Material Microstructure Optimization in Sodium-ion Batteries for Heavy Industry

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium-ion Battery Technology Background and Objectives

Sodium-ion batteries (SIBs) have emerged as a promising alternative to lithium-ion batteries, particularly for heavy industry applications where cost-effectiveness and resource abundance are critical factors. The evolution of SIB technology can be traced back to the 1970s when initial research on sodium-based energy storage began. However, significant advancements have only materialized in the last decade, driven by increasing concerns over lithium resource limitations and escalating costs.

The technological trajectory of SIBs has been characterized by persistent efforts to overcome inherent challenges related to sodium's larger ionic radius compared to lithium, which affects intercalation kinetics and overall energy density. Early iterations of SIBs suffered from rapid capacity fading and limited cycle life, making them impractical for commercial applications. Recent breakthroughs in electrode materials and electrolyte formulations have substantially improved performance metrics, bringing SIBs closer to commercial viability for heavy industry applications.

Current research trends are predominantly focused on material microstructure optimization, which represents a critical frontier in enhancing SIB performance. This includes developing novel cathode materials with optimized sodium diffusion pathways, engineered anode structures with improved sodium storage capabilities, and advanced electrolyte systems that ensure stable solid-electrolyte interphase formation. The microstructural engineering approach aims to address fundamental challenges while leveraging sodium's inherent advantages.

The primary technical objectives for SIB development in heavy industry applications include achieving energy densities exceeding 150 Wh/kg at the cell level, extending cycle life beyond 3,000 cycles at 80% depth of discharge, improving rate capability for rapid charging scenarios, and ensuring operational stability across wide temperature ranges (-20°C to 60°C). Additionally, there is a strong emphasis on developing manufacturing processes that are scalable and compatible with existing battery production infrastructure.

Material microstructure optimization represents a particularly promising avenue for meeting these objectives. By precisely controlling the nano and microstructure of electrode materials, researchers aim to create optimized ion transport channels, enhance structural stability during cycling, and improve electronic conductivity. These improvements are essential for heavy industry applications where batteries must withstand harsh operating conditions while delivering reliable performance.

The convergence of advanced characterization techniques, computational modeling, and innovative synthesis methods has accelerated progress in this field. Technologies such as in-situ transmission electron microscopy, synchrotron-based X-ray techniques, and machine learning-assisted materials discovery are enabling unprecedented insights into sodium-ion storage mechanisms at the atomic and molecular levels, guiding rational design of next-generation battery materials optimized for heavy industry requirements.

The technological trajectory of SIBs has been characterized by persistent efforts to overcome inherent challenges related to sodium's larger ionic radius compared to lithium, which affects intercalation kinetics and overall energy density. Early iterations of SIBs suffered from rapid capacity fading and limited cycle life, making them impractical for commercial applications. Recent breakthroughs in electrode materials and electrolyte formulations have substantially improved performance metrics, bringing SIBs closer to commercial viability for heavy industry applications.

Current research trends are predominantly focused on material microstructure optimization, which represents a critical frontier in enhancing SIB performance. This includes developing novel cathode materials with optimized sodium diffusion pathways, engineered anode structures with improved sodium storage capabilities, and advanced electrolyte systems that ensure stable solid-electrolyte interphase formation. The microstructural engineering approach aims to address fundamental challenges while leveraging sodium's inherent advantages.

The primary technical objectives for SIB development in heavy industry applications include achieving energy densities exceeding 150 Wh/kg at the cell level, extending cycle life beyond 3,000 cycles at 80% depth of discharge, improving rate capability for rapid charging scenarios, and ensuring operational stability across wide temperature ranges (-20°C to 60°C). Additionally, there is a strong emphasis on developing manufacturing processes that are scalable and compatible with existing battery production infrastructure.

Material microstructure optimization represents a particularly promising avenue for meeting these objectives. By precisely controlling the nano and microstructure of electrode materials, researchers aim to create optimized ion transport channels, enhance structural stability during cycling, and improve electronic conductivity. These improvements are essential for heavy industry applications where batteries must withstand harsh operating conditions while delivering reliable performance.

