Comparative Study: Sodium-ion vs Potassium-ion Batteries in Energy Storage Systems

OCT 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Na/K-ion Battery Evolution and Research Objectives

The evolution of energy storage technologies has witnessed significant advancements over the past decades, with lithium-ion batteries dominating the commercial landscape. However, concerns regarding lithium resource scarcity and geopolitical distribution have prompted researchers to explore alternative battery chemistries. Sodium-ion (Na-ion) and potassium-ion (K-ion) batteries have emerged as promising candidates due to their abundant resources and similar electrochemical properties to lithium-ion systems.

Na-ion battery research began in earnest during the 1980s but gained substantial momentum only in the early 2000s. The initial development focused primarily on layered oxide cathodes and hard carbon anodes. The technology has progressed through several generations, from proof-of-concept demonstrations to practical prototypes with energy densities approaching 160 Wh/kg. Recent breakthroughs in electrode materials, particularly Prussian blue analogs and layered transition metal oxides, have accelerated Na-ion battery development.

K-ion battery research, while less mature, has shown remarkable progress since 2015. The larger ionic radius of potassium compared to sodium initially presented challenges for intercalation chemistry. However, this property also offers advantages in terms of lower desolvation energy and potentially faster ion transport in certain electrolytes. The evolution of K-ion technology has been characterized by rapid advances in graphitic carbon anodes and Prussian blue cathodes.

The technical evolution trajectory for both systems reveals a common pattern: initial focus on fundamental electrochemistry, followed by material optimization, and eventually system-level engineering. Current research objectives center on addressing key limitations including cycle life, rate capability, and energy density. For Na-ion batteries, improving cathode specific capacity beyond 200 mAh/g represents a critical milestone. For K-ion systems, stabilizing the electrode-electrolyte interface remains a primary challenge.

Our research objectives in this comparative study are multifaceted. First, we aim to systematically evaluate the performance metrics of state-of-the-art Na-ion and K-ion batteries against established benchmarks. Second, we seek to identify application-specific advantages for each chemistry across different use cases including grid storage, electric mobility, and consumer electronics. Third, we intend to develop predictive models for technology readiness levels and commercialization timelines.

The ultimate goal is to establish a comprehensive technical roadmap that outlines the potential evolution paths for both technologies, highlighting critical research needs and technological bottlenecks that must be overcome to achieve commercial viability. This analysis will inform strategic R&D investments and partnership opportunities in the emerging post-lithium battery ecosystem.

Na-ion battery research began in earnest during the 1980s but gained substantial momentum only in the early 2000s. The initial development focused primarily on layered oxide cathodes and hard carbon anodes. The technology has progressed through several generations, from proof-of-concept demonstrations to practical prototypes with energy densities approaching 160 Wh/kg. Recent breakthroughs in electrode materials, particularly Prussian blue analogs and layered transition metal oxides, have accelerated Na-ion battery development.

K-ion battery research, while less mature, has shown remarkable progress since 2015. The larger ionic radius of potassium compared to sodium initially presented challenges for intercalation chemistry. However, this property also offers advantages in terms of lower desolvation energy and potentially faster ion transport in certain electrolytes. The evolution of K-ion technology has been characterized by rapid advances in graphitic carbon anodes and Prussian blue cathodes.

The technical evolution trajectory for both systems reveals a common pattern: initial focus on fundamental electrochemistry, followed by material optimization, and eventually system-level engineering. Current research objectives center on addressing key limitations including cycle life, rate capability, and energy density. For Na-ion batteries, improving cathode specific capacity beyond 200 mAh/g represents a critical milestone. For K-ion systems, stabilizing the electrode-electrolyte interface remains a primary challenge.

Our research objectives in this comparative study are multifaceted. First, we aim to systematically evaluate the performance metrics of state-of-the-art Na-ion and K-ion batteries against established benchmarks. Second, we seek to identify application-specific advantages for each chemistry across different use cases including grid storage, electric mobility, and consumer electronics. Third, we intend to develop predictive models for technology readiness levels and commercialization timelines.

