Benchmark Hybrid Manufacturing Approaches: Topology Optimization Integration

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hybrid Manufacturing Evolution and Objectives

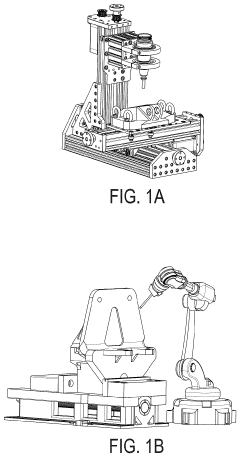

Hybrid manufacturing represents a significant evolution in manufacturing technologies, combining additive and subtractive processes to leverage the advantages of both approaches. The concept emerged in the early 2000s but gained substantial momentum over the past decade as industries sought more efficient, sustainable, and flexible production methods. Initially, hybrid manufacturing focused on simple combinations of processes, but has since evolved into sophisticated integrated systems capable of producing complex geometries with high precision and material efficiency.

The evolution trajectory shows three distinct phases: experimental combinations (2000-2010), integrated systems development (2010-2018), and current advanced optimization integration (2018-present). Each phase marked significant improvements in process control, material compatibility, and system integration capabilities. The transition from separate sequential operations to seamless in-process switching represents a fundamental shift in manufacturing paradigms.

Topology optimization, a computational method for material distribution optimization, has become increasingly central to hybrid manufacturing approaches. This integration aims to fully exploit the design freedom offered by additive manufacturing while maintaining the precision and surface quality advantages of subtractive processes. The convergence of these technologies enables the creation of components with optimized internal structures that would be impossible to produce using conventional manufacturing methods.

The primary objectives of benchmarking hybrid manufacturing approaches with topology optimization integration include establishing standardized performance metrics, identifying optimal process parameters for different material systems, and developing predictive models for process outcomes. These benchmarks are crucial for industry adoption as they provide quantifiable data on process reliability, repeatability, and economic viability.

Technical objectives focus on resolving interface challenges between additive and subtractive processes, minimizing residual stresses in hybrid-manufactured components, and developing adaptive control systems that can respond to in-process variations. Material-specific benchmarks aim to characterize the mechanical properties and microstructural features of components produced through hybrid routes compared to conventional manufacturing.

Long-term objectives include the development of integrated design-to-manufacturing workflows that seamlessly incorporate topology optimization algorithms with hybrid manufacturing constraints. This integration promises to revolutionize product development cycles by enabling simultaneous optimization of design, material usage, and manufacturing processes. The ultimate goal is to establish hybrid manufacturing with topology optimization as a mainstream production approach for high-value components in aerospace, medical, and automotive industries.

The evolution trajectory shows three distinct phases: experimental combinations (2000-2010), integrated systems development (2010-2018), and current advanced optimization integration (2018-present). Each phase marked significant improvements in process control, material compatibility, and system integration capabilities. The transition from separate sequential operations to seamless in-process switching represents a fundamental shift in manufacturing paradigms.

Topology optimization, a computational method for material distribution optimization, has become increasingly central to hybrid manufacturing approaches. This integration aims to fully exploit the design freedom offered by additive manufacturing while maintaining the precision and surface quality advantages of subtractive processes. The convergence of these technologies enables the creation of components with optimized internal structures that would be impossible to produce using conventional manufacturing methods.

The primary objectives of benchmarking hybrid manufacturing approaches with topology optimization integration include establishing standardized performance metrics, identifying optimal process parameters for different material systems, and developing predictive models for process outcomes. These benchmarks are crucial for industry adoption as they provide quantifiable data on process reliability, repeatability, and economic viability.

Technical objectives focus on resolving interface challenges between additive and subtractive processes, minimizing residual stresses in hybrid-manufactured components, and developing adaptive control systems that can respond to in-process variations. Material-specific benchmarks aim to characterize the mechanical properties and microstructural features of components produced through hybrid routes compared to conventional manufacturing.

Long-term objectives include the development of integrated design-to-manufacturing workflows that seamlessly incorporate topology optimization algorithms with hybrid manufacturing constraints. This integration promises to revolutionize product development cycles by enabling simultaneous optimization of design, material usage, and manufacturing processes. The ultimate goal is to establish hybrid manufacturing with topology optimization as a mainstream production approach for high-value components in aerospace, medical, and automotive industries.