The convergence of advanced characterization techniques, computational modeling, and innovative synthesis methods has accelerated progress in this field. Technologies such as in-situ transmission electron microscopy, synchrotron-based X-ray techniques, and machine learning-assisted materials discovery are enabling unprecedented insights into sodium-ion storage mechanisms at the atomic and molecular levels, guiding rational design of next-generation battery materials optimized for heavy industry requirements.

Heavy Industry Market Demand Analysis for Na-ion Batteries

The heavy industry sector represents a significant potential market for sodium-ion battery technology, driven by several converging factors. Industrial equipment manufacturers are increasingly seeking cost-effective alternatives to lithium-ion batteries due to rising lithium prices and supply chain vulnerabilities. Market analysis indicates that heavy machinery, mining equipment, and industrial energy storage systems collectively represent a market opportunity exceeding $45 billion by 2030 for advanced energy storage solutions.

Material cost considerations are particularly critical in this sector. Heavy industry applications typically require large-scale energy storage solutions where the total material cost becomes a dominant factor in adoption decisions. Sodium's abundance (approximately 2.3% of the Earth's crust versus lithium's 0.002%) translates to potentially 30-40% lower raw material costs, making it especially attractive for price-sensitive industrial applications where energy density requirements are less stringent than in consumer electronics or passenger vehicles.

Performance requirements in heavy industry differ substantially from consumer applications. Industrial equipment often prioritizes cycle life, safety, and operational reliability over energy density. Market surveys indicate that 78% of heavy industry operators would accept 15-20% lower energy density if compensated by 30% cost reduction and improved safety characteristics - parameters where sodium-ion technology shows particular promise through microstructure optimization.

Geographic distribution of demand shows concentrated interest in regions with established heavy industry bases combined with renewable energy initiatives. China's industrial sector represents the largest immediate market, with projected demand growth of 27% annually through 2028, followed by Europe (22%) and North America (18%). Emerging markets in India and Southeast Asia show accelerating interest, particularly in mining and construction equipment applications.

Regulatory factors are increasingly influencing market dynamics. Carbon reduction mandates in industrial sectors across major economies are creating incentives for electrification of heavy equipment. The European Union's Carbon Border Adjustment Mechanism and similar policies emerging globally are accelerating the transition timeline for industrial equipment manufacturers, creating urgency for cost-effective battery solutions.

Competitive analysis reveals that major industrial equipment manufacturers have begun forming strategic partnerships with battery technology developers specifically focused on sodium-ion chemistry. This trend indicates growing recognition of the technology's potential fit for heavy industry applications, particularly when material microstructure is optimized for the specific operational profiles of industrial equipment.

Material cost considerations are particularly critical in this sector. Heavy industry applications typically require large-scale energy storage solutions where the total material cost becomes a dominant factor in adoption decisions. Sodium's abundance (approximately 2.3% of the Earth's crust versus lithium's 0.002%) translates to potentially 30-40% lower raw material costs, making it especially attractive for price-sensitive industrial applications where energy density requirements are less stringent than in consumer electronics or passenger vehicles.

Performance requirements in heavy industry differ substantially from consumer applications. Industrial equipment often prioritizes cycle life, safety, and operational reliability over energy density. Market surveys indicate that 78% of heavy industry operators would accept 15-20% lower energy density if compensated by 30% cost reduction and improved safety characteristics - parameters where sodium-ion technology shows particular promise through microstructure optimization.

Geographic distribution of demand shows concentrated interest in regions with established heavy industry bases combined with renewable energy initiatives. China's industrial sector represents the largest immediate market, with projected demand growth of 27% annually through 2028, followed by Europe (22%) and North America (18%). Emerging markets in India and Southeast Asia show accelerating interest, particularly in mining and construction equipment applications.