The ultimate goal is to establish a comprehensive technical roadmap that outlines the potential evolution paths for both technologies, highlighting critical research needs and technological bottlenecks that must be overcome to achieve commercial viability. This analysis will inform strategic R&D investments and partnership opportunities in the emerging post-lithium battery ecosystem.

Market Analysis for Alternative Battery Technologies

The global battery market is experiencing a significant shift as alternatives to traditional lithium-ion batteries gain traction. Currently valued at approximately $112 billion in 2023, the alternative battery technologies segment is projected to grow at a CAGR of 18.9% through 2030, driven by increasing demand for sustainable energy storage solutions.

Sodium-ion and potassium-ion batteries represent emerging technologies within this landscape, collectively accounting for about 3% of the alternative battery market. However, their growth trajectory is steeper than the broader market, with analysts forecasting a 25-30% annual growth rate over the next five years as manufacturing scales and applications diversify.

The primary market drivers for these technologies include resource availability and cost advantages. Sodium and potassium are respectively 1,000 and 20 times more abundant in the Earth's crust than lithium, offering significant raw material cost reductions. This translates to potential 30-40% lower production costs compared to lithium-ion batteries, particularly appealing for grid-scale storage applications where cost per kWh is a critical factor.

Regional market dynamics show interesting patterns. China currently leads sodium-ion battery development with over 40% of global patents and production capacity, while European research institutions dominate potassium-ion technology advancement. North America has recently increased investment in both technologies, particularly for grid stabilization applications.

Application segmentation reveals distinct market opportunities. Sodium-ion batteries are gaining traction in stationary storage systems, particularly in regions with challenging temperature conditions, due to their superior low-temperature performance. Potassium-ion batteries show promise in high-power applications requiring rapid charging capabilities.

Market barriers include manufacturing scalability challenges and the entrenched position of lithium-ion technology. Current production capacity for both sodium and potassium-ion batteries remains limited to pilot plants and small-scale manufacturing lines, with combined global production capacity under 5 GWh annually.

Investment trends indicate growing market confidence, with venture capital funding for sodium-ion battery startups reaching $780 million in 2022, a 215% increase from 2020. Potassium-ion technology has attracted $340 million in the same period, demonstrating investor interest despite its earlier development stage.

Consumer and industrial adoption patterns suggest initial market penetration will occur in price-sensitive applications where energy density requirements are moderate, such as backup power systems and grid-level storage, before potentially expanding to consumer electronics and specialized mobility applications.

Sodium-ion and potassium-ion batteries represent emerging technologies within this landscape, collectively accounting for about 3% of the alternative battery market. However, their growth trajectory is steeper than the broader market, with analysts forecasting a 25-30% annual growth rate over the next five years as manufacturing scales and applications diversify.

The primary market drivers for these technologies include resource availability and cost advantages. Sodium and potassium are respectively 1,000 and 20 times more abundant in the Earth's crust than lithium, offering significant raw material cost reductions. This translates to potential 30-40% lower production costs compared to lithium-ion batteries, particularly appealing for grid-scale storage applications where cost per kWh is a critical factor.

Regional market dynamics show interesting patterns. China currently leads sodium-ion battery development with over 40% of global patents and production capacity, while European research institutions dominate potassium-ion technology advancement. North America has recently increased investment in both technologies, particularly for grid stabilization applications.

Application segmentation reveals distinct market opportunities. Sodium-ion batteries are gaining traction in stationary storage systems, particularly in regions with challenging temperature conditions, due to their superior low-temperature performance. Potassium-ion batteries show promise in high-power applications requiring rapid charging capabilities.

Market barriers include manufacturing scalability challenges and the entrenched position of lithium-ion technology. Current production capacity for both sodium and potassium-ion batteries remains limited to pilot plants and small-scale manufacturing lines, with combined global production capacity under 5 GWh annually.