Market Analysis for Topology-Optimized Manufacturing

The global market for topology-optimized manufacturing solutions has experienced significant growth over the past five years, with a compound annual growth rate exceeding 15%. This growth is primarily driven by industries seeking to reduce material costs while maintaining or improving component performance. Aerospace and automotive sectors currently represent the largest market segments, collectively accounting for approximately 60% of the total market share, as these industries benefit most immediately from weight reduction and performance optimization.

Market research indicates that North America leads in adoption of topology optimization technologies, followed closely by Europe and rapidly growing implementation in Asia-Pacific regions, particularly in Japan, South Korea, and China. The market is projected to reach $3.5 billion by 2026, representing a substantial opportunity for technology providers who can effectively integrate topology optimization with hybrid manufacturing approaches.

Customer demand analysis reveals three primary market drivers: cost reduction through material savings (typically 20-30% material reduction in optimized parts), performance enhancement through structural optimization, and sustainability benefits from reduced material consumption and improved energy efficiency. Early adopters report ROI periods of 12-18 months for implementation of integrated topology optimization systems.

Market segmentation shows distinct requirements across industries. While aerospace demands high-performance lightweight components with stringent certification requirements, automotive manufacturers prioritize cost-effective mass production capabilities. Medical device manufacturers, representing a smaller but rapidly growing segment at 12% of the market, focus on customization capabilities and biocompatibility of final products.

Competitive analysis identifies three tiers of market players: established CAE software providers expanding into manufacturing integration, specialized topology optimization startups offering innovative algorithms, and manufacturing equipment providers incorporating optimization capabilities into their hardware offerings. Recent market consolidation through acquisitions indicates the strategic importance major industrial players place on this technology.

Customer surveys highlight several market barriers to wider adoption, including high initial investment costs, lack of standardized workflows between design and manufacturing systems, and workforce training requirements. Organizations report implementation challenges particularly at the interface between topology optimization software and hybrid manufacturing execution systems, creating market opportunities for solutions that seamlessly bridge this gap.

Market research indicates that North America leads in adoption of topology optimization technologies, followed closely by Europe and rapidly growing implementation in Asia-Pacific regions, particularly in Japan, South Korea, and China. The market is projected to reach $3.5 billion by 2026, representing a substantial opportunity for technology providers who can effectively integrate topology optimization with hybrid manufacturing approaches.

Customer demand analysis reveals three primary market drivers: cost reduction through material savings (typically 20-30% material reduction in optimized parts), performance enhancement through structural optimization, and sustainability benefits from reduced material consumption and improved energy efficiency. Early adopters report ROI periods of 12-18 months for implementation of integrated topology optimization systems.

Market segmentation shows distinct requirements across industries. While aerospace demands high-performance lightweight components with stringent certification requirements, automotive manufacturers prioritize cost-effective mass production capabilities. Medical device manufacturers, representing a smaller but rapidly growing segment at 12% of the market, focus on customization capabilities and biocompatibility of final products.

Competitive analysis identifies three tiers of market players: established CAE software providers expanding into manufacturing integration, specialized topology optimization startups offering innovative algorithms, and manufacturing equipment providers incorporating optimization capabilities into their hardware offerings. Recent market consolidation through acquisitions indicates the strategic importance major industrial players place on this technology.

Customer surveys highlight several market barriers to wider adoption, including high initial investment costs, lack of standardized workflows between design and manufacturing systems, and workforce training requirements. Organizations report implementation challenges particularly at the interface between topology optimization software and hybrid manufacturing execution systems, creating market opportunities for solutions that seamlessly bridge this gap.