Regulatory factors are increasingly influencing market dynamics. Carbon reduction mandates in industrial sectors across major economies are creating incentives for electrification of heavy equipment. The European Union's Carbon Border Adjustment Mechanism and similar policies emerging globally are accelerating the transition timeline for industrial equipment manufacturers, creating urgency for cost-effective battery solutions.

Competitive analysis reveals that major industrial equipment manufacturers have begun forming strategic partnerships with battery technology developers specifically focused on sodium-ion chemistry. This trend indicates growing recognition of the technology's potential fit for heavy industry applications, particularly when material microstructure is optimized for the specific operational profiles of industrial equipment.

Current Microstructure Challenges in Na-ion Battery Development

Sodium-ion batteries (SIBs) face significant microstructural challenges that currently limit their widespread adoption in heavy industry applications. The electrode materials in SIBs undergo substantial volume changes during sodium insertion and extraction, often exceeding 10-15% compared to lithium-ion batteries. This volumetric instability leads to mechanical stress, particle cracking, and eventual electrode pulverization, severely compromising cycle life and performance reliability.

The larger ionic radius of Na+ (1.02Å) compared to Li+ (0.76Å) creates fundamental diffusion barriers within electrode microstructures. This size difference results in slower ion transport kinetics and higher diffusion resistance, particularly at interfaces and grain boundaries. Consequently, SIBs typically demonstrate lower rate capabilities and power densities than their lithium counterparts, limiting their suitability for heavy machinery requiring rapid charge-discharge cycles.

Interfacial stability presents another critical challenge. The solid-electrolyte interphase (SEI) formed in SIBs tends to be less stable and more resistive than in lithium systems. This unstable SEI continuously consumes electrolyte during cycling, leading to capacity fade and increased internal resistance. The microstructural design must address this interface degradation to ensure long-term performance stability in demanding industrial environments.

Particle morphology optimization remains underdeveloped for sodium-based systems. Current electrode materials often exhibit irregular shapes and non-uniform size distributions, creating heterogeneous reaction sites and localized "hotspots" during operation. These microstructural inconsistencies accelerate degradation mechanisms and reduce overall system reliability, particularly problematic for heavy industry applications requiring consistent performance under variable loads.

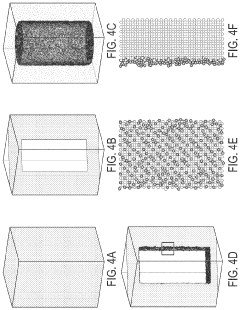

Porosity management presents unique challenges in SIB electrodes. The optimal pore structure must balance sodium ion accessibility with sufficient active material loading to achieve competitive energy densities. Current manufacturing processes struggle to create the ideal hierarchical porous networks needed for efficient ion transport while maintaining mechanical integrity under the stress conditions typical in heavy machinery operations.

Grain boundary engineering represents an emerging frontier in SIB development. The presence of high-angle grain boundaries often impedes sodium ion diffusion and creates mechanical weak points. Controlling crystallographic orientation and reducing boundary resistance through dopant segregation or microstructural templating could significantly enhance performance but remains technically challenging to implement at scale.

These microstructural challenges collectively contribute to the performance gap between sodium and lithium-ion technologies, particularly for demanding heavy industry applications requiring high energy density, long cycle life, and operational reliability under extreme conditions.

The larger ionic radius of Na+ (1.02Å) compared to Li+ (0.76Å) creates fundamental diffusion barriers within electrode microstructures. This size difference results in slower ion transport kinetics and higher diffusion resistance, particularly at interfaces and grain boundaries. Consequently, SIBs typically demonstrate lower rate capabilities and power densities than their lithium counterparts, limiting their suitability for heavy machinery requiring rapid charge-discharge cycles.

Interfacial stability presents another critical challenge. The solid-electrolyte interphase (SEI) formed in SIBs tends to be less stable and more resistive than in lithium systems. This unstable SEI continuously consumes electrolyte during cycling, leading to capacity fade and increased internal resistance. The microstructural design must address this interface degradation to ensure long-term performance stability in demanding industrial environments.