Investment trends indicate growing market confidence, with venture capital funding for sodium-ion battery startups reaching $780 million in 2022, a 215% increase from 2020. Potassium-ion technology has attracted $340 million in the same period, demonstrating investor interest despite its earlier development stage.

Consumer and industrial adoption patterns suggest initial market penetration will occur in price-sensitive applications where energy density requirements are moderate, such as backup power systems and grid-level storage, before potentially expanding to consumer electronics and specialized mobility applications.

Technical Barriers in Na/K-ion Battery Development

Despite significant advancements in sodium-ion and potassium-ion battery technologies, several critical technical barriers continue to impede their widespread commercial adoption. These challenges must be addressed to position Na-ion and K-ion batteries as viable alternatives to lithium-ion technologies in energy storage systems.

For sodium-ion batteries, electrode material limitations represent a primary challenge. The larger ionic radius of Na+ (1.02Å) compared to Li+ (0.76Å) causes greater volume expansion during charge-discharge cycles, leading to structural instability and capacity fading. Current cathode materials struggle to maintain stable crystal structures during repeated Na+ insertion/extraction, resulting in diminished cycle life and energy density limitations typically below 160 Wh/kg.

Electrolyte decomposition presents another significant barrier for Na-ion systems. The standard electrode potential of Na/Na+ (-2.71V vs. SHE) is higher than Li/Li+ (-3.04V vs. SHE), narrowing the electrochemical stability window and causing accelerated electrolyte degradation. This results in continuous SEI layer formation, increased internal resistance, and reduced coulombic efficiency over extended cycling.

Potassium-ion batteries face even more severe challenges due to the larger ionic radius of K+ (1.38Å). This causes extreme volume changes during cycling, leading to mechanical stress that can fracture electrode materials and degrade battery performance. The heavier mass of potassium ions also negatively impacts gravimetric energy density, creating a fundamental limitation for weight-sensitive applications.

Both technologies suffer from inadequate anode materials. While graphite serves effectively for lithium-ion batteries, it demonstrates poor intercalation properties for sodium ions. Although hard carbon offers better performance for Na-ion batteries, its capacity remains limited to approximately 300 mAh/g, significantly below theoretical expectations. For K-ion batteries, graphite can be utilized but suffers from severe volume expansion exceeding 60% during potassiation.

Manufacturing scalability presents additional challenges. Current production infrastructure is optimized for lithium-ion technology, requiring substantial modifications for Na/K-ion battery production. The development of specialized manufacturing processes, quality control protocols, and equipment calibration for these alternative chemistries necessitates significant capital investment.

Safety concerns also persist, particularly for K-ion batteries. Potassium's higher reactivity with moisture compared to sodium creates additional handling challenges during manufacturing and raises concerns about thermal runaway events in damaged cells. The development of robust safety mechanisms and specialized battery management systems remains an ongoing research priority.

For sodium-ion batteries, electrode material limitations represent a primary challenge. The larger ionic radius of Na+ (1.02Å) compared to Li+ (0.76Å) causes greater volume expansion during charge-discharge cycles, leading to structural instability and capacity fading. Current cathode materials struggle to maintain stable crystal structures during repeated Na+ insertion/extraction, resulting in diminished cycle life and energy density limitations typically below 160 Wh/kg.

Electrolyte decomposition presents another significant barrier for Na-ion systems. The standard electrode potential of Na/Na+ (-2.71V vs. SHE) is higher than Li/Li+ (-3.04V vs. SHE), narrowing the electrochemical stability window and causing accelerated electrolyte degradation. This results in continuous SEI layer formation, increased internal resistance, and reduced coulombic efficiency over extended cycling.