Current Challenges in Hybrid Manufacturing Integration

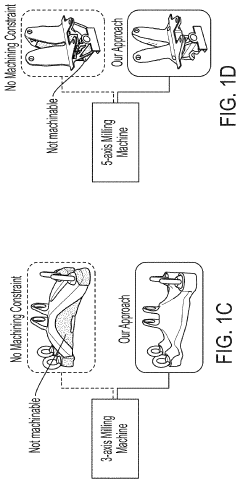

Despite the significant advancements in hybrid manufacturing technologies, several critical challenges persist in effectively integrating topology optimization with these manufacturing approaches. The fundamental challenge lies in the inherent disconnect between the theoretical freedom of topology optimization algorithms and the practical constraints of manufacturing processes. While topology optimization can generate complex, organic structures that maximize performance, these designs often contain features that are difficult or impossible to manufacture using conventional methods.

Material compatibility presents another significant hurdle. The integration of additive and subtractive processes often involves different materials with varying properties, creating challenges in ensuring structural integrity and performance consistency across the manufactured part. Interface regions between different materials or manufacturing processes frequently become weak points, compromising the overall performance of the optimized structure.

Process planning complexity increases exponentially when combining multiple manufacturing methods. Determining the optimal sequence of operations, tool paths, and process parameters becomes a multi-dimensional optimization problem that current software solutions struggle to address comprehensively. This complexity is further amplified when topology optimization introduces intricate geometries that require sophisticated manufacturing strategies.

Quality control and validation mechanisms remain underdeveloped for hybrid manufacturing processes. Traditional inspection methods often prove inadequate for assessing complex internal structures created through topology optimization and manufactured via hybrid approaches. The lack of standardized testing protocols specifically designed for topology-optimized hybrid parts hampers industry adoption.

Computational challenges persist in real-time process monitoring and adaptive control systems. Current simulation models struggle to accurately predict material behavior during multi-process manufacturing, particularly when dealing with the complex geometries resulting from topology optimization. This limitation affects both the design phase and in-process quality control.

Cost-effectiveness remains questionable for many applications. The additional complexity introduced by integrating topology optimization with hybrid manufacturing often results in increased production costs, longer lead times, and higher skill requirements for operators. These factors limit the industrial adoption of these advanced approaches, particularly in cost-sensitive sectors.

Standardization gaps further complicate implementation. The absence of industry-wide standards for hybrid manufacturing processes integrated with topology optimization creates barriers to interoperability between different systems and software platforms. This fragmentation slows technological progress and limits the potential for widespread adoption across manufacturing sectors.

Material compatibility presents another significant hurdle. The integration of additive and subtractive processes often involves different materials with varying properties, creating challenges in ensuring structural integrity and performance consistency across the manufactured part. Interface regions between different materials or manufacturing processes frequently become weak points, compromising the overall performance of the optimized structure.

Process planning complexity increases exponentially when combining multiple manufacturing methods. Determining the optimal sequence of operations, tool paths, and process parameters becomes a multi-dimensional optimization problem that current software solutions struggle to address comprehensively. This complexity is further amplified when topology optimization introduces intricate geometries that require sophisticated manufacturing strategies.

Quality control and validation mechanisms remain underdeveloped for hybrid manufacturing processes. Traditional inspection methods often prove inadequate for assessing complex internal structures created through topology optimization and manufactured via hybrid approaches. The lack of standardized testing protocols specifically designed for topology-optimized hybrid parts hampers industry adoption.

Computational challenges persist in real-time process monitoring and adaptive control systems. Current simulation models struggle to accurately predict material behavior during multi-process manufacturing, particularly when dealing with the complex geometries resulting from topology optimization. This limitation affects both the design phase and in-process quality control.

Cost-effectiveness remains questionable for many applications. The additional complexity introduced by integrating topology optimization with hybrid manufacturing often results in increased production costs, longer lead times, and higher skill requirements for operators. These factors limit the industrial adoption of these advanced approaches, particularly in cost-sensitive sectors.

Standardization gaps further complicate implementation. The absence of industry-wide standards for hybrid manufacturing processes integrated with topology optimization creates barriers to interoperability between different systems and software platforms. This fragmentation slows technological progress and limits the potential for widespread adoption across manufacturing sectors.