Particle morphology optimization remains underdeveloped for sodium-based systems. Current electrode materials often exhibit irregular shapes and non-uniform size distributions, creating heterogeneous reaction sites and localized "hotspots" during operation. These microstructural inconsistencies accelerate degradation mechanisms and reduce overall system reliability, particularly problematic for heavy industry applications requiring consistent performance under variable loads.

Porosity management presents unique challenges in SIB electrodes. The optimal pore structure must balance sodium ion accessibility with sufficient active material loading to achieve competitive energy densities. Current manufacturing processes struggle to create the ideal hierarchical porous networks needed for efficient ion transport while maintaining mechanical integrity under the stress conditions typical in heavy machinery operations.

Grain boundary engineering represents an emerging frontier in SIB development. The presence of high-angle grain boundaries often impedes sodium ion diffusion and creates mechanical weak points. Controlling crystallographic orientation and reducing boundary resistance through dopant segregation or microstructural templating could significantly enhance performance but remains technically challenging to implement at scale.

These microstructural challenges collectively contribute to the performance gap between sodium and lithium-ion technologies, particularly for demanding heavy industry applications requiring high energy density, long cycle life, and operational reliability under extreme conditions.

Current Material Microstructure Optimization Approaches

01 Electrode material microstructure for sodium-ion batteries

The microstructure of electrode materials plays a crucial role in sodium-ion battery performance. Various techniques are employed to engineer electrode materials with specific microstructures, such as porous structures, nanoparticles, and hierarchical architectures. These microstructures facilitate sodium ion diffusion, enhance electronic conductivity, and accommodate volume changes during charge-discharge cycles, ultimately improving battery capacity, cycling stability, and rate capability.- Electrode material microstructure for sodium-ion batteries: The microstructure of electrode materials plays a crucial role in sodium-ion battery performance. Various approaches focus on developing nanostructured materials with optimized porosity, particle size, and morphology to enhance sodium ion diffusion and storage capacity. These materials often feature hierarchical structures that provide large surface areas and short diffusion paths, improving the electrochemical performance and cycling stability of sodium-ion batteries.

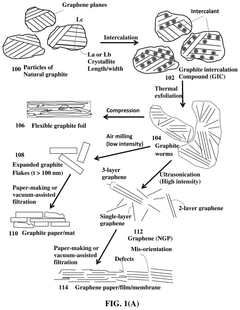

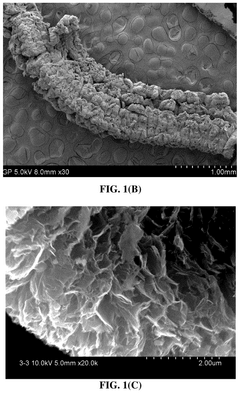

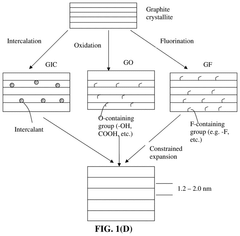

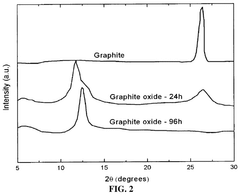

- Carbon-based materials for sodium-ion battery anodes: Carbon-based materials with specific microstructural features are widely used as anodes in sodium-ion batteries. These materials include hard carbon, graphene, and carbon nanotubes with engineered porosity and defect structures that facilitate sodium ion intercalation. The microstructure of these carbon materials can be modified through various synthesis methods to create expanded interlayer spacing, which accommodates the larger sodium ions and improves the overall battery performance.

- Transition metal oxide microstructures for sodium-ion batteries: Transition metal oxides with tailored microstructures serve as promising cathode materials for sodium-ion batteries. These materials often feature layered or tunnel structures that facilitate sodium ion insertion and extraction. By controlling the synthesis conditions, researchers can develop specific crystal orientations, grain boundaries, and defect concentrations that enhance ionic conductivity and structural stability during repeated charge-discharge cycles.