Potassium-ion batteries face even more severe challenges due to the larger ionic radius of K+ (1.38Å). This causes extreme volume changes during cycling, leading to mechanical stress that can fracture electrode materials and degrade battery performance. The heavier mass of potassium ions also negatively impacts gravimetric energy density, creating a fundamental limitation for weight-sensitive applications.

Both technologies suffer from inadequate anode materials. While graphite serves effectively for lithium-ion batteries, it demonstrates poor intercalation properties for sodium ions. Although hard carbon offers better performance for Na-ion batteries, its capacity remains limited to approximately 300 mAh/g, significantly below theoretical expectations. For K-ion batteries, graphite can be utilized but suffers from severe volume expansion exceeding 60% during potassiation.

Manufacturing scalability presents additional challenges. Current production infrastructure is optimized for lithium-ion technology, requiring substantial modifications for Na/K-ion battery production. The development of specialized manufacturing processes, quality control protocols, and equipment calibration for these alternative chemistries necessitates significant capital investment.

Safety concerns also persist, particularly for K-ion batteries. Potassium's higher reactivity with moisture compared to sodium creates additional handling challenges during manufacturing and raises concerns about thermal runaway events in damaged cells. The development of robust safety mechanisms and specialized battery management systems remains an ongoing research priority.

Current Na/K-ion Battery Design Approaches

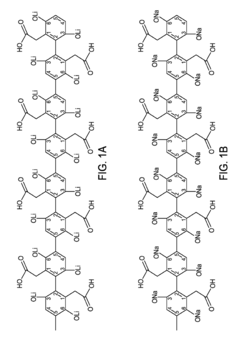

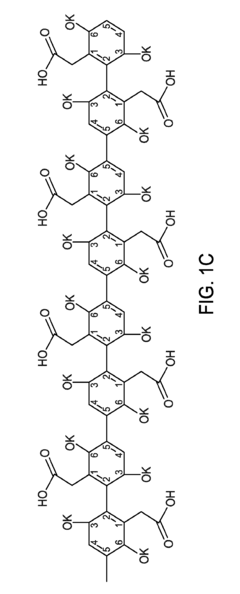

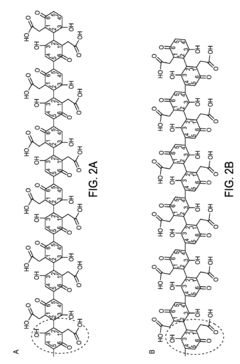

01 Electrode materials for sodium-ion and potassium-ion batteries

Various materials can be used as electrodes in sodium-ion and potassium-ion batteries to improve performance. These include carbon-based materials, metal oxides, and composite structures that enhance ion storage capacity and cycling stability. The selection of appropriate electrode materials is crucial for achieving high energy density and long cycle life in these alternative battery technologies.- Electrode materials for sodium-ion and potassium-ion batteries: Various materials can be used as electrodes in sodium-ion and potassium-ion batteries to improve performance. These include carbon-based materials, metal oxides, and composite structures that enhance ion storage capacity and cycling stability. The electrode materials are designed to accommodate the larger ionic radii of sodium and potassium ions compared to lithium ions, which requires specific structural considerations to facilitate efficient ion insertion and extraction.

- Electrolyte compositions for alkali metal batteries: Specialized electrolyte formulations are crucial for sodium-ion and potassium-ion batteries to ensure efficient ion transport between electrodes. These electrolytes typically consist of sodium or potassium salts dissolved in organic solvents, sometimes with additives to improve stability and conductivity. The electrolyte composition significantly affects battery performance metrics such as capacity, rate capability, and cycle life by influencing the formation of solid electrolyte interphase layers and ion mobility.

- Battery cell design and architecture: The physical design and architecture of sodium-ion and potassium-ion battery cells impact their overall performance and applicability. Innovations in cell configuration, including pouch, prismatic, and cylindrical formats, address challenges related to volume expansion during cycling and thermal management. Advanced cell designs incorporate features to accommodate the unique characteristics of sodium and potassium chemistries, such as specialized current collectors and optimized electrode spacing.

