 30%, driven by stringent carbon reduction policies and renewable energy mandates. North America accounts for 15%, with the remaining 5% distributed across other regions.

Consumer demand patterns show increasing preference for sustainable and cost-effective energy storage solutions. Survey data indicates that 78% of utility companies are considering sodium-ion technology for their future storage projects, citing lower costs and reduced supply chain risks compared to lithium-ion alternatives. The absence of critical materials like cobalt and lithium in sodium-ion batteries enhances their market appeal amid growing concerns about resource scarcity.

Economic factors further strengthen the market outlook for porosity-optimized sodium-ion batteries. Production costs are estimated to be 30-40% lower than comparable lithium-ion systems, primarily due to the abundance of sodium resources and simpler manufacturing processes. This cost advantage is particularly significant for large-scale renewable integration projects where capital expenditure is a critical consideration.

Market barriers include technological maturity concerns and established lithium-ion infrastructure. However, recent advancements in porosity engineering have significantly improved the performance metrics of sodium-ion batteries, narrowing the gap with incumbent technologies and accelerating market adoption rates.

The integration of sodium-ion batteries with renewable energy systems presents a compelling market opportunity. Wind and solar power generation, which accounted for over 10% of global electricity production in 2022, requires efficient energy storage solutions to address intermittency issues. Sodium-ion batteries, especially those with optimized porosity structures, are increasingly viewed as viable alternatives to lithium-ion technologies for grid-scale storage applications.

Market segmentation reveals distinct application areas where porosity-enhanced sodium-ion batteries show particular promise. Grid-scale energy storage represents the largest segment, with an estimated market share of 45%. Residential energy storage systems follow at 30%, while commercial and industrial applications account for approximately 25%. The growth in distributed energy resources and microgrids is expected to further expand these market segments.

Regional analysis indicates that Asia-Pacific currently dominates the sodium-ion battery market with approximately 50% share, led by China's aggressive development in this technology. Europe follows with 30%, driven by stringent carbon reduction policies and renewable energy mandates. North America accounts for 15%, with the remaining 5% distributed across other regions.

Consumer demand patterns show increasing preference for sustainable and cost-effective energy storage solutions. Survey data indicates that 78% of utility companies are considering sodium-ion technology for their future storage projects, citing lower costs and reduced supply chain risks compared to lithium-ion alternatives. The absence of critical materials like cobalt and lithium in sodium-ion batteries enhances their market appeal amid growing concerns about resource scarcity.

Economic factors further strengthen the market outlook for porosity-optimized sodium-ion batteries. Production costs are estimated to be 30-40% lower than comparable lithium-ion systems, primarily due to the abundance of sodium resources and simpler manufacturing processes. This cost advantage is particularly significant for large-scale renewable integration projects where capital expenditure is a critical consideration.

Market barriers include technological maturity concerns and established lithium-ion infrastructure. However, recent advancements in porosity engineering have significantly improved the performance metrics of sodium-ion batteries, narrowing the gap with incumbent technologies and accelerating market adoption rates.

Porosity Engineering Challenges in Na-ion Technology

Despite significant advancements in sodium-ion battery technology, porosity engineering remains one of the most challenging aspects in the development of high-performance Na-ion systems for renewable energy integration. The porous structure of electrodes and separators critically influences ion transport kinetics, electrolyte wetting, and overall battery performance. However, optimizing porosity presents several complex challenges that require innovative solutions.

The primary challenge lies in achieving the delicate balance between porosity and mechanical integrity. Higher porosity facilitates faster ion transport and better electrolyte penetration but often compromises the structural stability and volumetric energy density of electrodes. This trade-off becomes particularly problematic during the repeated volume changes associated with sodium insertion/extraction, which are more pronounced than in lithium-ion systems due to the larger ionic radius of sodium (1.02Å vs. 0.76Å for lithium).

Controlling pore size distribution represents another significant hurdle. Sodium-ion transport requires specifically tailored pore architectures with optimal pore sizes typically ranging from mesopores (2-50nm) to small macropores. Current synthesis methods struggle to precisely control hierarchical pore structures that can simultaneously accommodate the larger sodium ions while maintaining sufficient active material loading.

The interaction between electrolyte and porous structures presents additional complications. Sodium-based electrolytes often exhibit different wetting behaviors and viscosity characteristics compared to lithium counterparts, necessitating specialized porosity designs. The formation of solid electrolyte interphase (SEI) within porous structures is also less understood in Na-ion systems, creating challenges for long-term stability and performance prediction.