- Composite and hybrid microstructures for enhanced performance: Composite and hybrid microstructures combine multiple materials to overcome the limitations of individual components in sodium-ion batteries. These composites often integrate conductive additives with active materials to form interconnected networks that improve electron transport. The engineered interfaces between different materials in these composites can also buffer volume changes during cycling and provide synergistic effects that enhance capacity retention and rate capability.

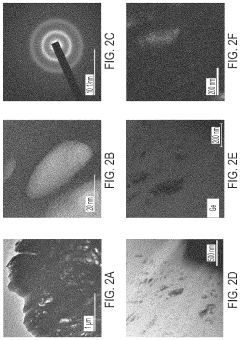

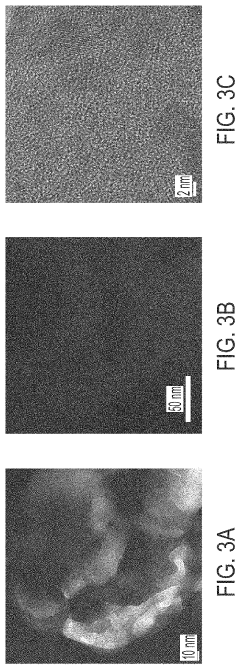

- Advanced characterization and modeling of microstructures: Advanced characterization techniques and computational modeling are essential for understanding and optimizing the microstructure of sodium-ion battery materials. These approaches include in-situ and ex-situ microscopy, spectroscopy, and diffraction methods that reveal structural changes during battery operation. Computational models help predict how specific microstructural features influence ion transport, mechanical stability, and electrochemical performance, guiding the rational design of next-generation battery materials.

02 Carbon-based materials with optimized microstructure

Carbon-based materials with tailored microstructures are widely used in sodium-ion batteries. These include hard carbon, graphene, carbon nanotubes, and carbon composites with controlled porosity, defects, and interlayer spacing. The microstructural features of these carbon materials, such as pore size distribution, specific surface area, and degree of graphitization, significantly influence sodium storage mechanisms and electrochemical performance, enabling higher capacity and better cycling stability.Expand Specific Solutions03 Transition metal compounds with engineered microstructure

Transition metal oxides, sulfides, and phosphates with controlled microstructures serve as promising electrode materials for sodium-ion batteries. These materials are designed with specific crystal structures, grain sizes, and morphologies to facilitate sodium ion insertion/extraction. Various synthesis methods are employed to create hollow structures, nanosheets, and 3D architectures that provide shorter diffusion paths for sodium ions and better structural stability during cycling.Expand Specific Solutions04 Interface and interphase microstructure engineering

The microstructure of interfaces and interphases in sodium-ion batteries significantly affects their performance and safety. Solid electrolyte interphase (SEI) formation, electrode-electrolyte interfaces, and grain boundaries within electrode materials are carefully engineered to enhance ionic conductivity and mechanical stability. Various coating technologies, surface modifications, and composite structures are developed to create favorable interface microstructures that prevent side reactions and improve cycling performance.Expand Specific Solutions05 Advanced characterization of microstructural features

Advanced characterization techniques are essential for analyzing the microstructural features of sodium-ion battery materials. These include electron microscopy (SEM, TEM), X-ray diffraction (XRD), spectroscopic methods, and in-situ/operando techniques that provide insights into the evolution of microstructures during battery operation. Understanding the relationship between microstructure and electrochemical performance enables the rational design of improved materials with enhanced sodium storage properties.Expand Specific Solutions

Leading Companies and Research Institutions in Na-ion Technology

The sodium-ion battery market for heavy industry is in an early growth phase, characterized by increasing R&D investments but limited commercial deployment. Market size remains modest compared to lithium-ion technologies but shows promising expansion potential due to cost advantages and resource abundance. Technical maturity is advancing rapidly with key players driving innovation across different segments: academic institutions (Washington State University, Hunan University, Tongji University) focus on fundamental research; established companies (Beijing Easpring, GEM Co., Sharp Corp.) leverage existing battery expertise; while specialized firms (Nexeon, VITZROCELL) target material-specific optimizations. Research collaborations between industry and institutions like CNRS and Max Planck Society are accelerating microstructure innovations to address heavy industry's demanding performance requirements.