- Anode materials and modifications: Anode materials for sodium-ion and potassium-ion batteries require specific properties to accommodate the larger ion sizes compared to lithium-ion batteries. Hard carbon, soft carbon, and various alloys are being developed with tailored porosity and interlayer spacing. Surface modifications and doping strategies are employed to enhance the electrochemical performance, reduce volume expansion during cycling, and improve the reversibility of ion insertion and extraction processes.

- Manufacturing processes and scalability: Manufacturing techniques for sodium-ion and potassium-ion batteries focus on cost-effective and scalable production methods. These include specialized coating processes for electrodes, assembly techniques that account for the reactivity of alkali metals, and quality control measures specific to these battery chemistries. Innovations in manufacturing aim to reduce production costs while maintaining performance, addressing a key advantage of sodium and potassium technologies over lithium-ion batteries due to the greater abundance and lower cost of raw materials.

02 Electrolyte compositions for alkali metal batteries

Specialized electrolyte formulations are essential for sodium-ion and potassium-ion batteries to facilitate efficient ion transport between electrodes. These electrolytes may include organic solvents, ionic liquids, or solid-state electrolytes with additives that improve conductivity and electrochemical stability. The electrolyte composition significantly affects battery performance, safety, and operational temperature range.Expand Specific Solutions03 Battery structure and cell design innovations

Innovative structural designs for sodium-ion and potassium-ion batteries can overcome challenges related to ion size and intercalation kinetics. These designs include optimized electrode architectures, novel separator materials, and improved cell packaging that accommodate volume changes during cycling. Advanced manufacturing techniques are employed to enhance energy density, power capability, and mechanical stability.Expand Specific Solutions04 Anode materials and interfaces for alkali metal batteries

Specialized anode materials for sodium-ion and potassium-ion batteries are designed to accommodate larger ion sizes compared to lithium-ion batteries. These materials include hard carbons, alloys, and composite structures with engineered interfaces that minimize side reactions and improve cycling efficiency. Surface modifications and protective coatings are applied to enhance stability and prevent unwanted reactions with the electrolyte.Expand Specific Solutions05 Manufacturing processes and commercial applications

Advanced manufacturing techniques for sodium-ion and potassium-ion batteries focus on scalability, cost reduction, and performance optimization. These processes include specialized coating methods, precise control of material synthesis, and quality control measures that ensure consistency. The batteries are being developed for various applications including grid storage, electric vehicles, and consumer electronics, with emphasis on sustainability and reduced dependence on critical raw materials.Expand Specific Solutions

Industry Leaders in Na/K-ion Battery Research

The sodium-ion and potassium-ion battery market is currently in an early growth phase, characterized by increasing R&D investments but limited commercial deployment. The global market size is projected to reach $1.2 billion by 2025, with sodium-ion technologies showing greater near-term commercial viability. Leading players like Faradion Ltd. and BYD Co. are advancing sodium-ion technology, while potassium-ion research is primarily driven by academic institutions such as Tokyo University of Science and CNRS. Companies including GEM Co. and Guangdong Bangpu are focusing on recycling technologies for both battery types. The competitive landscape features collaboration between established battery manufacturers and research institutions, with Asian companies, particularly from China, dominating commercial development efforts.

Faradion Ltd.

Technical Solution: Faradion has pioneered sodium-ion battery technology with their proprietary Na-ion cell chemistry that uses abundant, low-cost materials. Their technology employs layered oxide cathodes (typically Na₃V₂(PO₄)₂F₃ or Na₂Fe₂(SO₄)₃) and hard carbon anodes derived from sustainable sources. Faradion's batteries operate on the same intercalation principle as lithium-ion batteries but replace lithium with sodium ions. Their cells achieve energy densities of 140-160 Wh/kg, which is competitive with LFP lithium-ion batteries. The company has demonstrated cycle life exceeding 2,000 cycles at 80% depth of discharge, with operating temperature ranges from -20°C to +60°C. Faradion's technology eliminates the need for copper current collectors, using aluminum instead, which reduces material costs by approximately 30% compared to lithium-ion batteries.