Manufacturing scalability of precisely engineered porous structures remains problematic. While laboratory-scale techniques like templating methods and freeze-casting can create well-defined porous architectures, translating these approaches to industrial-scale production while maintaining porosity control presents significant engineering challenges. Cost-effective manufacturing processes that can reliably produce optimized porous structures are still under development.

Environmental factors also impact porosity engineering. Humidity sensitivity during manufacturing and storage can alter the intended porous structure of Na-ion battery components. Additionally, the thermal expansion coefficient differences between the active materials and the pore-forming agents can lead to microstructural defects during thermal processing steps.

Addressing these challenges requires interdisciplinary approaches combining materials science, electrochemistry, and advanced manufacturing techniques. Recent research has begun exploring biomimetic approaches, 3D printing technologies, and artificial intelligence-assisted materials design to overcome these porosity engineering hurdles in next-generation sodium-ion battery systems.

The primary challenge lies in achieving the delicate balance between porosity and mechanical integrity. Higher porosity facilitates faster ion transport and better electrolyte penetration but often compromises the structural stability and volumetric energy density of electrodes. This trade-off becomes particularly problematic during the repeated volume changes associated with sodium insertion/extraction, which are more pronounced than in lithium-ion systems due to the larger ionic radius of sodium (1.02Å vs. 0.76Å for lithium).

Controlling pore size distribution represents another significant hurdle. Sodium-ion transport requires specifically tailored pore architectures with optimal pore sizes typically ranging from mesopores (2-50nm) to small macropores. Current synthesis methods struggle to precisely control hierarchical pore structures that can simultaneously accommodate the larger sodium ions while maintaining sufficient active material loading.

The interaction between electrolyte and porous structures presents additional complications. Sodium-based electrolytes often exhibit different wetting behaviors and viscosity characteristics compared to lithium counterparts, necessitating specialized porosity designs. The formation of solid electrolyte interphase (SEI) within porous structures is also less understood in Na-ion systems, creating challenges for long-term stability and performance prediction.

Manufacturing scalability of precisely engineered porous structures remains problematic. While laboratory-scale techniques like templating methods and freeze-casting can create well-defined porous architectures, translating these approaches to industrial-scale production while maintaining porosity control presents significant engineering challenges. Cost-effective manufacturing processes that can reliably produce optimized porous structures are still under development.

Environmental factors also impact porosity engineering. Humidity sensitivity during manufacturing and storage can alter the intended porous structure of Na-ion battery components. Additionally, the thermal expansion coefficient differences between the active materials and the pore-forming agents can lead to microstructural defects during thermal processing steps.

Addressing these challenges requires interdisciplinary approaches combining materials science, electrochemistry, and advanced manufacturing techniques. Recent research has begun exploring biomimetic approaches, 3D printing technologies, and artificial intelligence-assisted materials design to overcome these porosity engineering hurdles in next-generation sodium-ion battery systems.

Current Porosity Control Techniques for Na-ion Electrodes

01 Porous electrode materials for sodium-ion batteries

Porous electrode materials can significantly enhance the performance of sodium-ion batteries by providing larger surface areas for sodium ion insertion/extraction. These materials facilitate faster ion diffusion and electron transfer, leading to improved capacity and rate capability. Various manufacturing techniques can be employed to create controlled porosity in electrode materials, including template-assisted synthesis and chemical etching methods.- Porous electrode materials for sodium-ion batteries: Porous electrode materials enhance sodium-ion battery performance by providing larger surface areas for ion transport and storage. These materials facilitate faster sodium ion diffusion and intercalation, improving charge-discharge rates and overall battery efficiency. Various manufacturing techniques can create controlled porosity in electrode materials, including templating methods and chemical etching processes, resulting in optimized pore size distribution for sodium ion storage.

- Carbon-based porous materials for sodium-ion battery anodes: Porous carbon-based materials serve as effective anode materials in sodium-ion batteries due to their high surface area and stable structure. These materials, including hard carbon, carbon nanotubes, and graphene derivatives, feature hierarchical pore structures that accommodate sodium ion insertion and extraction while minimizing volume changes during cycling. The porosity of these carbon materials can be tailored through activation processes to optimize sodium storage capacity and cycling stability.