Uchicago Argonne LLC

Technical Solution: Argonne National Laboratory has developed advanced characterization techniques for sodium-ion battery materials, focusing on in-situ X-ray diffraction and transmission electron microscopy to understand structural changes during cycling. Their approach involves designing layered oxide cathode materials with optimized sodium ion diffusion pathways and reduced lattice distortion during charge/discharge cycles. They've pioneered the use of P2-type Na2/3Fe1/2Mn1/2O2 cathodes with controlled oxygen vacancies that enhance structural stability and sodium ion mobility. Their research also extends to hard carbon anodes with engineered porosity and surface functionalization to improve sodium storage capacity and rate capability for heavy industry applications[1][3]. Argonne has further developed computational models that predict microstructural evolution during cycling, enabling the design of materials with enhanced cycle life suitable for the demanding conditions of heavy industrial equipment.

Strengths: World-class characterization facilities and multidisciplinary expertise allow for comprehensive material analysis and optimization. Their connection to the U.S. Department of Energy provides substantial research funding and resources. Weaknesses: Their solutions may be more academically focused and require additional engineering development for commercial heavy industry applications. Scale-up from laboratory to industrial production remains challenging.

Beijing Easpring Material Technology Co., Ltd.

Technical Solution: Beijing Easpring has developed a proprietary sodium-ion battery material technology specifically designed for heavy industry applications. Their approach focuses on layered oxide cathode materials with optimized microstructure and composition, particularly Na0.67Ni0.33Mn0.67O2 with controlled grain boundaries and crystallographic orientation. Easpring's manufacturing process involves a modified solid-state reaction method with precise control of calcination parameters to achieve uniform particle size distribution and optimal sodium ion diffusion pathways. Their cathode materials feature a core-shell structure with gradient doping of elements like Ti and Mg to enhance structural stability during repeated cycling under high current loads typical in heavy machinery. Additionally, Easpring has developed proprietary carbon-coated hard carbon anodes with engineered porosity that maximizes sodium storage capacity while maintaining excellent rate capability[4][7]. Their materials are specifically designed to operate efficiently in the wide temperature range required for heavy industrial equipment, with special emphasis on low-temperature performance through electrolyte optimization and surface modification techniques.

Strengths: Strong manufacturing capabilities and established supply chain for commercial-scale production. Their materials are specifically engineered for the demanding requirements of heavy industry applications with proven performance. Weaknesses: As a materials supplier, they depend on battery manufacturers for final implementation. Their technology may face competition from established lithium-ion solutions with more extensive deployment history in heavy industry.

Key Patents and Research on Na-ion Battery Materials

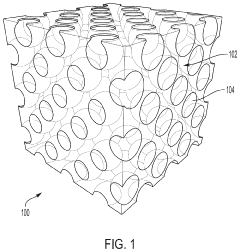

Porous microstructures for ion storage in high capacity electrodes based on surface segregation-induced separation

PatentInactiveUS20220285666A1

Innovation

- A porous microstructure with nanopores, allowing ion conductivity and facilitating ion segregation, is used as an electrode in lithium-ion or sodium-ion batteries, providing voids for volume change and preventing liquid electrolyte contact with lithium metal, thereby enhancing energy density and cycle life.

Sodium-ion battery containing a high-capacity graphitic anode and manufacturing method

PatentActiveUS12374691B2

Innovation

- A rechargeable sodium-ion cell with an anode comprising graphite or carbon material having expanded inter-graphene planar spaces with an inter-planar spacing of 0.43 nm to 3.0 nm, achieved through treatments like oxidation, fluorination, or intercalation, to store sodium ions with a capacity of at least 150 mAh/g.