Existing Benchmark Methodologies and Frameworks

01 Integration of Topology Optimization in Additive Manufacturing

Topology optimization algorithms are integrated with additive manufacturing processes to create optimized structures with reduced material usage while maintaining mechanical performance. This approach enables the design of complex geometries that would be impossible to produce using traditional manufacturing methods. The integration allows for weight reduction, improved strength-to-weight ratios, and customization of parts based on specific loading conditions and constraints.- Topology optimization for additive manufacturing: Topology optimization techniques are integrated with additive manufacturing processes to create optimized structures with complex geometries. This approach allows for the design of lightweight components with enhanced mechanical properties by optimizing material distribution based on specific performance requirements. The integration enables designers to exploit the design freedom offered by additive manufacturing while ensuring structural integrity and functional performance.

- Multi-material and multi-process hybrid manufacturing: Hybrid manufacturing approaches combine multiple materials and processes to achieve optimized components with tailored properties. These systems integrate additive and subtractive manufacturing techniques in a single platform, allowing for the production of complex parts with high precision. The topology optimization algorithms specifically account for the different material properties and manufacturing constraints of each process, resulting in functionally graded structures with optimized performance characteristics.

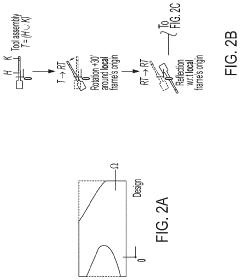

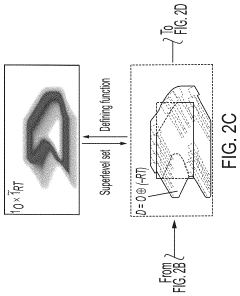

- Design optimization for hybrid manufacturing constraints: Specialized algorithms have been developed to account for the unique constraints of hybrid manufacturing processes during topology optimization. These methods consider build orientation, support structures, thermal effects, and machining accessibility to ensure manufacturability of the optimized designs. The integration of manufacturing constraints directly into the optimization process results in designs that are not only theoretically optimal but also practically manufacturable without significant post-processing modifications.

- Digital twin integration with topology optimization: Digital twin technology is being integrated with topology optimization and hybrid manufacturing to create a comprehensive framework for design, simulation, and production. This approach enables real-time monitoring and adjustment of manufacturing parameters based on simulation results, ensuring that the manufactured parts match the optimized design. The digital twin captures the entire manufacturing process chain, allowing for predictive analysis and optimization of both the design and manufacturing parameters simultaneously.

- AI-driven optimization for hybrid manufacturing: Artificial intelligence and machine learning techniques are being applied to enhance topology optimization for hybrid manufacturing processes. These AI-driven approaches can predict manufacturing outcomes, identify optimal process parameters, and suggest design modifications to improve manufacturability. The integration of AI with topology optimization enables more efficient exploration of the design space, faster convergence to optimal solutions, and better adaptation to changing manufacturing conditions or requirements.

02 Multi-material and Multi-process Hybrid Manufacturing Systems

Hybrid manufacturing systems combine multiple materials and processes such as additive manufacturing with subtractive techniques (milling, grinding) in a single platform. These integrated systems enable the production of complex components with varying material properties and precise surface finishes. The combination of processes allows for optimization of both the internal structure through topology optimization and the external features through precision machining.Expand Specific Solutions03 Computational Methods for Process Parameter Optimization

Advanced computational methods are developed to optimize process parameters in hybrid manufacturing. These methods include machine learning algorithms, simulation-based optimization, and digital twins that predict and control the manufacturing process. By optimizing parameters such as build orientation, layer thickness, and tool paths, manufacturers can achieve better quality, reduced production time, and lower costs while maintaining the benefits of topology-optimized designs.Expand Specific Solutions04 Design for Hybrid Manufacturing with Integrated Constraints

Design methodologies specifically tailored for hybrid manufacturing incorporate manufacturing constraints directly into the topology optimization process. These approaches consider build direction limitations, support structure requirements, thermal distortion, and machining accessibility. By integrating these constraints early in the design phase, the resulting components are optimized not only for performance but also for manufacturability, reducing the need for design iterations and post-processing.Expand Specific Solutions05 Validation and Quality Control Systems for Topology-Optimized Parts