- Transition metal oxide porous structures for cathodes: Porous transition metal oxide structures are developed as cathode materials for sodium-ion batteries, offering enhanced ionic conductivity and structural stability. These materials feature controlled porosity that facilitates sodium ion diffusion while maintaining structural integrity during repeated charge-discharge cycles. Various synthesis methods, including hydrothermal processes and sol-gel techniques, are employed to create optimized porous architectures with high sodium storage capacity and improved cycling performance.

- Electrolyte infiltration and ionic transport in porous structures: The porosity of electrode materials significantly affects electrolyte infiltration and ionic transport in sodium-ion batteries. Optimized pore size distribution and connectivity ensure efficient electrolyte penetration throughout the electrode structure, facilitating sodium ion movement between electrodes. Research focuses on understanding the relationship between porosity parameters (pore size, volume, and distribution) and electrolyte wetting properties to enhance ionic conductivity and reduce internal resistance in sodium-ion batteries.

- Manufacturing techniques for controlled porosity in battery components: Advanced manufacturing techniques are developed to create controlled porosity in sodium-ion battery components, including electrodes, separators, and current collectors. These techniques include freeze-drying, template-assisted synthesis, and 3D printing methods that enable precise control over pore size, distribution, and connectivity. The engineered porosity enhances battery performance by optimizing ion transport pathways, increasing active material utilization, and improving mechanical stability during cycling.

02 Carbon-based porous materials for sodium-ion battery electrodes

Carbon-based materials with optimized porosity structures are widely used in sodium-ion batteries due to their excellent electrical conductivity and structural stability. These materials include hard carbon, graphene, and carbon nanotubes with engineered pore sizes and distributions. The hierarchical porous structure allows for efficient sodium ion storage while maintaining structural integrity during charge-discharge cycles, resulting in enhanced battery performance and cycle life.Expand Specific Solutions03 Metal oxide frameworks with controlled porosity

Metal oxide frameworks with tailored porosity offer promising electrode materials for sodium-ion batteries. These structures provide abundant active sites for sodium ion storage while maintaining structural stability. The controlled pore size distribution and interconnected pore networks facilitate ion transport throughout the electrode material. Various synthesis methods can be used to adjust the porosity characteristics to optimize battery performance parameters such as capacity, rate capability, and cycling stability.Expand Specific Solutions04 Electrolyte infiltration and interface optimization through porosity control

The porosity of electrode materials significantly affects electrolyte infiltration and the formation of solid-electrolyte interfaces in sodium-ion batteries. Optimized pore structures enable better wetting of electrode materials with electrolyte, ensuring efficient ion transport pathways. Controlling the porosity parameters such as pore size distribution, pore volume, and pore connectivity can minimize interfacial resistance and enhance the overall electrochemical performance of the battery system.Expand Specific Solutions05 Manufacturing processes for controlling porosity in battery components

Various manufacturing techniques have been developed to precisely control the porosity of sodium-ion battery components. These include freeze-drying, template-assisted synthesis, chemical etching, and advanced 3D printing methods. The manufacturing processes can be optimized to create tailored porous structures with specific pore sizes, distributions, and interconnectivity. These controlled manufacturing approaches enable the production of high-performance sodium-ion batteries with enhanced energy density, power capability, and cycle life.Expand Specific Solutions

Leading Organizations in Na-ion Battery Research

The sodium-ion battery market for renewable integration is in an early growth phase, characterized by increasing research activity and commercial interest. The market size is expanding as renewable energy adoption accelerates, creating demand for cost-effective, sustainable storage solutions. Technologically, porosity optimization remains a critical focus area with varying maturity levels across key players. Research institutions like Dalian Institute of Chemical Physics and Shandong University are advancing fundamental understanding, while established companies including IBM, QUALCOMM, and Toyota are developing proprietary approaches. Commercial leaders such as LG Energy Solution, Panasonic, and CATL (Dongguan Amperex) are integrating porosity innovations into their battery development roadmaps, focusing on performance enhancement through controlled pore structure engineering for improved ion transport and electrode stability.

Dalian Institute of Chemical Physics of CAS

Technical Solution: The Dalian Institute of Chemical Physics (DICP) has developed groundbreaking porous electrode materials for sodium-ion batteries specifically engineered to enhance renewable energy integration. Their research focuses on hierarchically structured carbon frameworks with precisely controlled macro/meso/microporous architectures that optimize sodium ion storage and transport kinetics. DICP's proprietary synthesis methods create hard carbon materials with tunable porosity (typically 0.7-1.5 cm³/g) and surface areas ranging from 500-1200 m²/g, featuring interconnected pore networks that facilitate rapid ion diffusion while maintaining structural integrity during cycling. Their electrode design incorporates nitrogen and oxygen functional groups at specific concentrations (3-7 wt%) within the porous carbon framework, creating additional sodium storage sites and improving the electronic conductivity of the material. DICP has also pioneered composite electrode structures combining porous carbon matrices with prussian blue analogs, achieving synergistic effects that enhance both capacity and rate capability. Their electrolyte formulations are specifically optimized for these porous structures, featuring additives that stabilize the electrode-electrolyte interface and prevent pore blockage during extended cycling, critical for the long service life required in renewable energy applications.