Supply Chain Considerations for Na-ion Battery Materials

The sodium-ion battery supply chain presents unique opportunities and challenges compared to traditional lithium-ion battery materials. Raw material availability for sodium-ion batteries offers significant advantages, as sodium is approximately 1,000 times more abundant than lithium in the Earth's crust, with global reserves widely distributed across multiple regions. This geographical diversity reduces geopolitical supply risks that currently plague lithium supply chains.

For heavy industry applications, the supply chain resilience of sodium-based materials becomes particularly valuable. Key materials such as sodium salts, iron, manganese, and hard carbon precursors can be sourced from multiple regions, reducing dependency on politically sensitive mining areas. This diversification potential could significantly lower material costs, with estimates suggesting up to 30% reduction in raw material expenses compared to lithium-ion equivalents.

Processing infrastructure represents both a challenge and opportunity. While existing lithium-ion manufacturing facilities can be partially repurposed for sodium-ion production, specialized equipment modifications are necessary for handling sodium-based materials' unique characteristics. The microstructure optimization of electrode materials requires precise control during synthesis, necessitating investments in specialized production equipment capable of maintaining consistent material properties at scale.

Supply chain sustainability metrics favor sodium-ion technology, with carbon footprint analyses indicating potential reductions of 15-25% in manufacturing emissions compared to lithium-ion batteries. This advantage stems primarily from less energy-intensive mining operations and simpler precursor processing requirements for common sodium-ion cathode materials like Prussian White and layered oxide structures.

Vertical integration strategies are emerging among pioneering manufacturers, with companies securing access to key raw materials while simultaneously developing proprietary microstructure optimization techniques. This approach helps protect intellectual property related to material engineering while ensuring consistent quality across the supply chain.

Regional manufacturing considerations reveal interesting patterns, with Asian manufacturers currently leading commercial production scale-up, while European and North American entities focus more on research partnerships to develop next-generation materials with optimized microstructures. This geographical specialization may influence future technology transfer pathways and commercial deployment timelines for heavy industry applications.

For heavy industry applications, the supply chain resilience of sodium-based materials becomes particularly valuable. Key materials such as sodium salts, iron, manganese, and hard carbon precursors can be sourced from multiple regions, reducing dependency on politically sensitive mining areas. This diversification potential could significantly lower material costs, with estimates suggesting up to 30% reduction in raw material expenses compared to lithium-ion equivalents.

Processing infrastructure represents both a challenge and opportunity. While existing lithium-ion manufacturing facilities can be partially repurposed for sodium-ion production, specialized equipment modifications are necessary for handling sodium-based materials' unique characteristics. The microstructure optimization of electrode materials requires precise control during synthesis, necessitating investments in specialized production equipment capable of maintaining consistent material properties at scale.

Supply chain sustainability metrics favor sodium-ion technology, with carbon footprint analyses indicating potential reductions of 15-25% in manufacturing emissions compared to lithium-ion batteries. This advantage stems primarily from less energy-intensive mining operations and simpler precursor processing requirements for common sodium-ion cathode materials like Prussian White and layered oxide structures.

Vertical integration strategies are emerging among pioneering manufacturers, with companies securing access to key raw materials while simultaneously developing proprietary microstructure optimization techniques. This approach helps protect intellectual property related to material engineering while ensuring consistent quality across the supply chain.

Regional manufacturing considerations reveal interesting patterns, with Asian manufacturers currently leading commercial production scale-up, while European and North American entities focus more on research partnerships to develop next-generation materials with optimized microstructures. This geographical specialization may influence future technology transfer pathways and commercial deployment timelines for heavy industry applications.