Specialized validation and quality control systems are developed for topology-optimized parts produced through hybrid manufacturing. These systems include in-situ monitoring, non-destructive testing methods, and digital inspection techniques that ensure the manufactured parts meet design specifications. The integration of real-time feedback mechanisms allows for process adjustments during manufacturing, ensuring that the complex geometries resulting from topology optimization are produced with high accuracy and reliability.Expand Specific Solutions

Leading Organizations in Hybrid Manufacturing

The hybrid manufacturing landscape integrating topology optimization is evolving rapidly, currently transitioning from early adoption to growth phase. The global market is expanding at approximately 15-20% annually, driven by increasing demand for lightweight, high-performance components across aerospace, automotive, and medical sectors. Leading academic institutions (Zhejiang University, Huazhong University, Georgia Tech, Waterloo) are advancing theoretical frameworks, while industrial players demonstrate varying technological maturity. Siemens and Autodesk lead with comprehensive commercial solutions, while Dassault Systèmes and Rolls-Royce focus on specialized applications. Companies like Honda and U.S. Steel are exploring implementation strategies, indicating the technology's growing cross-industry relevance despite remaining challenges in standardization and process integration.

Zhejiang University

Technical Solution: Zhejiang University has developed an innovative research-focused approach to topology optimization for hybrid manufacturing that emphasizes multi-scale structural optimization. Their methodology incorporates novel mathematical formulations for handling the unique constraints of combined additive and subtractive processes. The university's research team has created algorithms that specifically address the anisotropic material properties resulting from layer-by-layer additive manufacturing [10]. Their approach includes topology optimization techniques that account for the thermal history of the additive process and its effect on material properties. Zhejiang University has pioneered methods for integrating lattice structures with solid regions in a single component, optimizing each for their specific functional requirements. Their research includes advanced homogenization techniques that efficiently model complex microstructures within the topology optimization framework. The university has also developed specialized post-processing algorithms that translate optimized topologies into manufacturing instructions that minimize the need for support structures and maximize the efficiency of the hybrid manufacturing process [11].

Strengths: Cutting-edge research approaches not constrained by commercial considerations, strong mathematical foundations, and novel algorithms specifically designed for hybrid manufacturing challenges. Weaknesses: Less emphasis on industrial implementation and user interface development, and potential gaps between theoretical research and practical manufacturing constraints.

Siemens AG

Technical Solution: Siemens AG has developed an integrated hybrid manufacturing approach that combines topology optimization with additive and subtractive manufacturing processes. Their solution utilizes a multi-objective optimization algorithm that simultaneously considers design constraints, material properties, and manufacturing limitations. The platform incorporates simulation-driven design tools that predict structural performance while optimizing material distribution. Siemens' approach includes a specialized software module within their NX platform that enables seamless transition between design optimization and manufacturing planning [1]. Their system employs machine learning algorithms to analyze historical manufacturing data and predict optimal process parameters for hybrid manufacturing scenarios. The technology also features real-time monitoring capabilities that allow for adaptive control during the manufacturing process, ensuring that the optimized topology is accurately reproduced in the final component [3].

Strengths: Comprehensive integration across the entire design-to-manufacturing workflow, strong simulation capabilities, and extensive industrial validation across multiple sectors. Weaknesses: High implementation costs, steep learning curve for users, and potential compatibility issues when integrating with non-Siemens manufacturing equipment.

Critical Patents in Topology-Driven Hybrid Manufacturing

Automated design and optimization for accessibility in subtractive manufacturing

PatentActiveUS20210390229A1

Innovation

- A methodology that incorporates accessibility constraints through the definition of an inaccessibility measure field, which quantifies the spatial inaccessibility of design features by subtractive manufacturing tools, coupled with sensitivity fields to prevent the formation of inaccessible regions, ensuring designs can be manufactured via multi-axis machining.