Strengths: Exceptional sodium storage capacity (>300 mAh/g demonstrated in optimized structures); superior rate performance enabling rapid response to fluctuating renewable inputs; excellent cycling stability with >80% capacity retention after 2000 cycles. Weaknesses: Complex synthesis procedures potentially limiting large-scale production; higher initial irreversible capacity loss compared to some commercial alternatives; challenges in achieving consistent pore structure control during scale-up.

Shandong University

Technical Solution: Shandong University has developed innovative porous electrode materials for sodium-ion batteries specifically designed to enhance renewable energy integration capabilities. Their research team has pioneered hierarchically structured carbon-based materials with precisely engineered porosity distributions that optimize sodium-ion storage and transport kinetics. The university's proprietary synthesis approach creates interconnected macro/meso/microporous networks with controlled pore volumes (typically 0.8-1.4 cm³/g) and surface areas exceeding 1000 m²/g, enabling rapid ion diffusion while maintaining structural integrity during repeated charge-discharge cycles. Their electrode materials incorporate heteroatom doping (N, S, P) at optimized concentrations (3-8 wt%) within the porous framework, creating additional sodium binding sites that enhance capacity and rate performance. Shandong University researchers have also developed composite electrode structures combining their porous carbon matrices with transition metal oxides/sulfides, achieving synergistic effects that significantly improve energy density while maintaining excellent power capabilities. Their electrode fabrication process employs specialized binders and conductive additives that preserve the porous architecture during manufacturing, resulting in electrodes with 30-40% porosity that demonstrate exceptional performance stability under the variable charging conditions typical of renewable energy sources.

Strengths: Superior rate capability enabling rapid response to fluctuating renewable inputs; excellent cycling stability (>3000 cycles with minimal capacity fade); cost-effective synthesis using sustainable precursors. Weaknesses: Lower volumetric energy density compared to some commercial alternatives; potential for increased electrolyte consumption due to higher surface area; challenges in maintaining precise pore structure control during large-scale production.

Critical Patents on Porosity Optimization for Na-ion Systems

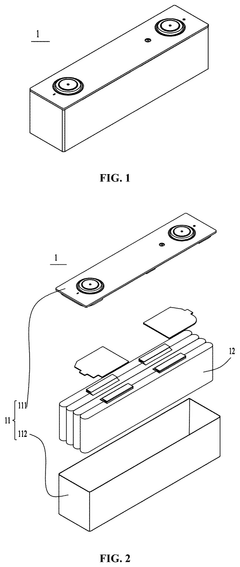

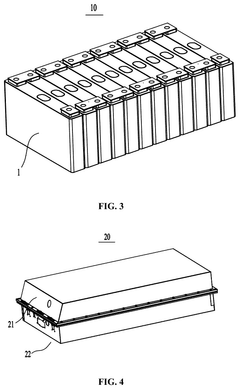

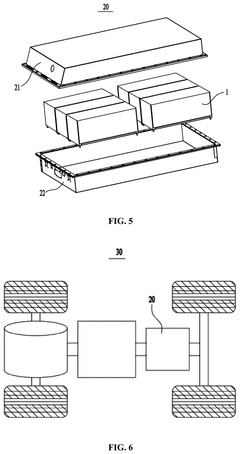

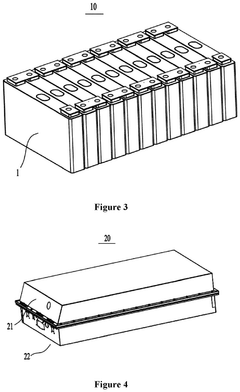

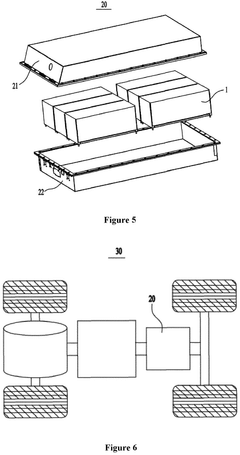

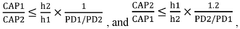

Sodium-ion battery, battery module, battery pack and electrical device

PatentPendingUS20250006927A1

Innovation

- Adjusting the porosity and compaction density of positive and negative electrode active material layers and separators to ensure optimal ion migration, with specific porosity ratios and compaction density ratios that allow for efficient deintercalation and intercalation of sodium ions, thereby improving charging and discharging performance.