Strengths: Uses abundant, low-cost materials (sodium is ~1000x more abundant than lithium); operates safely at wider temperature ranges; can be transported at zero voltage (zero energy) state, reducing shipping costs and risks; lower manufacturing costs due to aluminum current collectors instead of copper. Weaknesses: Lower energy density compared to high-end Li-ion batteries; still facing challenges in commercial-scale manufacturing; relatively new technology with limited field deployment history.

Tokyo University of Science

Technical Solution: Tokyo University of Science has developed innovative potassium-ion battery (PIB) technology focusing on novel electrode materials and electrolyte systems. Their research team has created Prussian blue analogues (PBAs) as cathode materials, specifically K₂Fe[Fe(CN)₆] structures that demonstrate high theoretical capacity (170 mAh/g) and stable cycling performance. For anodes, they've pioneered the use of hard carbon materials with expanded interlayer spacing to accommodate the larger K⁺ ions (1.38Å vs. 1.02Å for Na⁺). Their electrolyte research has yielded optimized formulations using KPF₆ salt in mixed carbonate solvents with additives that form stable solid electrolyte interphase (SEI) layers. The university's PIB prototypes have achieved energy densities approaching 200 Wh/kg with cycling stability of over 1000 cycles at 80% capacity retention. Their research has demonstrated that PIBs can potentially deliver higher voltage platforms (up to 4.3V) than sodium-ion alternatives, resulting in higher theoretical energy densities.

Strengths: Higher theoretical energy density than sodium-ion batteries due to potassium's lower standard electrode potential; potassium resources are abundant and widely distributed globally; potential for faster ionic conductivity due to weaker Lewis acidity of K⁺ ions. Weaknesses: Larger ionic radius of K⁺ causes more significant volume changes during cycling, leading to structural stability issues; higher reactivity of potassium metal with electrolytes creates safety challenges; currently lower cycling stability compared to commercial lithium-ion batteries.

Key Patents and Breakthroughs in Na/K-ion Technology

Method for producing lithium-ion, sodium-ion and potassium-ion batteries with increased safety

PatentInactiveUS20190058193A1

Innovation

- The production of lithiated pyomelanin (LPM), sodiated pyomelanin (SPM), and potassiated pyomelanin (PPM) through dissolving melanin in alkaline solutions, reducing, titrating, dialyzing, and lyophilizing to create stable, non-aqueous battery components that control lithium ion release and reduce the risk of metallic lithium formation, thereby enhancing safety.

Sodium-ion battery and energy storage device

PatentWO2024125486A1

Innovation

- Lithium element is added to the positive electrode layer of the sodium-ion battery to form an SEI film containing an organic and inorganic mixture of sodium and lithium, which improves the surface structure stability of the negative electrode material and the sodium ion transport capability, ensuring sufficient and sufficient electrochemically active alkaline ions. High ionic conductivity of the electrolyte.

Raw Material Supply Chain Analysis

The raw material supply chain for sodium-ion and potassium-ion batteries represents a critical factor in their commercial viability and sustainability. Sodium resources demonstrate significant advantages in terms of abundance and distribution, with sodium being the sixth most abundant element in the Earth's crust (2.8%) compared to lithium (0.006%) and potassium (2.6%). This abundance translates to lower extraction costs and reduced geopolitical supply risks.

Sodium carbonate, a primary precursor for sodium-ion batteries, is primarily sourced from natural deposits or produced through the Solvay process. The global production capacity exceeds 70 million tons annually, with major suppliers distributed across diverse regions including the United States, China, India, and several European countries. This geographical diversity significantly reduces supply chain vulnerabilities compared to lithium, which is concentrated in the "Lithium Triangle" of South America.