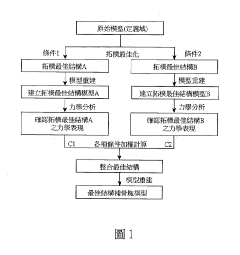

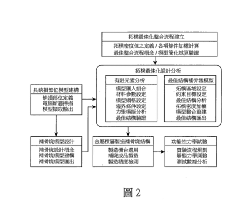

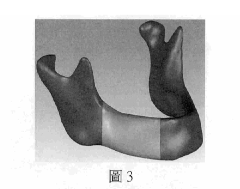

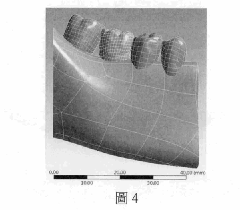

Method of integration of topology optimization, complementary bone structure manufactured by the method, and method for manufacturing the structure capable of providing multi-faceted mechanical support while maintaining light weight

PatentActiveTW202017536A

Innovation

- A topological optimization integration method combining density matrices from multiple mechanical conditions, using weighted operations to create a three-dimensional structural model, integrated with finite element analysis and metal laminated manufacturing, to design a bone prosthetic structure that meets clinical needs.

Material Compatibility and Process Parameters

Material compatibility represents a critical challenge in hybrid manufacturing approaches that integrate topology optimization. The successful implementation of these advanced manufacturing methodologies depends heavily on understanding the complex interactions between different materials and their behavior under various process parameters. When combining additive and subtractive manufacturing techniques, material selection must account for both the initial build requirements and subsequent machining operations.

Metals used in hybrid manufacturing exhibit varying responses to thermal gradients during additive processes. Aluminum alloys, while lightweight and corrosion-resistant, present challenges with thermal conductivity that can affect dimensional accuracy. Titanium alloys offer excellent strength-to-weight ratios but require careful parameter control to prevent oxidation and porosity issues. Steel variants demonstrate good machinability post-deposition but may experience residual stress accumulation that affects final part performance.

Process parameters significantly influence material behavior and final part quality. Laser power settings in powder bed fusion processes directly impact melt pool characteristics, affecting grain structure and mechanical properties. Scan speed and pattern selection influence thermal history and resultant microstructure development. Layer thickness decisions represent a critical trade-off between build speed and surface quality, with thinner layers generally providing better resolution but extending production time.

Temperature management emerges as a paramount concern across hybrid manufacturing platforms. Pre-heating strategies can reduce thermal gradients and associated distortion, while controlled cooling paths help minimize residual stress accumulation. For multi-material applications, interface temperature control becomes essential to ensure proper bonding without compromising structural integrity.

Build orientation decisions significantly impact both material deposition characteristics and subsequent machining operations. Vertical structures may require additional support material that must be compatible with both the primary build material and removal processes. Horizontal features often demonstrate anisotropic properties that must be accounted for in topology optimization algorithms.

Standardization of process parameters remains an ongoing challenge in the field. Current research indicates that material-specific parameter libraries are being developed, but significant gaps exist in understanding the complex interactions between process variables across different equipment platforms. Computational models that can predict material behavior under varying process conditions are advancing but require extensive validation against experimental data.

The development of closed-loop monitoring systems represents a promising approach to material compatibility challenges. Real-time adjustment of process parameters based on thermal imaging, melt pool monitoring, and layer inspection technologies enables adaptive control strategies that can accommodate material-specific requirements throughout the build process.

Metals used in hybrid manufacturing exhibit varying responses to thermal gradients during additive processes. Aluminum alloys, while lightweight and corrosion-resistant, present challenges with thermal conductivity that can affect dimensional accuracy. Titanium alloys offer excellent strength-to-weight ratios but require careful parameter control to prevent oxidation and porosity issues. Steel variants demonstrate good machinability post-deposition but may experience residual stress accumulation that affects final part performance.

Process parameters significantly influence material behavior and final part quality. Laser power settings in powder bed fusion processes directly impact melt pool characteristics, affecting grain structure and mechanical properties. Scan speed and pattern selection influence thermal history and resultant microstructure development. Layer thickness decisions represent a critical trade-off between build speed and surface quality, with thinner layers generally providing better resolution but extending production time.

Temperature management emerges as a paramount concern across hybrid manufacturing platforms. Pre-heating strategies can reduce thermal gradients and associated distortion, while controlled cooling paths help minimize residual stress accumulation. For multi-material applications, interface temperature control becomes essential to ensure proper bonding without compromising structural integrity.