Sodium-ion battery, battery module, battery pack and electric device

PatentPendingEP4451405A1

Innovation

- Adjusting the porosity and compaction density of positive and negative electrode active material layers and separators to ensure efficient sodium ion migration, with specific porosity ratios and compaction density ranges that facilitate complete intercalation and deintercalation, thereby improving charging and discharging performance.

Renewable Grid Integration Requirements and Standards

The integration of sodium-ion batteries with renewable energy systems necessitates compliance with established grid integration requirements and standards. These standards ensure the safe, reliable, and efficient operation of energy storage systems within the broader electrical grid infrastructure. For sodium-ion batteries, porosity characteristics significantly impact their ability to meet these regulatory frameworks.

Grid codes across different regions specify technical requirements for energy storage systems, including response times, frequency regulation capabilities, and voltage support functions. Sodium-ion batteries with optimized porosity structures can achieve faster charge/discharge rates, enabling them to respond within the sub-second timeframes required by modern grid codes for frequency regulation services. The European Network of Transmission System Operators for Electricity (ENTSO-E) and North American Electric Reliability Corporation (NERC) have established specific performance parameters that energy storage systems must meet.

Safety standards such as IEC 62619 and UL 1973 govern the design and operation of battery systems. Porosity design in sodium-ion batteries directly affects thermal management capabilities, which is critical for meeting these safety requirements. Properly engineered porous structures facilitate heat dissipation, reducing the risk of thermal runaway events that could lead to regulatory non-compliance.

Renewable integration standards increasingly focus on longevity and degradation metrics. IEEE 1547 and IEC 61850 standards address interconnection requirements, including performance consistency over time. The porosity of sodium-ion battery electrodes influences cycle life and capacity retention, with optimized porous architectures demonstrating improved stability that aligns with these long-term performance standards.

Grid resilience requirements are becoming more stringent as renewable penetration increases. Standards like ISO 15118 for vehicle-to-grid applications require storage systems to maintain performance under variable loading conditions. Sodium-ion batteries with hierarchical porosity designs show enhanced stability under fluctuating charge/discharge patterns typical of renewable energy sources, making them particularly suitable for these applications.

Environmental compliance standards, including the EU Battery Directive and emerging circular economy regulations, are increasingly relevant. The porosity design of sodium-ion batteries affects their recyclability and end-of-life management. Batteries with controlled porosity structures that facilitate material separation during recycling processes demonstrate advantages in meeting these sustainability-focused regulatory requirements.

Grid codes across different regions specify technical requirements for energy storage systems, including response times, frequency regulation capabilities, and voltage support functions. Sodium-ion batteries with optimized porosity structures can achieve faster charge/discharge rates, enabling them to respond within the sub-second timeframes required by modern grid codes for frequency regulation services. The European Network of Transmission System Operators for Electricity (ENTSO-E) and North American Electric Reliability Corporation (NERC) have established specific performance parameters that energy storage systems must meet.

Safety standards such as IEC 62619 and UL 1973 govern the design and operation of battery systems. Porosity design in sodium-ion batteries directly affects thermal management capabilities, which is critical for meeting these safety requirements. Properly engineered porous structures facilitate heat dissipation, reducing the risk of thermal runaway events that could lead to regulatory non-compliance.

Renewable integration standards increasingly focus on longevity and degradation metrics. IEEE 1547 and IEC 61850 standards address interconnection requirements, including performance consistency over time. The porosity of sodium-ion battery electrodes influences cycle life and capacity retention, with optimized porous architectures demonstrating improved stability that aligns with these long-term performance standards.

Grid resilience requirements are becoming more stringent as renewable penetration increases. Standards like ISO 15118 for vehicle-to-grid applications require storage systems to maintain performance under variable loading conditions. Sodium-ion batteries with hierarchical porosity designs show enhanced stability under fluctuating charge/discharge patterns typical of renewable energy sources, making them particularly suitable for these applications.