Potassium resources, while also relatively abundant, face more complex extraction challenges. Potassium is primarily obtained from potash mining operations, with approximately 83% of global reserves located in just three countries: Canada (25%), Belarus (18%), and Russia (40%). This concentration creates potential supply chain vulnerabilities that could impact large-scale potassium-ion battery production.

The manufacturing processes for both battery types require transition metals for cathode materials. Sodium-ion batteries typically utilize manganese, iron, and copper, which are widely available and have established supply chains. Potassium-ion batteries often require similar materials but may also utilize more specialized compounds depending on the specific chemistry employed.

Cost analysis reveals significant advantages for sodium-based systems. Raw material costs for sodium-ion batteries are estimated to be 30-50% lower than lithium-ion equivalents and approximately 20% lower than potassium-ion alternatives. The average cost of sodium carbonate ($300-400/ton) compares favorably to potassium carbonate ($900-1,200/ton) and lithium carbonate ($15,000-20,000/ton as of 2023).

Environmental impact assessments indicate that sodium extraction generally has a lower ecological footprint than both lithium and potassium extraction processes. Water usage for sodium carbonate production averages 15-20 cubic meters per ton, compared to 50-65 cubic meters for lithium extraction and 25-40 cubic meters for potassium mining operations.

Supply chain resilience modeling suggests that sodium-ion battery production faces fewer bottlenecks and resource constraints, potentially enabling faster scaling of manufacturing capacity to meet growing energy storage demands. Current projections indicate that raw material availability would support annual production capacity of over 100 GWh for sodium-ion batteries by 2030, compared to 40-60 GWh for potassium-ion systems.

Sodium carbonate, a primary precursor for sodium-ion batteries, is primarily sourced from natural deposits or produced through the Solvay process. The global production capacity exceeds 70 million tons annually, with major suppliers distributed across diverse regions including the United States, China, India, and several European countries. This geographical diversity significantly reduces supply chain vulnerabilities compared to lithium, which is concentrated in the "Lithium Triangle" of South America.

Potassium resources, while also relatively abundant, face more complex extraction challenges. Potassium is primarily obtained from potash mining operations, with approximately 83% of global reserves located in just three countries: Canada (25%), Belarus (18%), and Russia (40%). This concentration creates potential supply chain vulnerabilities that could impact large-scale potassium-ion battery production.

The manufacturing processes for both battery types require transition metals for cathode materials. Sodium-ion batteries typically utilize manganese, iron, and copper, which are widely available and have established supply chains. Potassium-ion batteries often require similar materials but may also utilize more specialized compounds depending on the specific chemistry employed.

Cost analysis reveals significant advantages for sodium-based systems. Raw material costs for sodium-ion batteries are estimated to be 30-50% lower than lithium-ion equivalents and approximately 20% lower than potassium-ion alternatives. The average cost of sodium carbonate ($300-400/ton) compares favorably to potassium carbonate ($900-1,200/ton) and lithium carbonate ($15,000-20,000/ton as of 2023).

Environmental impact assessments indicate that sodium extraction generally has a lower ecological footprint than both lithium and potassium extraction processes. Water usage for sodium carbonate production averages 15-20 cubic meters per ton, compared to 50-65 cubic meters for lithium extraction and 25-40 cubic meters for potassium mining operations.

Supply chain resilience modeling suggests that sodium-ion battery production faces fewer bottlenecks and resource constraints, potentially enabling faster scaling of manufacturing capacity to meet growing energy storage demands. Current projections indicate that raw material availability would support annual production capacity of over 100 GWh for sodium-ion batteries by 2030, compared to 40-60 GWh for potassium-ion systems.