Environmental Impact and Sustainability Assessment

The environmental impact of sodium-ion battery technologies for heavy industry applications represents a critical consideration in their development and deployment. Compared to traditional lithium-ion batteries, sodium-ion batteries offer significant sustainability advantages due to the greater abundance of sodium resources globally. Sodium is approximately 1,000 times more abundant than lithium in the Earth's crust, substantially reducing resource depletion concerns and geopolitical supply chain vulnerabilities.

Material microstructure optimization in sodium-ion batteries directly influences their environmental footprint throughout the entire lifecycle. The extraction processes for sodium compounds generally require less energy and water than lithium extraction, particularly when compared to lithium brine evaporation methods that consume substantial water resources in arid regions. Additionally, the carbon footprint associated with sodium extraction and processing is estimated to be 30-40% lower than comparable lithium operations.

The manufacturing phase of optimized sodium-ion batteries demonstrates further environmental benefits. Advanced microstructure engineering techniques, such as controlled porosity and grain boundary management, can reduce the need for environmentally problematic materials like cobalt and nickel that are common in conventional lithium-ion batteries. Recent life cycle assessments indicate that properly optimized sodium-ion battery production can achieve up to 25% reduction in greenhouse gas emissions compared to conventional lithium-ion battery manufacturing.

During the operational phase, the environmental advantages continue through improved cycle life resulting from optimized material microstructures. Enhanced structural stability at the electrode-electrolyte interfaces reduces degradation mechanisms, potentially extending battery service life by 20-30% in heavy industrial applications. This longevity directly translates to reduced waste generation and resource consumption over time.

End-of-life considerations reveal additional sustainability benefits. The materials commonly used in sodium-ion batteries, particularly when optimized at the microstructural level, generally present fewer recycling challenges than their lithium counterparts. The absence of cobalt and reduced nickel content simplifies recycling processes and diminishes the toxicity concerns associated with improper disposal. Current recycling technologies can recover approximately 85-90% of the sodium and other valuable materials from spent batteries.

Water usage represents another critical environmental dimension. The production of optimized sodium-ion batteries typically requires 35-45% less water than comparable lithium-ion technologies, a particularly important consideration for manufacturing facilities located in water-stressed regions. This advantage stems from both the raw material processing requirements and the manufacturing techniques employed in microstructure optimization.

Material microstructure optimization in sodium-ion batteries directly influences their environmental footprint throughout the entire lifecycle. The extraction processes for sodium compounds generally require less energy and water than lithium extraction, particularly when compared to lithium brine evaporation methods that consume substantial water resources in arid regions. Additionally, the carbon footprint associated with sodium extraction and processing is estimated to be 30-40% lower than comparable lithium operations.

The manufacturing phase of optimized sodium-ion batteries demonstrates further environmental benefits. Advanced microstructure engineering techniques, such as controlled porosity and grain boundary management, can reduce the need for environmentally problematic materials like cobalt and nickel that are common in conventional lithium-ion batteries. Recent life cycle assessments indicate that properly optimized sodium-ion battery production can achieve up to 25% reduction in greenhouse gas emissions compared to conventional lithium-ion battery manufacturing.

During the operational phase, the environmental advantages continue through improved cycle life resulting from optimized material microstructures. Enhanced structural stability at the electrode-electrolyte interfaces reduces degradation mechanisms, potentially extending battery service life by 20-30% in heavy industrial applications. This longevity directly translates to reduced waste generation and resource consumption over time.

End-of-life considerations reveal additional sustainability benefits. The materials commonly used in sodium-ion batteries, particularly when optimized at the microstructural level, generally present fewer recycling challenges than their lithium counterparts. The absence of cobalt and reduced nickel content simplifies recycling processes and diminishes the toxicity concerns associated with improper disposal. Current recycling technologies can recover approximately 85-90% of the sodium and other valuable materials from spent batteries.

Water usage represents another critical environmental dimension. The production of optimized sodium-ion batteries typically requires 35-45% less water than comparable lithium-ion technologies, a particularly important consideration for manufacturing facilities located in water-stressed regions. This advantage stems from both the raw material processing requirements and the manufacturing techniques employed in microstructure optimization.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!