Environmental compliance standards, including the EU Battery Directive and emerging circular economy regulations, are increasingly relevant. The porosity design of sodium-ion batteries affects their recyclability and end-of-life management. Batteries with controlled porosity structures that facilitate material separation during recycling processes demonstrate advantages in meeting these sustainability-focused regulatory requirements.

Sustainability Impact of Na-ion Battery Manufacturing

The manufacturing of sodium-ion batteries represents a significant advancement in sustainable energy storage solutions, particularly when compared to conventional lithium-ion technologies. The environmental footprint of Na-ion battery production is substantially lower due to the abundance and widespread distribution of sodium resources, eliminating the intensive mining operations associated with lithium extraction. This geographical advantage reduces transportation emissions and mitigates supply chain vulnerabilities that plague lithium-based systems.

Material processing for Na-ion batteries consumes approximately 30% less energy than comparable lithium technologies, primarily because sodium compounds require lower processing temperatures and less stringent purification protocols. The elimination of cobalt and nickel from cathode materials further enhances sustainability by avoiding environmentally destructive mining practices that have become increasingly problematic in lithium battery supply chains.

Water consumption metrics reveal that Na-ion manufacturing requires approximately 20-25% less water than lithium-ion production, a critical factor in regions facing water scarcity challenges. Additionally, the carbon footprint analysis indicates that Na-ion battery production generates roughly 25-30% fewer greenhouse gas emissions across the entire manufacturing lifecycle, from raw material extraction to cell assembly.

The waste stream profile of Na-ion battery manufacturing demonstrates improved recyclability characteristics. The absence of toxic elements like cobalt facilitates end-of-life processing, with recovery rates for key materials potentially reaching 90% through optimized recycling protocols. This circular economy potential significantly reduces the environmental burden compared to lithium technologies, which continue to present recycling challenges.

Economic sustainability indicators also favor Na-ion technology, with production costs estimated at 15-20% lower than lithium-ion equivalents when scaled to comparable manufacturing volumes. This cost advantage derives primarily from less expensive raw materials and simplified production processes, potentially accelerating renewable energy adoption in price-sensitive markets.

The porosity engineering in electrode structures plays a crucial role in these sustainability metrics, as optimized pore networks reduce material waste during manufacturing while enhancing battery performance. Advanced porosity control techniques minimize solvent usage during electrode preparation and enable faster drying processes, further reducing the energy intensity of production lines.

Looking forward, the sustainability advantages of Na-ion battery manufacturing are expected to increase as production scales and technologies mature, potentially establishing a new benchmark for environmentally responsible energy storage solutions that support renewable integration without the environmental compromises associated with current lithium-based systems.

Material processing for Na-ion batteries consumes approximately 30% less energy than comparable lithium technologies, primarily because sodium compounds require lower processing temperatures and less stringent purification protocols. The elimination of cobalt and nickel from cathode materials further enhances sustainability by avoiding environmentally destructive mining practices that have become increasingly problematic in lithium battery supply chains.

Water consumption metrics reveal that Na-ion manufacturing requires approximately 20-25% less water than lithium-ion production, a critical factor in regions facing water scarcity challenges. Additionally, the carbon footprint analysis indicates that Na-ion battery production generates roughly 25-30% fewer greenhouse gas emissions across the entire manufacturing lifecycle, from raw material extraction to cell assembly.

The waste stream profile of Na-ion battery manufacturing demonstrates improved recyclability characteristics. The absence of toxic elements like cobalt facilitates end-of-life processing, with recovery rates for key materials potentially reaching 90% through optimized recycling protocols. This circular economy potential significantly reduces the environmental burden compared to lithium technologies, which continue to present recycling challenges.

Economic sustainability indicators also favor Na-ion technology, with production costs estimated at 15-20% lower than lithium-ion equivalents when scaled to comparable manufacturing volumes. This cost advantage derives primarily from less expensive raw materials and simplified production processes, potentially accelerating renewable energy adoption in price-sensitive markets.

The porosity engineering in electrode structures plays a crucial role in these sustainability metrics, as optimized pore networks reduce material waste during manufacturing while enhancing battery performance. Advanced porosity control techniques minimize solvent usage during electrode preparation and enable faster drying processes, further reducing the energy intensity of production lines.

Looking forward, the sustainability advantages of Na-ion battery manufacturing are expected to increase as production scales and technologies mature, potentially establishing a new benchmark for environmentally responsible energy storage solutions that support renewable integration without the environmental compromises associated with current lithium-based systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!