Environmental Impact Assessment

The environmental impact assessment of sodium-ion and potassium-ion batteries reveals significant differences compared to conventional lithium-ion technologies. Both sodium and potassium resources demonstrate superior geographical distribution and abundance, with sodium constituting approximately 2.6% of the Earth's crust and potassium about 2.1%, compared to lithium's mere 0.002%. This widespread availability reduces the environmental degradation associated with concentrated mining operations and minimizes geopolitical supply risks.

Manufacturing processes for Na-ion and K-ion batteries generally require lower energy inputs than their lithium counterparts. Research indicates that sodium-ion battery production can reduce energy consumption by approximately 18-20% compared to lithium-ion manufacturing, while potassium-ion batteries show potential reductions of 15-17%. This translates directly to lower carbon emissions during the manufacturing phase, with estimated reductions of 20-25% for Na-ion and 17-22% for K-ion technologies.

Water usage represents another critical environmental consideration. Lithium extraction, particularly from brine operations, consumes between 500,000 to 2 million liters of water per ton of lithium produced. Comparatively, sodium and potassium extraction methods typically require 40-60% less water, significantly reducing pressure on water resources in extraction regions.

End-of-life management presents both challenges and opportunities. Current recycling infrastructure is primarily optimized for lithium-ion batteries, requiring adaptation for Na-ion and K-ion technologies. However, the inherent material composition of these alternative batteries—particularly the absence of cobalt and reduced nickel content—minimizes toxic waste generation. Preliminary studies suggest that recycling processes for Na-ion batteries could be 15-30% less energy-intensive than those for lithium-ion equivalents.

Life cycle assessments indicate that sodium-ion batteries demonstrate approximately 25-30% lower global warming potential compared to lithium-ion batteries, while potassium-ion batteries show reductions of 20-28%. These advantages primarily stem from reduced extraction impacts and simplified manufacturing processes. However, current energy density limitations mean more battery material may be required for equivalent storage capacity, potentially offsetting some environmental benefits.

Land use impacts also differ significantly. Lithium extraction, particularly from salt flats, can disrupt up to 400-500 hectares per production facility. Sodium and potassium extraction typically affects 30-40% less land area and causes less permanent alteration to local ecosystems, particularly regarding groundwater systems and habitat fragmentation.

Manufacturing processes for Na-ion and K-ion batteries generally require lower energy inputs than their lithium counterparts. Research indicates that sodium-ion battery production can reduce energy consumption by approximately 18-20% compared to lithium-ion manufacturing, while potassium-ion batteries show potential reductions of 15-17%. This translates directly to lower carbon emissions during the manufacturing phase, with estimated reductions of 20-25% for Na-ion and 17-22% for K-ion technologies.

Water usage represents another critical environmental consideration. Lithium extraction, particularly from brine operations, consumes between 500,000 to 2 million liters of water per ton of lithium produced. Comparatively, sodium and potassium extraction methods typically require 40-60% less water, significantly reducing pressure on water resources in extraction regions.

End-of-life management presents both challenges and opportunities. Current recycling infrastructure is primarily optimized for lithium-ion batteries, requiring adaptation for Na-ion and K-ion technologies. However, the inherent material composition of these alternative batteries—particularly the absence of cobalt and reduced nickel content—minimizes toxic waste generation. Preliminary studies suggest that recycling processes for Na-ion batteries could be 15-30% less energy-intensive than those for lithium-ion equivalents.

Life cycle assessments indicate that sodium-ion batteries demonstrate approximately 25-30% lower global warming potential compared to lithium-ion batteries, while potassium-ion batteries show reductions of 20-28%. These advantages primarily stem from reduced extraction impacts and simplified manufacturing processes. However, current energy density limitations mean more battery material may be required for equivalent storage capacity, potentially offsetting some environmental benefits.

Land use impacts also differ significantly. Lithium extraction, particularly from salt flats, can disrupt up to 400-500 hectares per production facility. Sodium and potassium extraction typically affects 30-40% less land area and causes less permanent alteration to local ecosystems, particularly regarding groundwater systems and habitat fragmentation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!