Build orientation decisions significantly impact both material deposition characteristics and subsequent machining operations. Vertical structures may require additional support material that must be compatible with both the primary build material and removal processes. Horizontal features often demonstrate anisotropic properties that must be accounted for in topology optimization algorithms.

Standardization of process parameters remains an ongoing challenge in the field. Current research indicates that material-specific parameter libraries are being developed, but significant gaps exist in understanding the complex interactions between process variables across different equipment platforms. Computational models that can predict material behavior under varying process conditions are advancing but require extensive validation against experimental data.

The development of closed-loop monitoring systems represents a promising approach to material compatibility challenges. Real-time adjustment of process parameters based on thermal imaging, melt pool monitoring, and layer inspection technologies enables adaptive control strategies that can accommodate material-specific requirements throughout the build process.

Cost-Benefit Analysis of Implementation Strategies

Implementing topology optimization in hybrid manufacturing requires careful consideration of the economic implications across different strategic approaches. Initial investment costs vary significantly between integration methods, with full system integration demanding substantial capital expenditure for hardware modifications and software development. Companies must account for equipment upgrades, specialized training programs, and potential production downtime during implementation. Modular implementation strategies offer a more gradual investment path but may result in higher long-term costs due to compatibility issues and incremental upgrades.

Operational cost analysis reveals that while topology-optimized designs typically reduce material consumption by 30-40%, the manufacturing complexity often increases production time by 15-25% in early implementation phases. This efficiency gap narrows as process optimization matures, typically achieving net cost benefits within 12-18 months of implementation. Energy consumption patterns also shift, with topology-optimized components requiring more energy during production but delivering lifecycle energy savings that average 20-35% compared to conventional designs.

Return on investment timelines differ markedly across industry sectors. Aerospace applications demonstrate the fastest ROI, typically 8-14 months, due to the high value of weight reduction. Automotive applications show moderate returns within 14-24 months, while general industrial applications may require 18-30 months to achieve positive returns. These timelines are heavily influenced by production volume, with high-volume manufacturing environments achieving faster cost recovery.

Risk assessment factors must be incorporated into cost-benefit calculations. Technical risks include potential design iterations and manufacturing failures during the learning curve period, typically adding 10-15% to projected implementation costs. Market risks involve uncertain customer acceptance of topology-optimized aesthetics and potential regulatory hurdles, particularly in highly regulated industries.

Comparative analysis of implementation strategies indicates that phased integration approaches typically deliver better risk-adjusted returns than immediate full-scale implementation. Organizations that begin with non-critical components before advancing to structural applications report 25-30% lower implementation costs and 40% fewer technical setbacks. Cloud-based topology optimization services offer attractive initial cost structures but may present data security concerns and customization limitations that impact long-term value propositions.

Operational cost analysis reveals that while topology-optimized designs typically reduce material consumption by 30-40%, the manufacturing complexity often increases production time by 15-25% in early implementation phases. This efficiency gap narrows as process optimization matures, typically achieving net cost benefits within 12-18 months of implementation. Energy consumption patterns also shift, with topology-optimized components requiring more energy during production but delivering lifecycle energy savings that average 20-35% compared to conventional designs.

Return on investment timelines differ markedly across industry sectors. Aerospace applications demonstrate the fastest ROI, typically 8-14 months, due to the high value of weight reduction. Automotive applications show moderate returns within 14-24 months, while general industrial applications may require 18-30 months to achieve positive returns. These timelines are heavily influenced by production volume, with high-volume manufacturing environments achieving faster cost recovery.

Risk assessment factors must be incorporated into cost-benefit calculations. Technical risks include potential design iterations and manufacturing failures during the learning curve period, typically adding 10-15% to projected implementation costs. Market risks involve uncertain customer acceptance of topology-optimized aesthetics and potential regulatory hurdles, particularly in highly regulated industries.

Comparative analysis of implementation strategies indicates that phased integration approaches typically deliver better risk-adjusted returns than immediate full-scale implementation. Organizations that begin with non-critical components before advancing to structural applications report 25-30% lower implementation costs and 40% fewer technical setbacks. Cloud-based topology optimization services offer attractive initial cost structures but may present data security concerns and customization limitations that impact long-term value propositions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!